Patents

Literature

89results about How to "Reduced connection reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

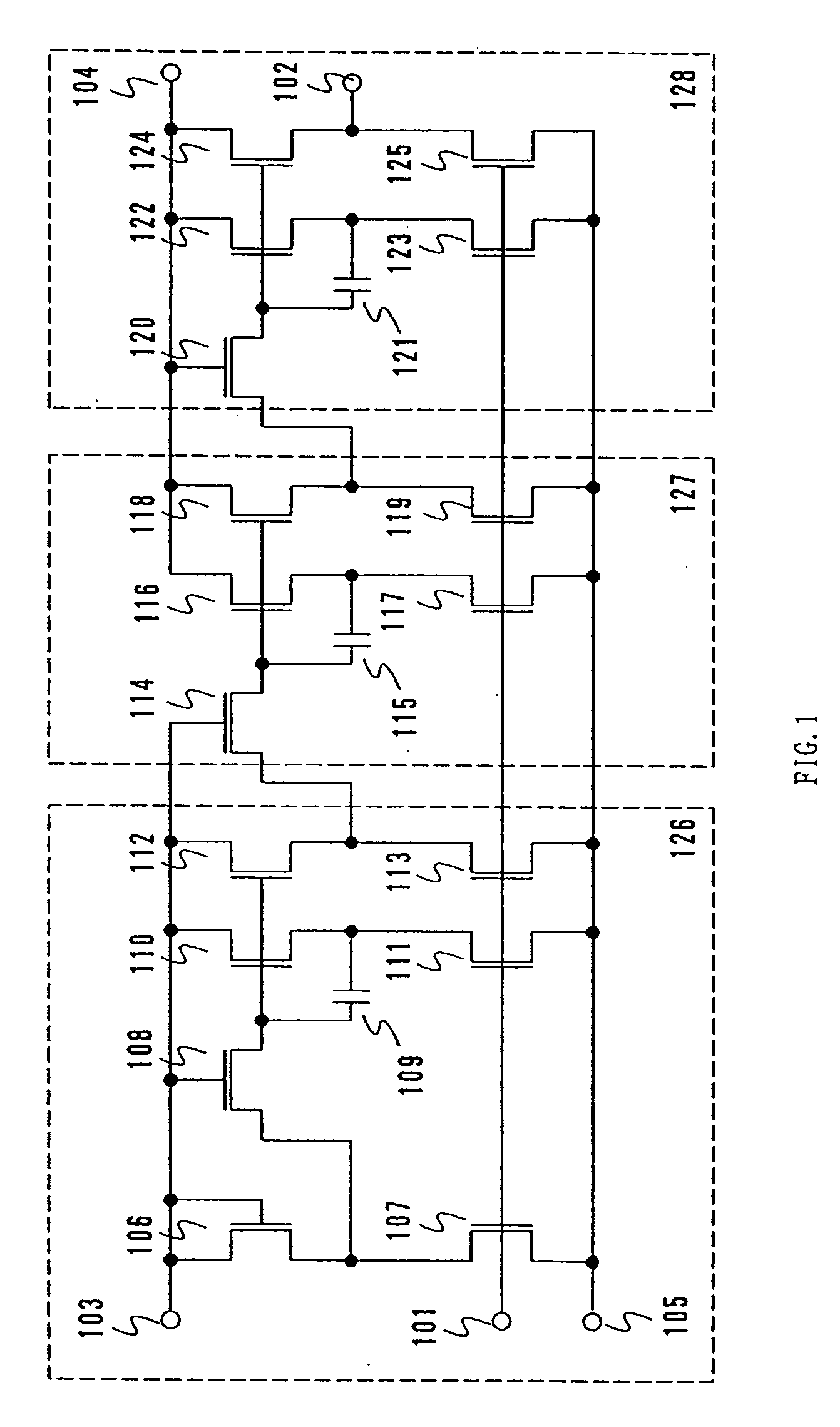

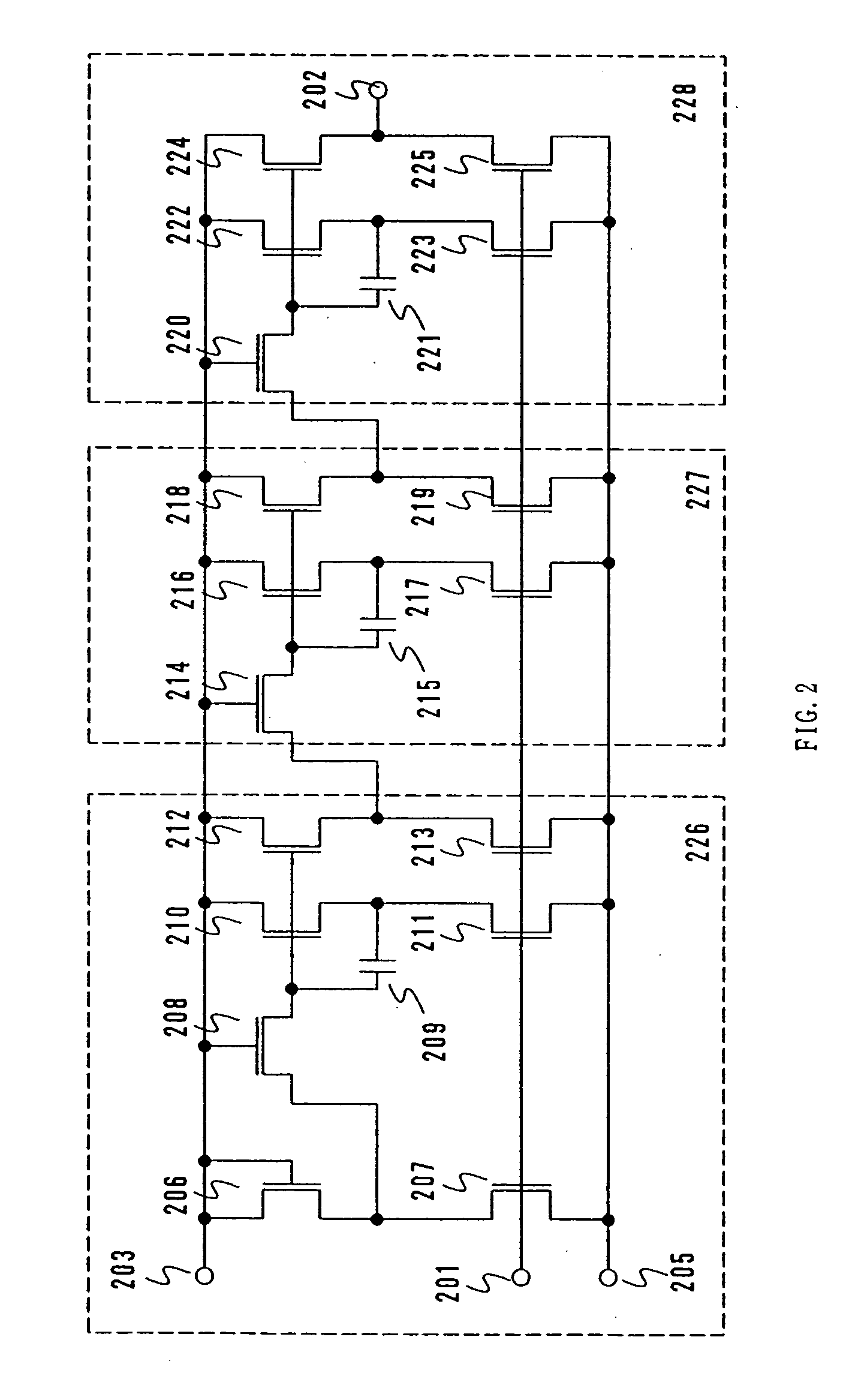

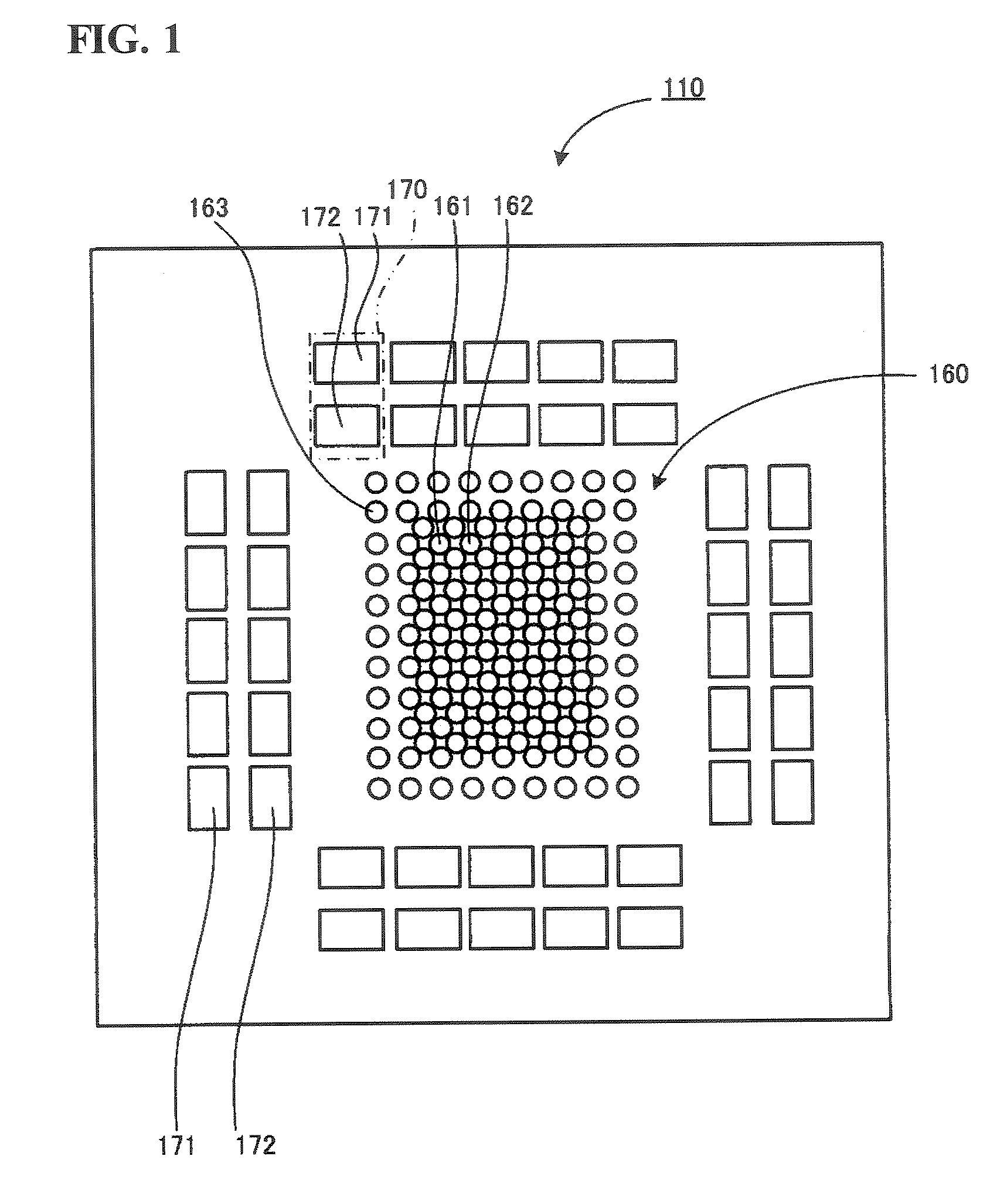

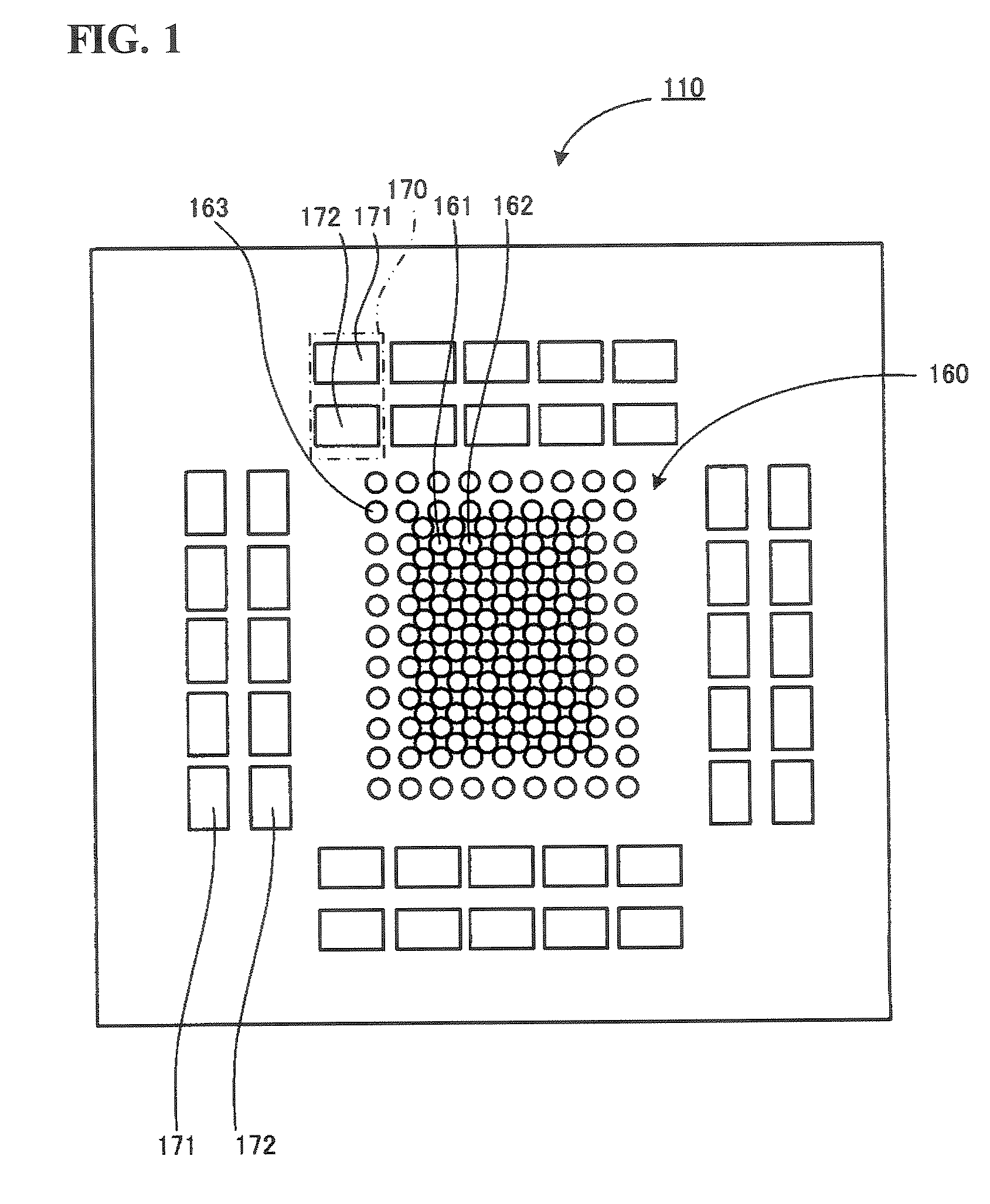

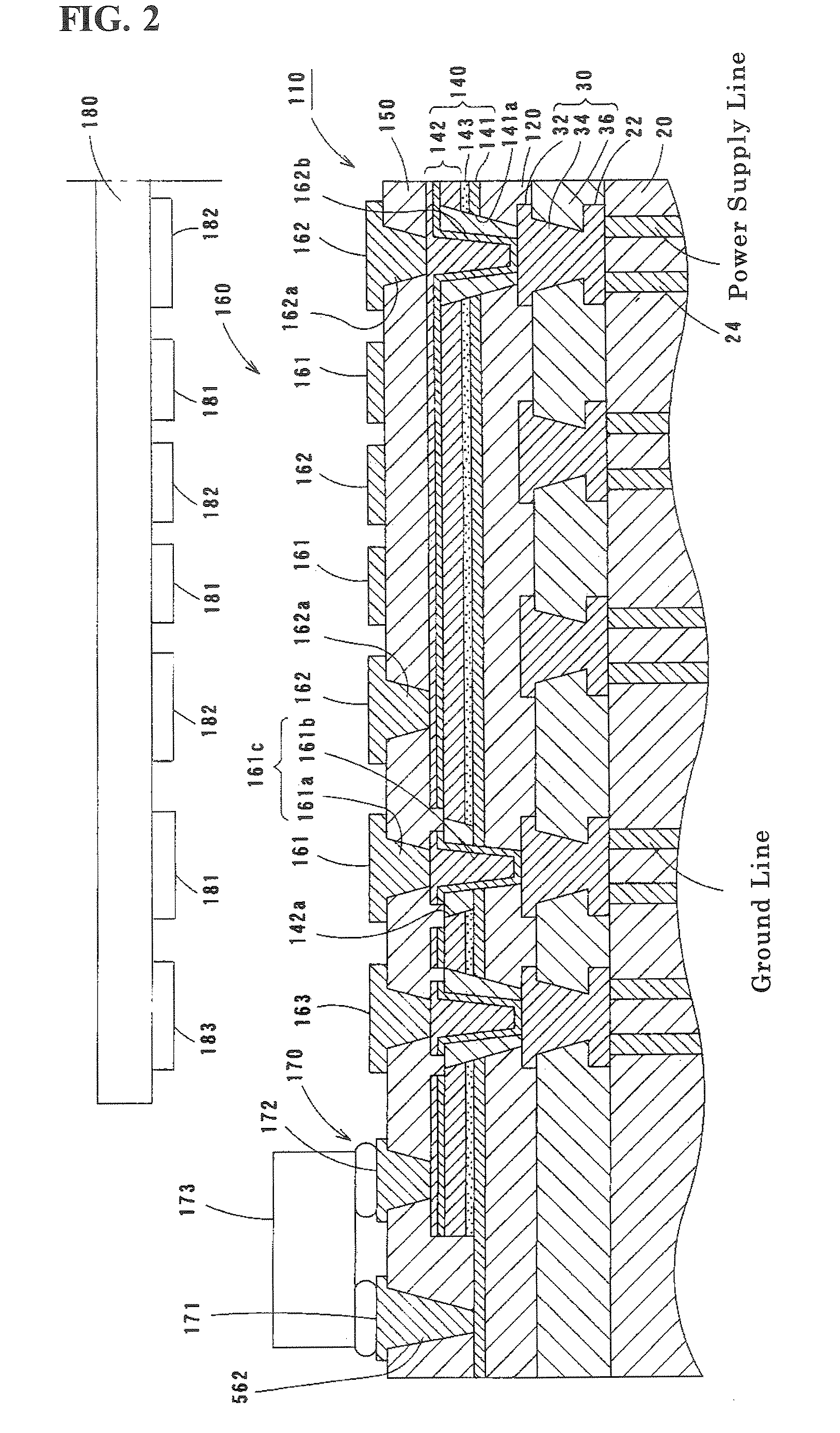

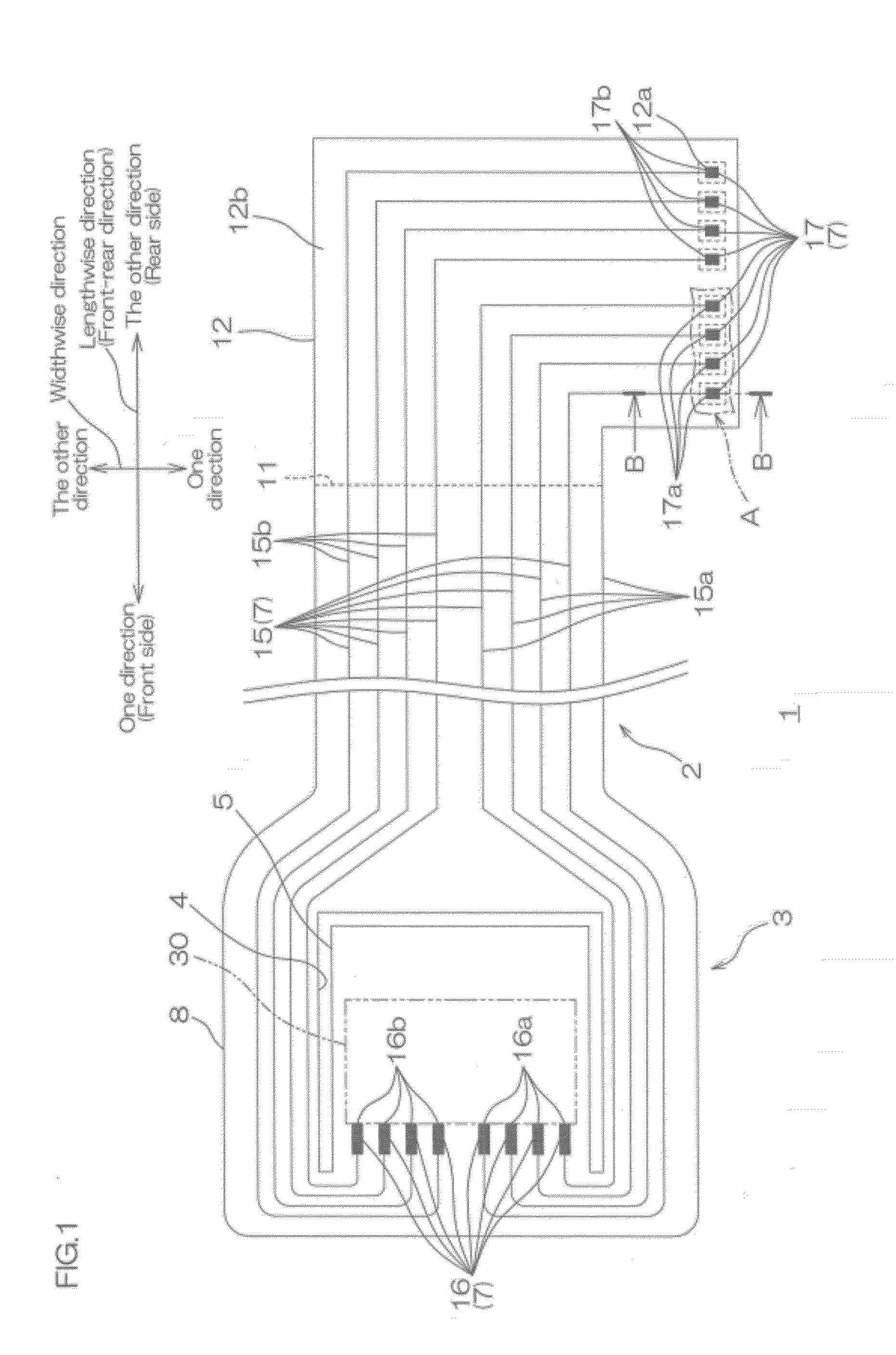

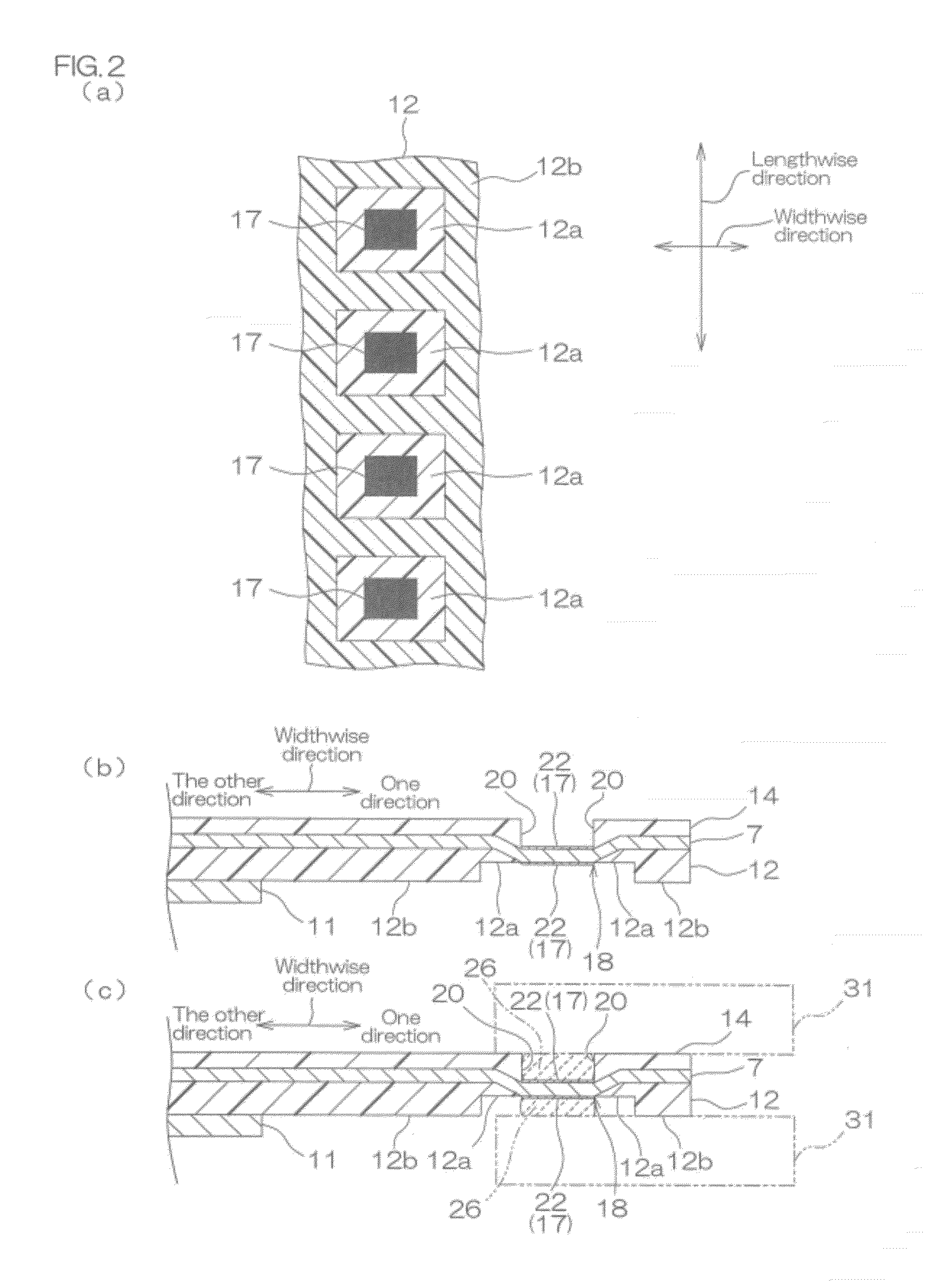

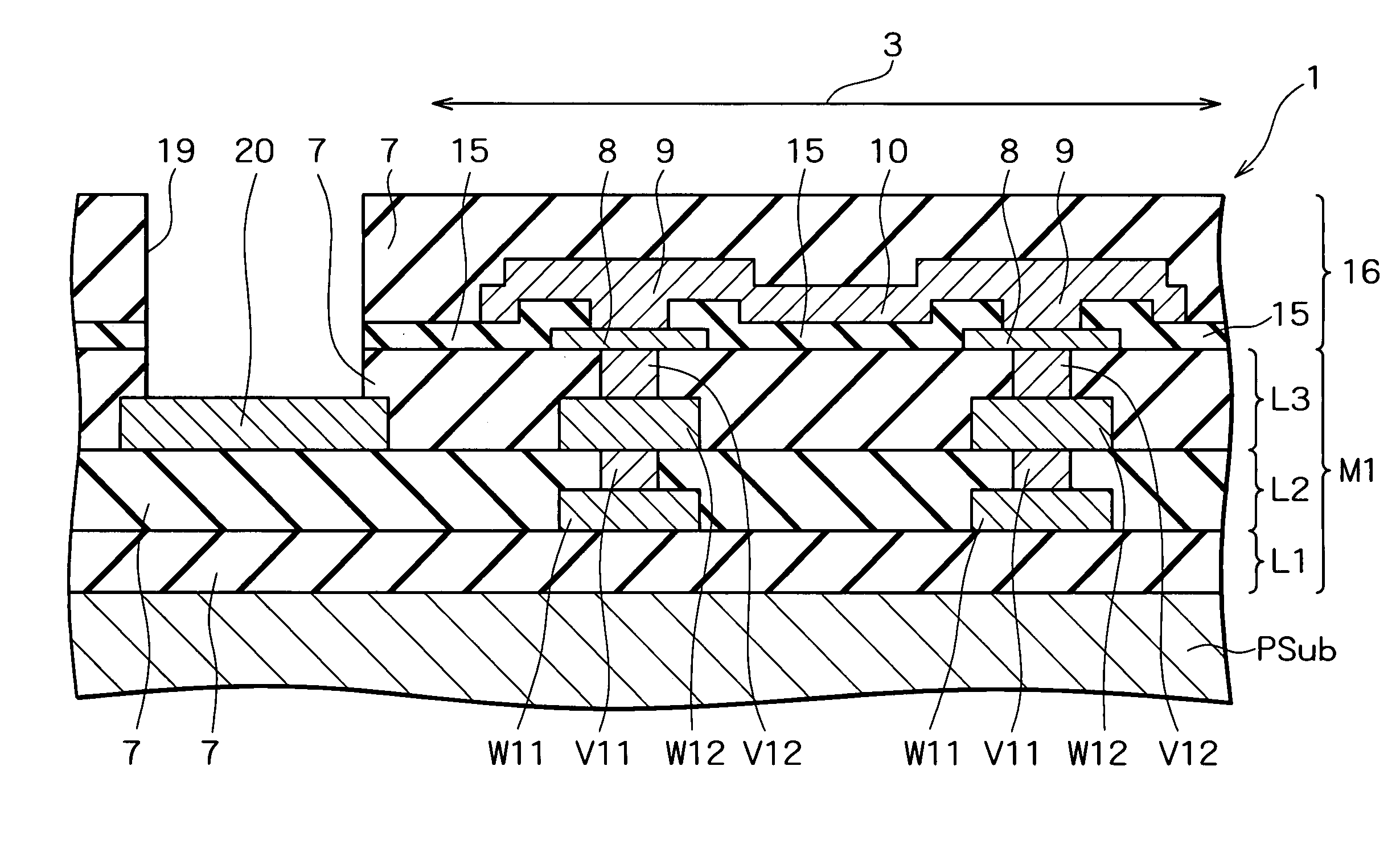

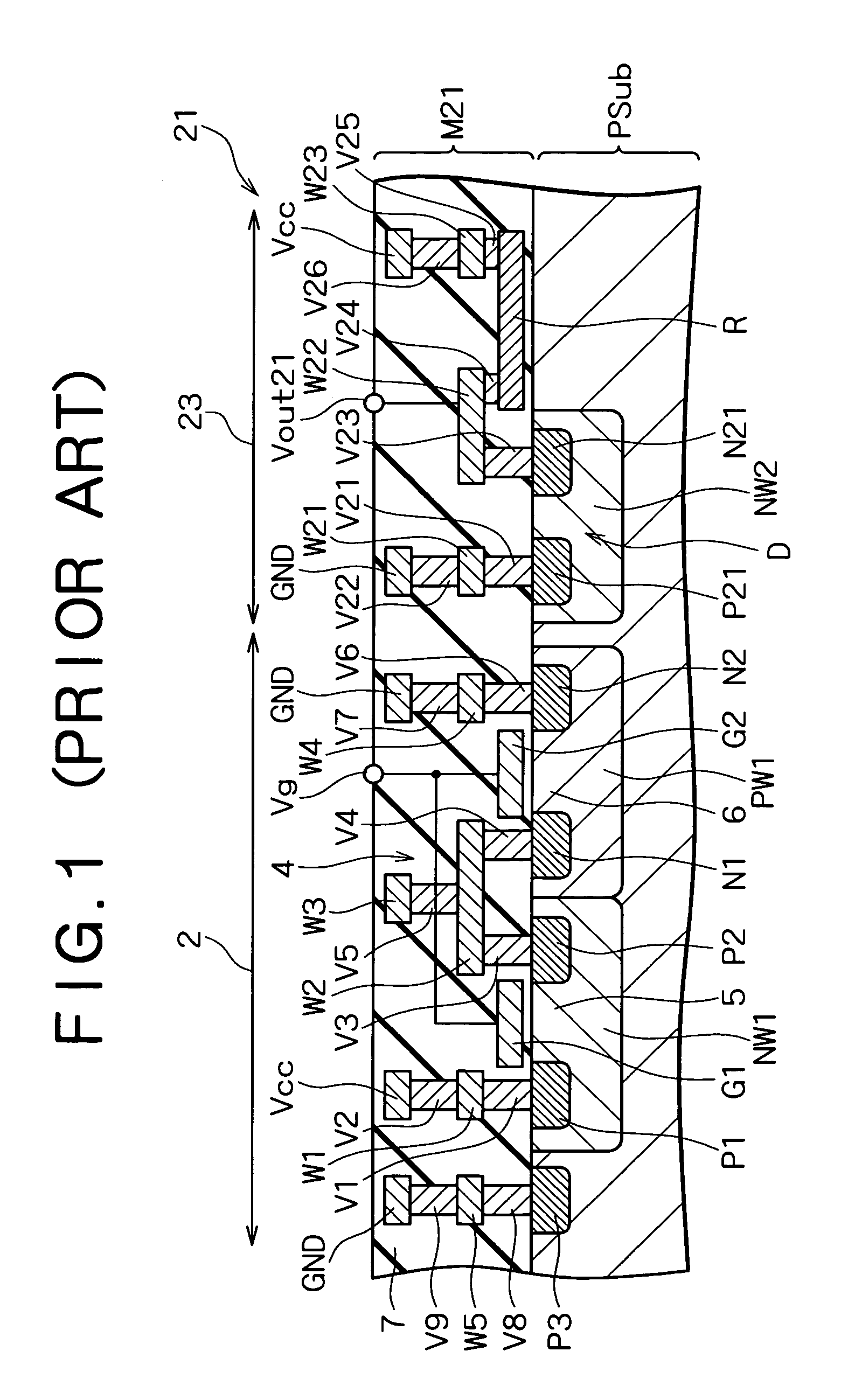

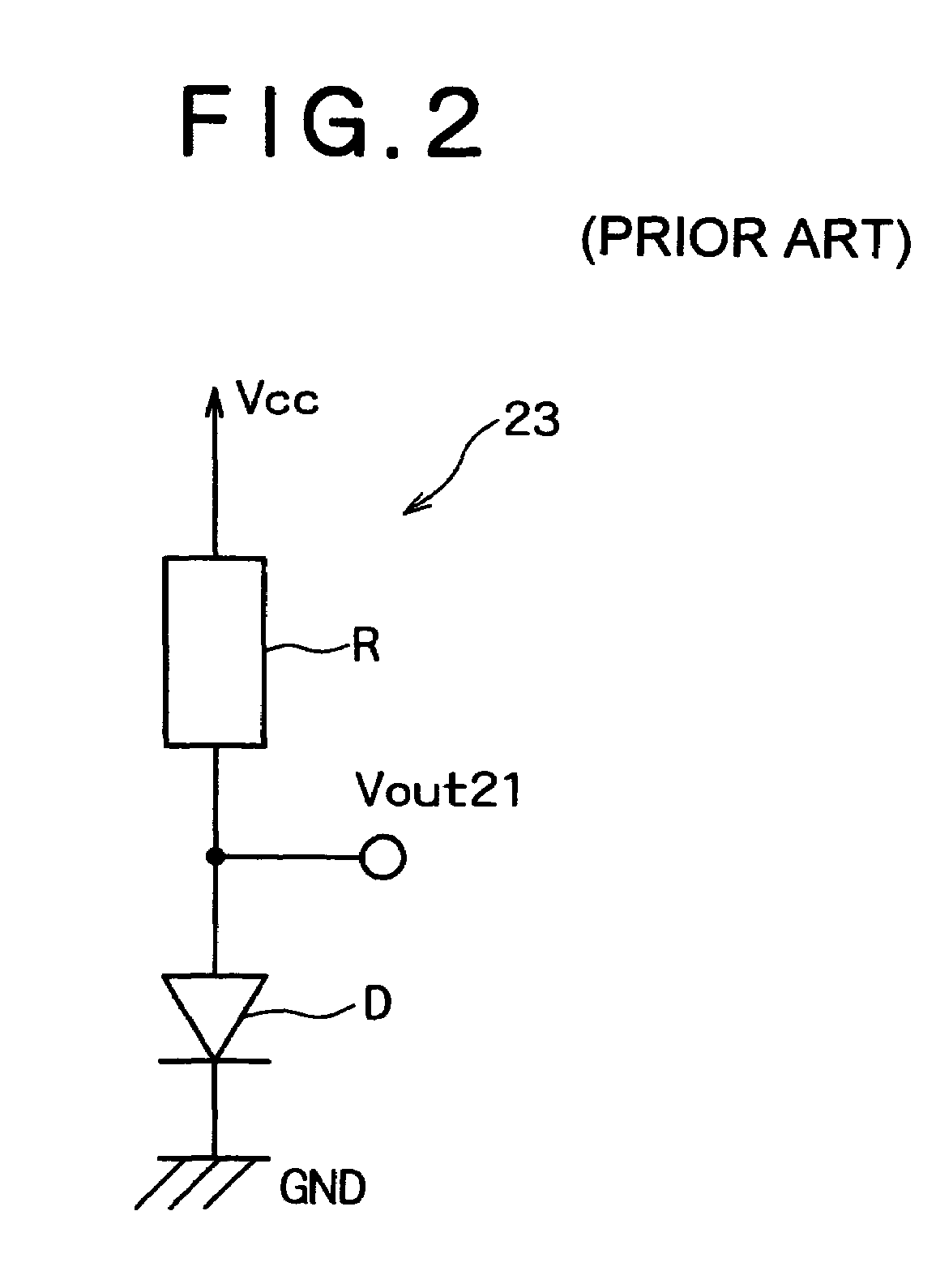

Display device

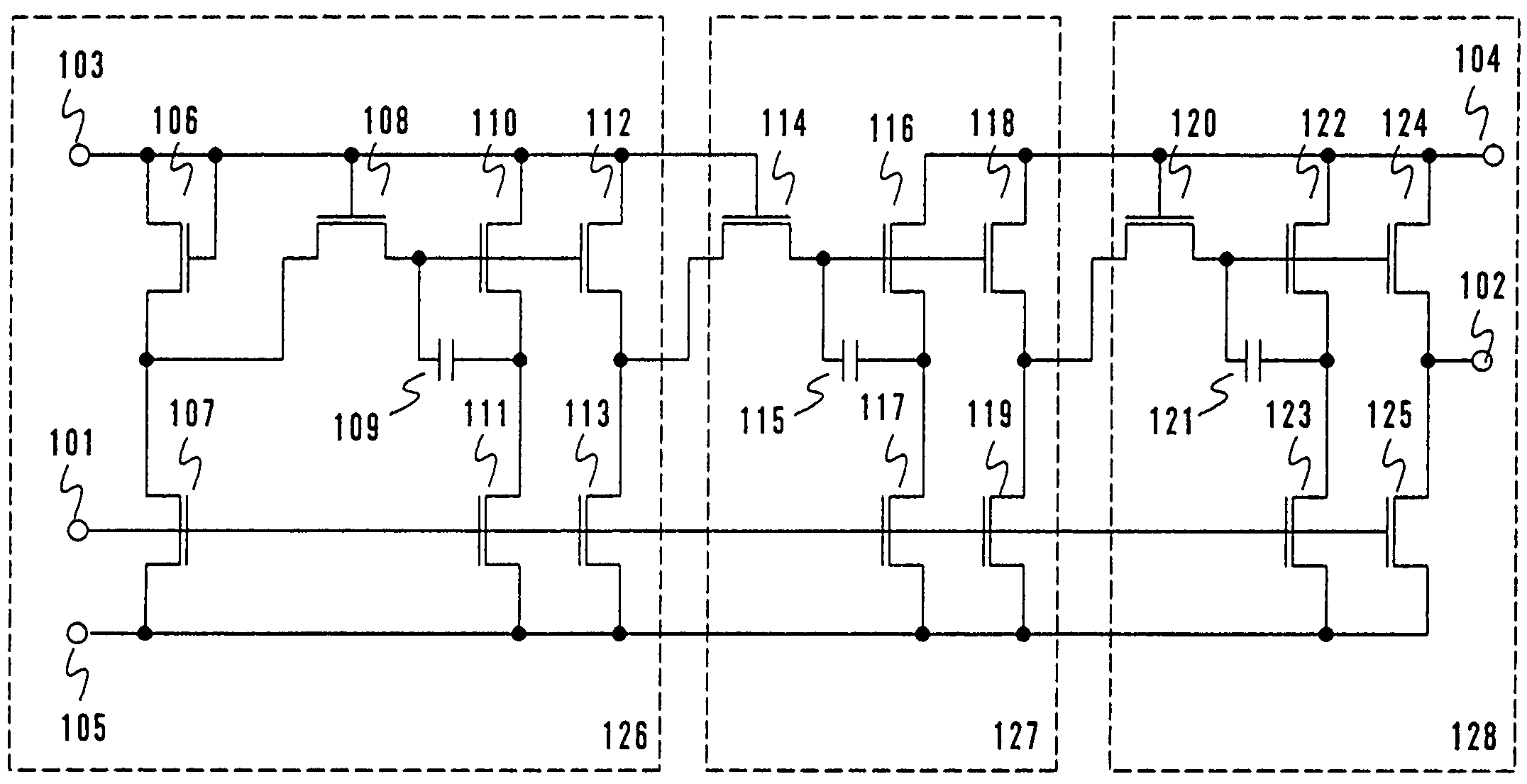

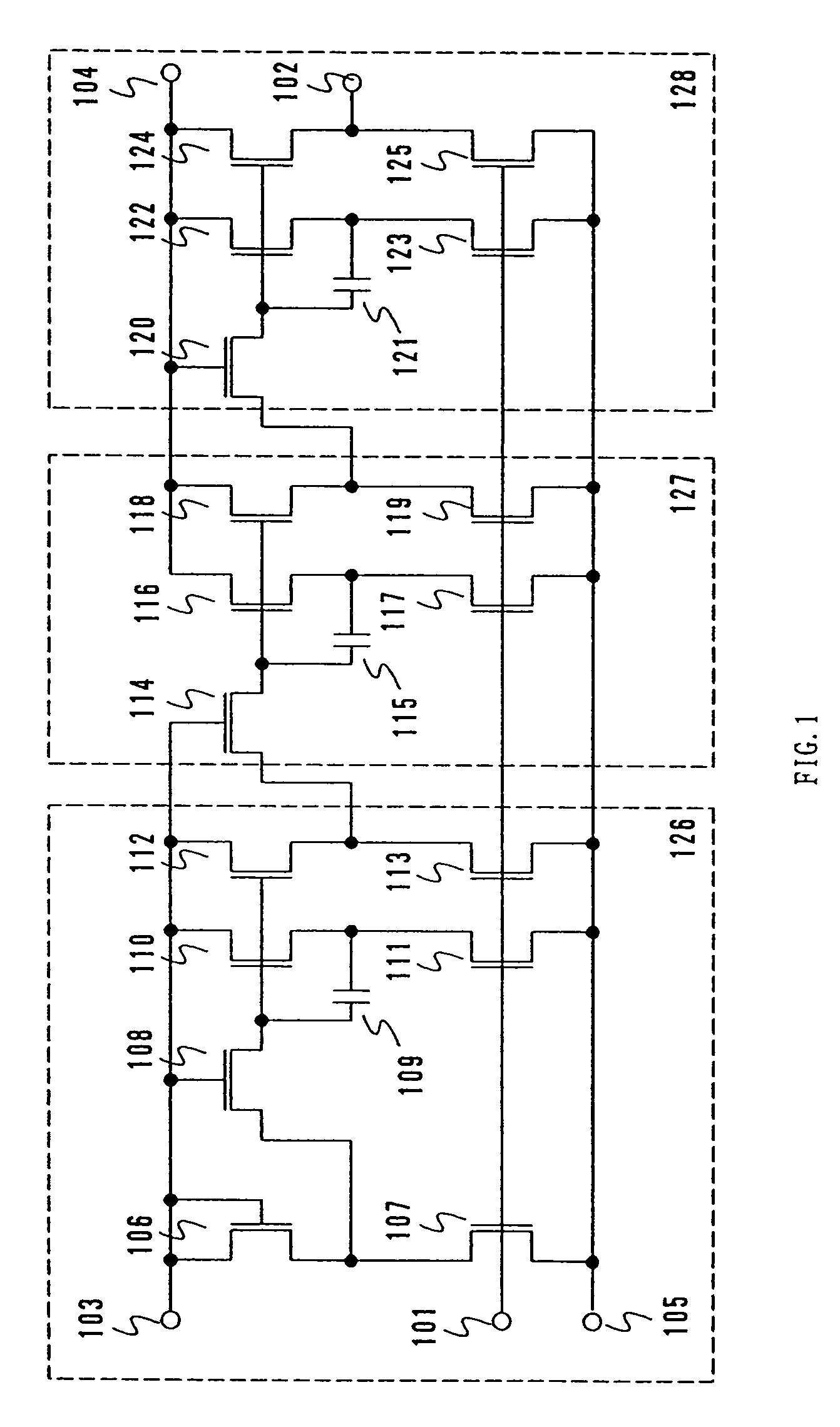

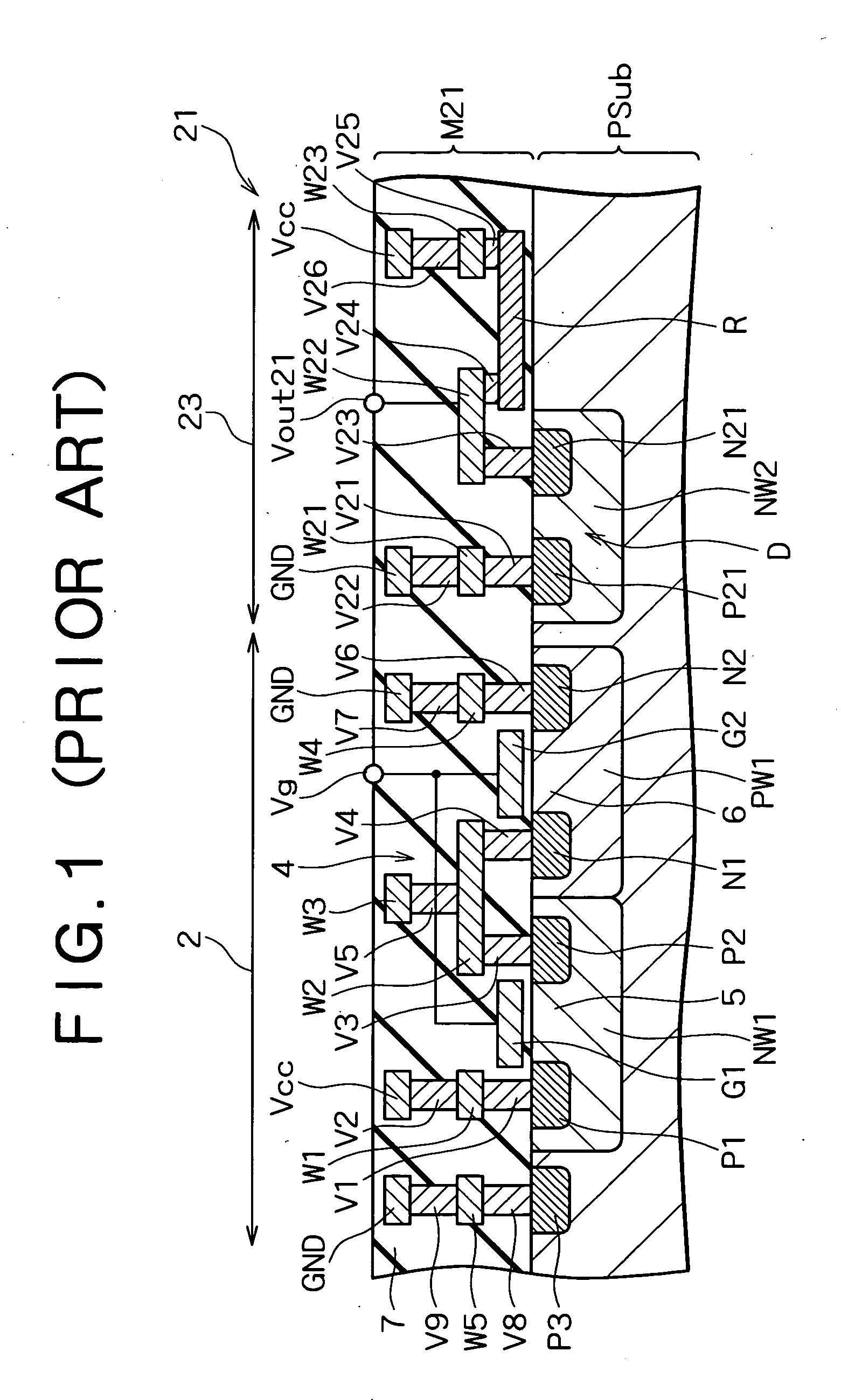

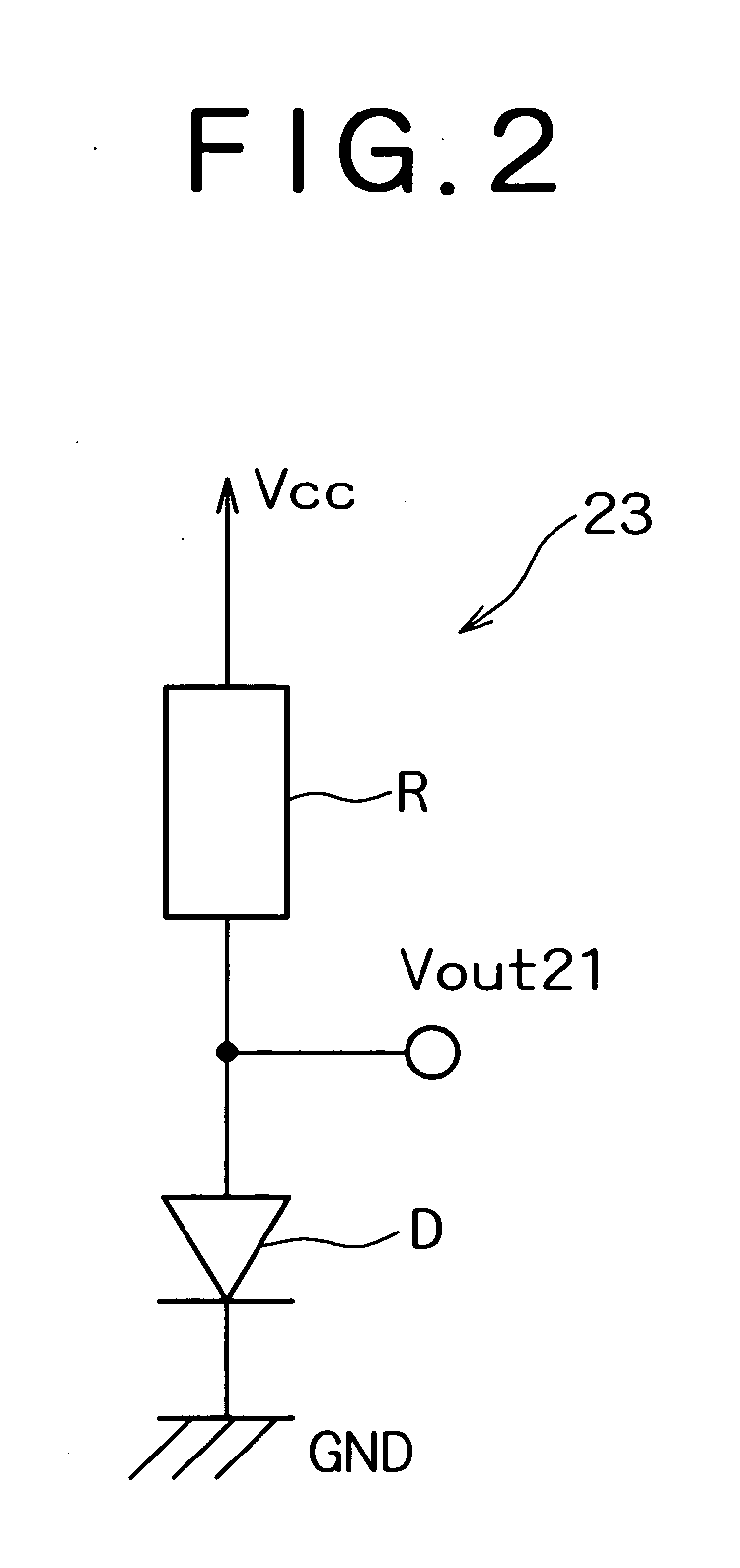

InactiveUS7511709B2High implementation costReduced connection reliabilityTransistorSolid-state devicesDriver circuitShift register

When semi-amorphous TFTs are used for forming a signal line driver circuit and a pixel, a large amplitude is required for driving the pixel, and a large power supply voltage is thus needed. On the other hand, when a shift register is made up of transistors having a single conductivity, a bootstrap circuit is required, and a voltage over a power supply is applied to a specific element. Therefore, not both the driving amplitude and the reliability can be achieved with a single power supply. According to the invention, a level shifter having a single conductivity is provided to solve such a problem.

Owner:SEMICON ENERGY LAB CO LTD

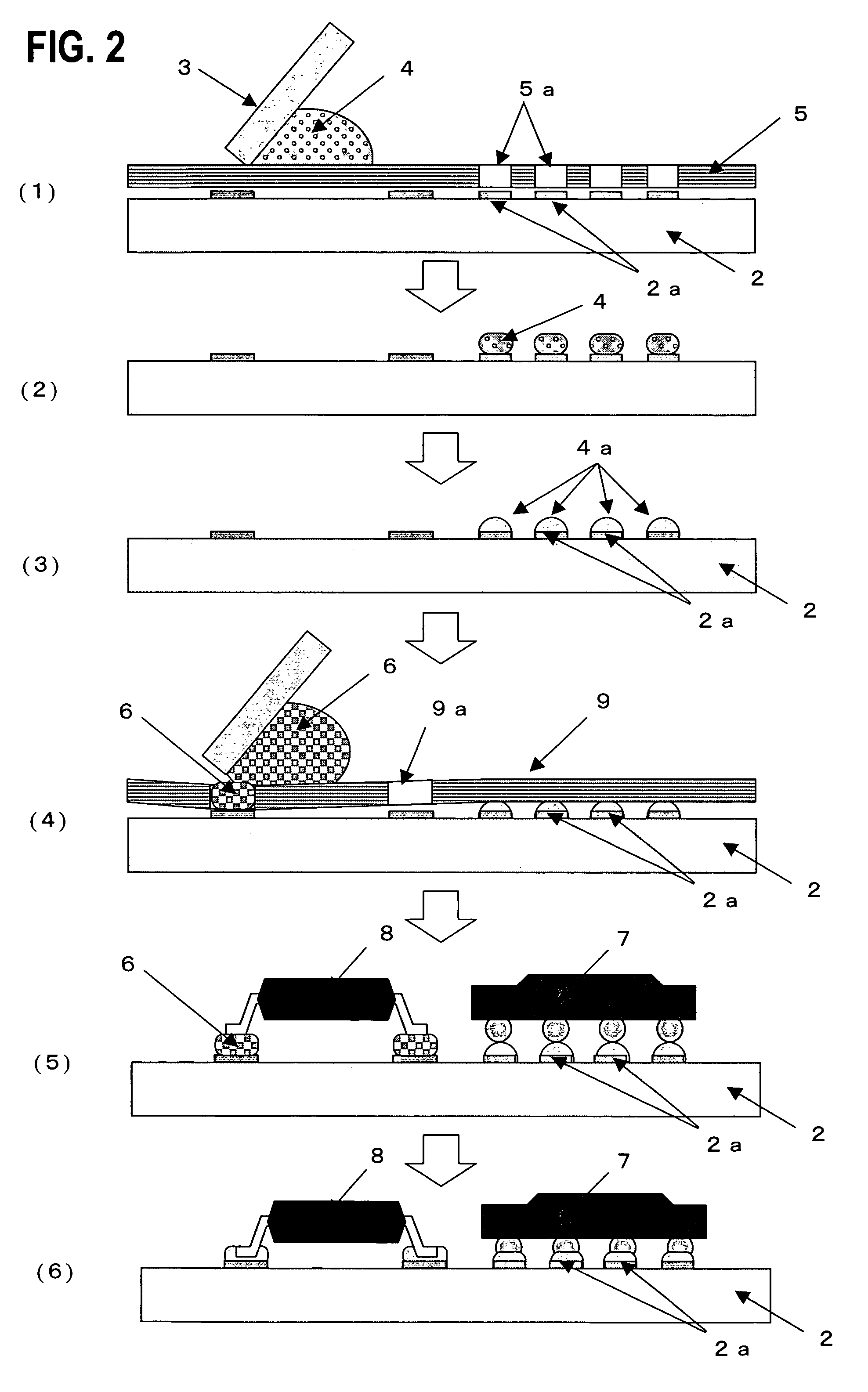

Method of manufacturing printed-circuit board

InactiveUS6889433B1Reduced connection reliabilityHigh densityLine/current collector detailsInsulating substrate metal adhesion improvementConductive pasteEngineering

By filling a predetermined amount of conductive paste into an opening for forming a through hole or a VH formed in a resin insulating layer of a circuit board, and pressurizing the filled conductive paste under the condition of reduced pressure, removing air bubble strapped in the conductive paste.

Owner:IBIDEN CO LTD

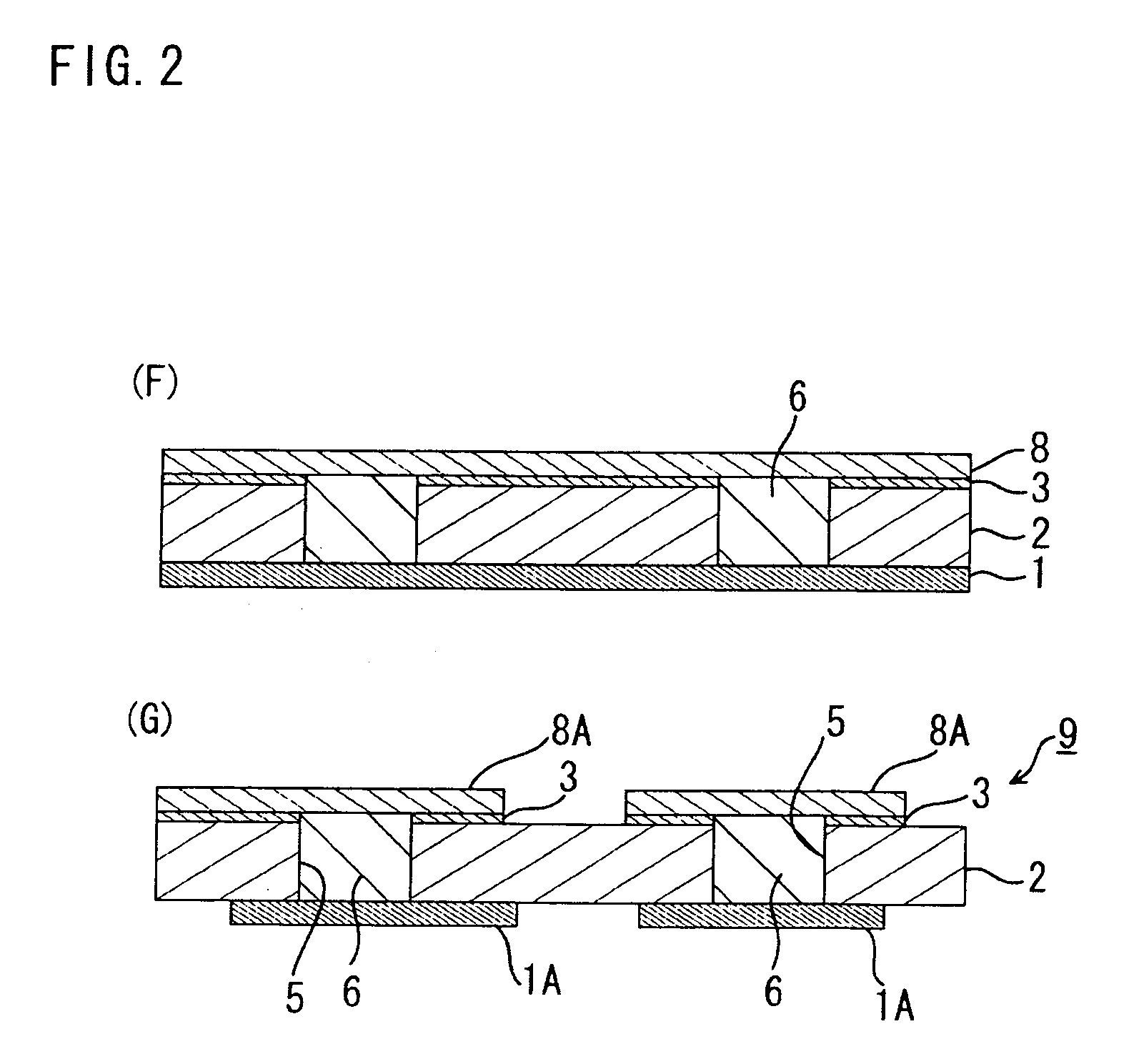

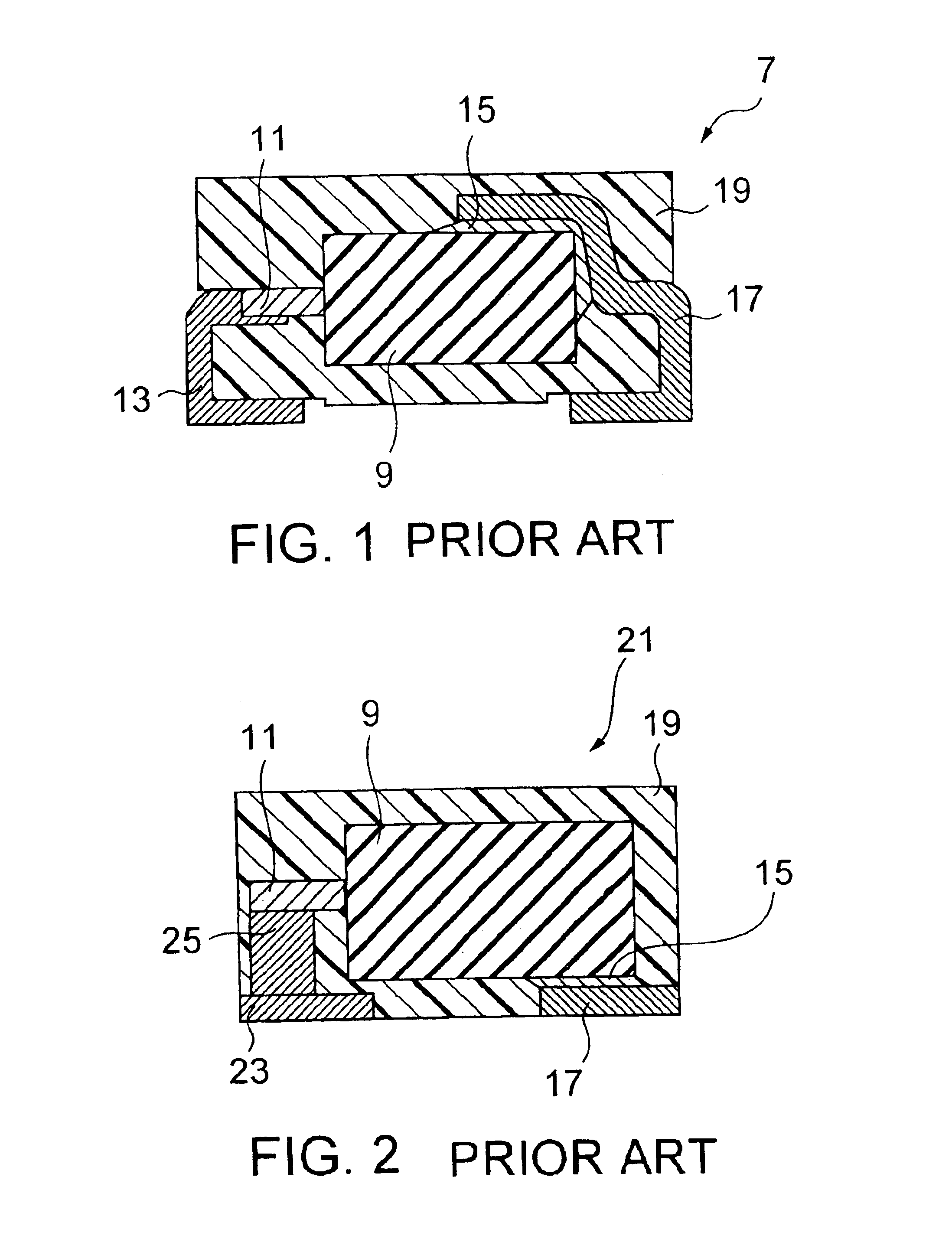

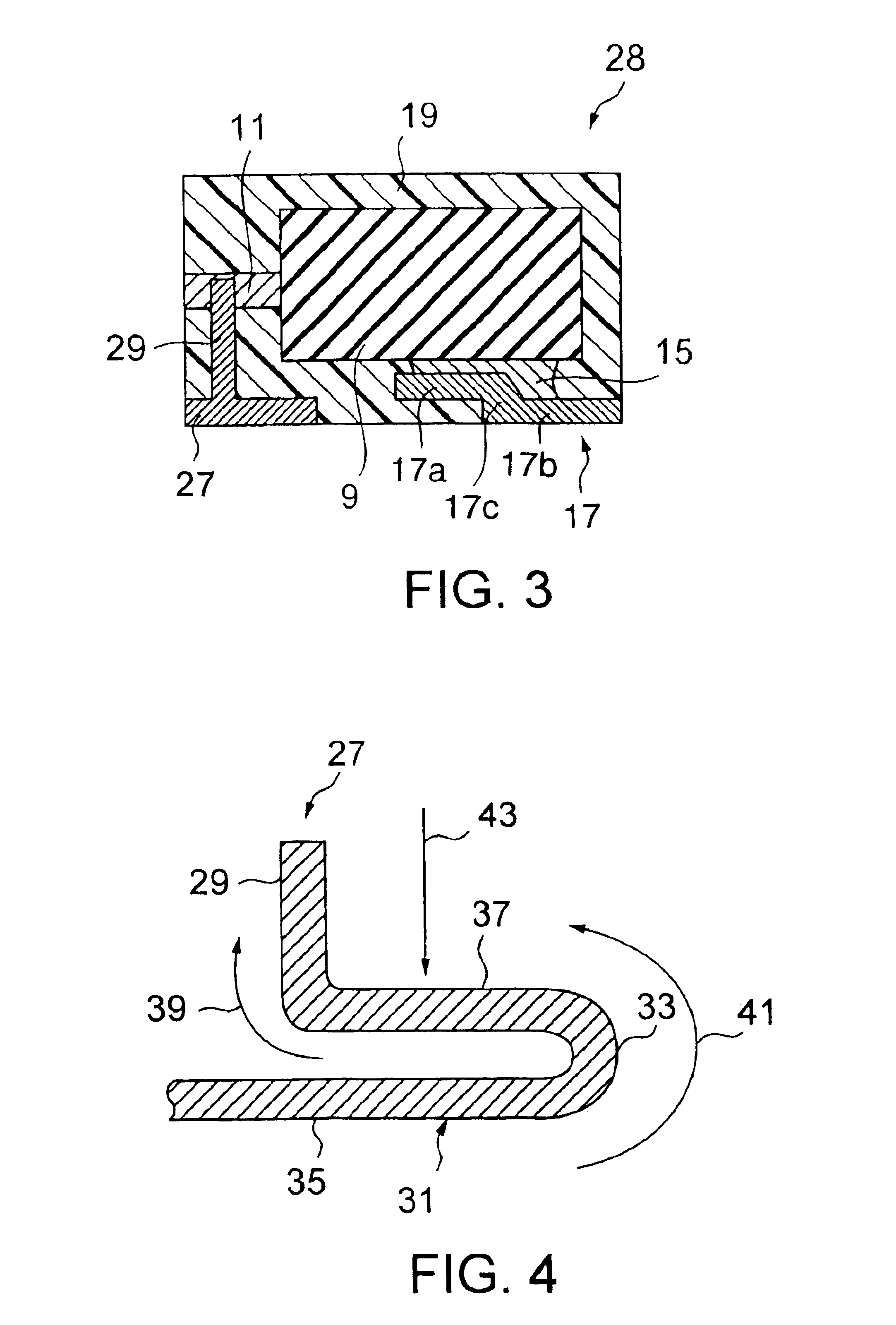

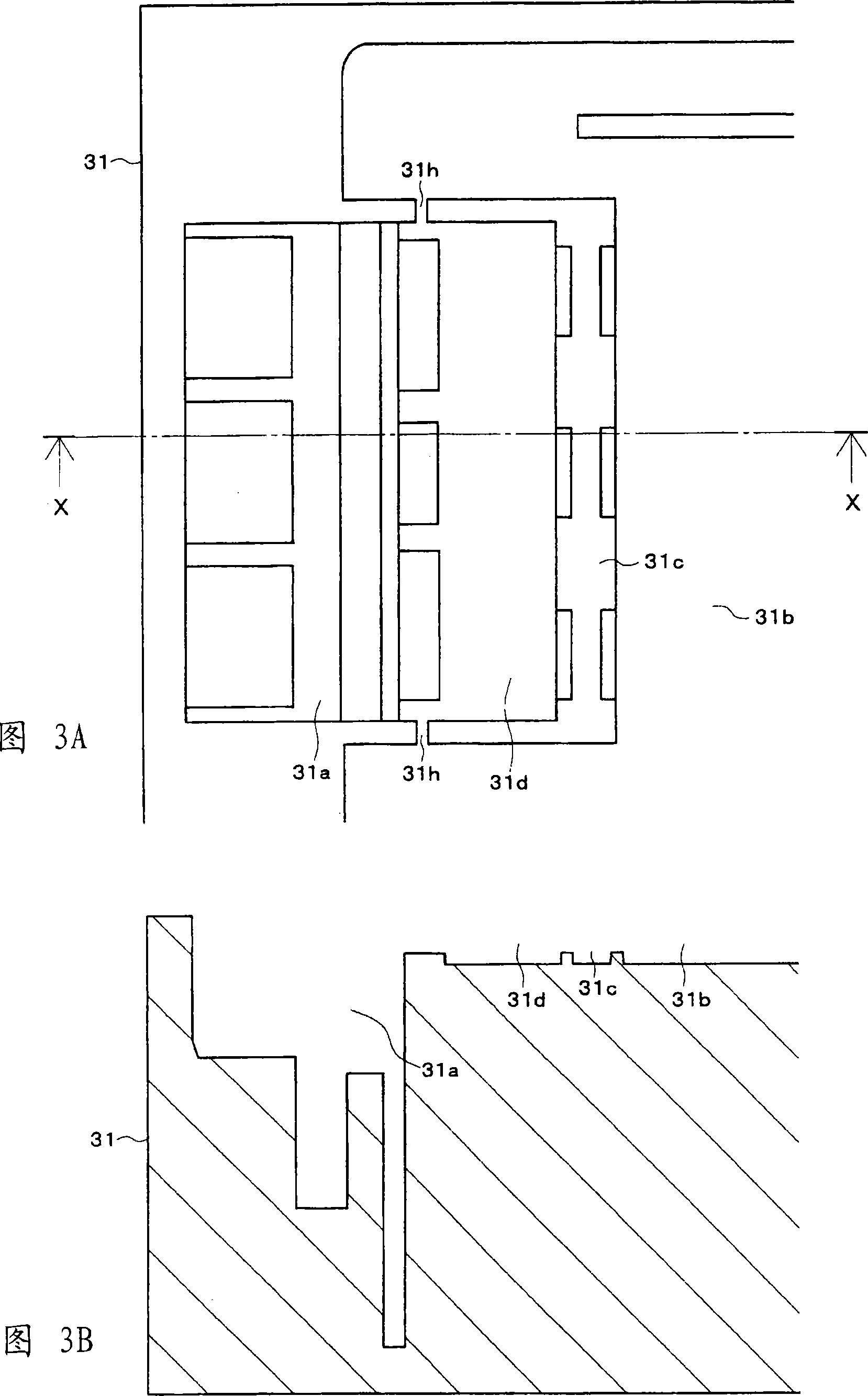

Solid electrolytic capacitor

InactiveUS6920037B2Small sizeLarge capacitanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisEngineering

In a solid electrolytic capacitor, an anode terminal (27 in FIG. 3) has a T-shaped section in which two plate pieces intersect at right angles. One of the two plate pieces is exposed to the mounting surface of the solid electrolytic capacitor, while the other is perpendicularly erected to an anode lead (11). The two plate pieces are made of a series of continuous members.

Owner:TOKIN CORP

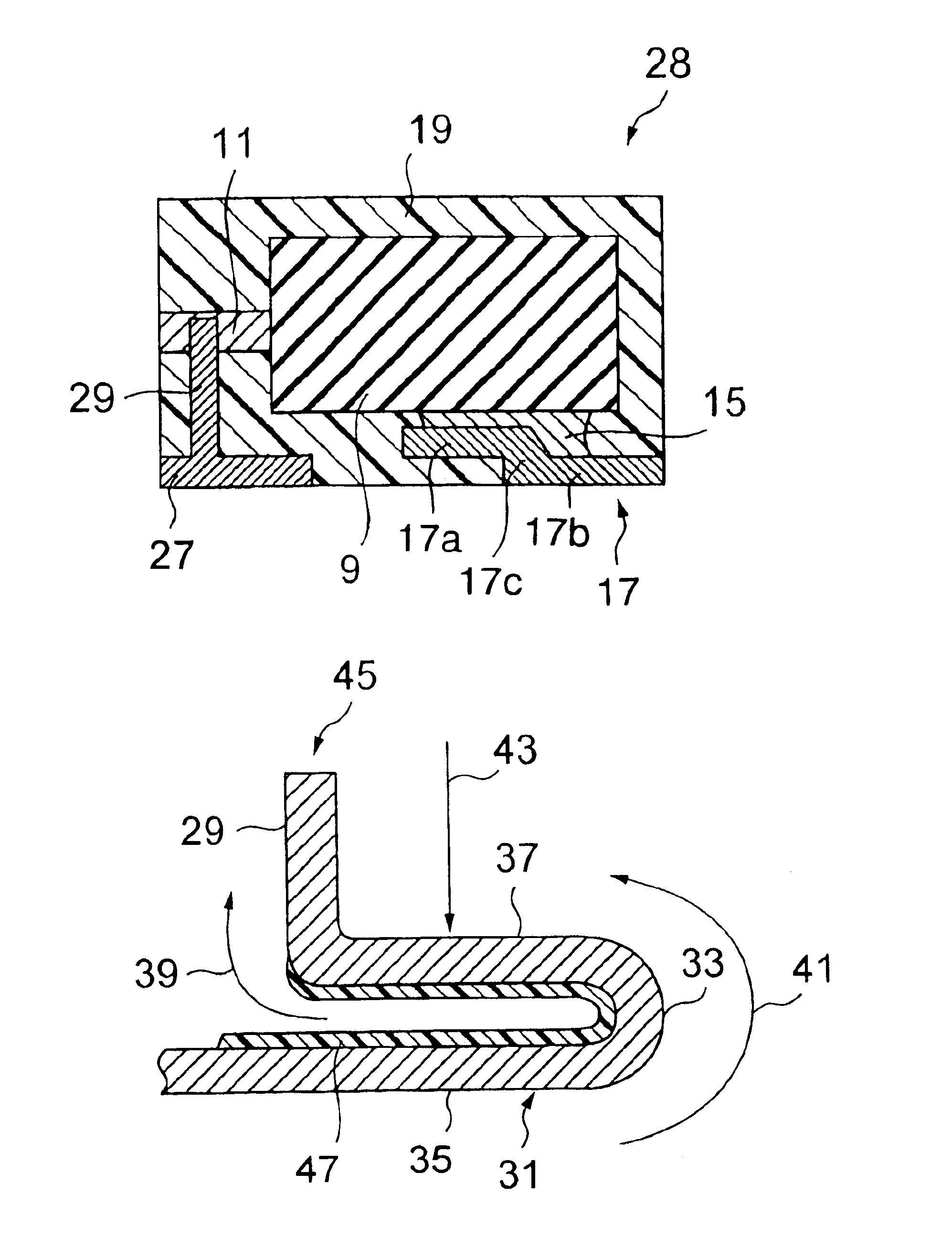

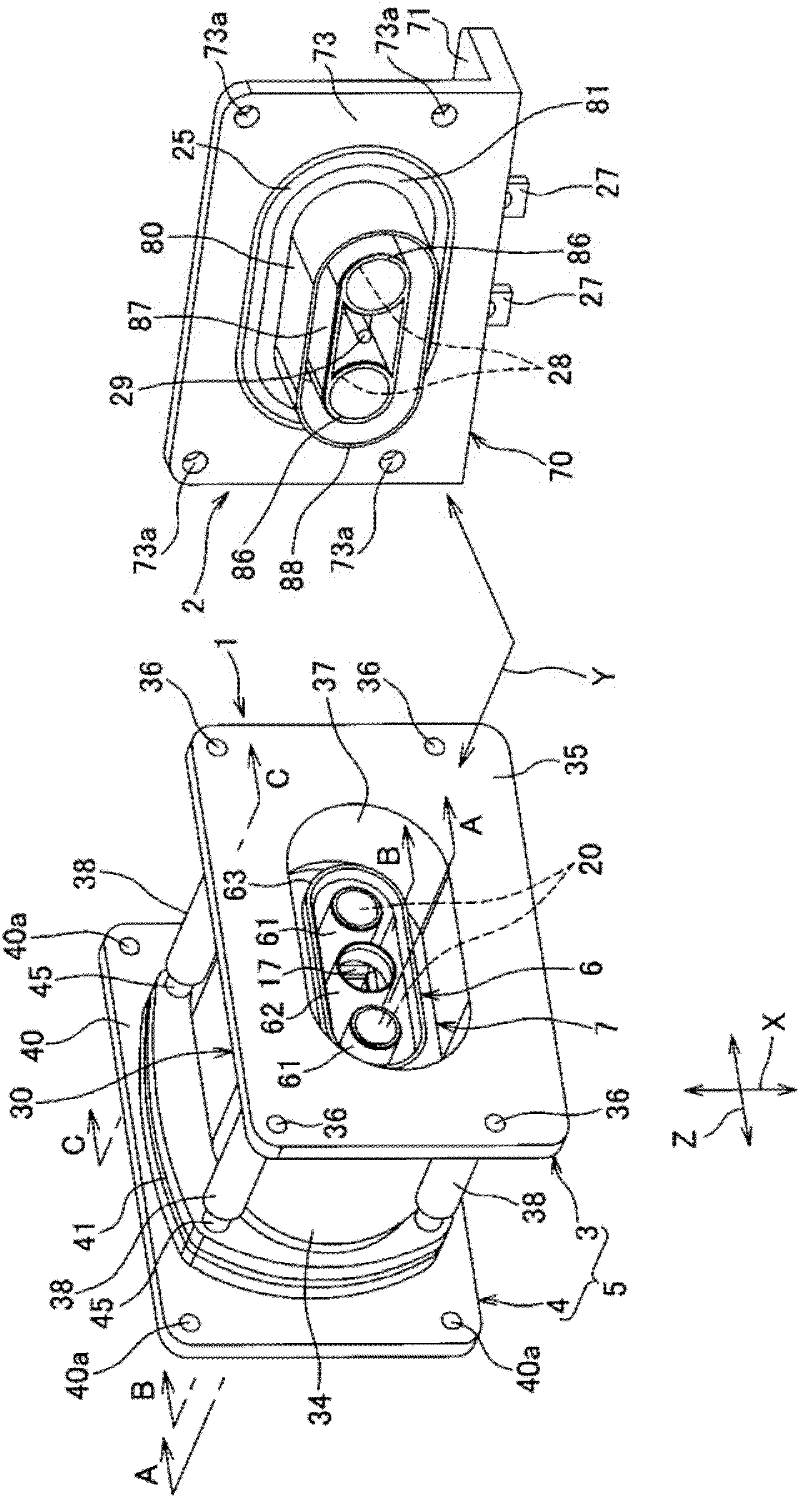

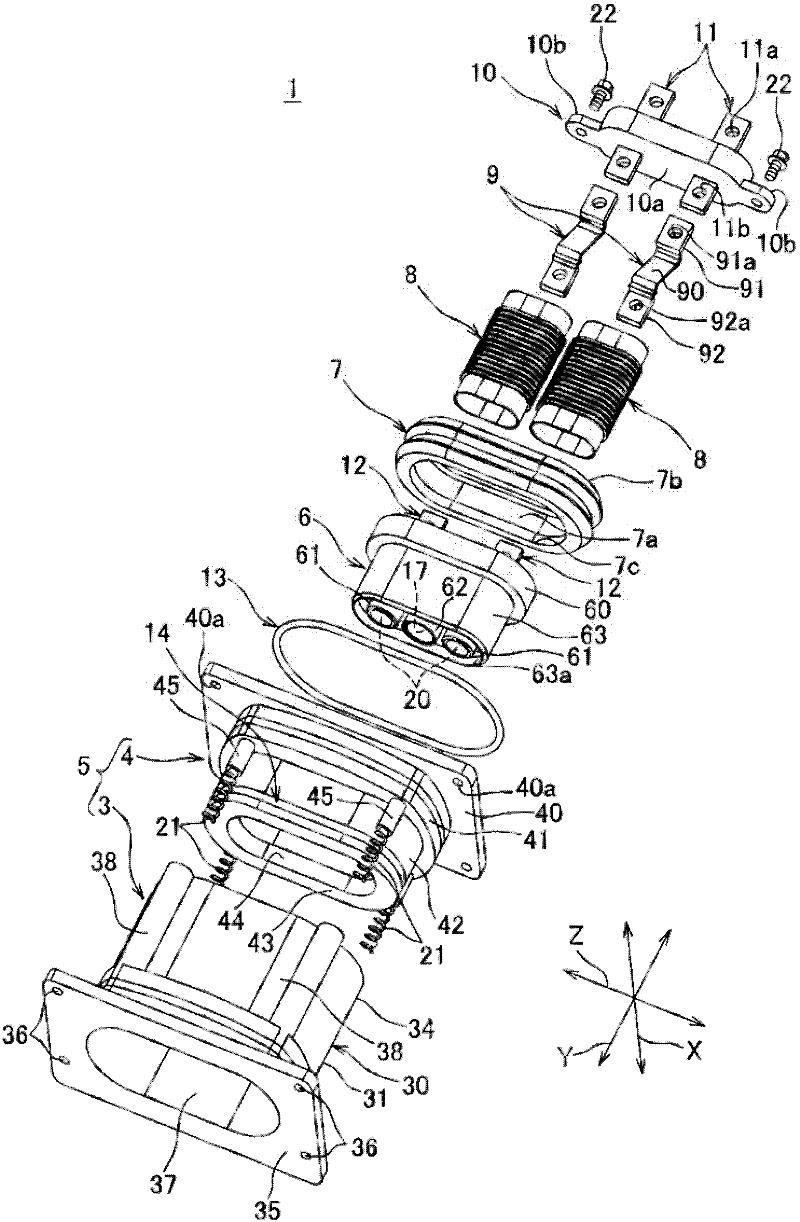

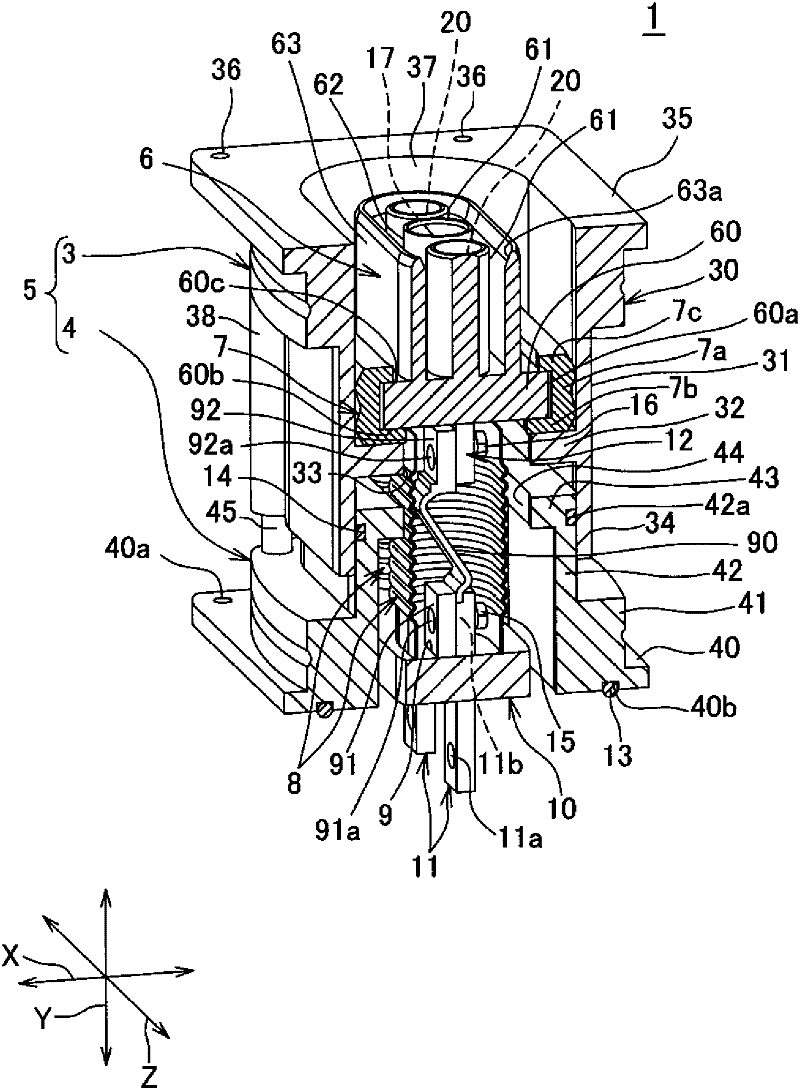

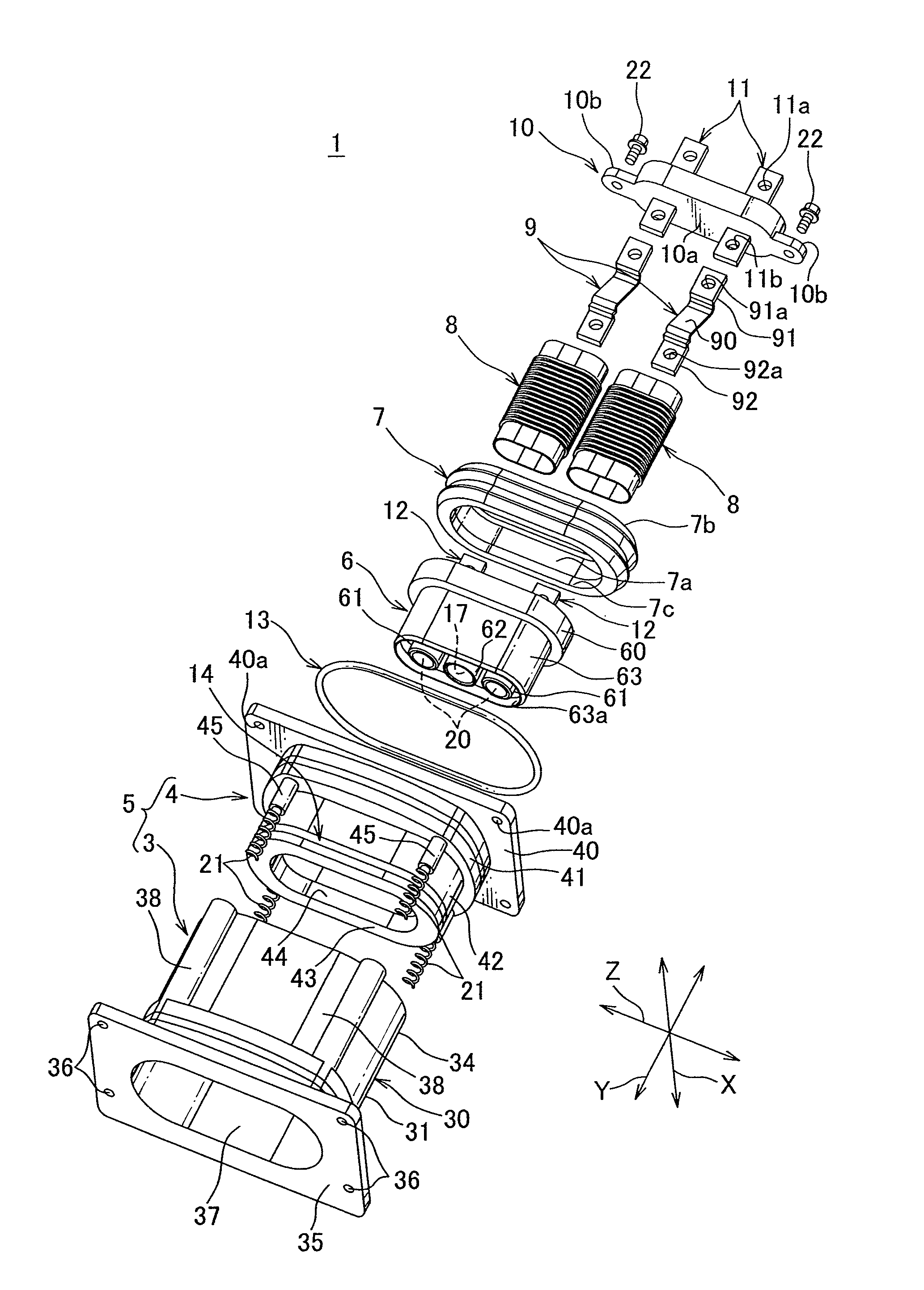

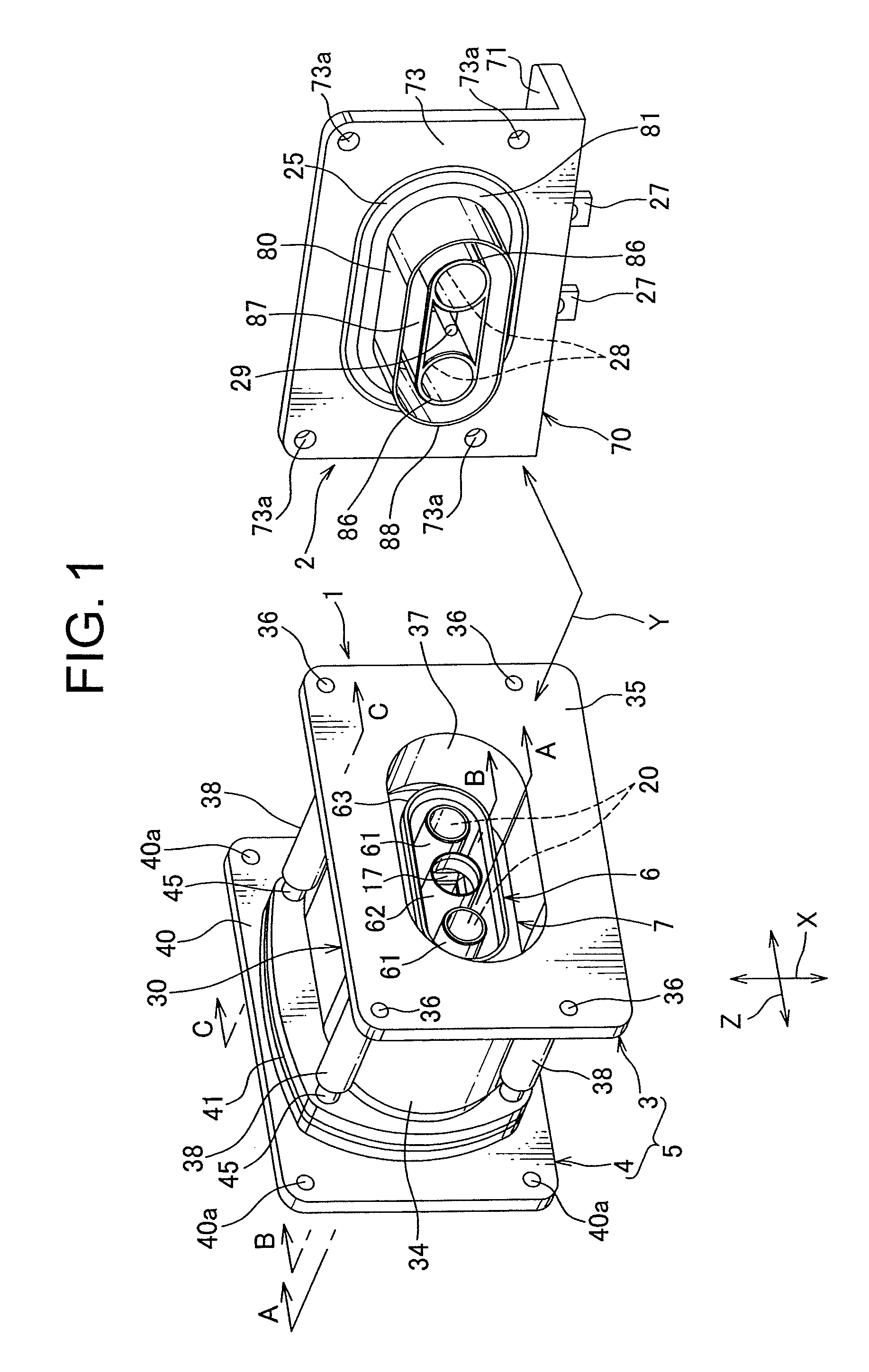

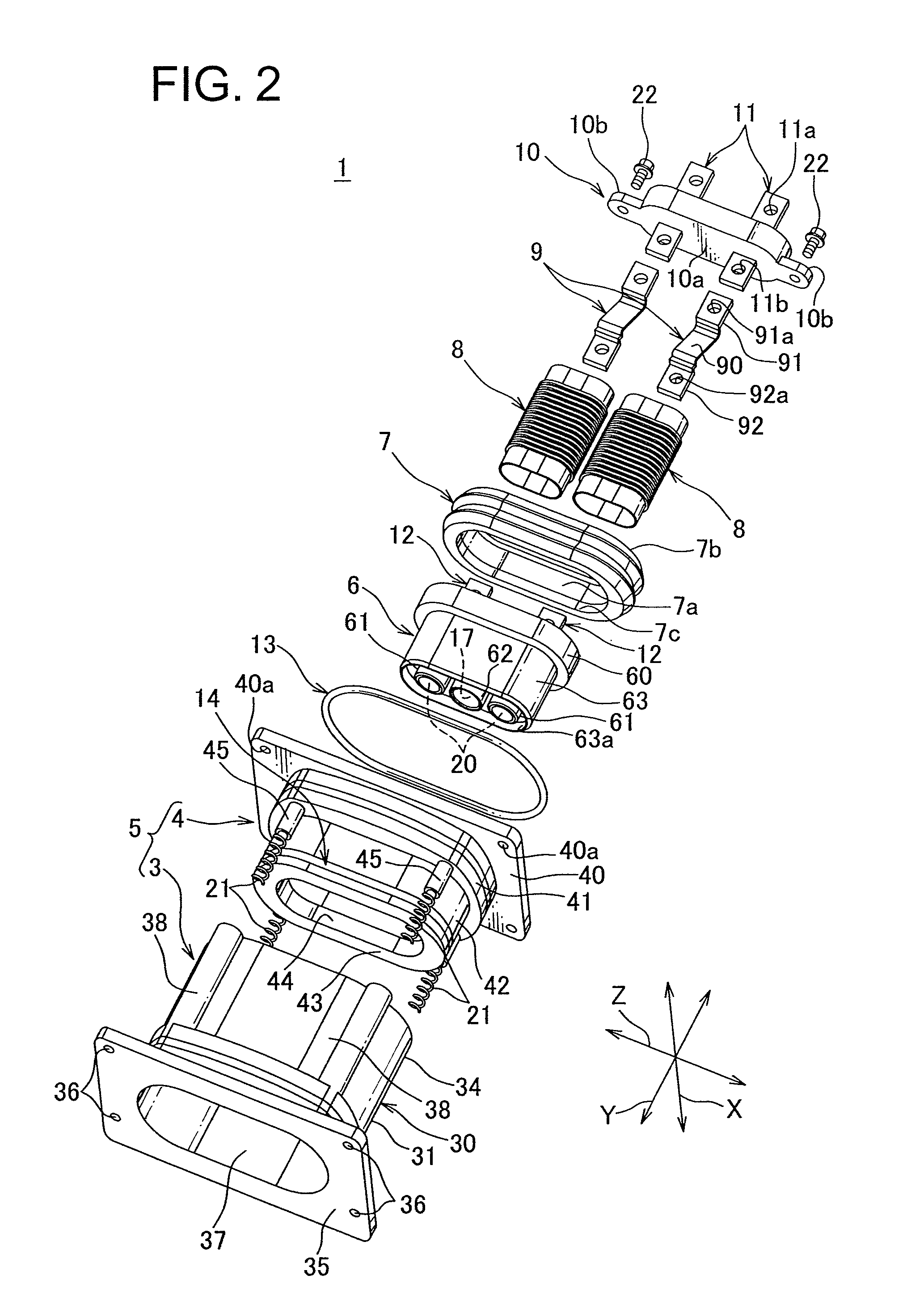

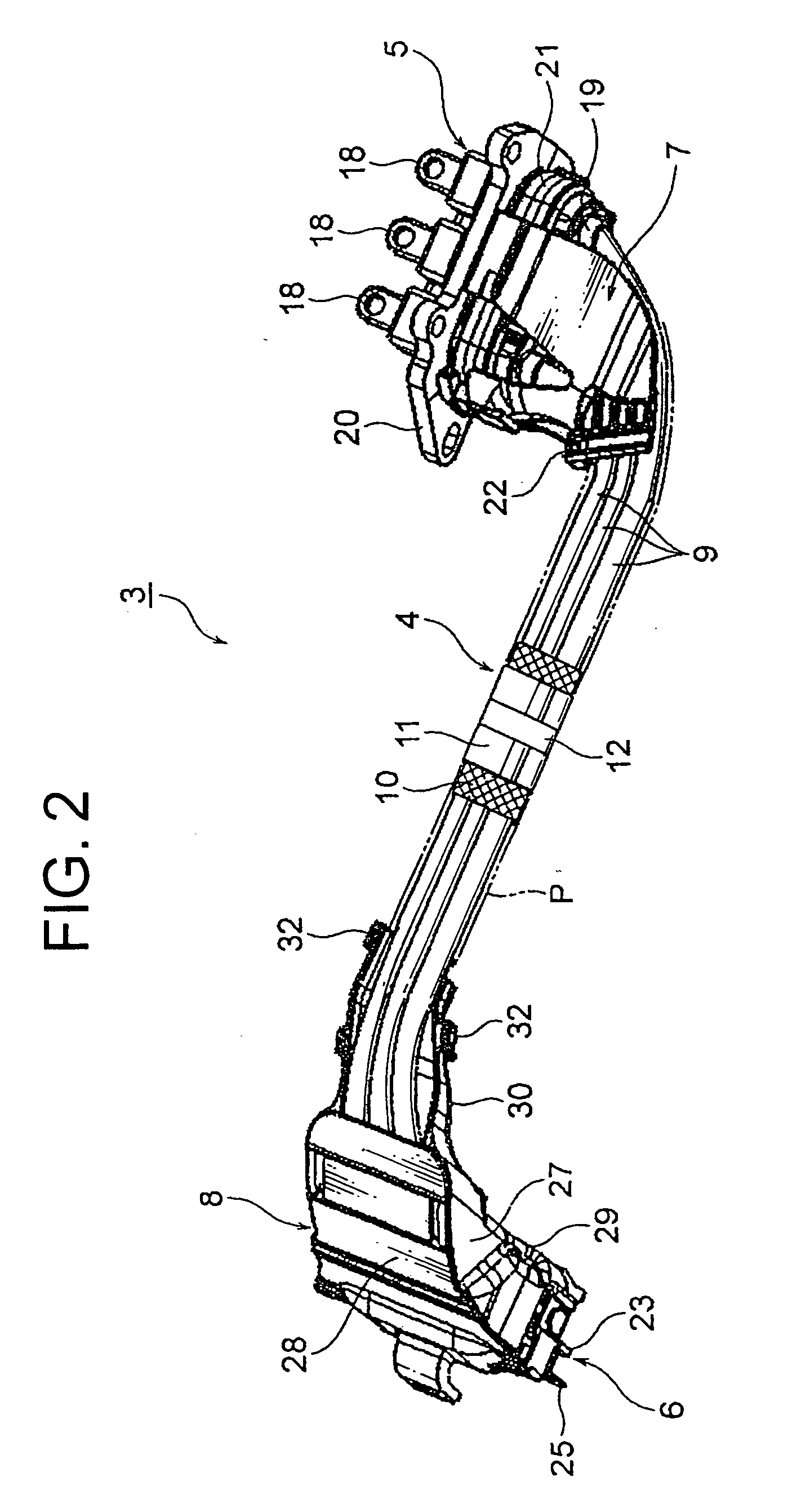

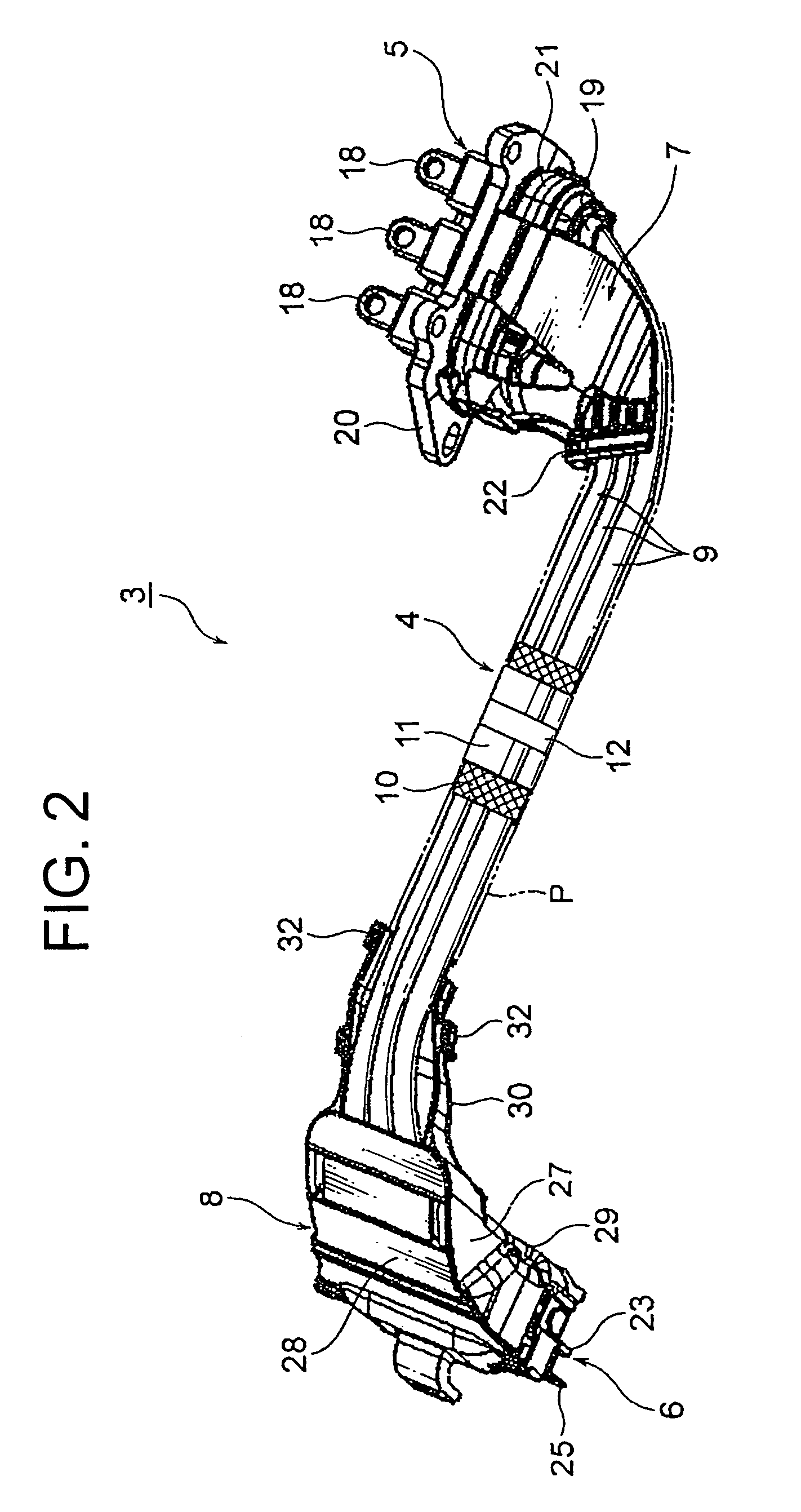

Connector

ActiveCN102449858AReduce stressReduced connection reliabilityVehicle connectorsCouplings bases/casesEngineeringElectric wire

Provided is a connector which can absorb the position gap with respect to a counterpart connector, and can maintain an excellent connection with an electric circuit within a case to which the connector is attached. The connector (1) connected to a counterpart connector secured to a case of a motor is comprised of an outer housing (5) attached to a case of an inverter; a first inner housing (6) which contains a first terminal (20) engaged with a terminal of the counterpart connector and which is contained in the outer housing (5) so as to move in an engaging direction (Y) of the first terminal (20) and a direction intersecting with the engaging direction (Y) in order to engage with the counterpart connector; a second inner housing (10) which contains a second terminal (11) electrically connected to an electric circuit within the case and which is fixed within the outer housing (5); a connection portion (9) which is composed of a braided electric wire (90) and which electrically connects the first terminal (20) to the second terminal (11); and a packing (7) attached to the first inner housing (6).

Owner:YAZAKI CORP

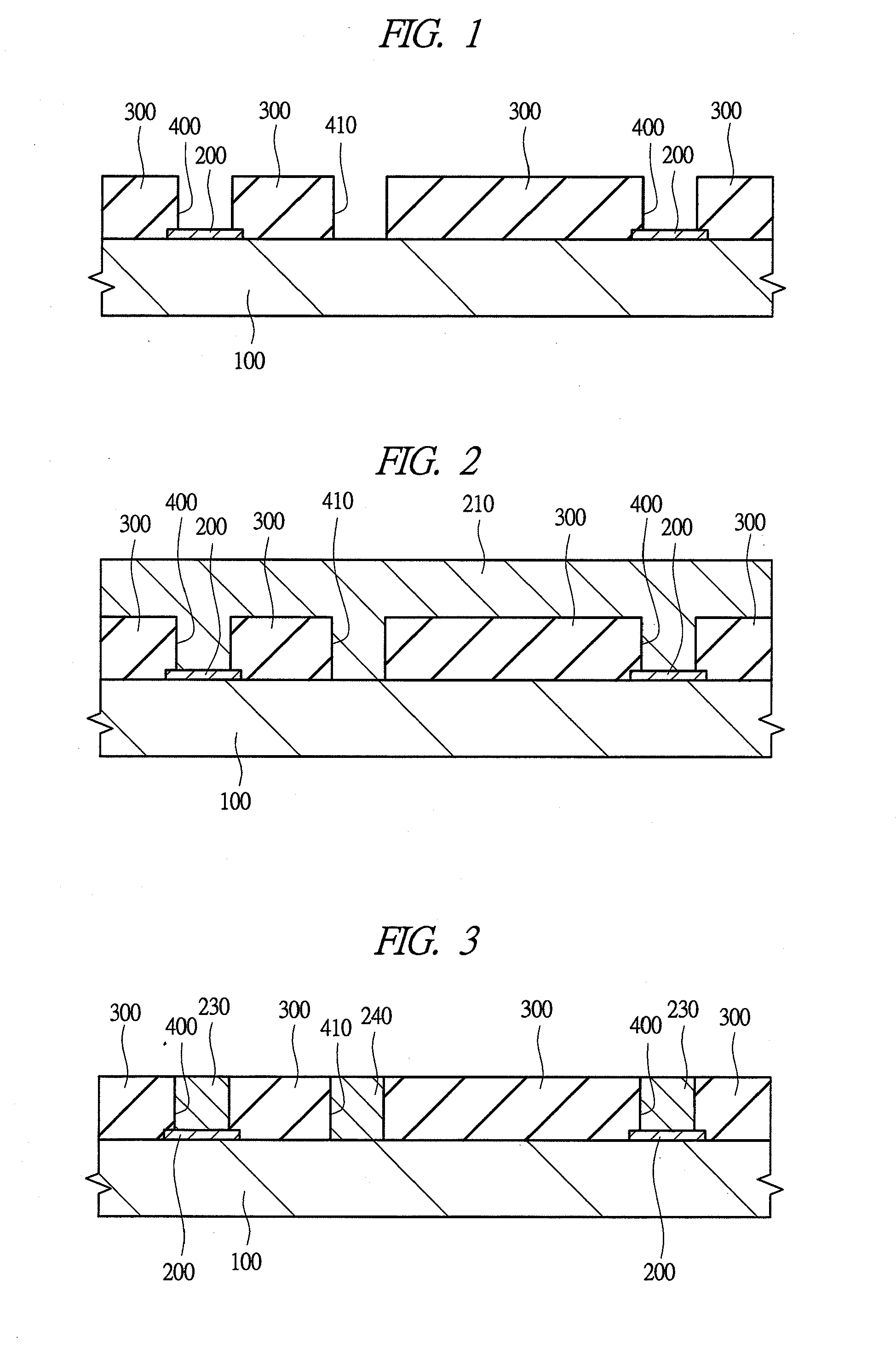

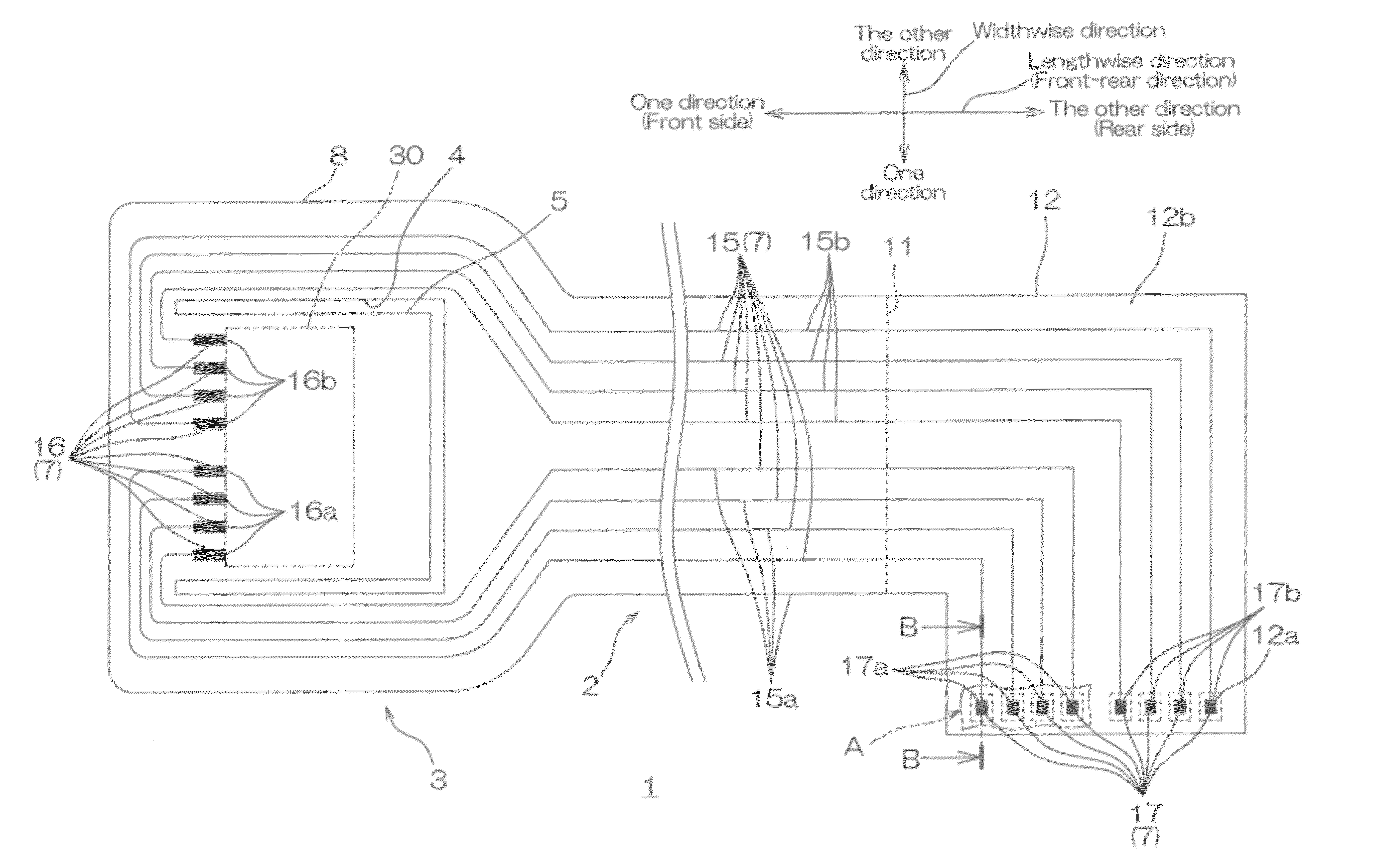

Display device

InactiveUS20050012887A1High implementation costReduced connection reliabilityTransistorSolid-state devicesDriver circuitShift register

When semi-amorphous TFTs are used for forming a signal line driver circuit and a pixel, a large amplitude is required for driving the pixel, and a large power supply voltage is thus needed. On the other hand, when a shift register is made up of transistors having a single conductivity, a bootstrap circuit is required, and a voltage over a power supply is applied to a specific element. Therefore, not both the driving amplitude and the reliability can be achieved with a single power supply. According to the invention, a level shifter having a single conductivity is provided to solve such a problem.

Owner:SEMICON ENERGY LAB CO LTD

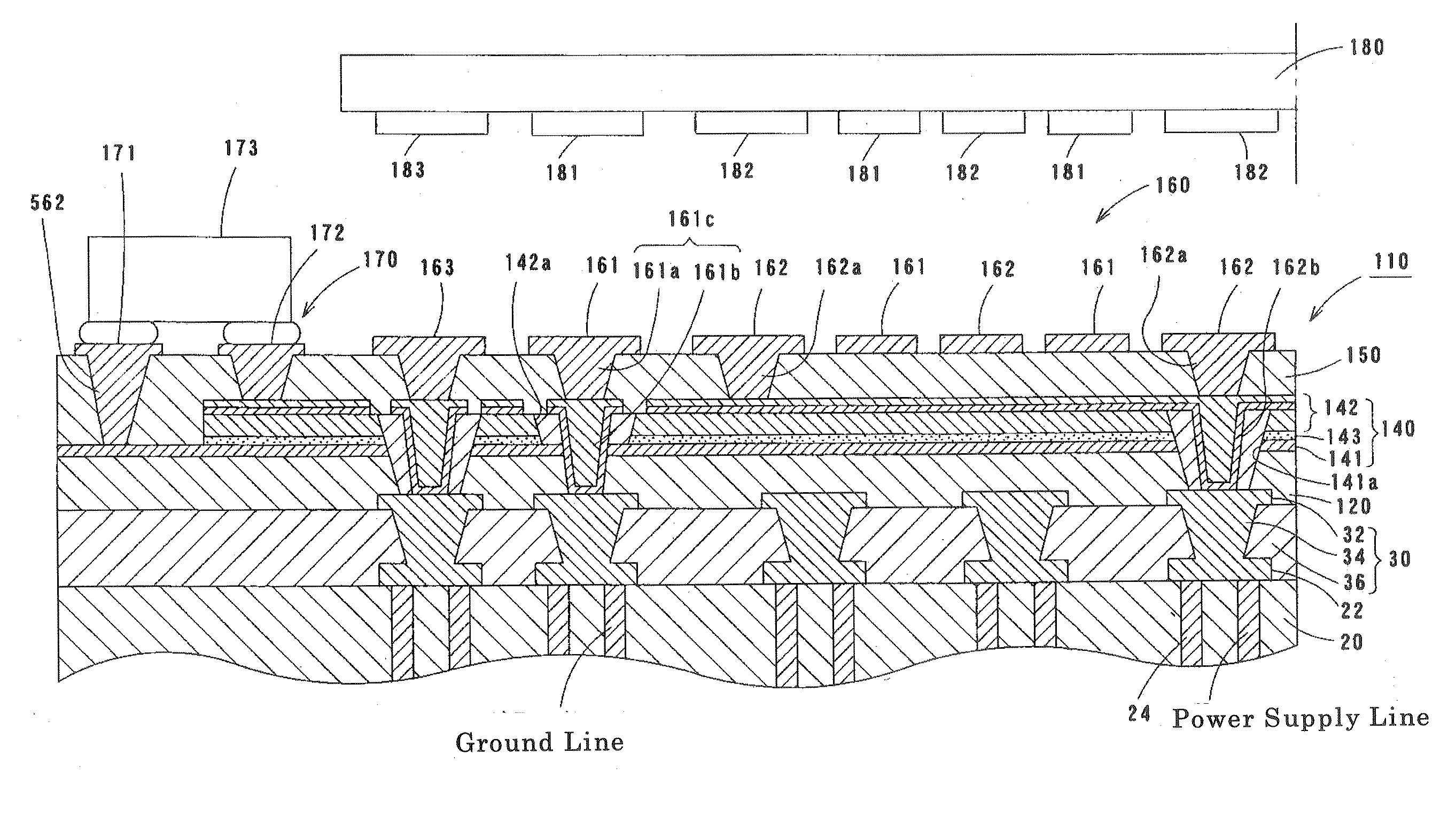

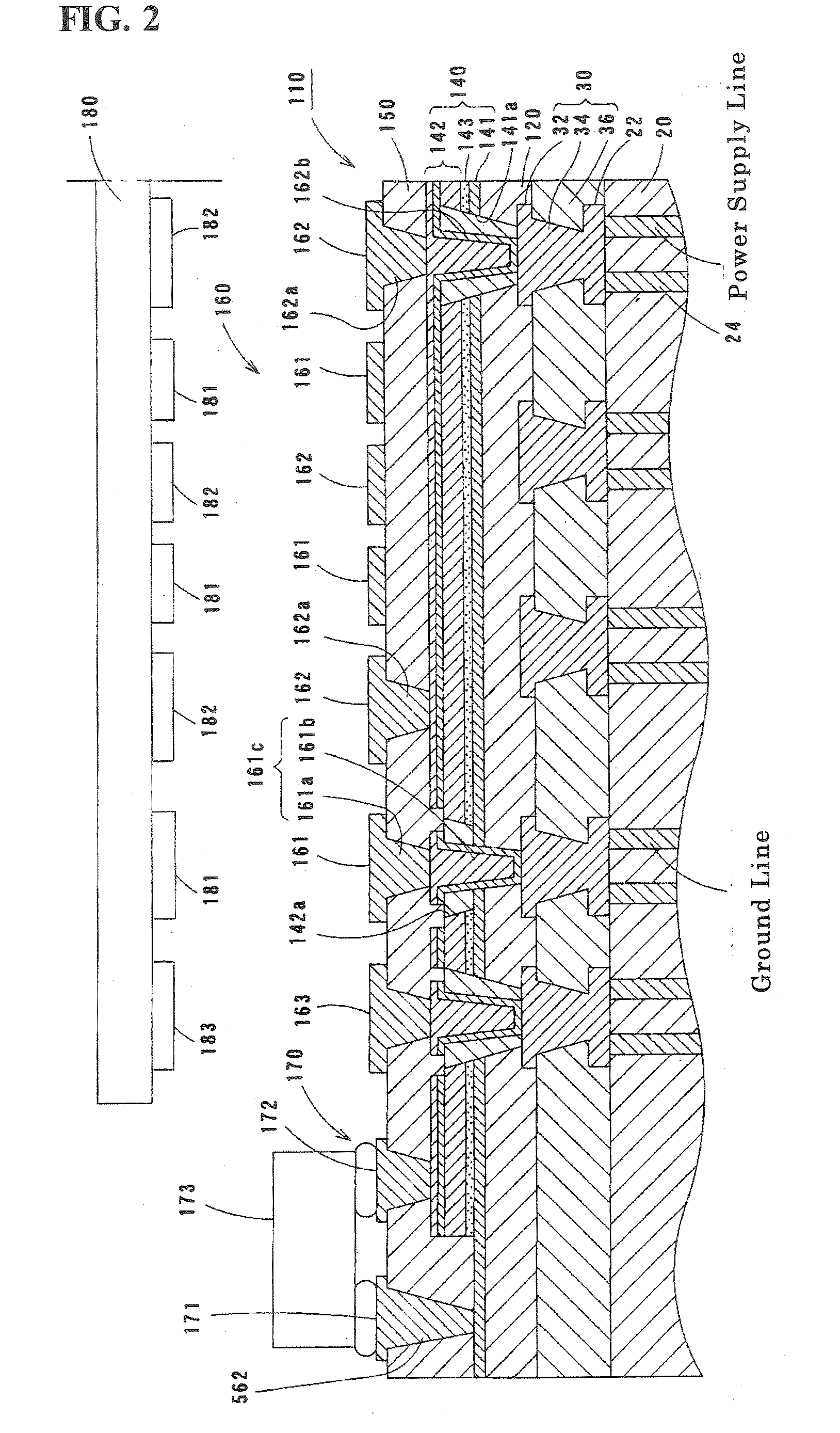

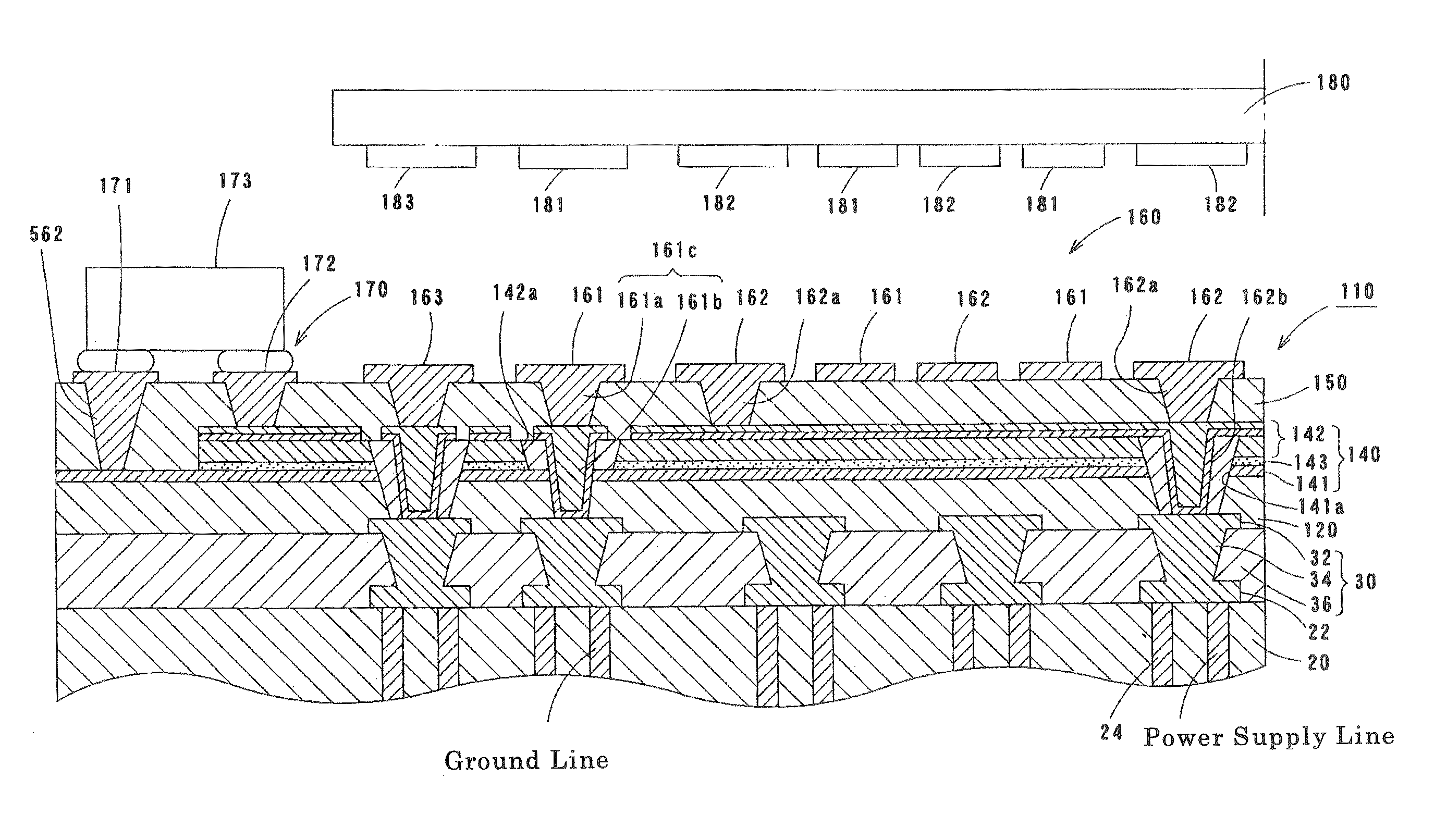

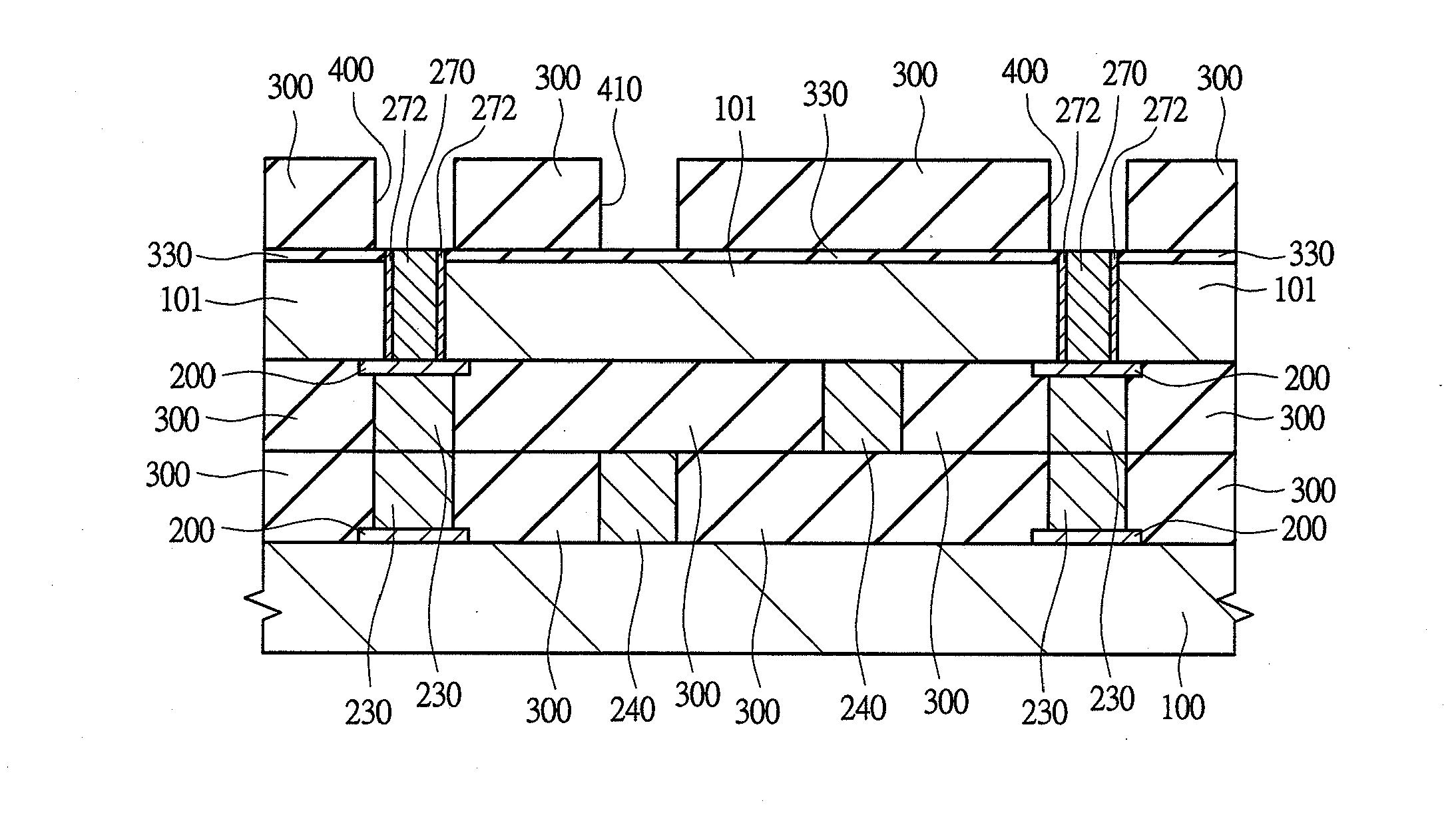

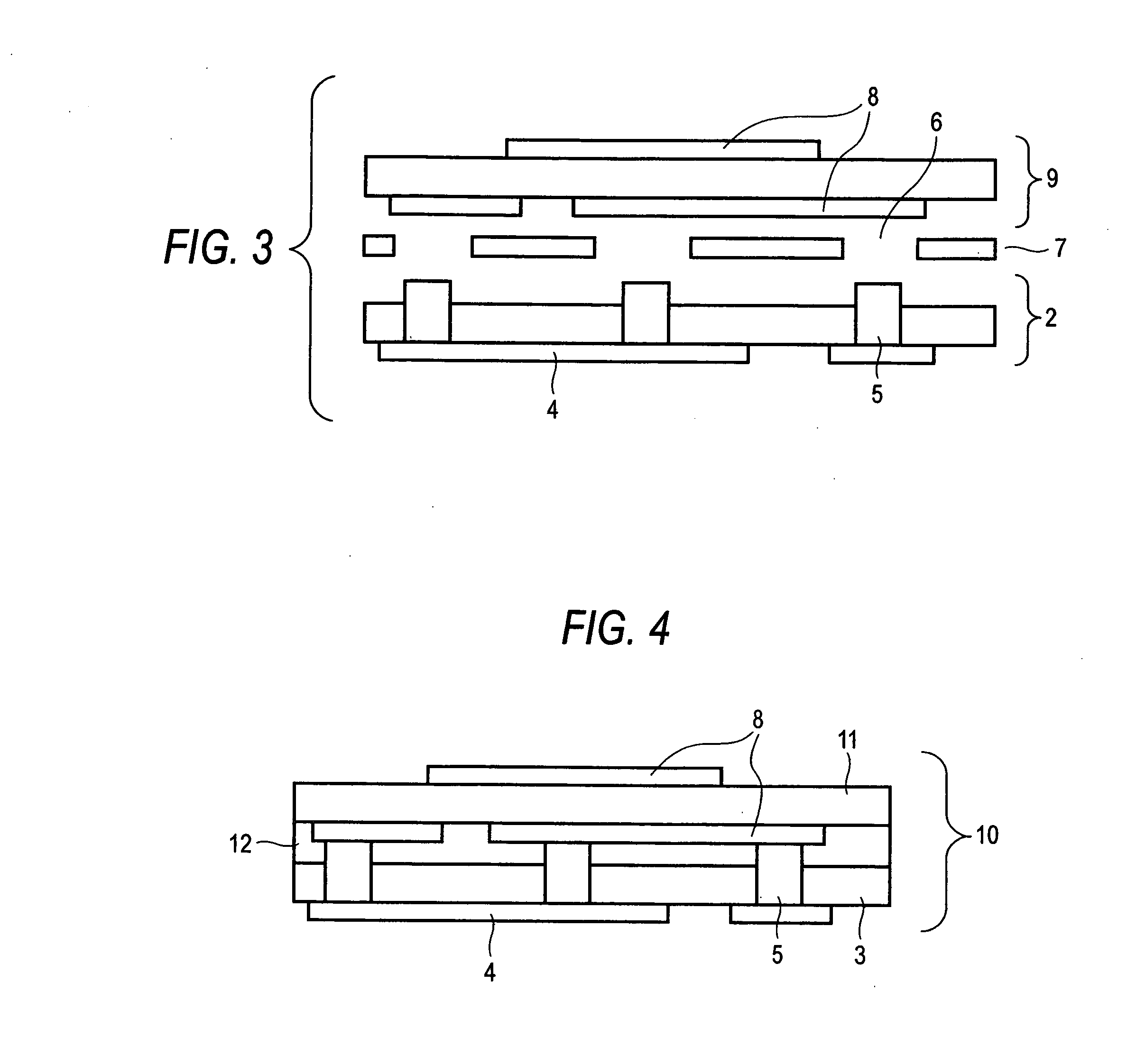

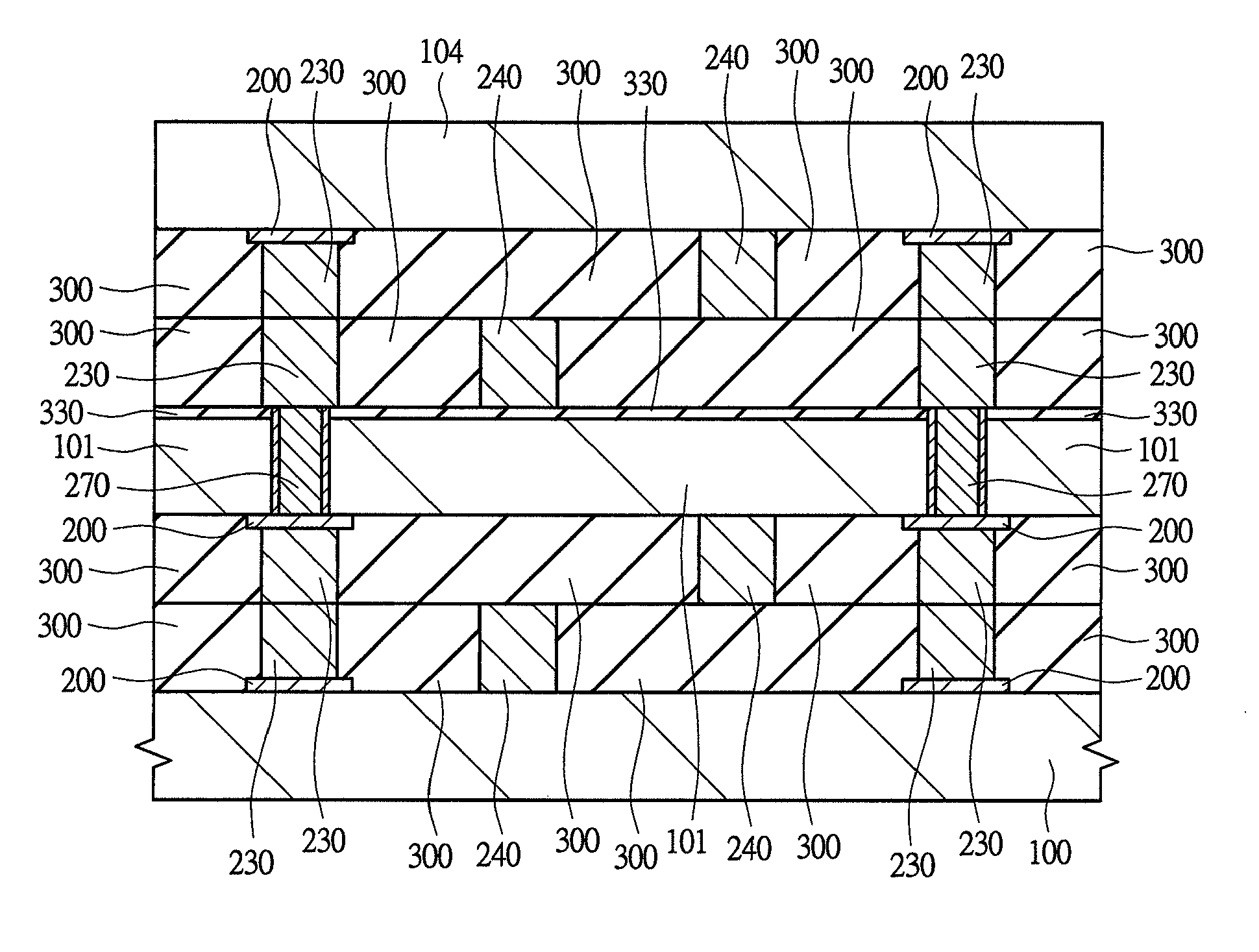

Multilayer printed wiring board

ActiveUS20090129039A1Simple designIncrease capacitanceSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorDielectric layer

A multilayer printed wiring board includes a mounting portion supporting a semiconductor device and a layered capacitor portion including first and second layered electrodes and a ceramic high-dielectric layer therebetween. The first layered electrode is connected to a ground line and the second layered electrode is connected to a power supply line. The ratio of number of via holes, each constituting a conducting path part electrically connecting a ground pad to the ground line of a wiring pattern and passing through the second layered electrode in non-contact, to number of ground pads is 0.05 to 0.7. The ratio of number of second rod-shaped conductors, each constituting a conducting path part electrically connecting a power supply pad to the power supply line of the wiring pattern and passing through the first layered electrode in non-contact, to number of power supply pad is 0.05 to 0.7.

Owner:IBIDEN CO LTD

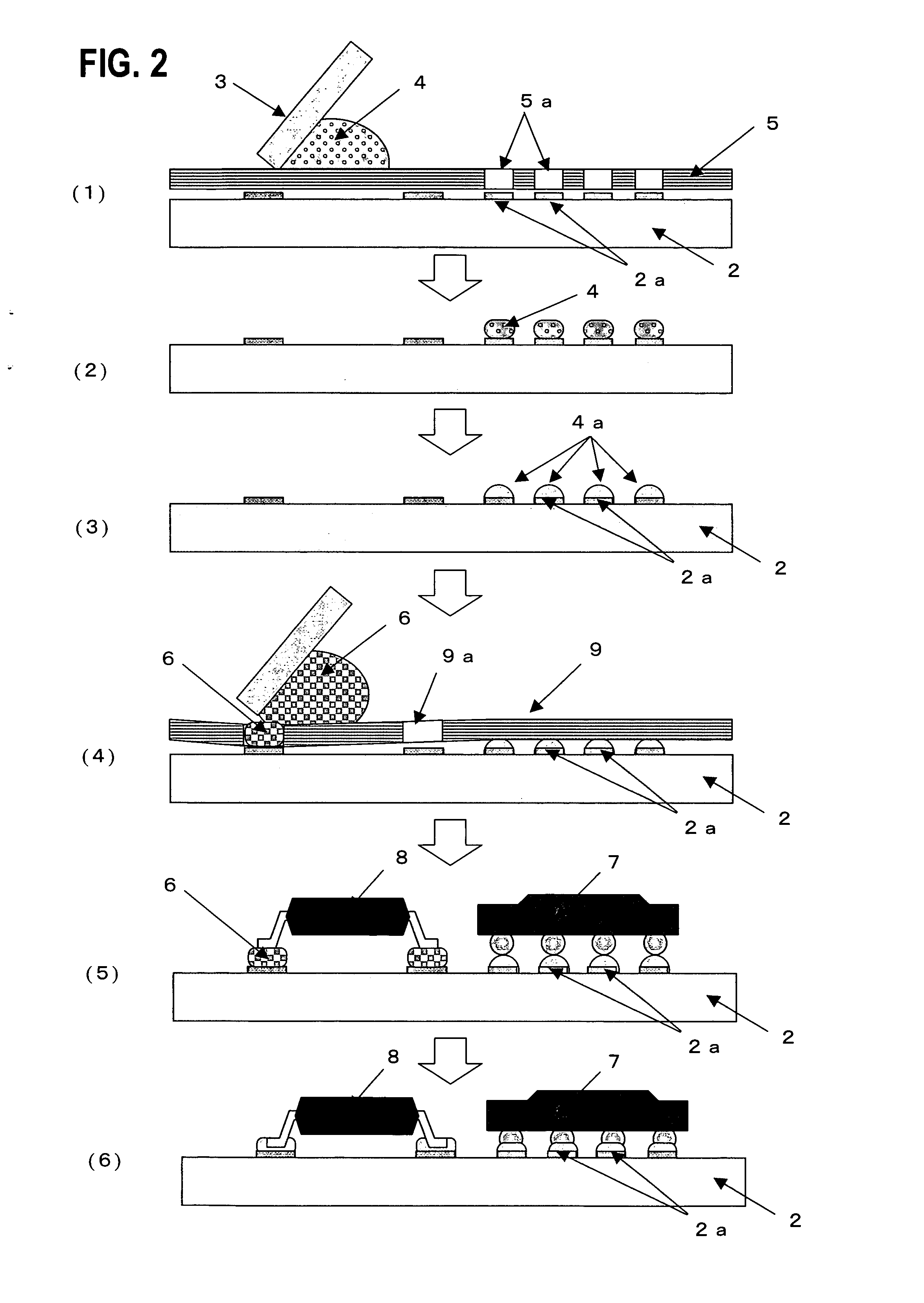

Method for manufacturing a printed circuit board for electronic devices and an electronic device using the same

ActiveUS20070090171A1Low reliabilityReduced connection reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsSolder pasteMaterials science

A soldering technology, particularly a lead-free soldering technology, that can secure the reliability of a whole electronic device is provided. In a method for manufacturing a printed circuit board for electronic devices with a substrate to which a plurality of electronic parts having connection terminals with different metal compositions are connected by soldering, a plurality of solder pastes comprising solder components with different compositions are used, and when the electronic parts are connected by soldering to the substrate, a solder paste having a solder component with a different composition is used for each of the metal compositions for the connection terminals of the electronic parts.

Owner:FUJITSU LTD

Multilayer printed wiring board

ActiveUS7649748B2Satisfied with the effectAvoid failureSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorEngineering

A multilayer printed wiring board includes a mounting portion supporting a semiconductor device and a layered capacitor portion including first and second layered electrodes and a ceramic high-dielectric layer therebetween. The first layered electrode is connected to a ground line and the second layered electrode is connected to a power supply line. The ratio of number of via holes, each constituting a conducting path part electrically connecting a ground pad to the ground line of a wiring pattern and passing through the second layered electrode in non-contact, to number of ground pads is 0.05 to 0.7. The ratio of number of second rod-shaped conductors, each constituting a conducting path part electrically connecting a power supply pad to the power supply line of the wiring pattern and passing through the first layered electrode in non-contact, to number of power supply pad is 0.05 to 0.7.

Owner:IBIDEN CO LTD

Floating connector with flexible conductive member

ActiveUS8408927B2Reduced connection reliabilitySave storage spaceVehicle connectorsElectric discharge tubesEngineeringElectrical and Electronics engineering

There is provided a connector 1 connected to a mating connector, fixed in a case of a motor, comprising: an outer housing 5 attached to the case; a first inner housing 6 accommodating a first terminal 20 engaging to the mating connector, being accommodated in the outer housing 5 movably in the engaging direction Y of the first terminal 20 and in the intersectional direction of the engaging direction Y; a first inner connector 6 engaging to the mating connector; a second inner housing 10 accommodating a second terminal 11 electrically connected to a electric circuit in the case and being fixed in the outer housing 5 and a braided wire 90, and further including a connection portion 9 connecting the first terminal 20 and the second terminal 11 and a packing 7 attached to the first inner housing.

Owner:YAZAKI CORP

Semiconductor device and method of manufacturing the same

InactiveUS20120256311A1Reduce planarityReduced connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesHeat resistanceElectrical connection

A bump electrode, a dummy bump, and a heat-resistant polymer film, whose upper-surface heights are uniformed, are formed on each of a first silicon substrate and a second silicon substrate, and then, the first silicon substrate and the second silicon substrate are bonded to each other so that the bump electrodes formed on the respective substrates are electrically connected to each other. At this time, the dummy bump is arranged so as to be bonded to the heat-resistant polymer film on the silicon substrate opposed thereto, so that a semiconductor device having both of good electrical connection between the bump electrodes and bump protection performance obtained by a polymer film with high heat resistance and without voids can be achieved.

Owner:HITACHI LTD

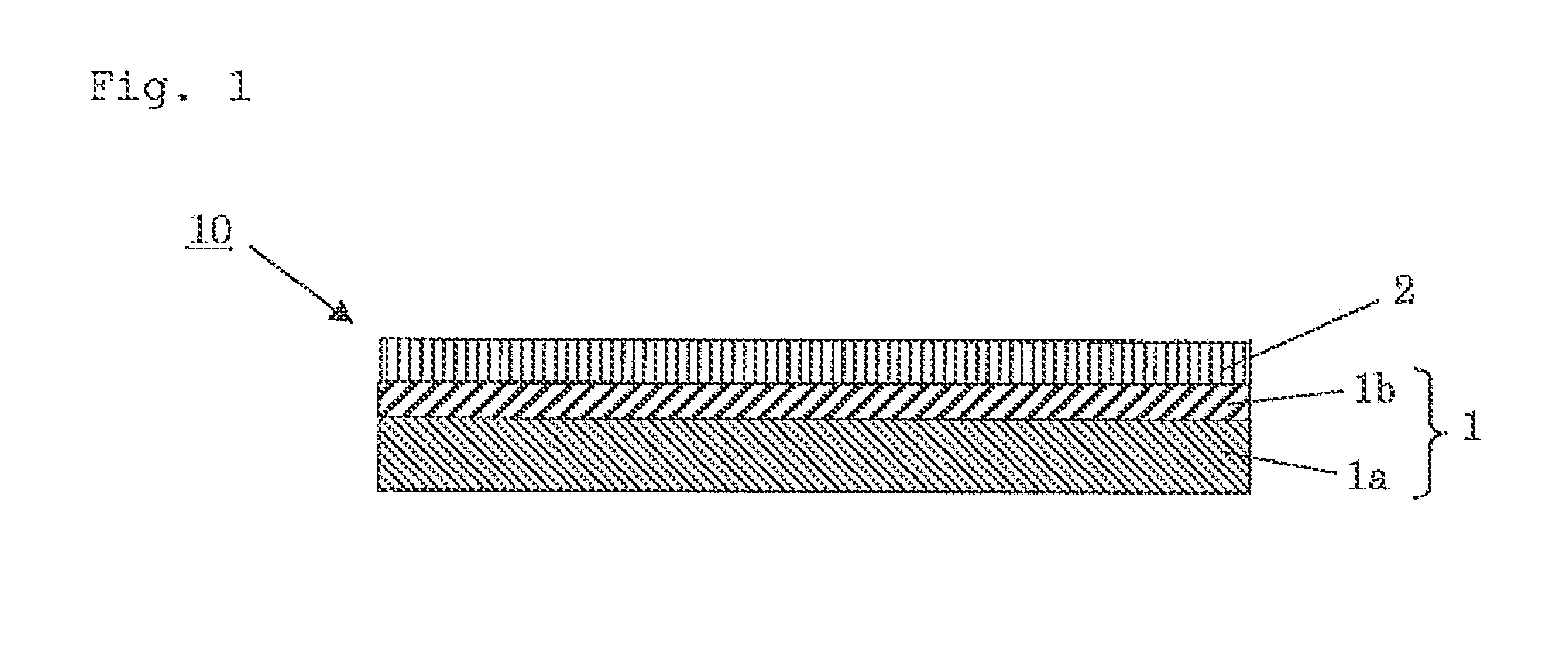

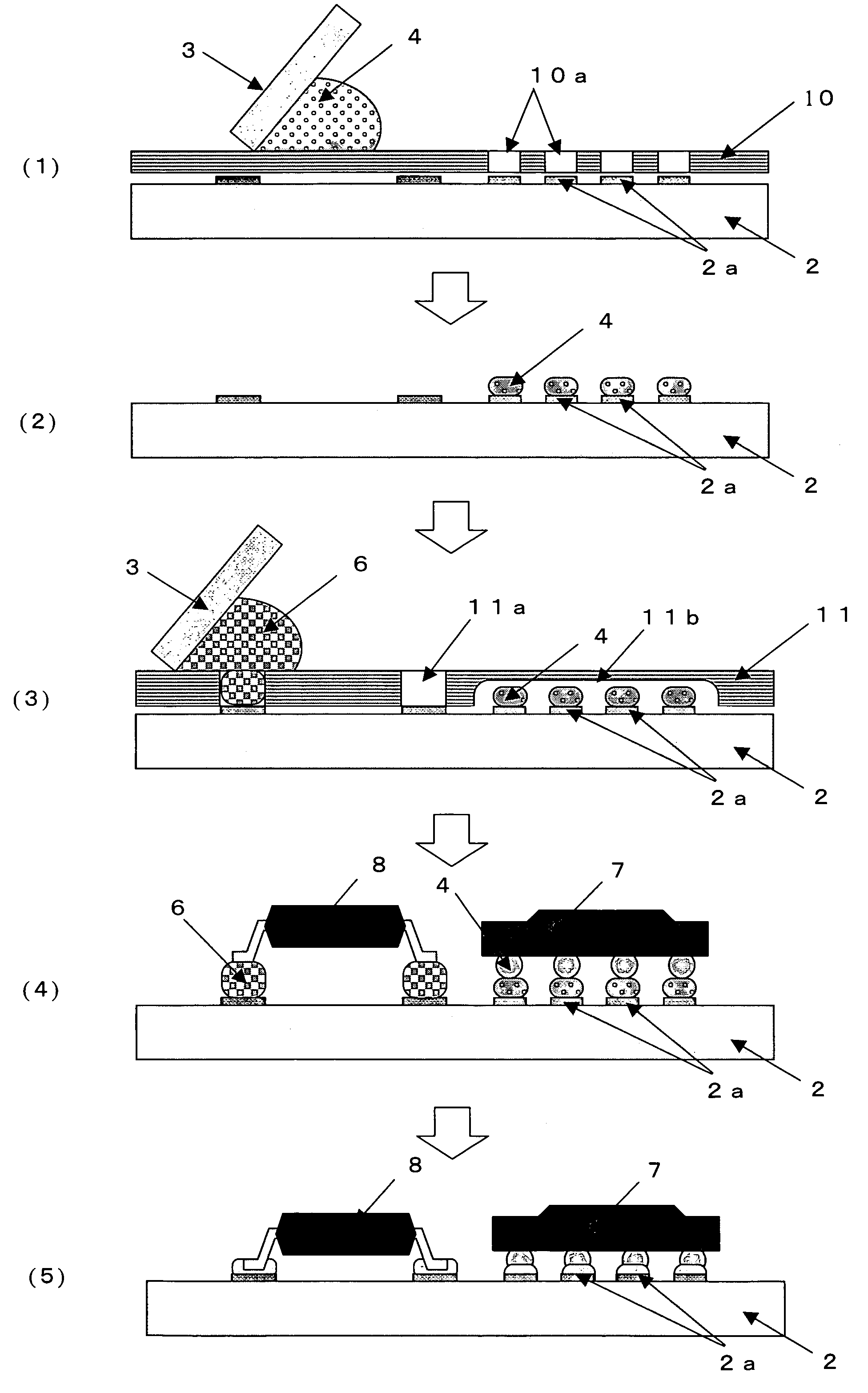

Method for producing semiconductor device

InactiveUS20130157415A1Reduce adhesionReduced connection reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingFilling materialsEngineering

There is provided a method for producing a semiconductor device, capable of suppressing generation of voids at an interface between a semiconductor element and an under-fill sheet to produce a semiconductor device with high reliability. The method includes providing a sealing sheet having a support and an under-fill material laminated on the support; thermally pressure-bonding a circuit surface of a semiconductor wafer, on which a connection member is formed, and the under-fill material of the sealing sheet under conditions of a reduced-pressure atmosphere of 10000 Pa or less, a bonding pressure of 0.2 MPa or more and a heat pressure-bonding temperature of 40° C. or higher; dicing the semiconductor wafer to form a semiconductor element with the under-fill material; and electrically connecting the semiconductor element and the adherend through the connection member while filling a space between the adherend and the semiconductor element using the under-fill material.

Owner:NITTO DENKO CORP

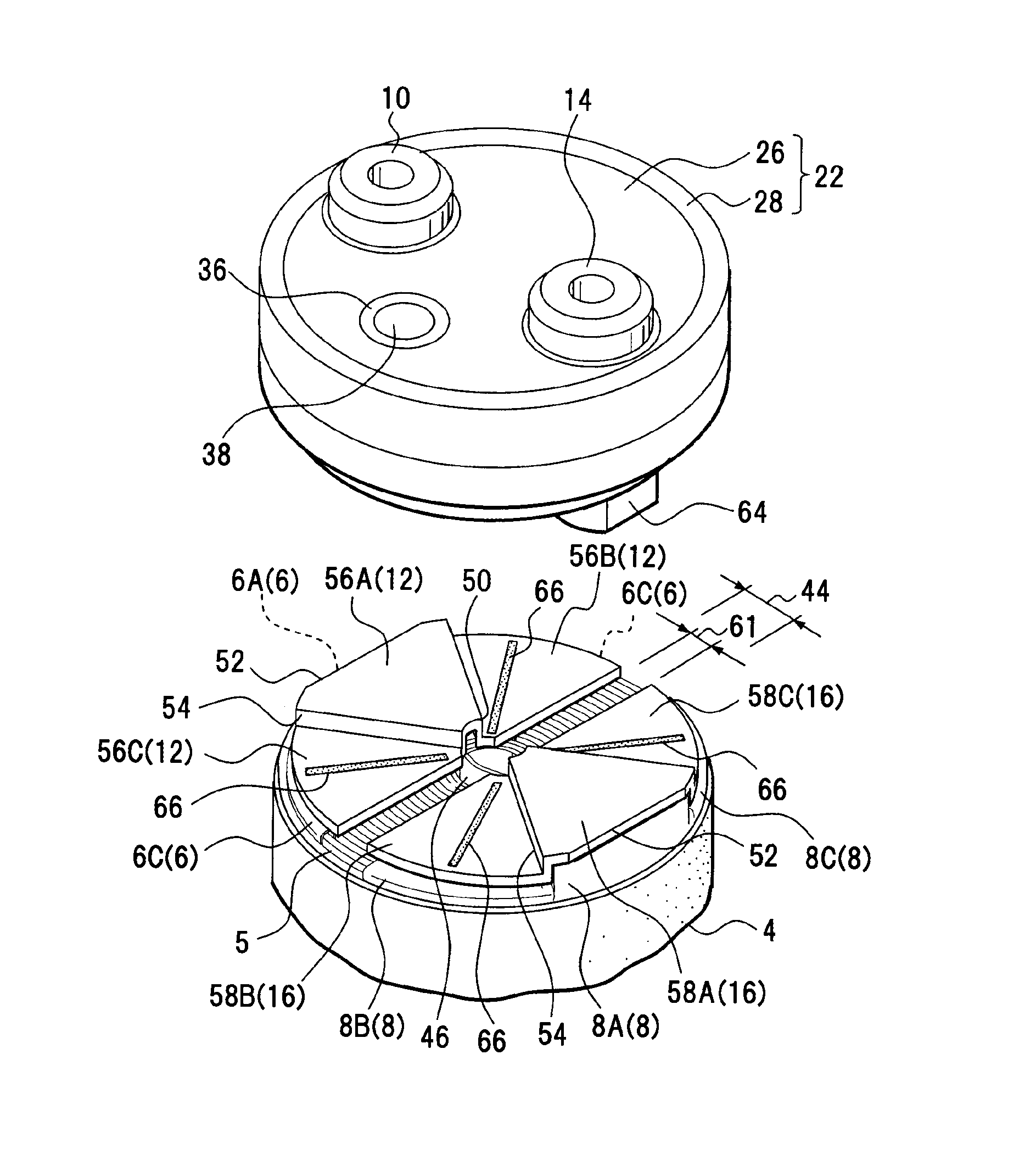

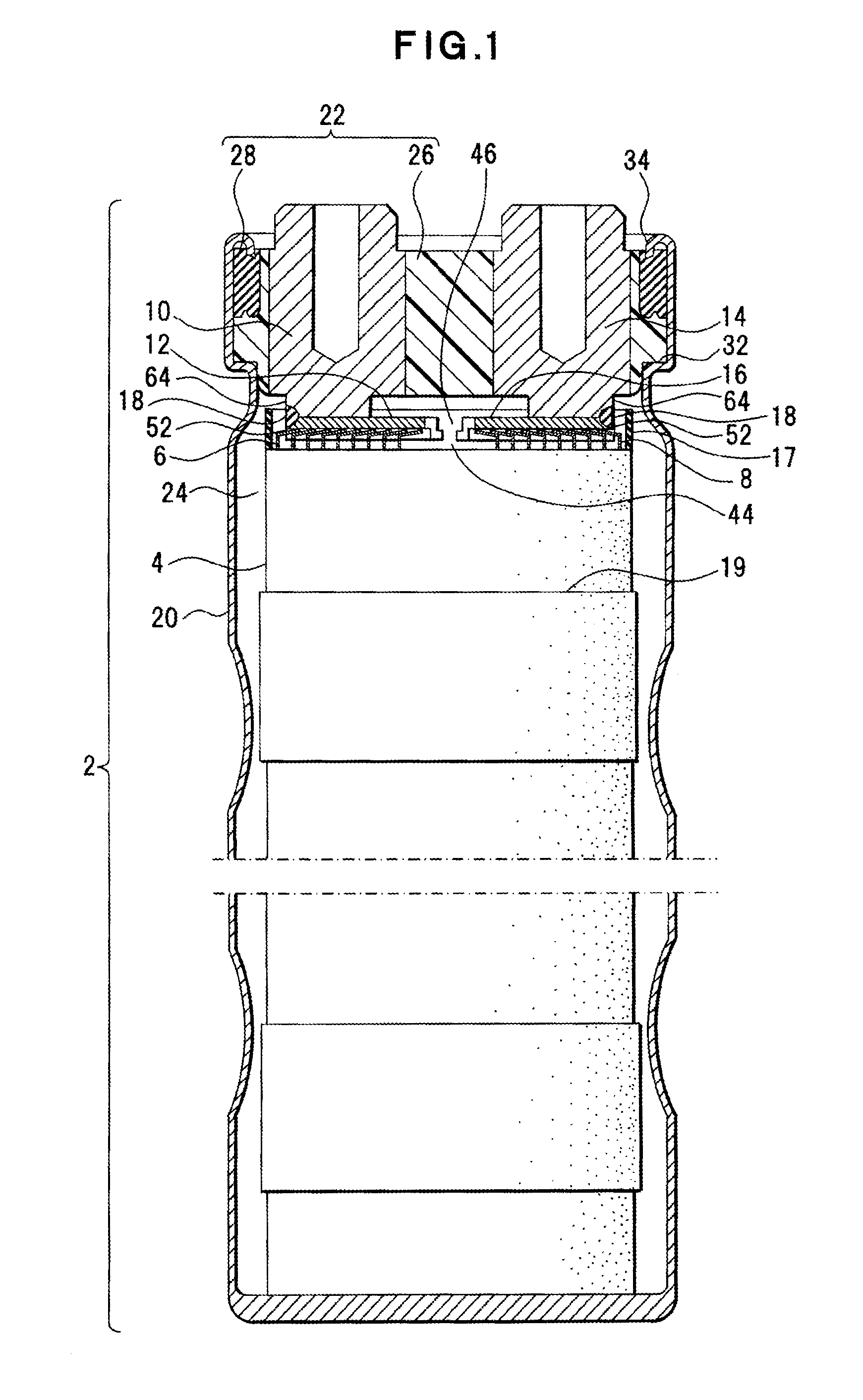

Capacitor and method for manufacturing the same

ActiveUS20130250475A1Lower internal resistanceReduced connection reliabilityFixed capacitor electrodesCapacitor terminalsEngineeringCapacitor

A capacitor includes a capacitor element that is a wound element or an element other than the wound element, and that includes electrode bodies each of which is in an anode side and a cathode side, and separators that intervenes between the electrode bodies; a sealing member that seals an opening of a case member accommodating the capacitor element; at least one electrode protrusion that protrudes from one of the electrode bodies on an element end-face of the capacitor element, at least one of current collector plate that is connected to the electric protrusion; and at least one terminal member that is disposed in the sealing member, and is superposed on the current collector plate, a side face part of the terminal member being welded to a side face part of the current collector plate.

Owner:NIPPON CHIMI CON CORP

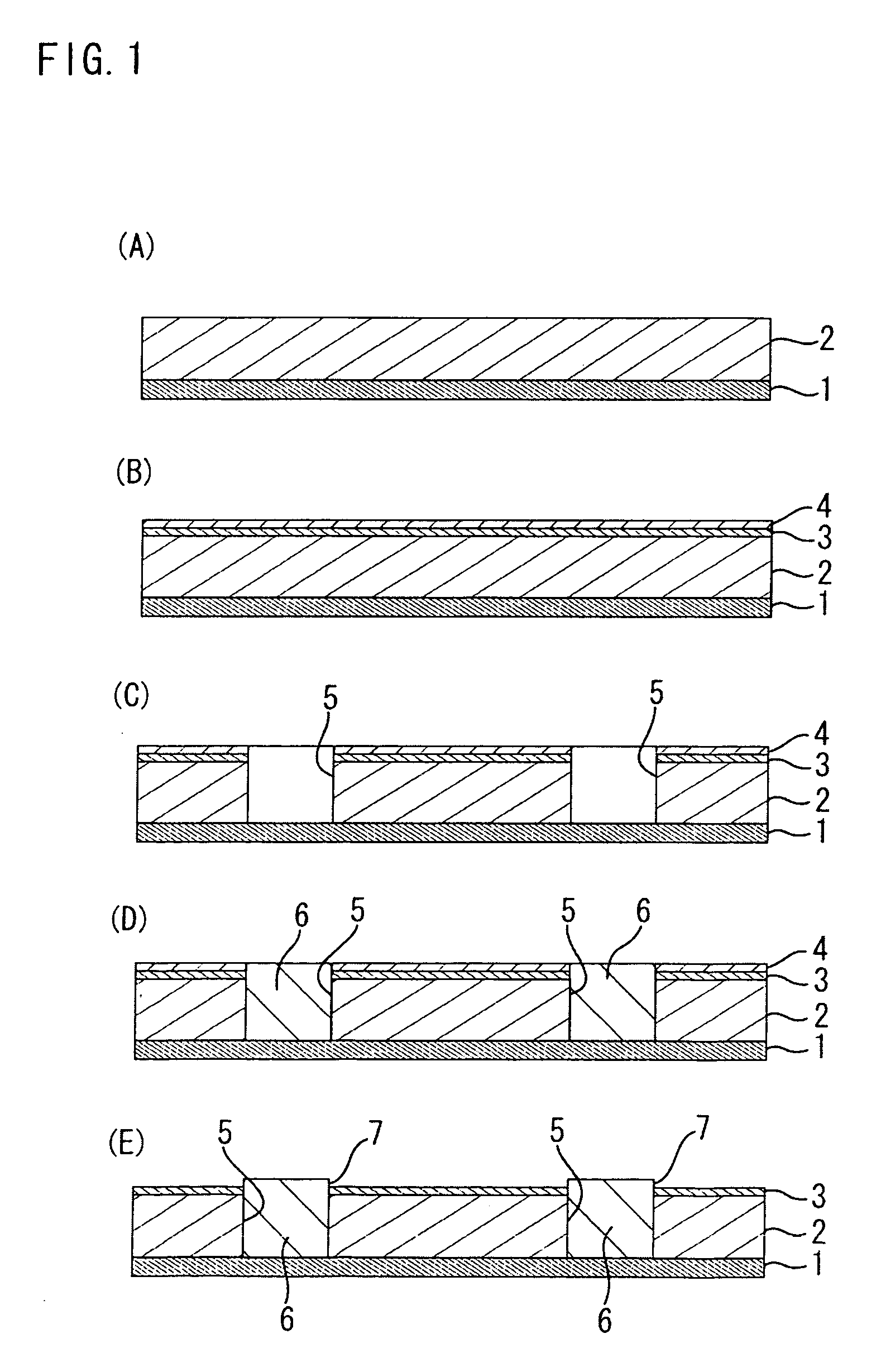

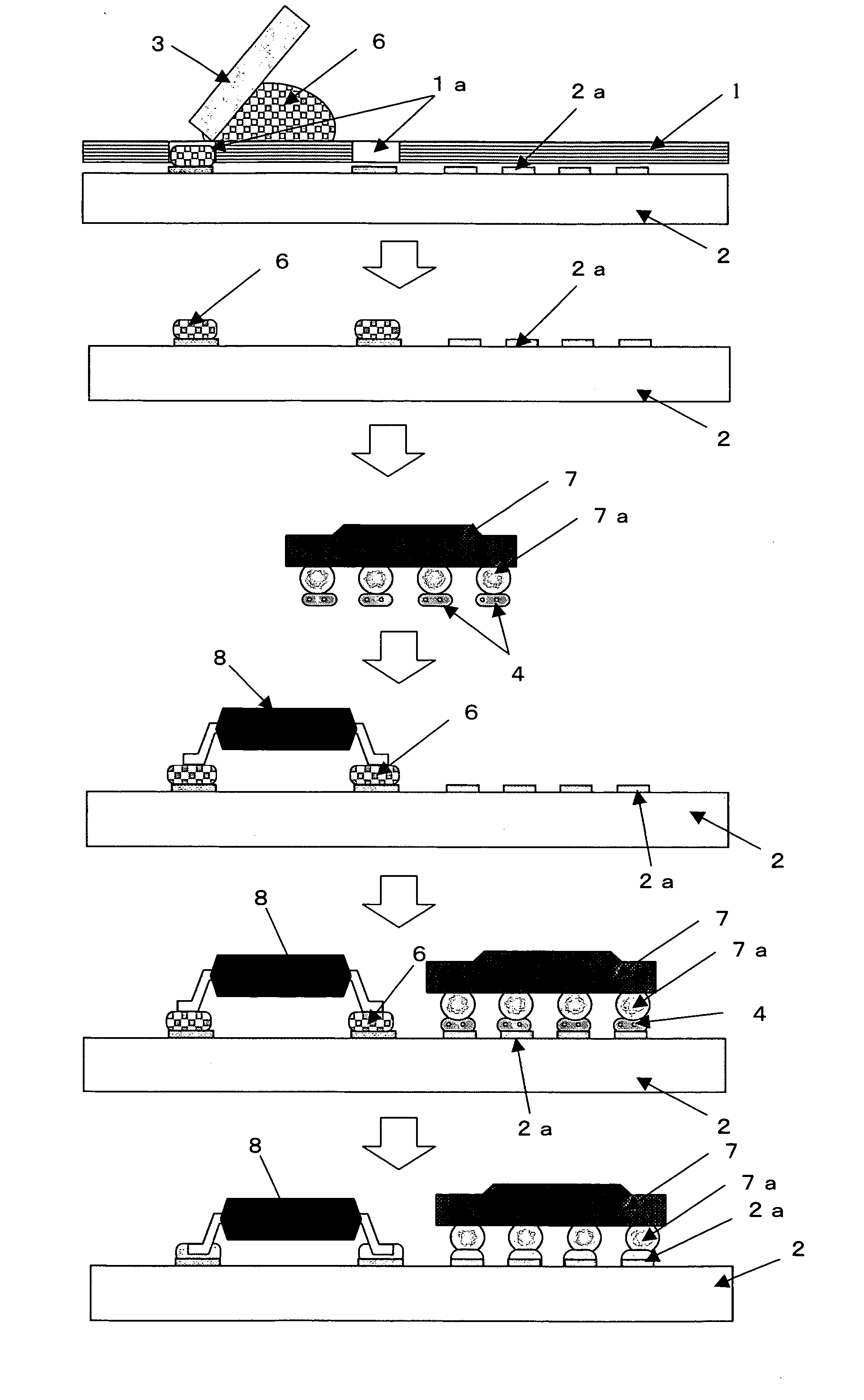

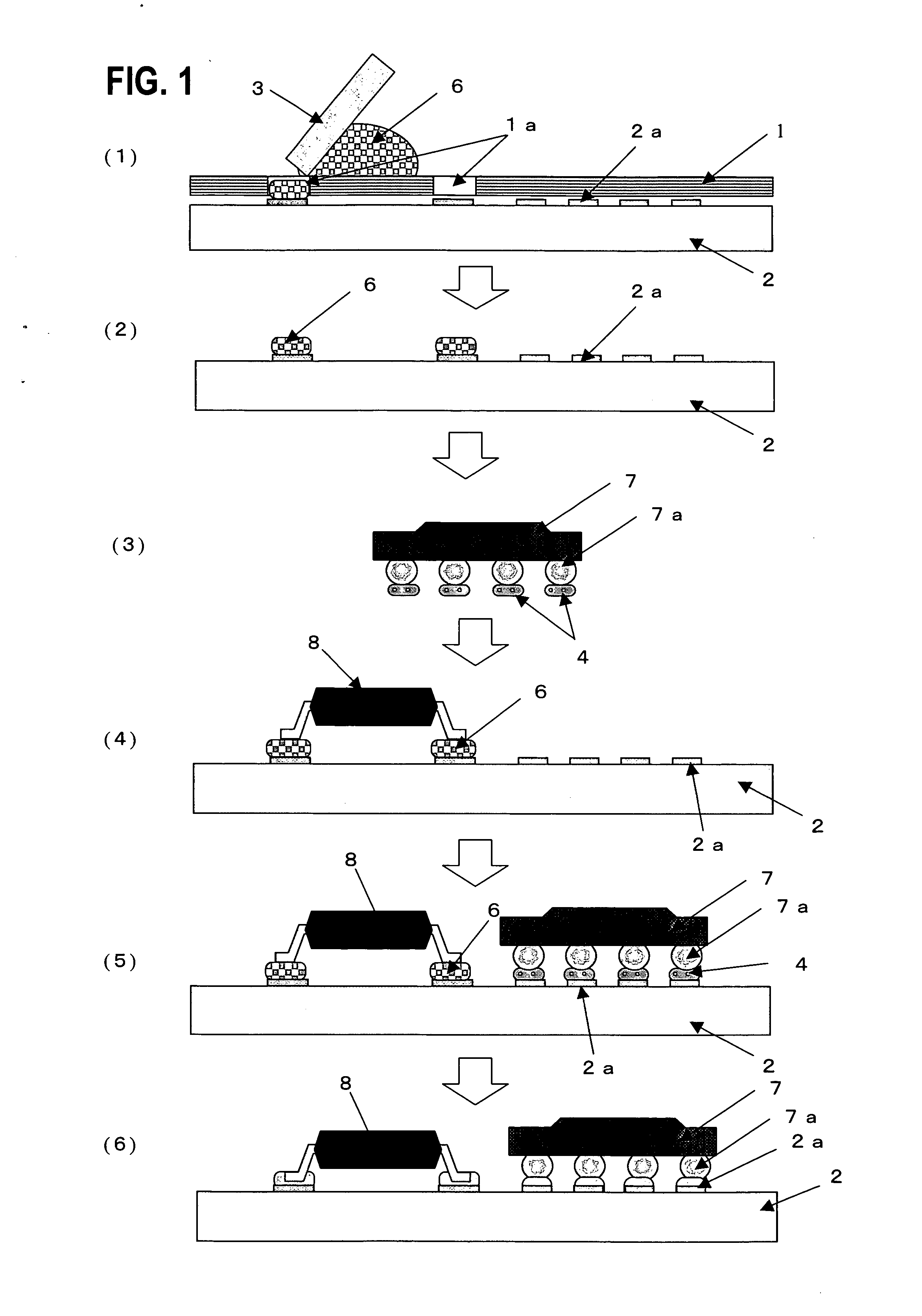

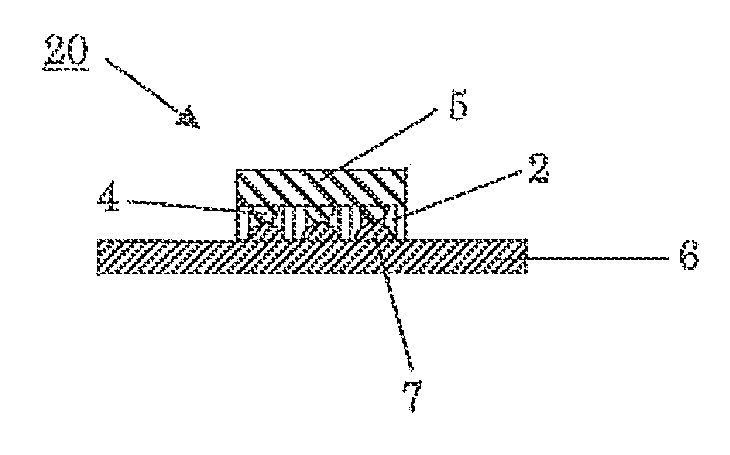

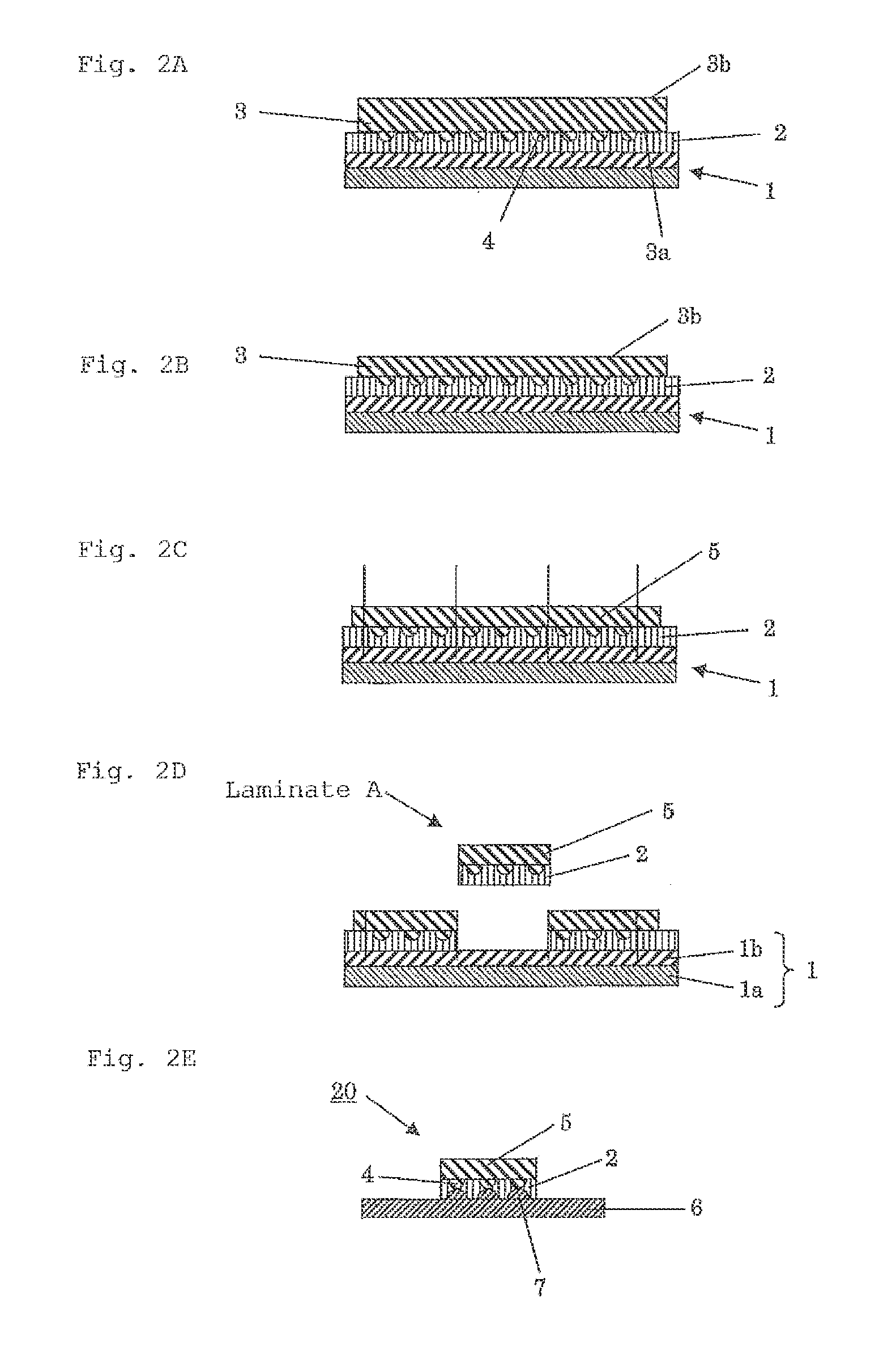

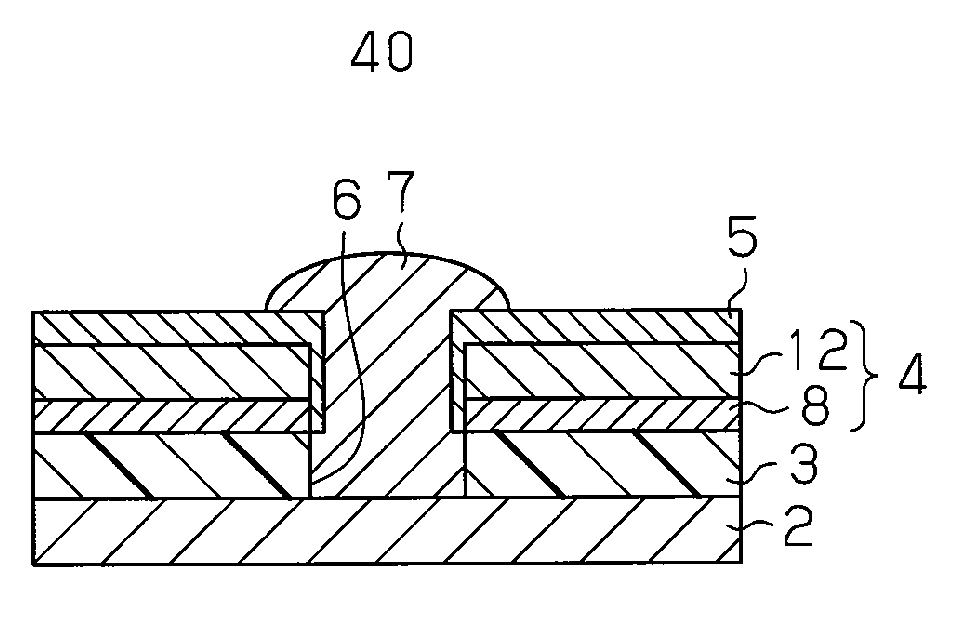

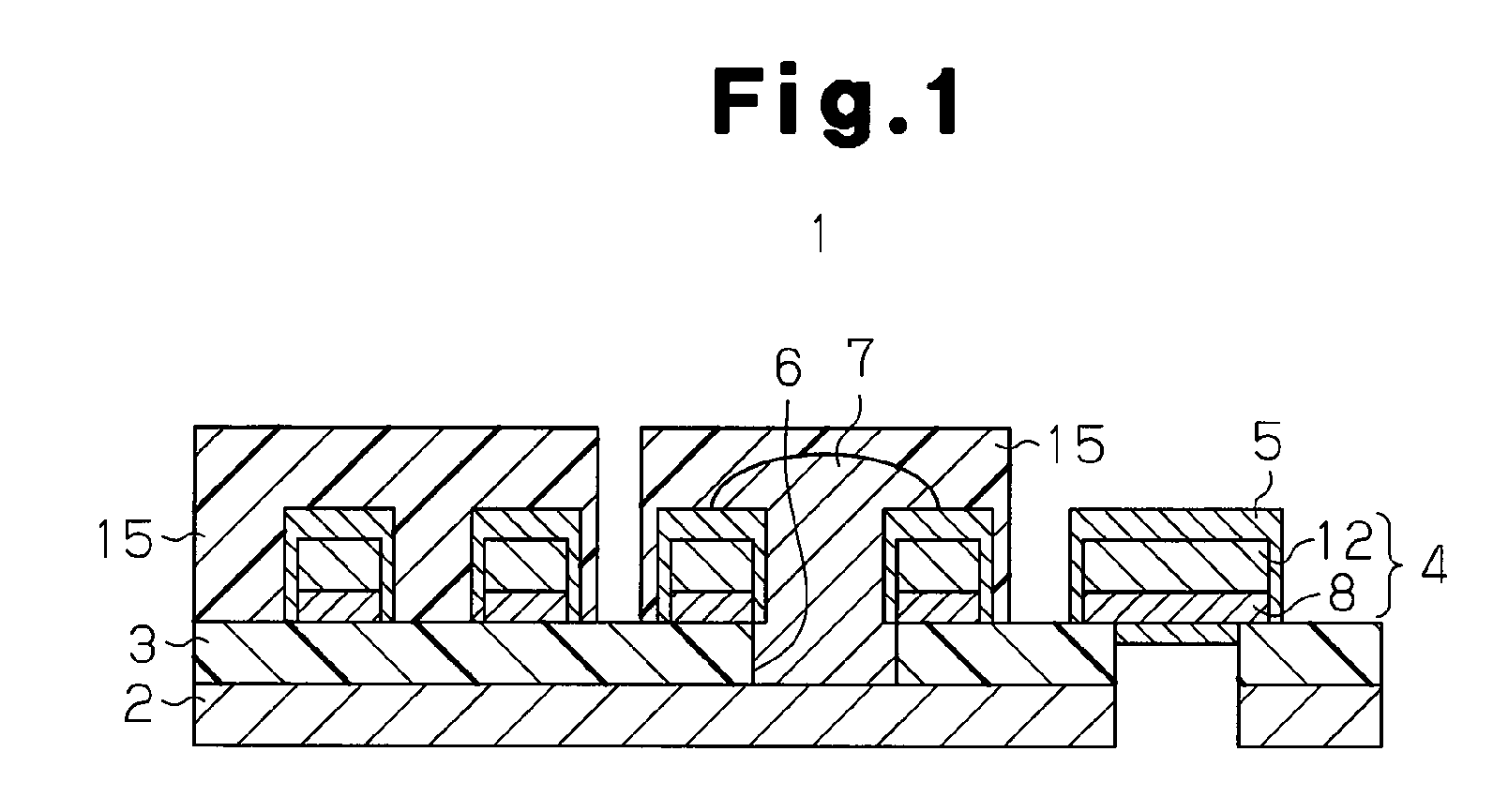

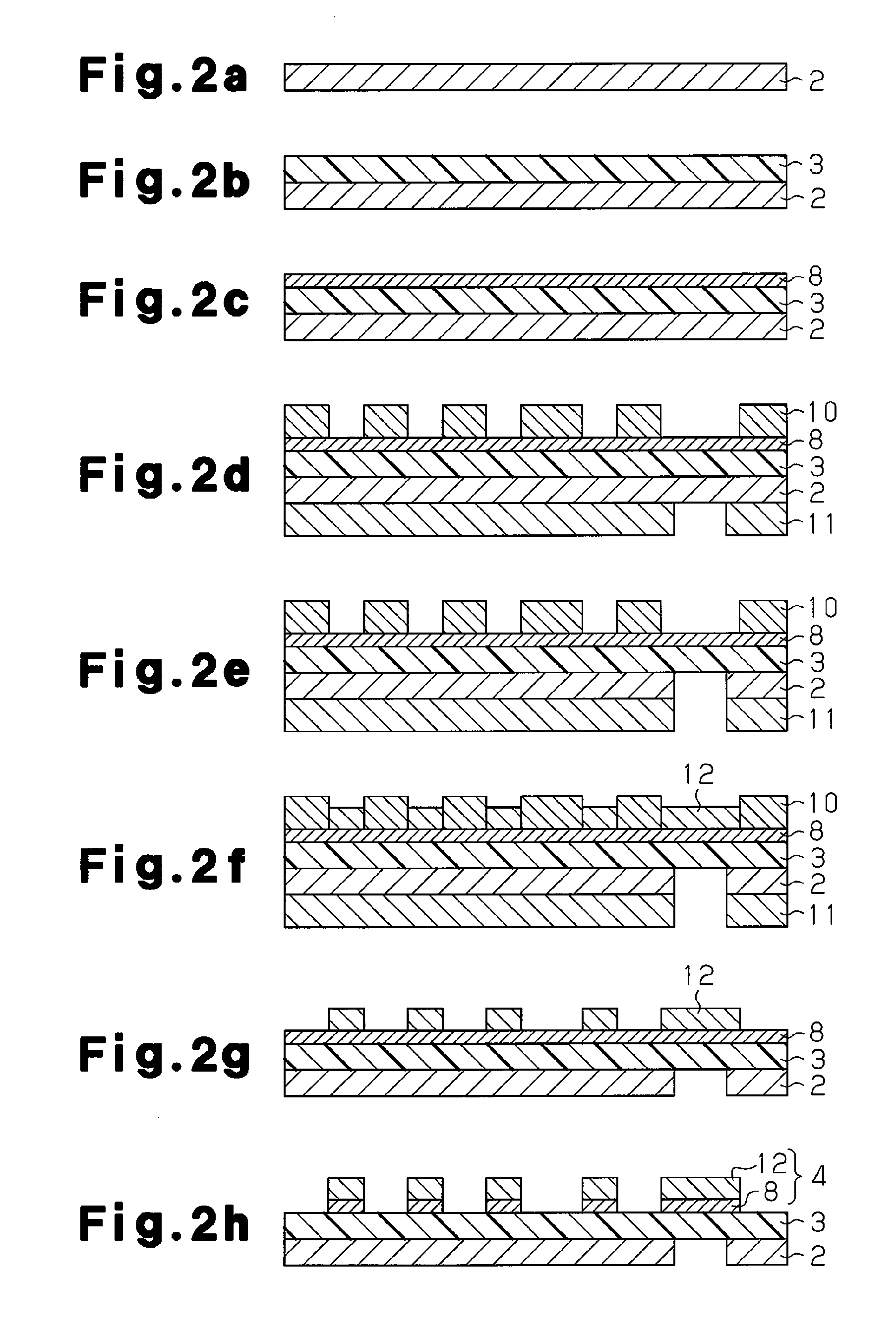

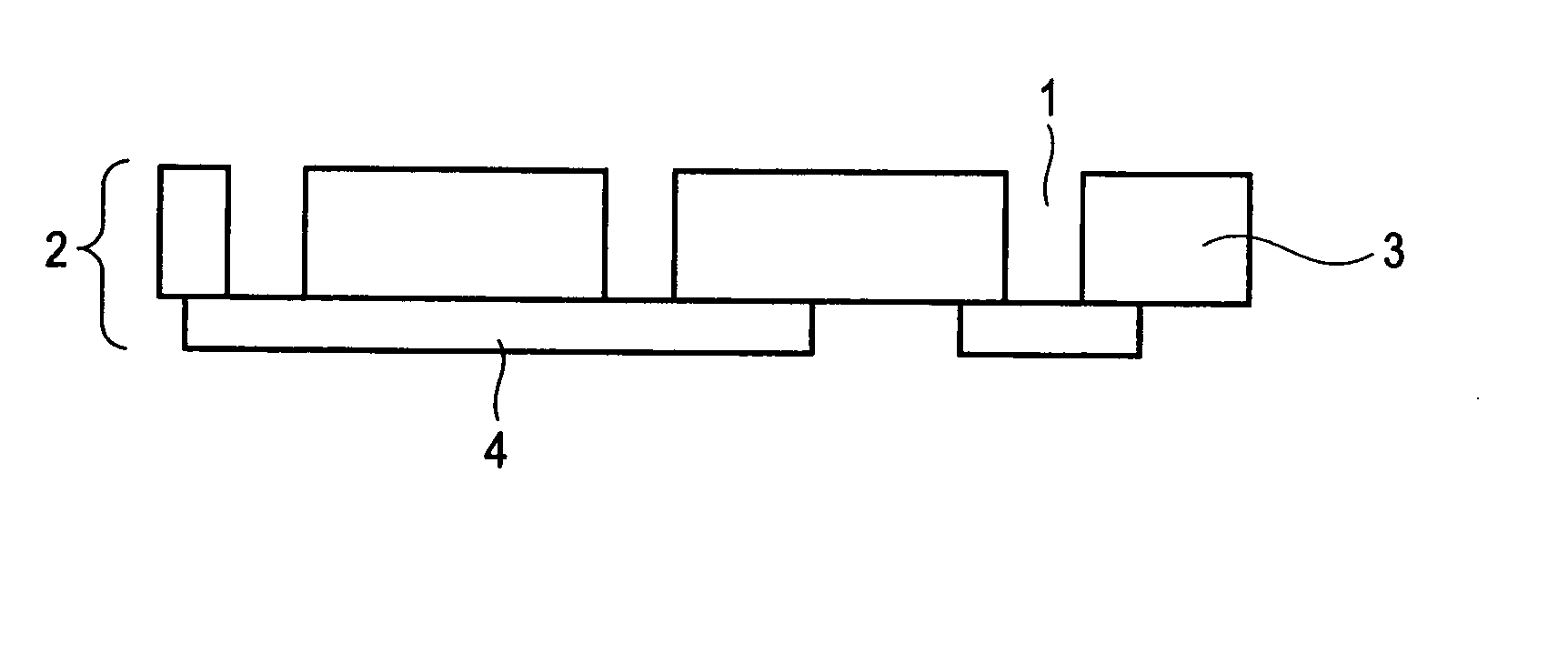

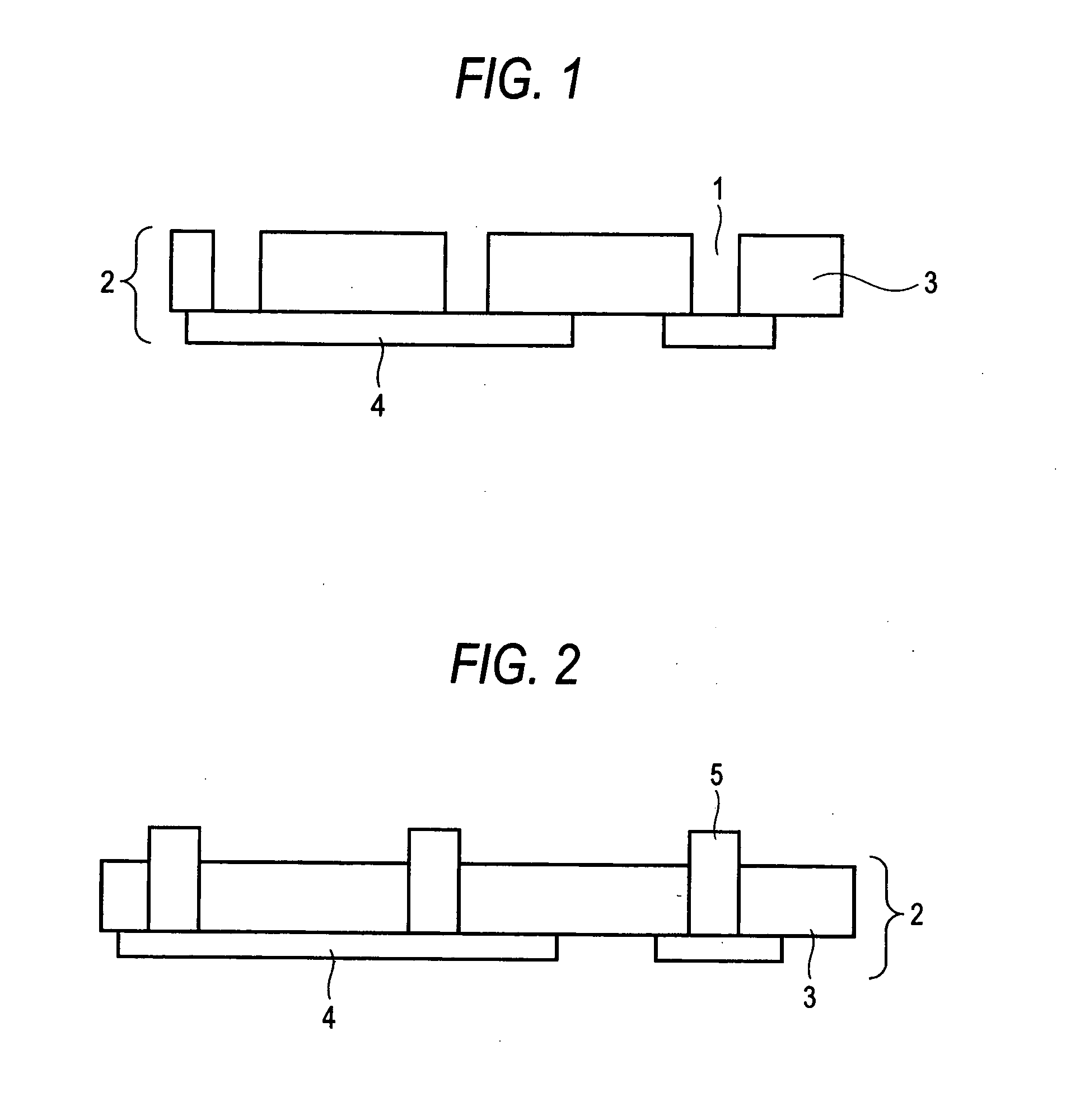

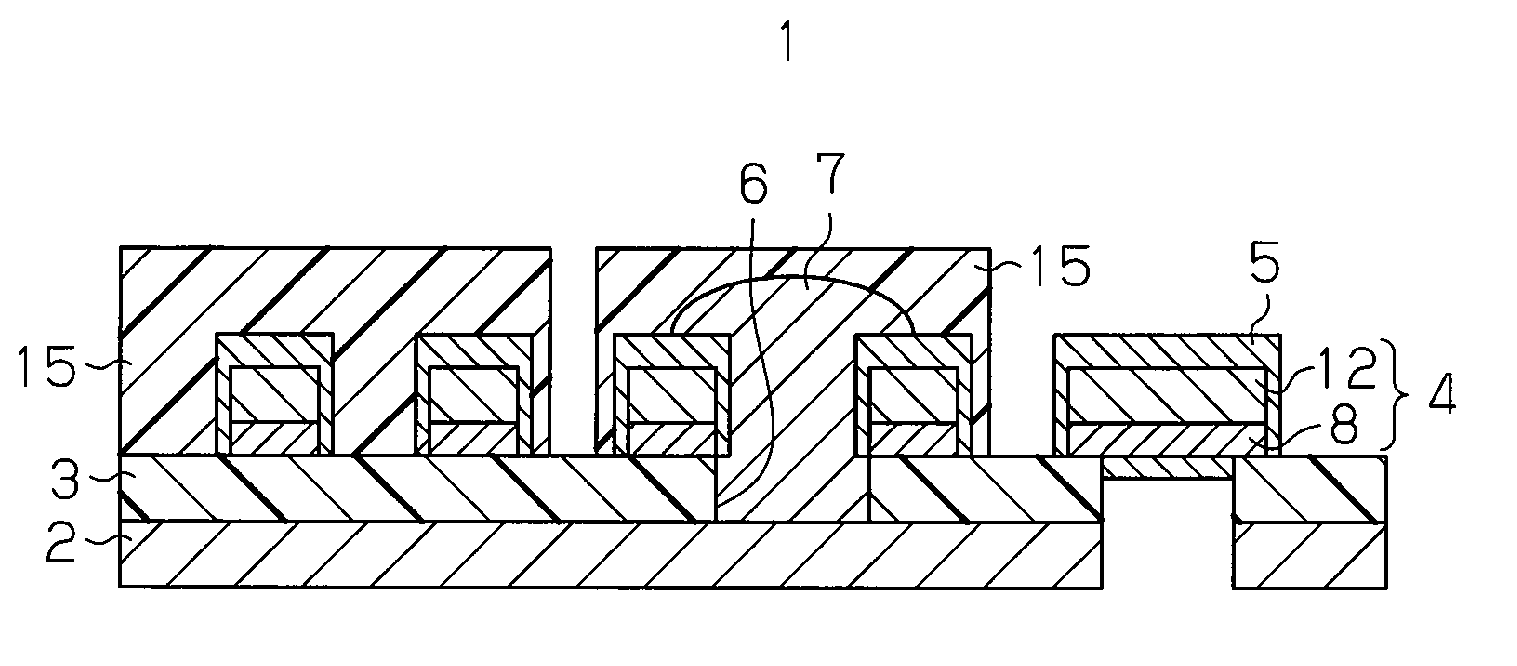

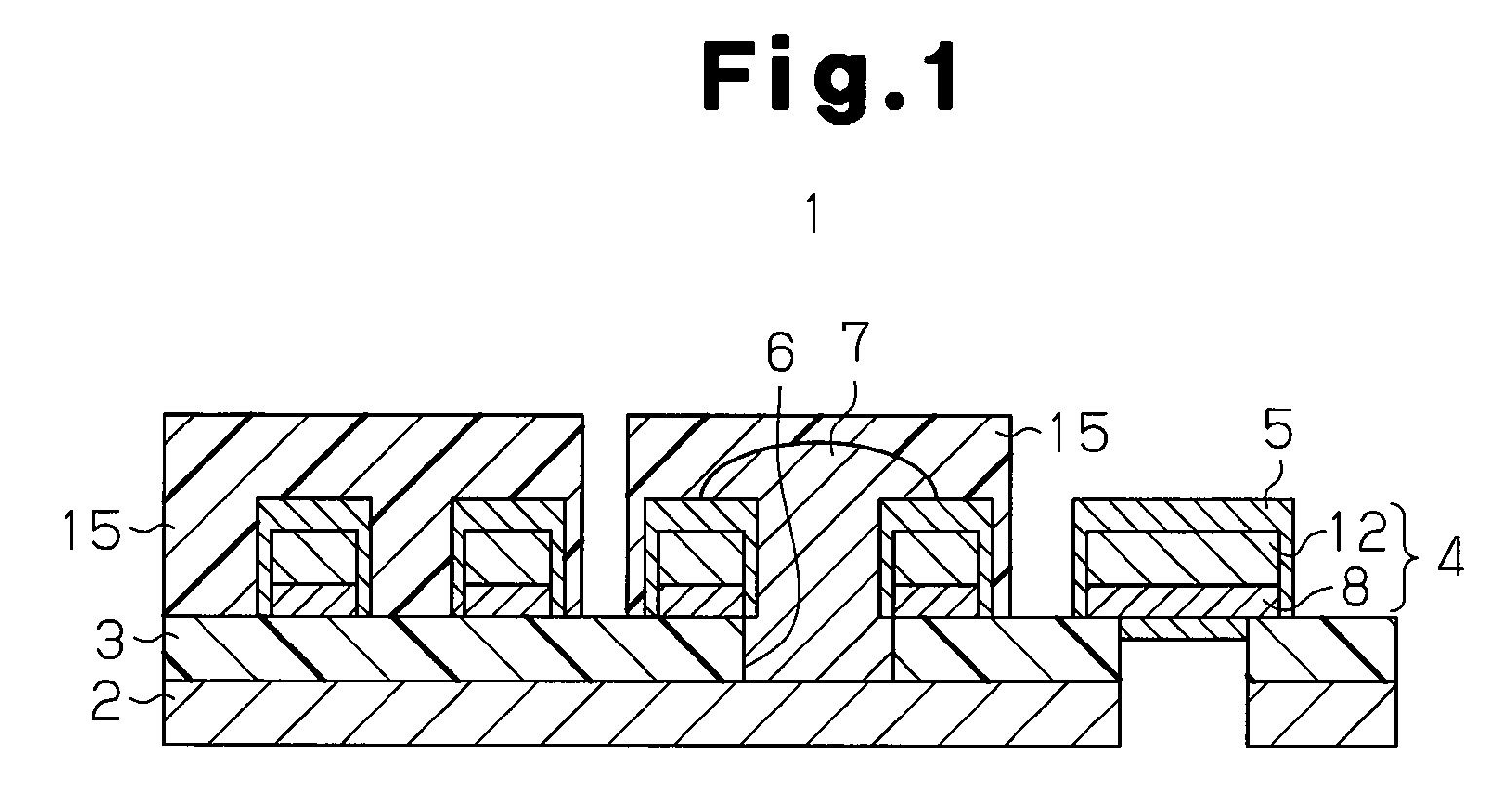

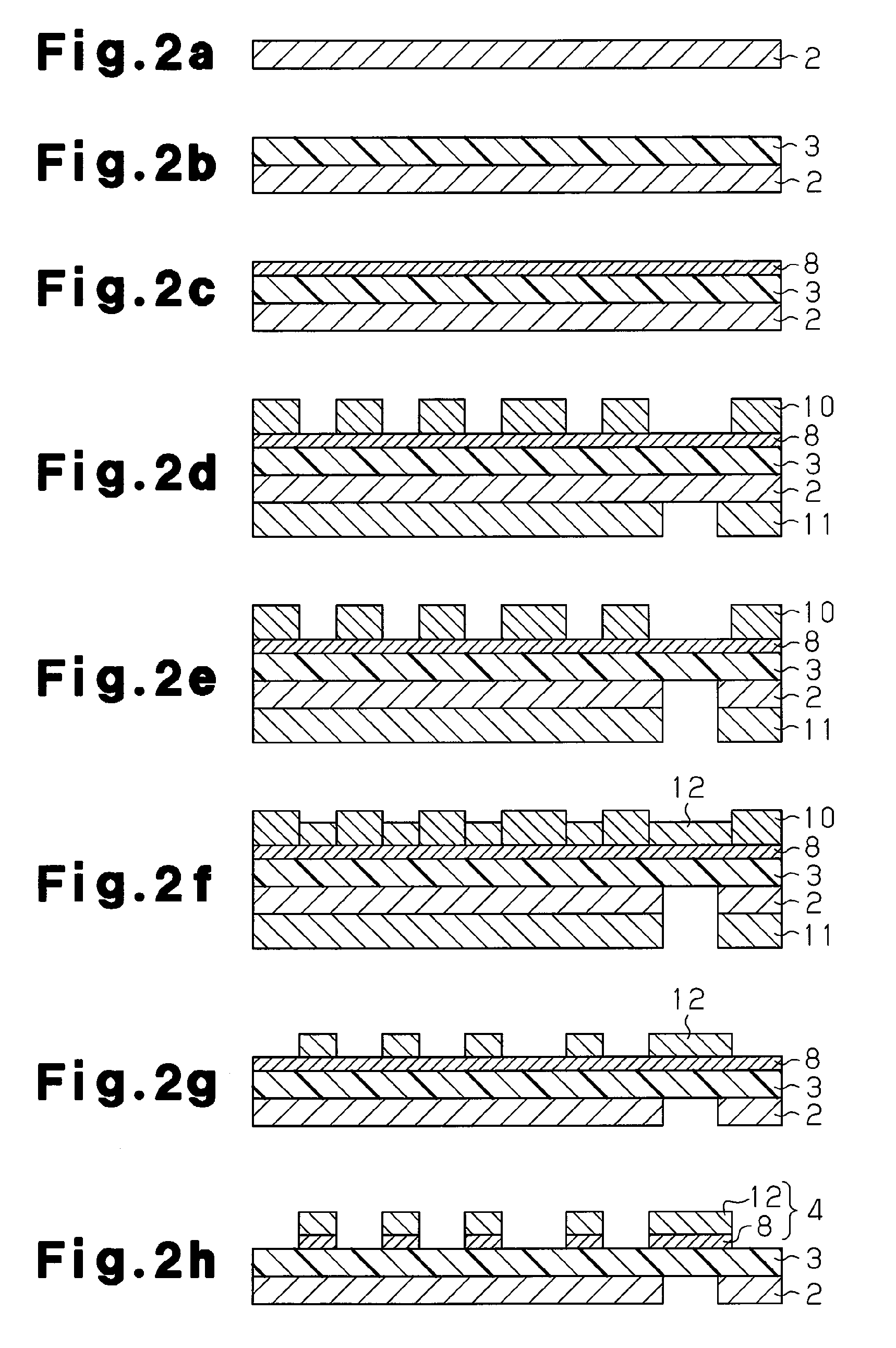

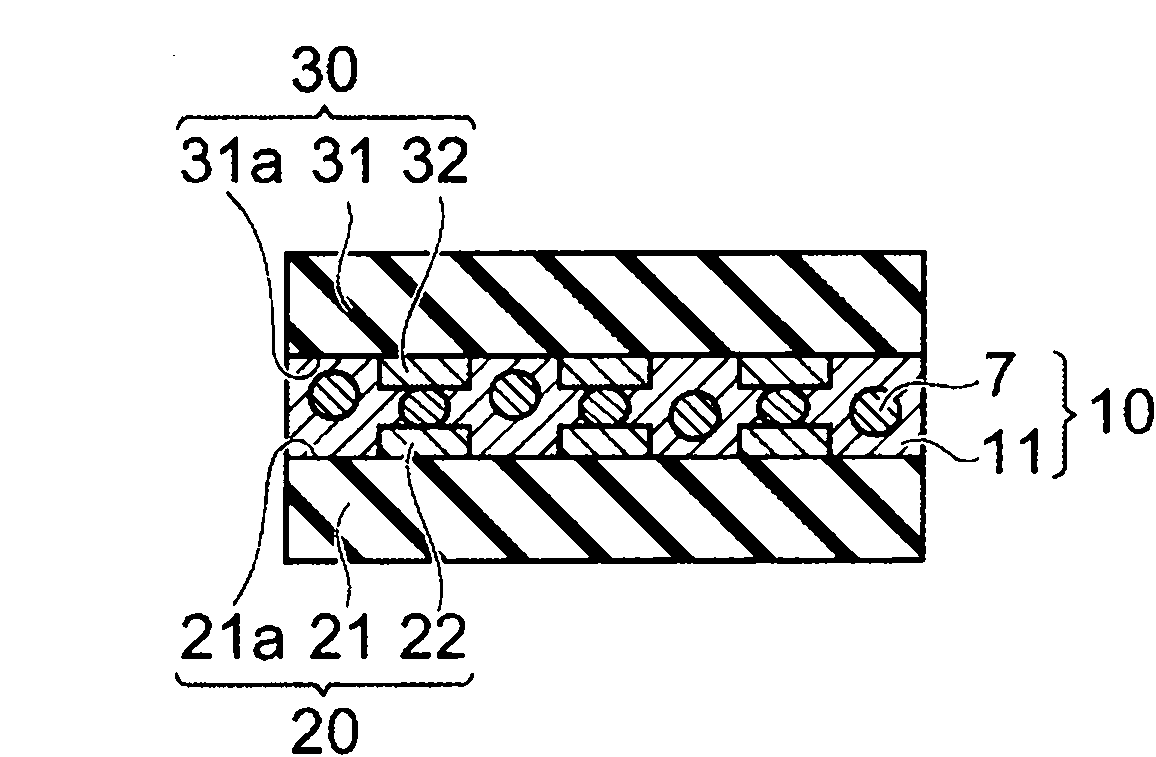

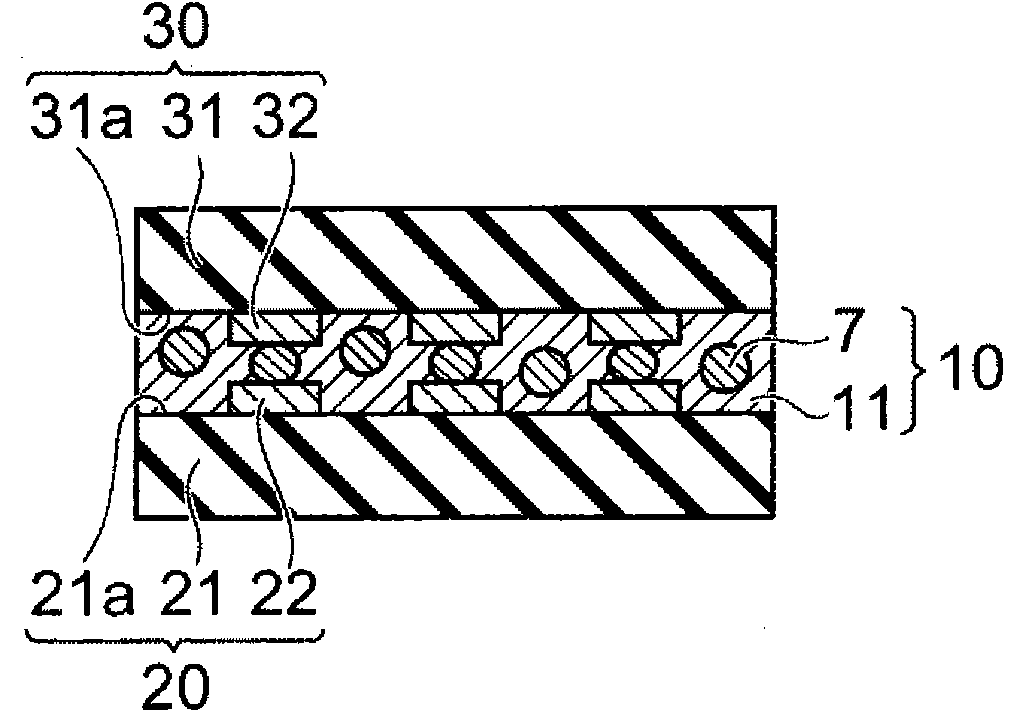

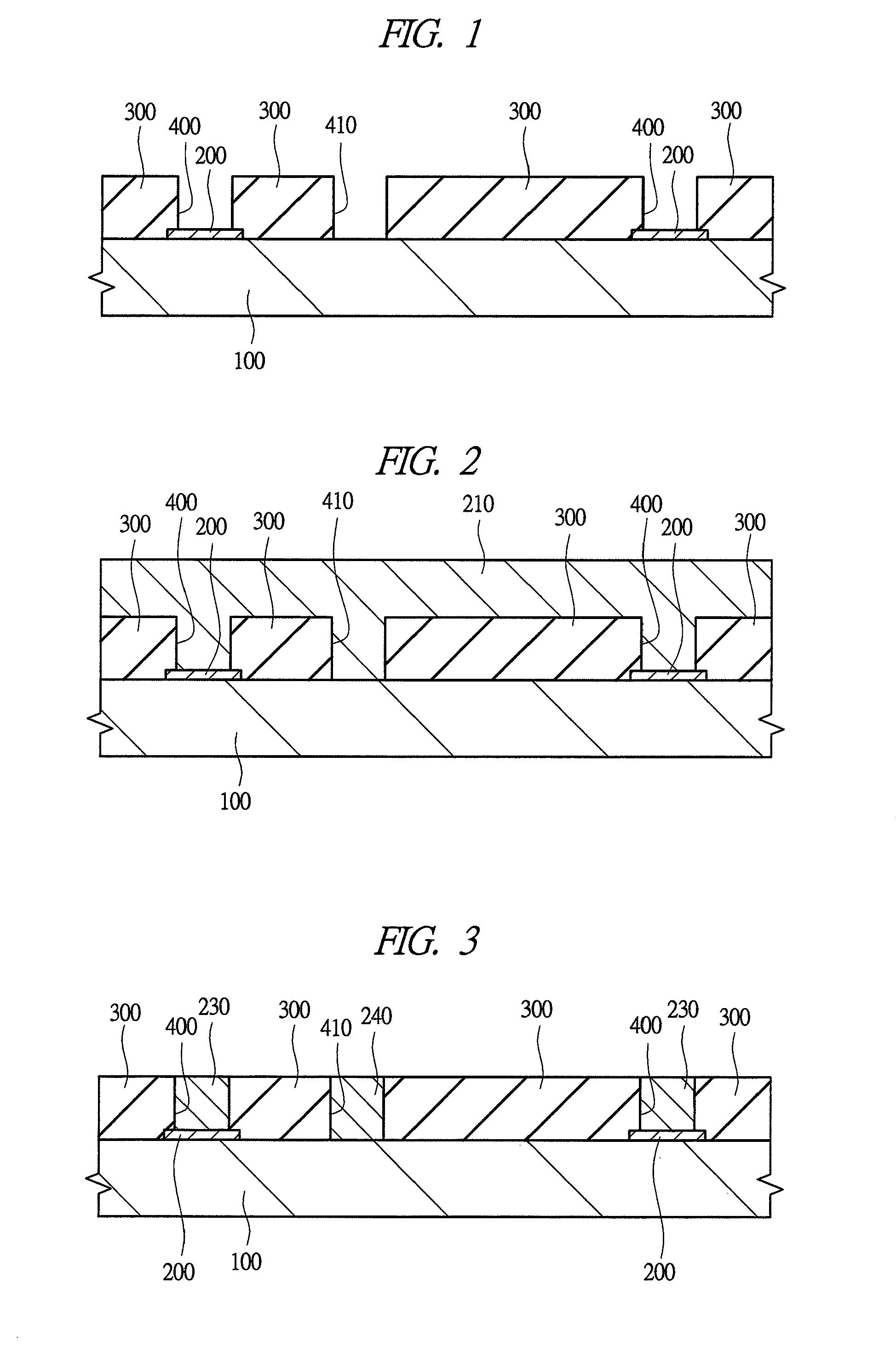

Printed wiring board and method for manufacturing the same

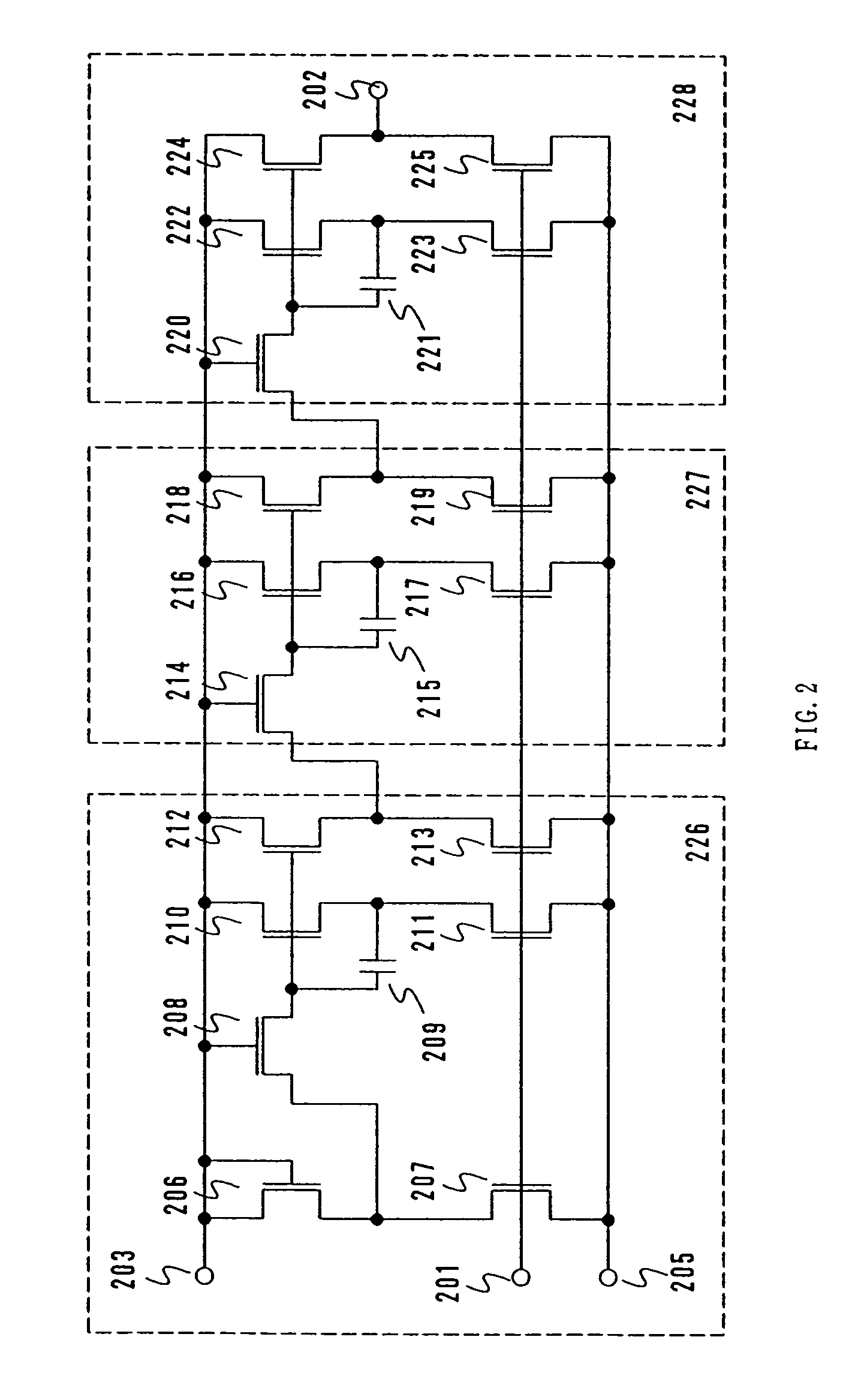

ActiveUS20100044094A1Improve the immunityFirmly connectedPrinted circuit aspectsNon-conductive material with dispersed conductive materialConductive pasteOptoelectronics

The printed wiring board 1 includes the metallic substrate 2, the insulating layer 3 provided on the surface of the metallic substrate 2, and the conductive layer 4 formed on the surface of the insulating layer 3. The conductive layer 4 is electrically connected to the metallic substrate 2. A bottomed via hole or a through hole 6 is formed in the insulating layer 3 and the conducive layer 4. The via hole has a bottom in the metallic substrate 2, and has a wall surface in the insulating layer 3 and in the conductive layer 4. The through hole 6 extends through the insulating layer 3, the conductive layer 4, and the metallic substrate 2. Conductive paste 7 fills the bottomed via hole or the through hole 6 to electrically connect the metallic substrate 2 and the conductive layer 4 with each other. The printed wiring board 1 is subjected to a process in which current is applied to the interface between the metallic substrate 2 and the conductive paste 7.

Owner:SUMITOMO ELECTRIC IND LTD +1

Integrated circuit device

ActiveUS20050161822A1High SNRConnection reliability be lowerThermometer detailsSemiconductor/solid-state device detailsIntegrated circuitTungsten

In a temperature sensor section of a semiconductor integrated circuit device, first vias of tungsten are formed at the topmost layer of a multi-layer wiring layer and pads of titanium are provided on regions of the multi-layer wiring layer which covers the vias. An insulating layer is provided in such a way as to cover the multi-layer wiring layer and the pads, second vias are so formed as to reach the pads. Vanadium oxide is buried in the second vias by reactive sputtering, and a temperature monitor part of vanadium oxide is provided in such a way as to connect the second vias each other. Accordingly, the temperature monitor part is connected between the two wires.

Owner:RENESAS ELECTRONICS CORP

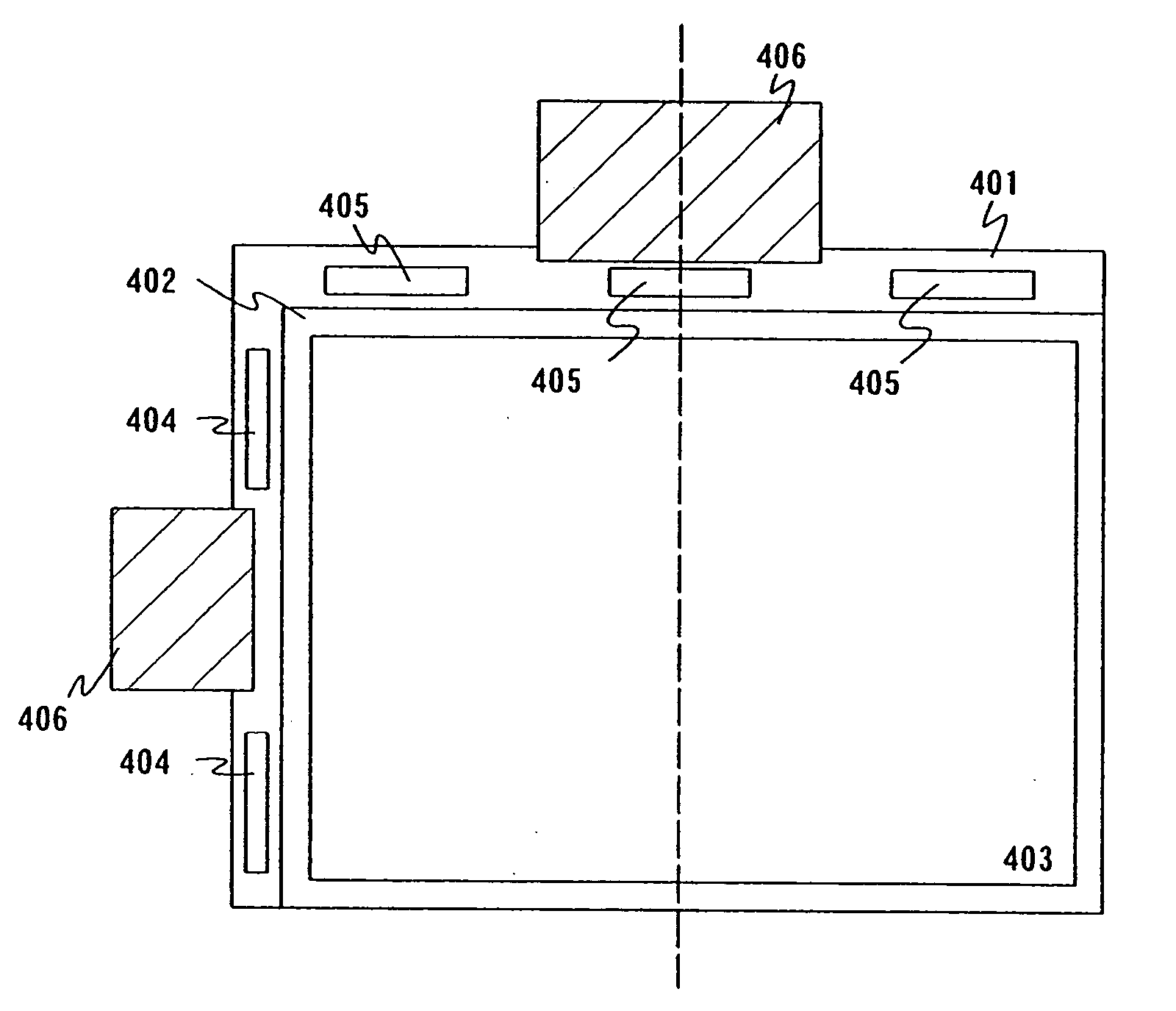

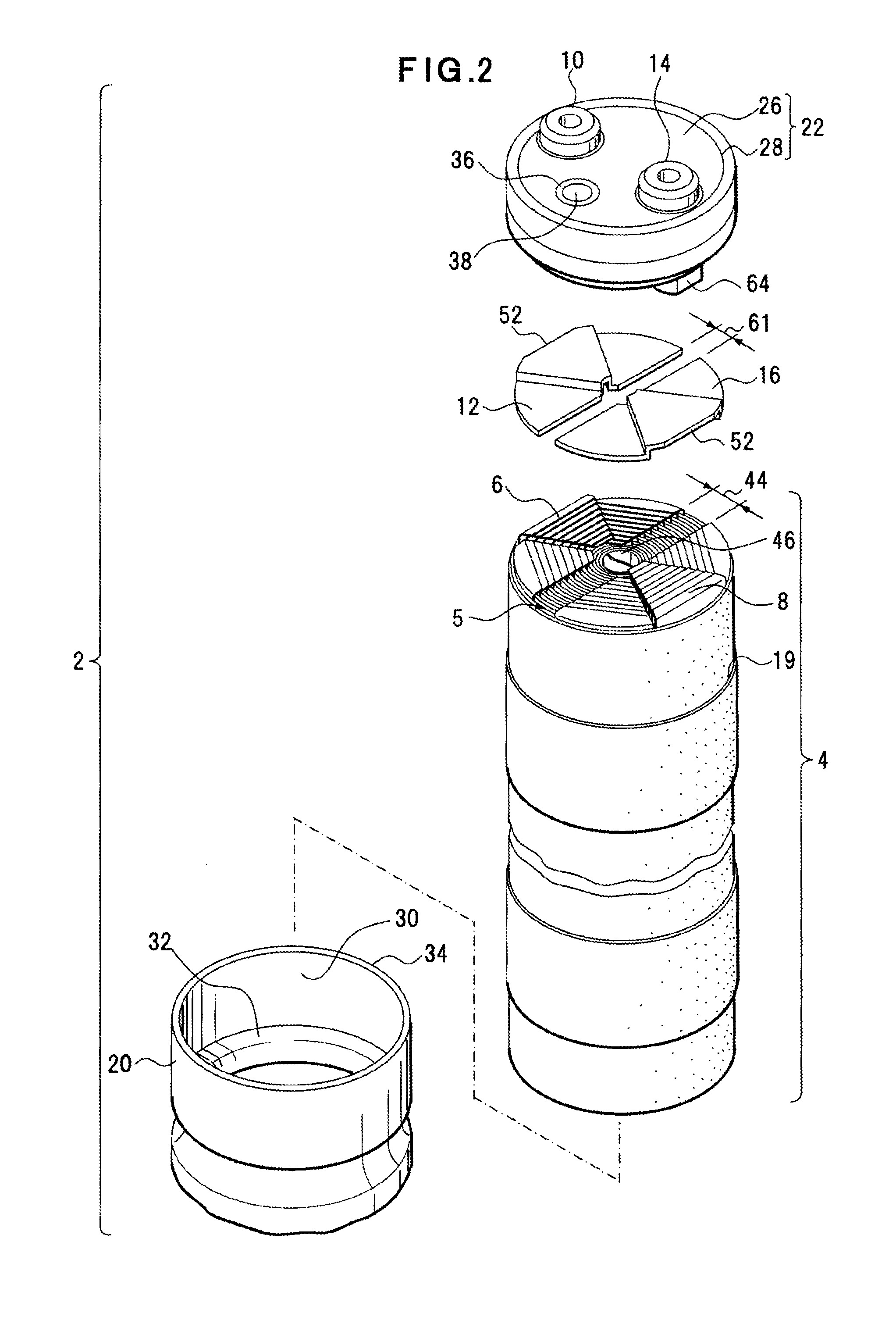

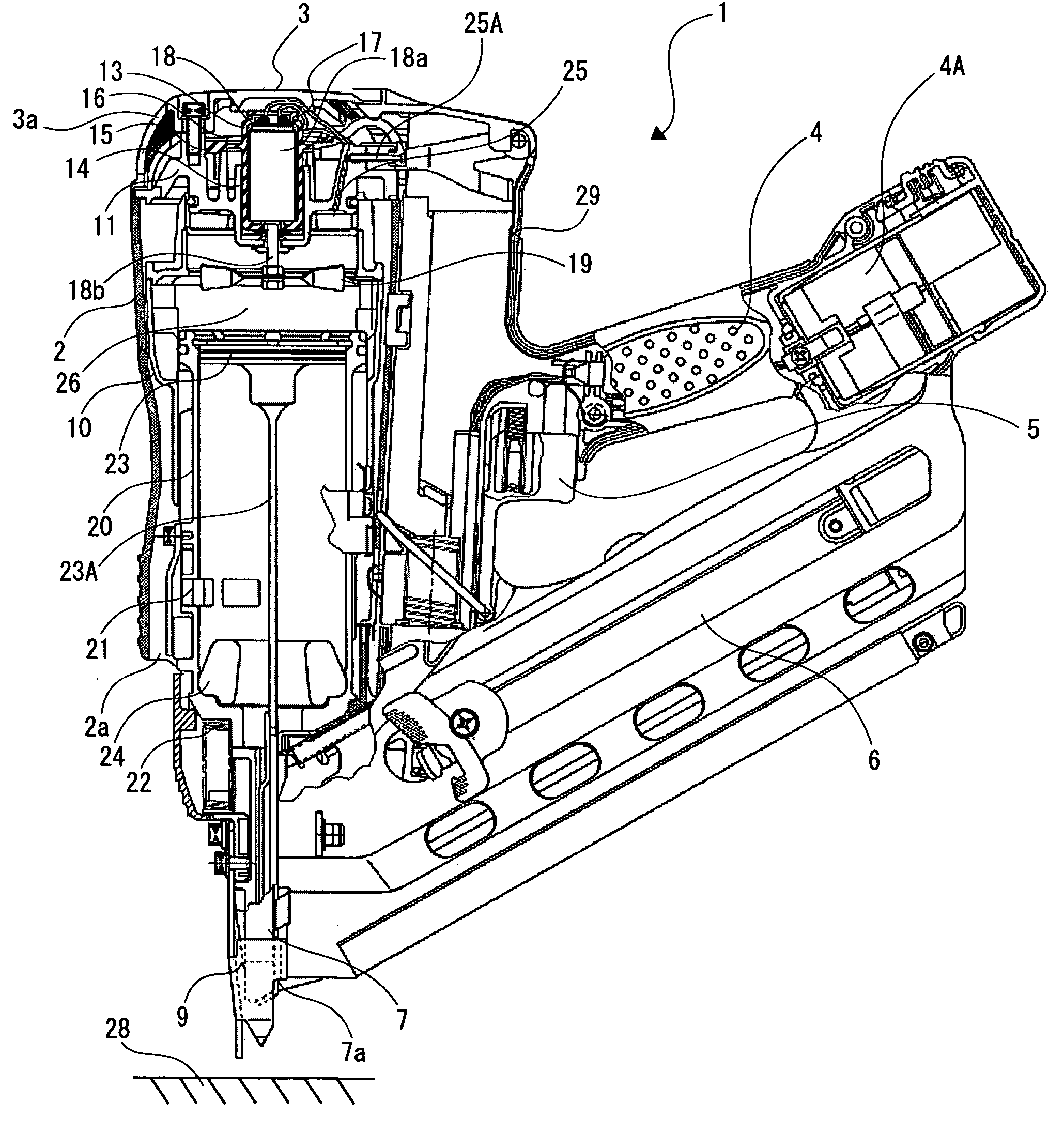

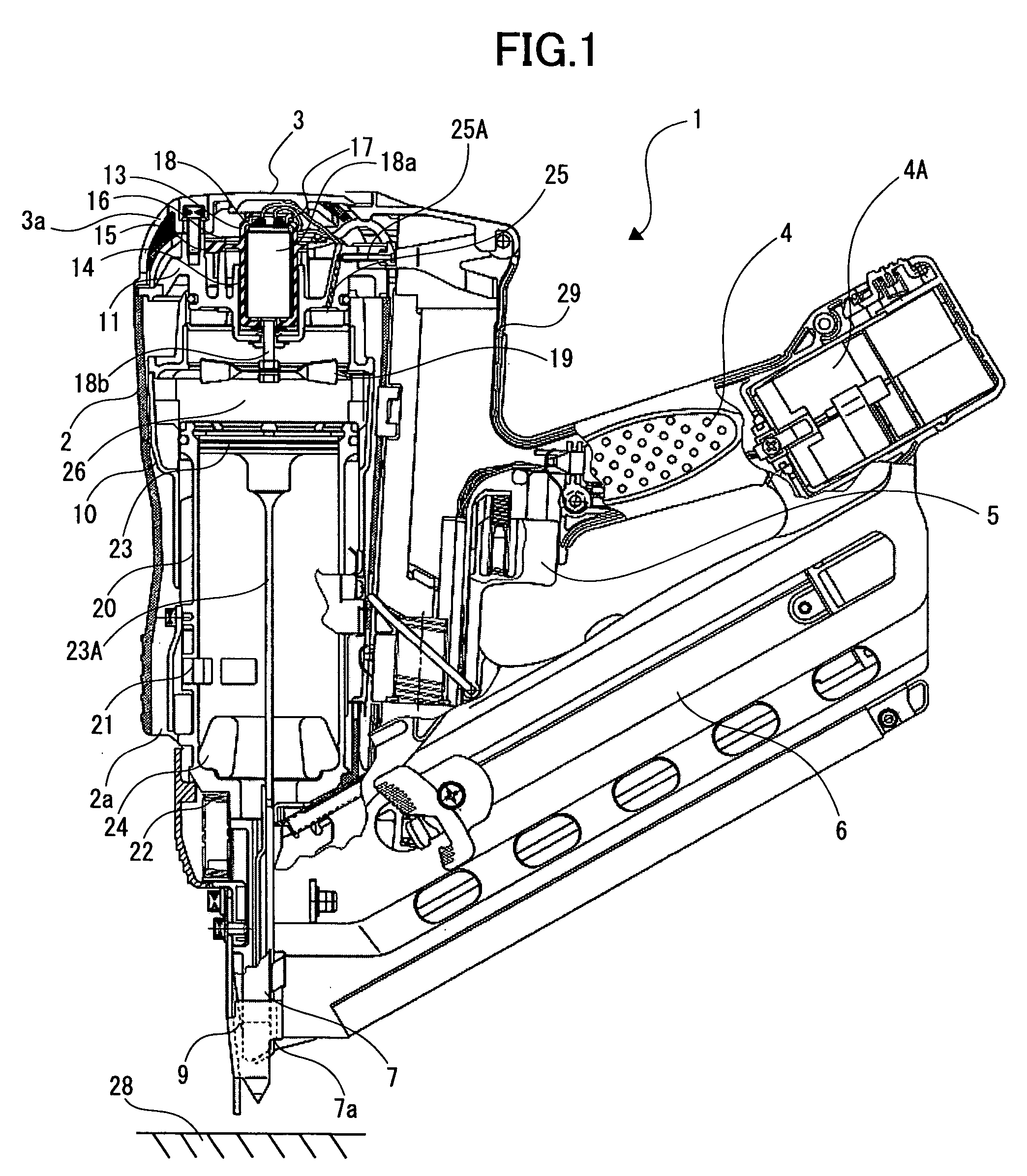

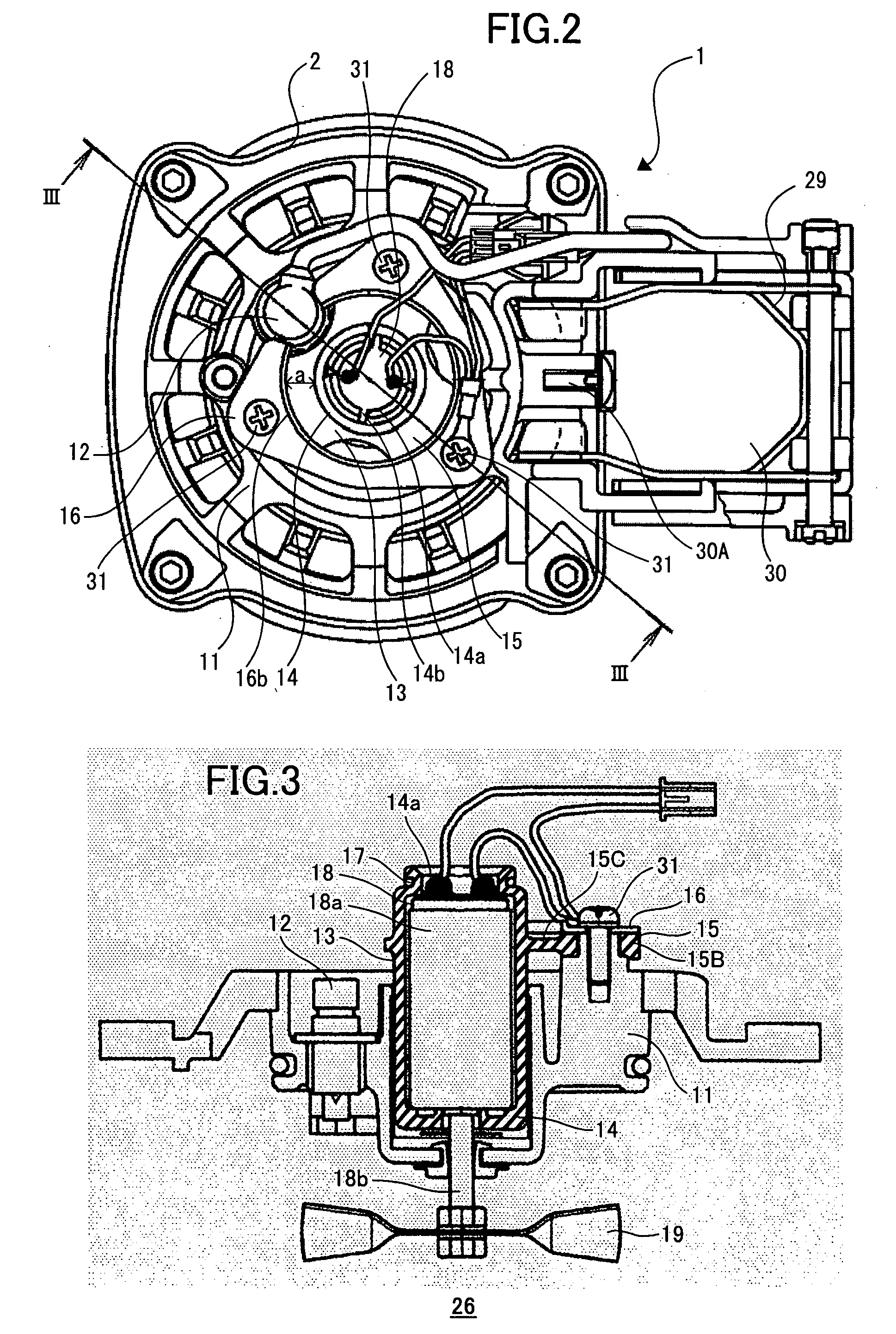

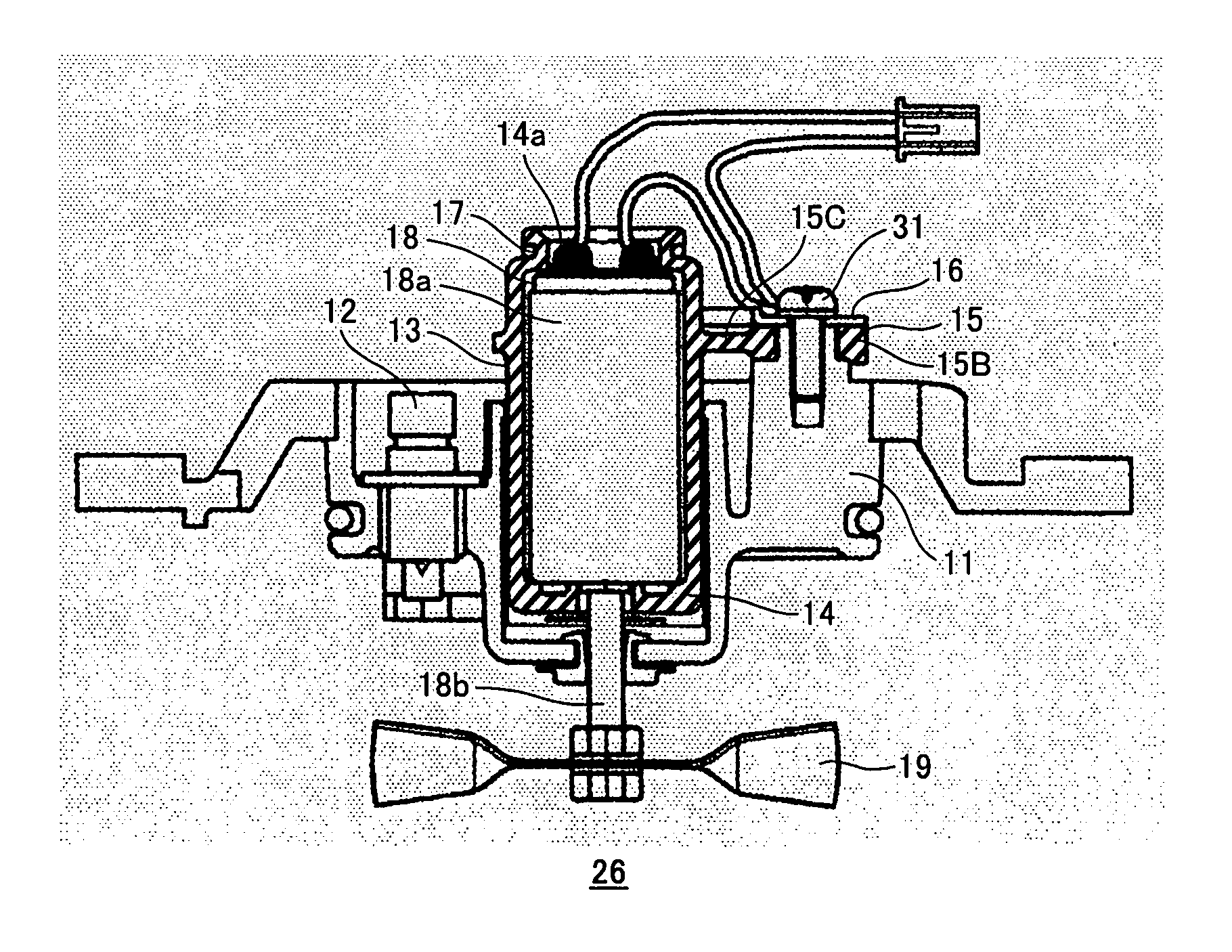

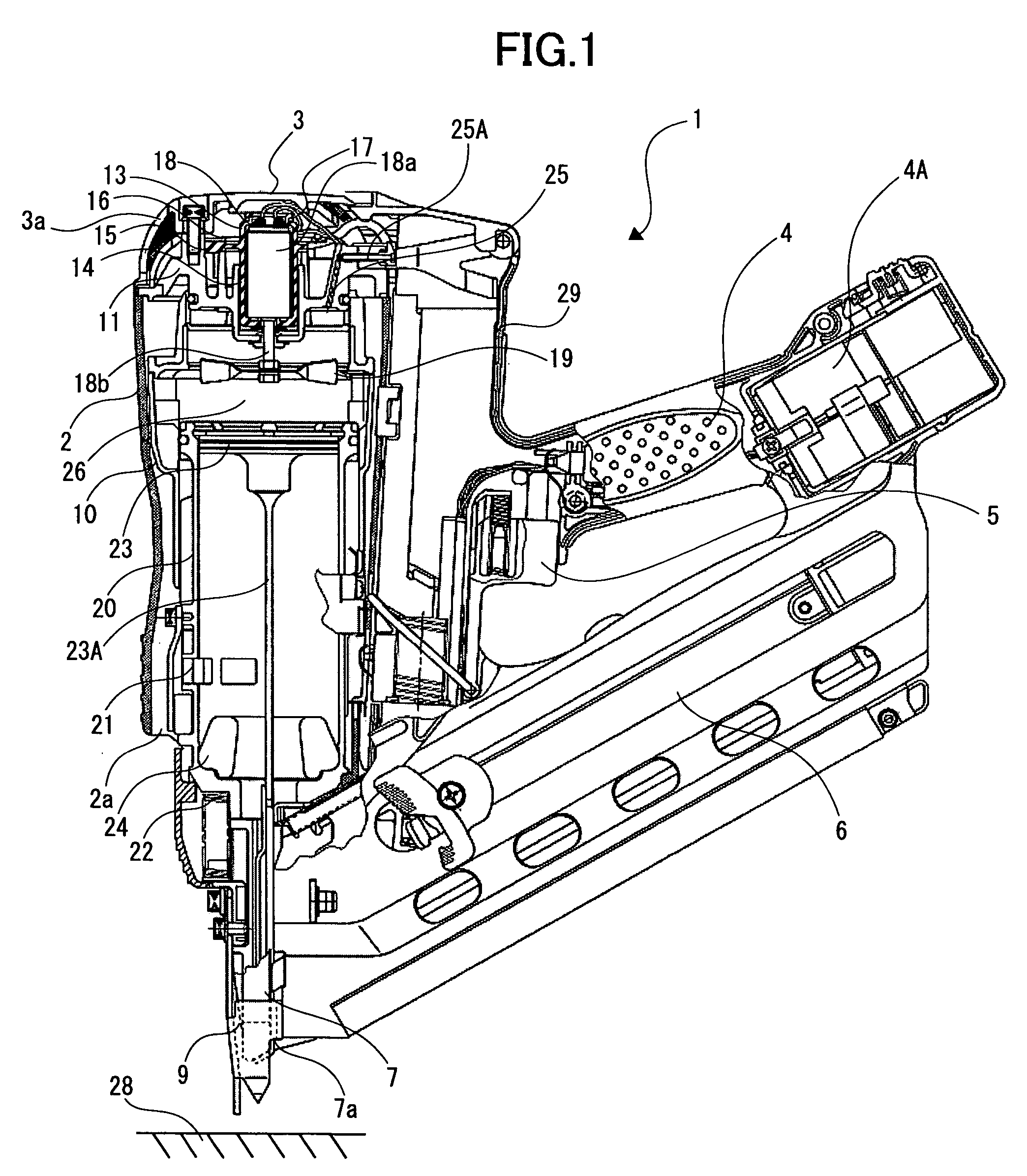

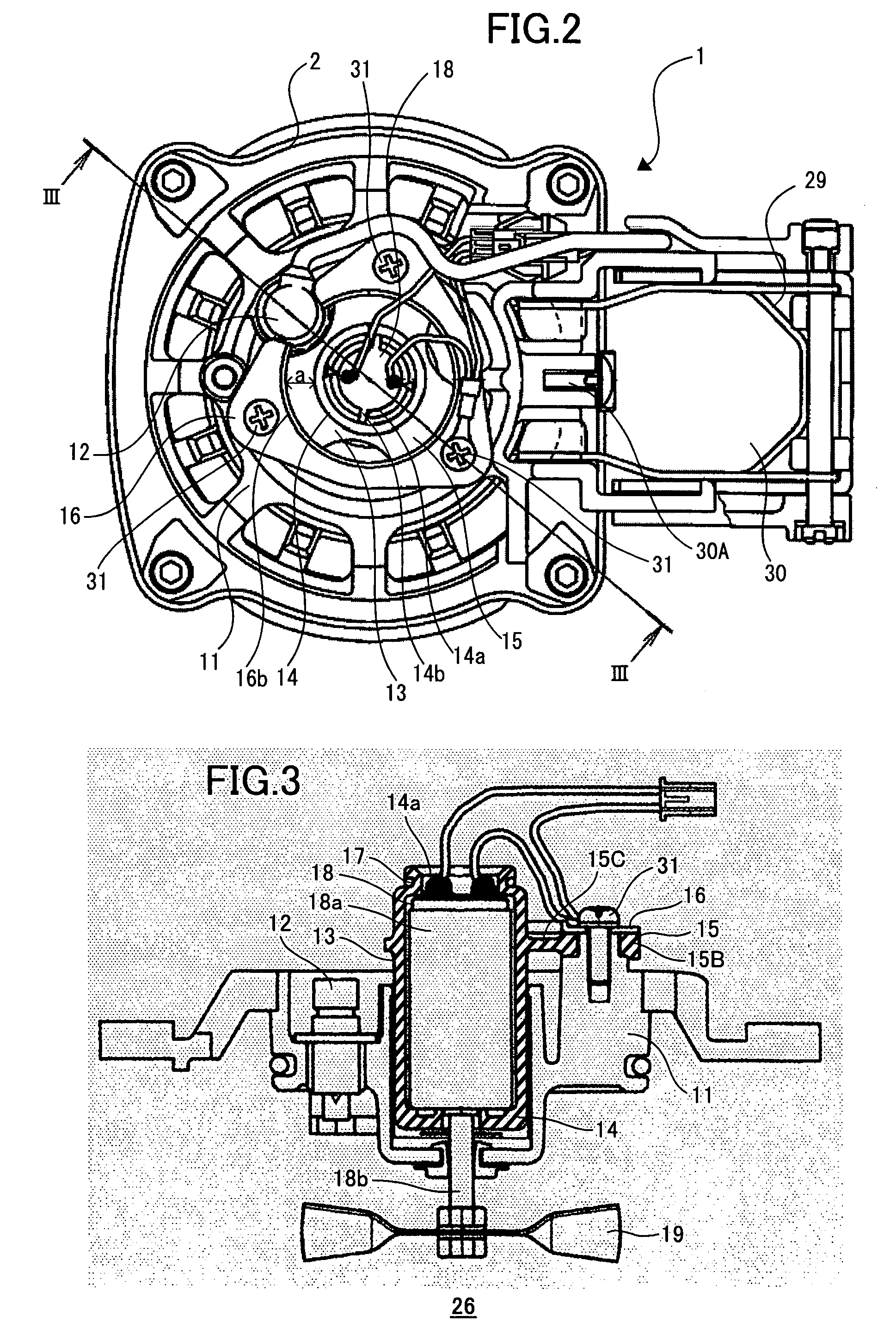

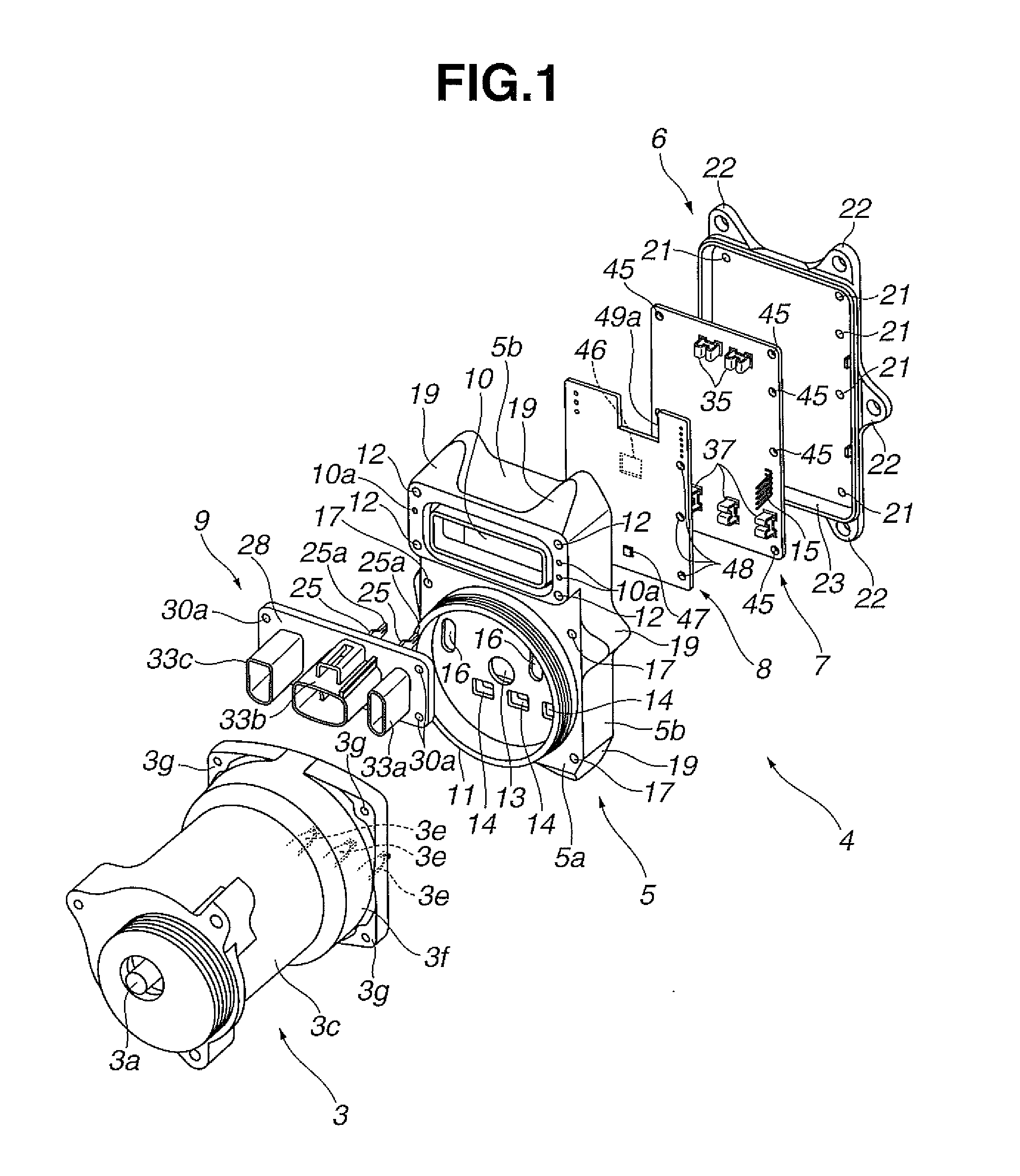

Combustion type power tool having motor suspension arrangement

InactiveUS20050218179A1Increase production costDecreased reliability in connectionStapling toolsFree piston enginesCombustionElectric machinery

A combustion type power tool having a motor suspension arrangement capable of buffering a shock applied to a motor. An integral buffer member made from an elastic material is fixed to a head cap. The buffer member includes a motor storage section in which a motor casing is stored, and a plurality of buffer segments extending radially outwardly from the motor storage section and integrally therewith. Each radially outer end portion of each buffer segment is fixed to the head cap for floatingly supporting the motor storage section.

Owner:HITACHI KOKI CO LTD

Combustion type power tool having motor suspension arrangement

InactiveUS7073468B2Increase production costReduced connection reliabilityStapling toolsFree piston enginesCombustionEngineering

A combustion type power tool having a motor suspension arrangement capable of buffering a shock applied to a motor. An integral buffer member made from an elastic material is fixed to a head cap. The buffer member includes a motor storage section in which a motor casing is stored, and a plurality of buffer segments extending radially outwardly from the motor storage section and integrally therewith. Each radially outer end portion of each buffer segment is fixed to the head cap for floatingly supporting the motor storage section.

Owner:KOKI HLDG CO LTD

Conductive Paste and Method for Manufacturing Multilayer Printed Wiring Board Using the Same

ActiveUS20080099121A1Increased resistance in connectionReduced connection reliabilityConductive materialNon-conductive material with dispersed conductive materialConductive pasteEpoxy

There is provided a conductive paste obtained by kneading conductive particles into an epoxy resin and having good filling ability into a via hole, which can form a connected portion wherein the connection resistance does not change with time even under high temperature and high humidity conditions. Also, there is provided a method for manufacturing a multilayer printed wiring board using the conductive paste.A conductive paste containing conductive particles and a resin mixture wherein the content of the epoxy resin having a molecular weight of 10,000 or more is from 30 to 90% by weight in the total resin component and whose elastic modulus at 85° C. after curing is 2 GPa or less, the content of the conductive particle being from 30 to 75% by volume. Furthermore, a method for manufacturing a multilayer printed wiring board using the conductive paste.

Owner:SUMITOMO ELECTRIC IND LTD

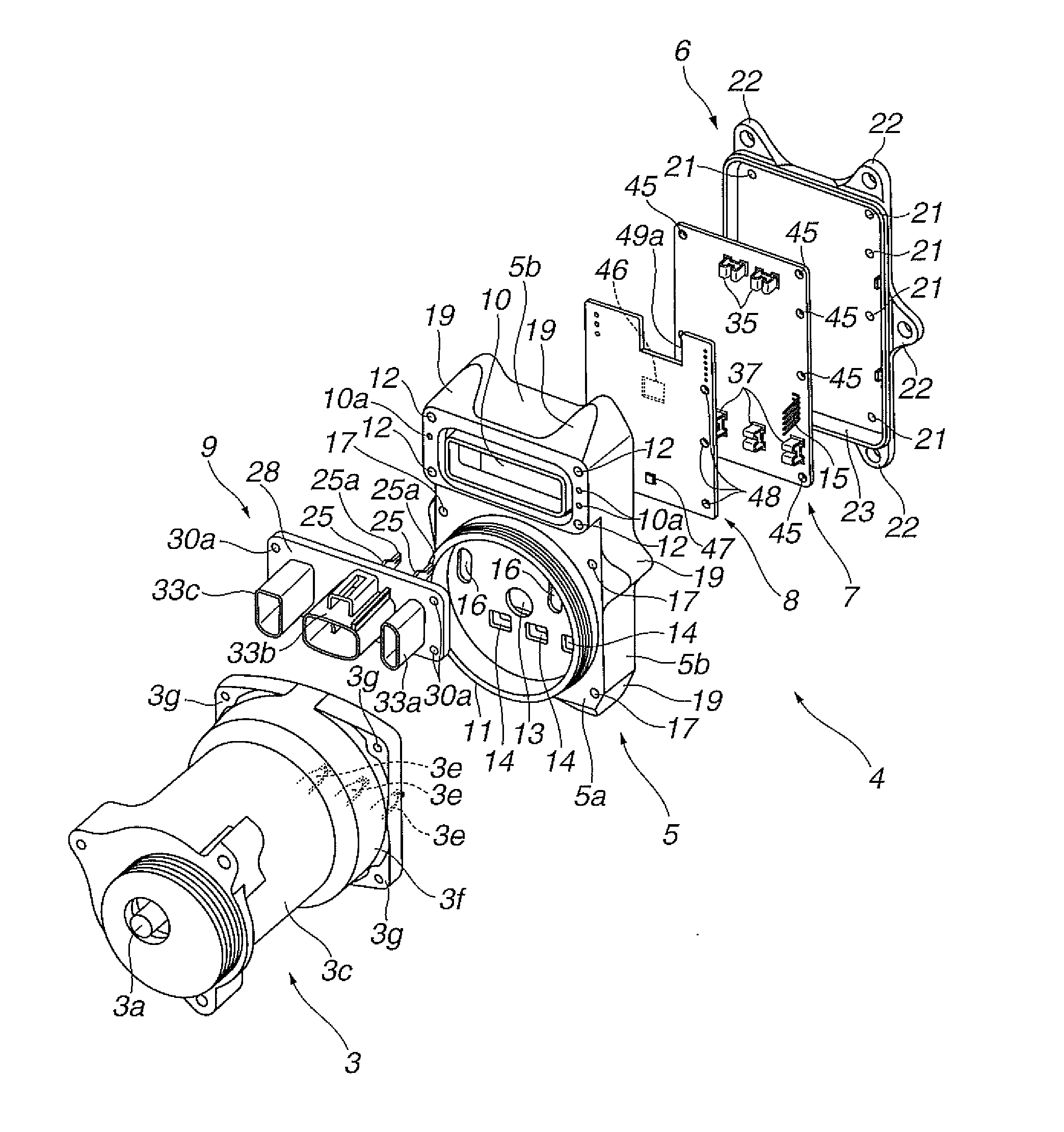

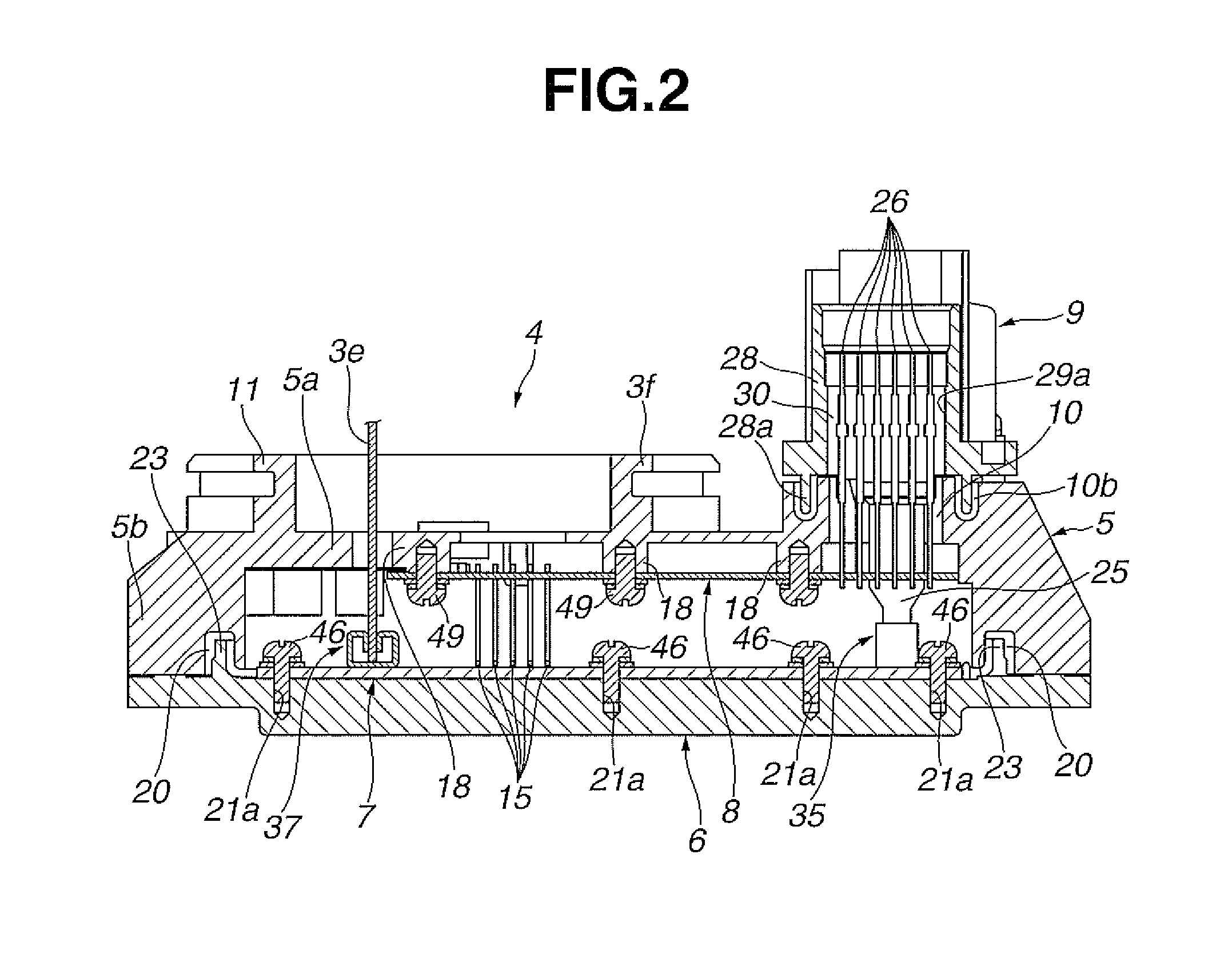

Electronic Control Device

ActiveUS20160244088A1Reduced connection reliabilityImprove connection reliabilityClosed casingsCasings with display/control unitsElectricityElectric power system

An electronic control unit includes a casing and a cover which are mutually bonded. A drive circuit board which drives a motor unit is fixed to the cover and, on the other hand, a control circuit board which controls the drive circuit board is fixed to the casing. An electrical connector which supplies an electric power to each board and a motor unit is attached on an opening section of the casing. First power supply terminals of this electrical connector and the motor unit and second power supply terminals of the drive circuit board are directly electrically connected by a bonding of both of casing and the cover.

Owner:HITACHI ASTEMO LTD

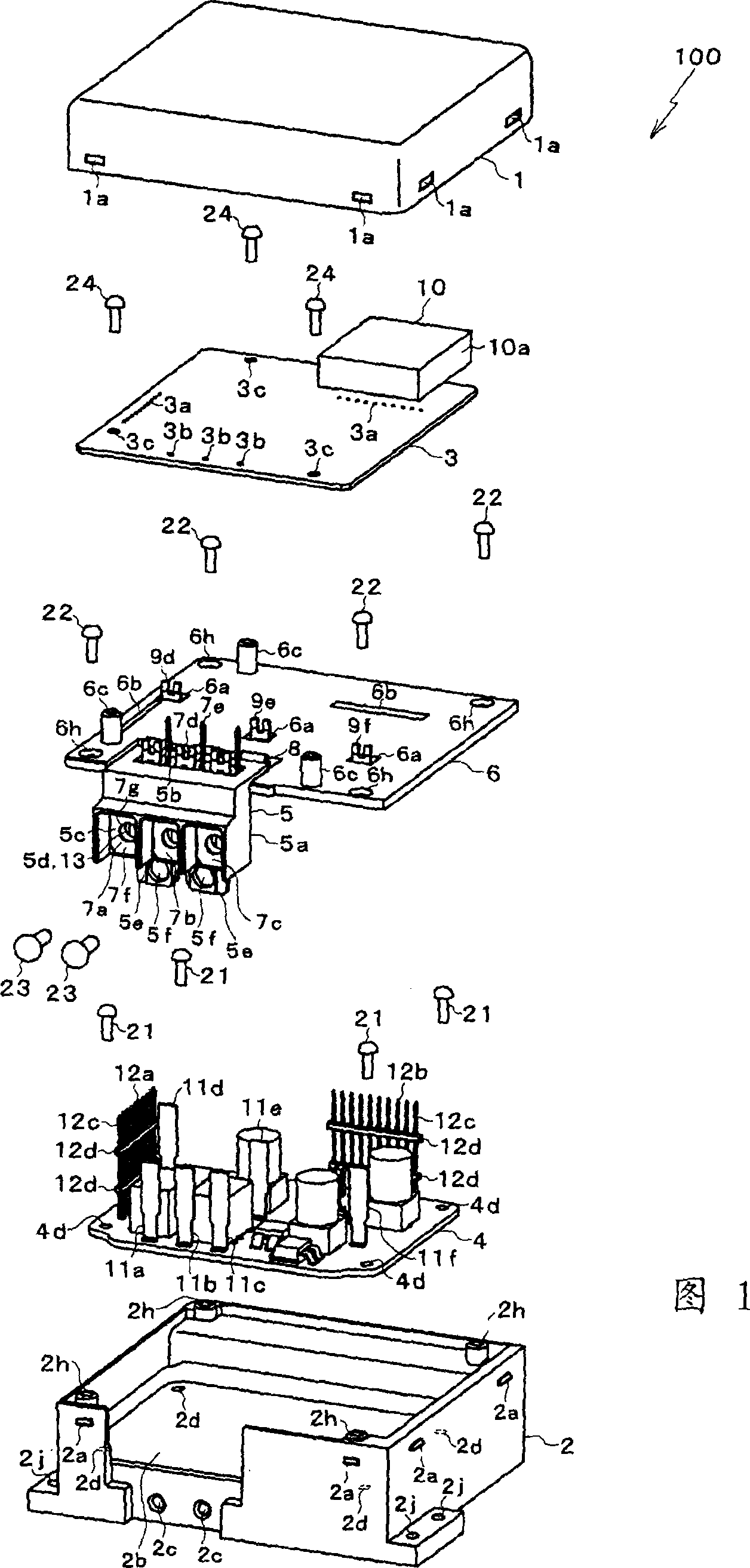

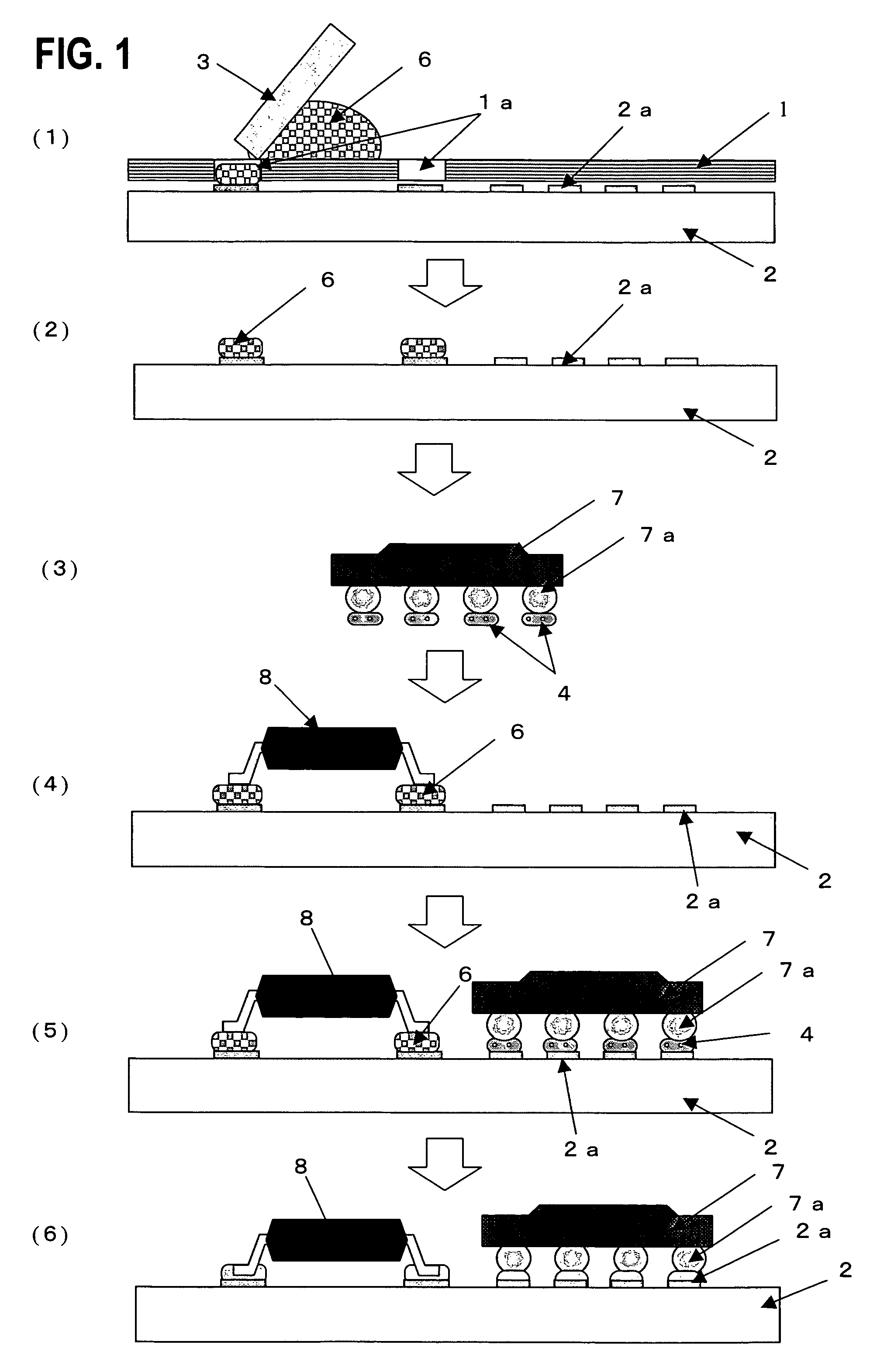

Electronic equipment and method of manufacturing the electronic equipment

InactiveCN101093920AReduced connection reliabilityVehicle connectorsContact member cases/bases manufactureComputer moduleEngineering

To prevent lowering of connection reliability of soldering connection portions of electronic equipment, there is provided electronic equipment which is equipped with a connector electrically connected to an electric motor, a control board and a power module board to which the connectors and other electric parts are electrically connected by soldering, a base for supporting the boards and the connector while overlapped with the boards and cases for fixing the connector while the connector is exposed from an opening portion, and fixing the boards while the boards and the base are accommodated in the cases. The connector is supported by the base through a beam as a flexible metal piece.

Owner:OMRON AUTOMOTIVE ELECTRONICS CO LTD

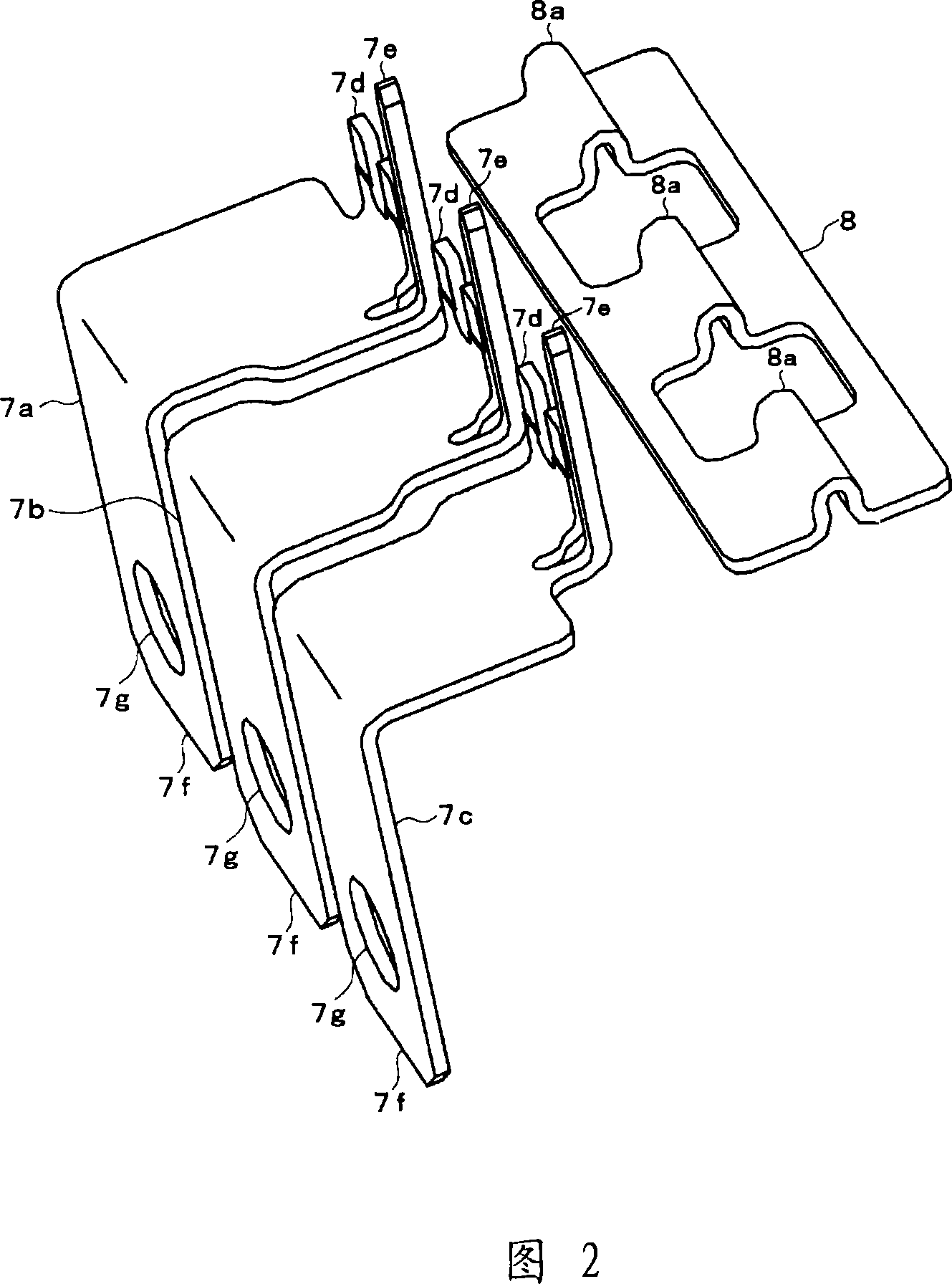

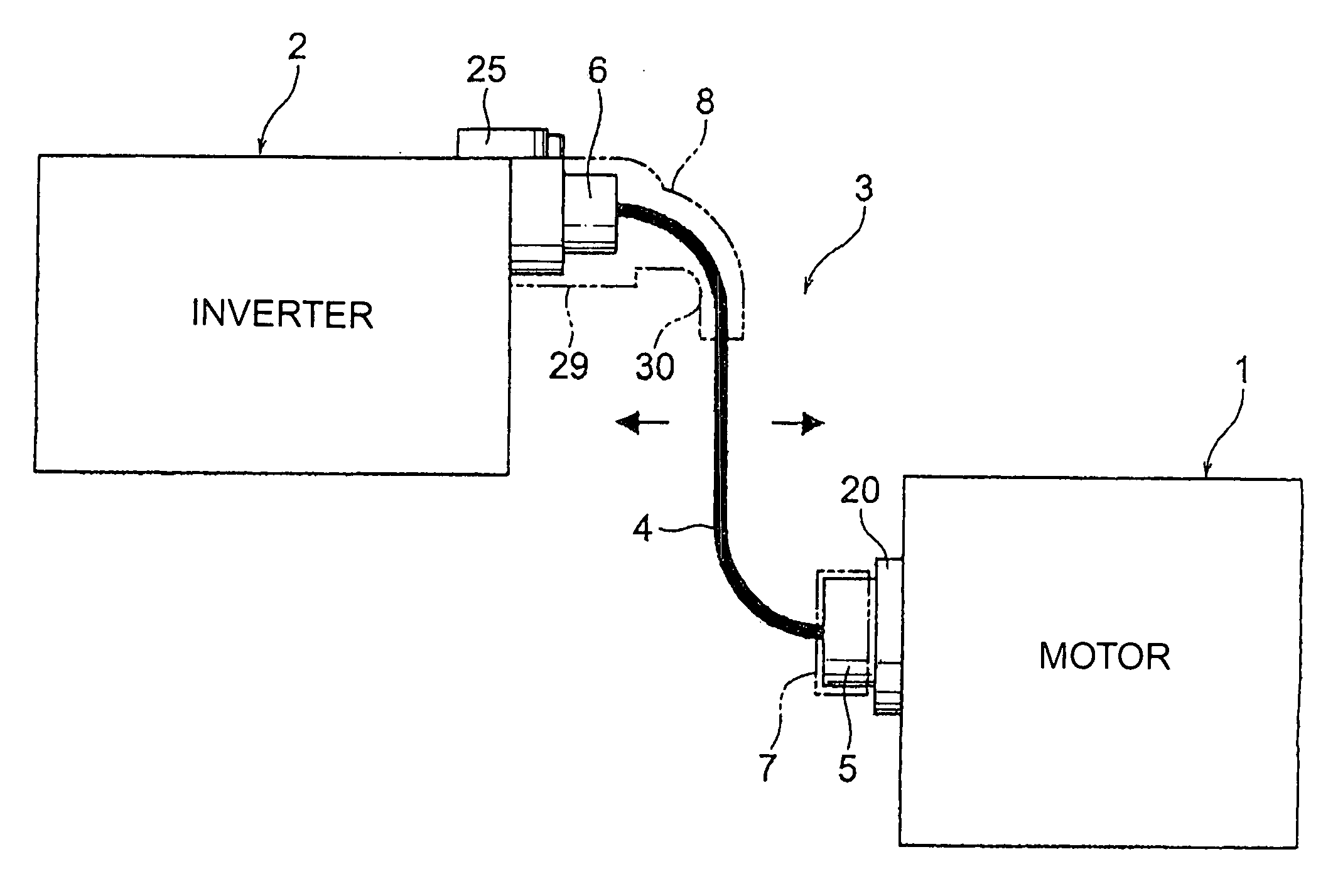

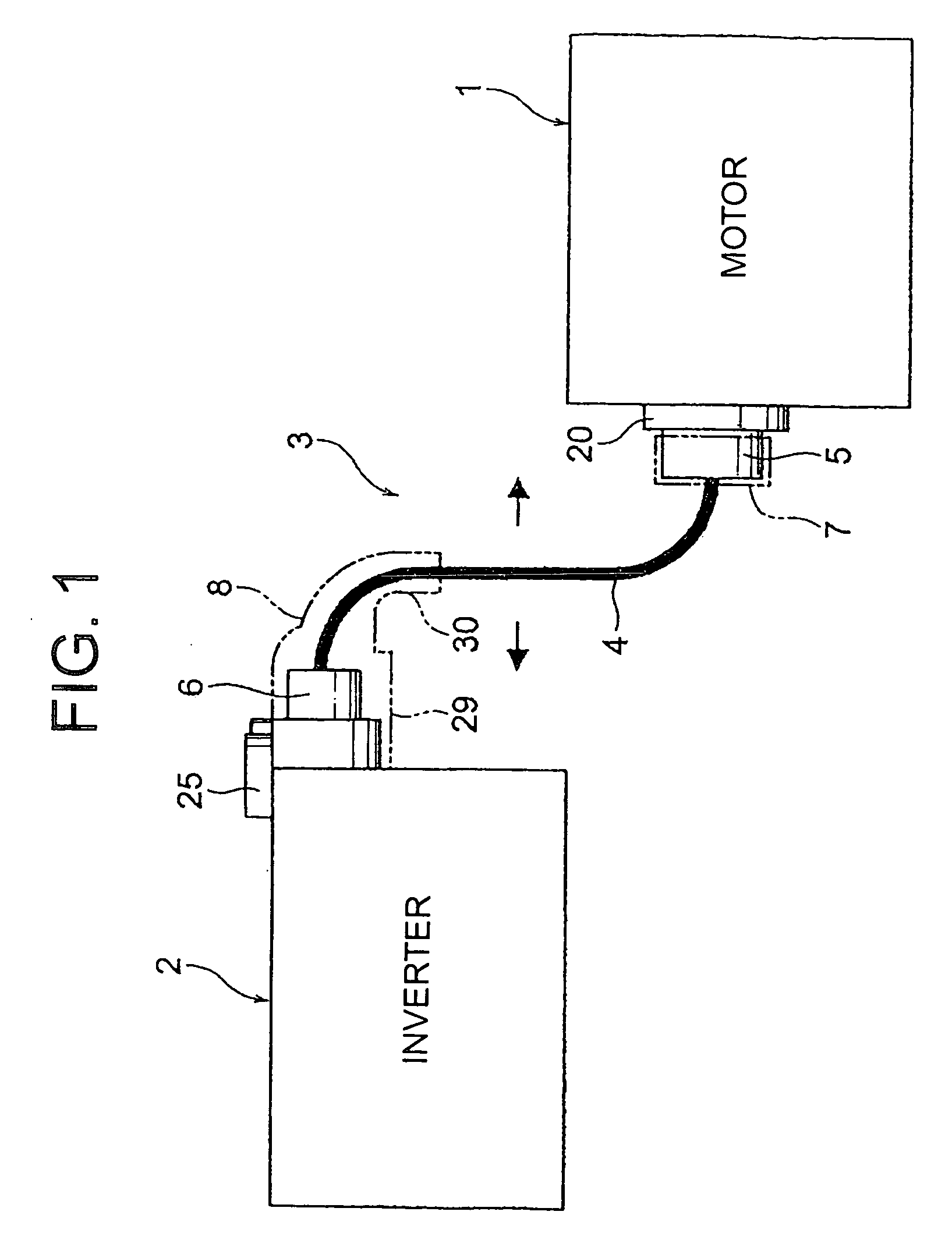

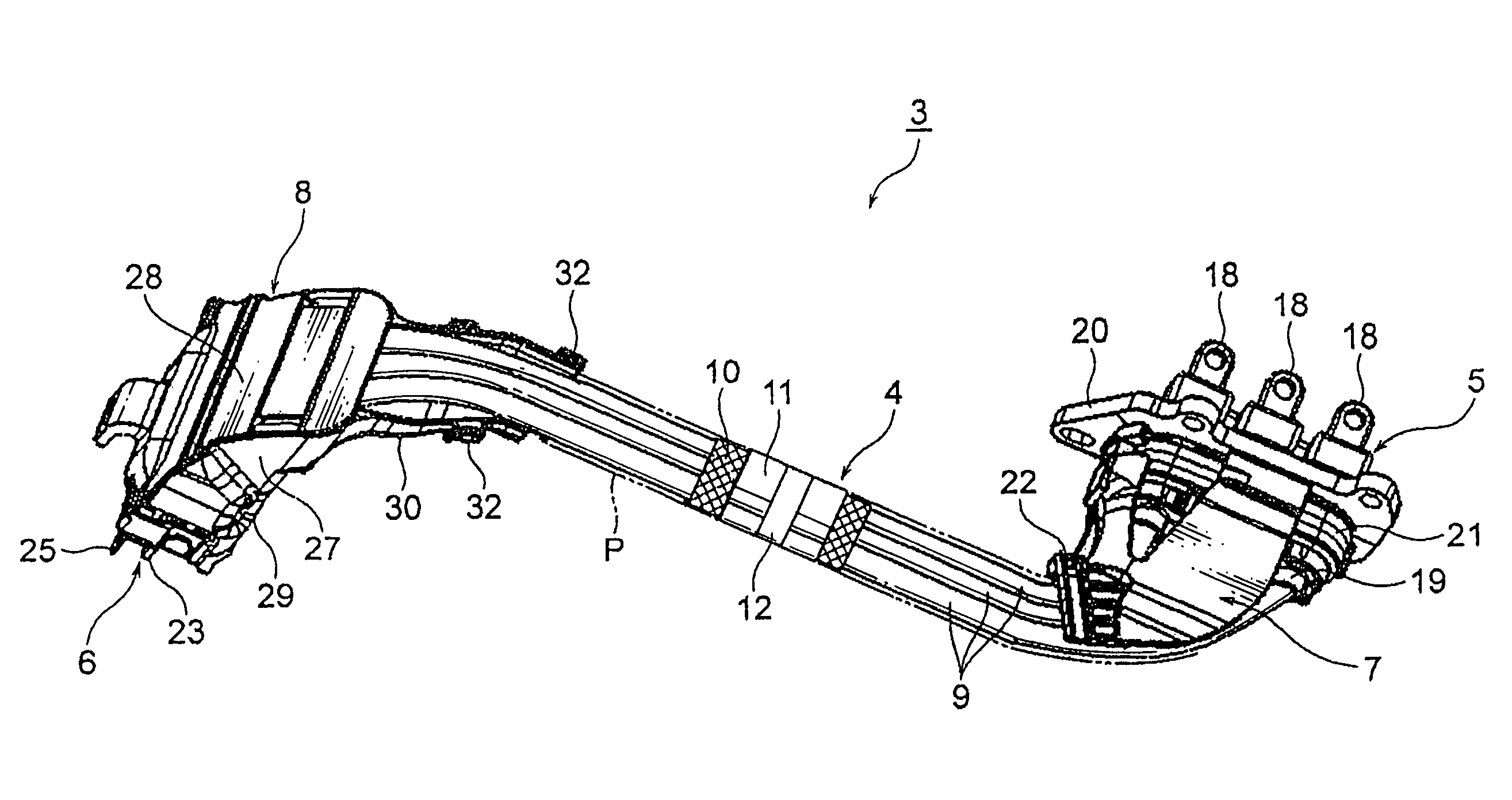

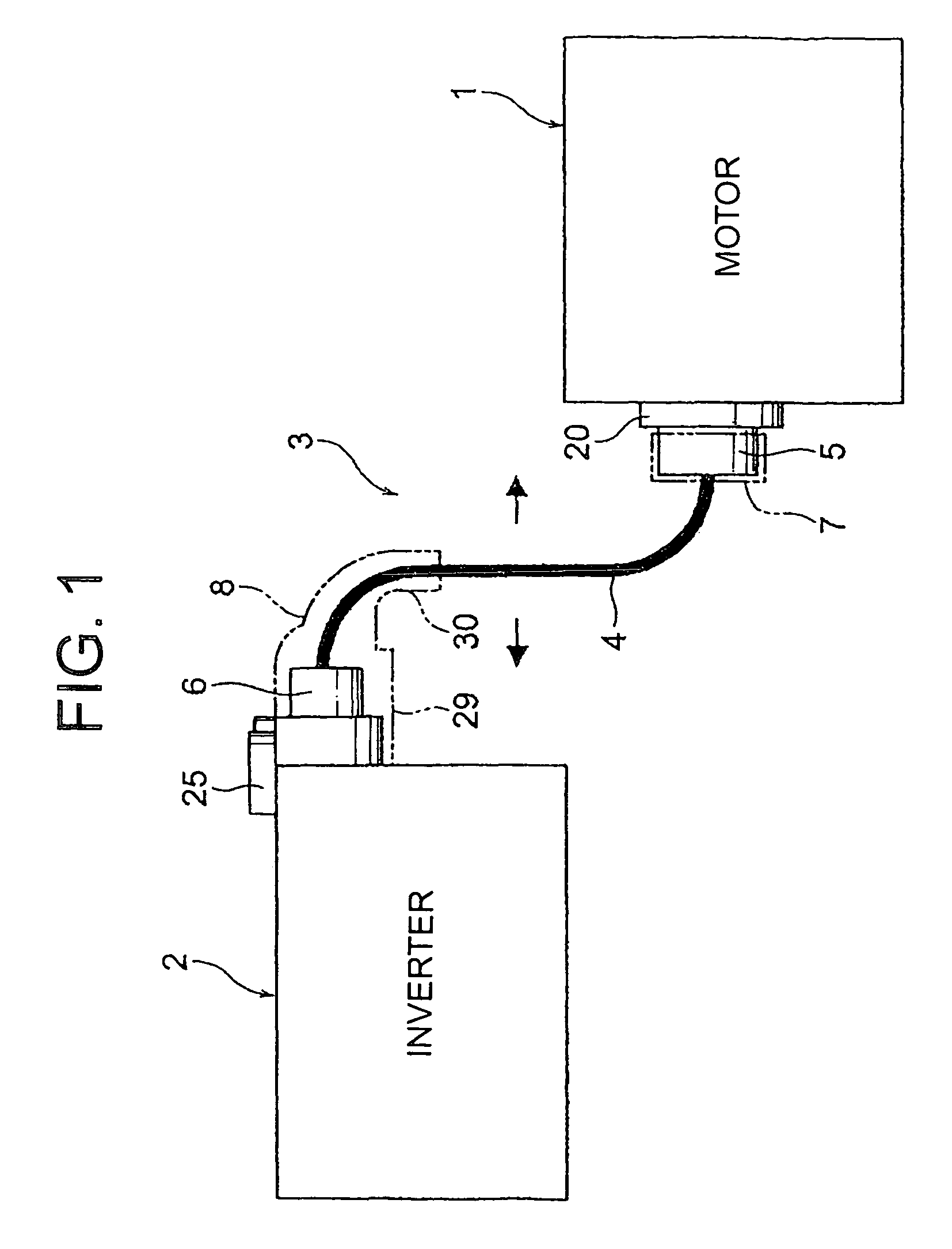

Motor cable device and resin component employed thereto

ActiveUS20100248529A1Good connection conditionPrevent damageAssociation with control/drive circuitsRelieving strain on wire connectionEngineeringElectric motor

The motor cable device which can prevent damage on an inverter-side connecting member of the motor cable device and lowering in a connecting reliability of the inverter-side connecting member is provided. Also, a resin component used in the above-described motor cable device is provided. The motor cable device electrically connects a motor and an inverter and includes an inverter-side protector and a motor-side protector. The inverter-side protector includes a fixed end which is directly or indirectly fixed to the inverter and which supports the inverter-side connecting member. A swinging motion absorbing portion is formed continuously to the fixed end, the swinging motion absorbing portion being arranged to support a cable body at the inverter-side connecting member and absorb the swinging motion generated at the cable body of the motor cable device, is further included.

Owner:YAZAKI CORP

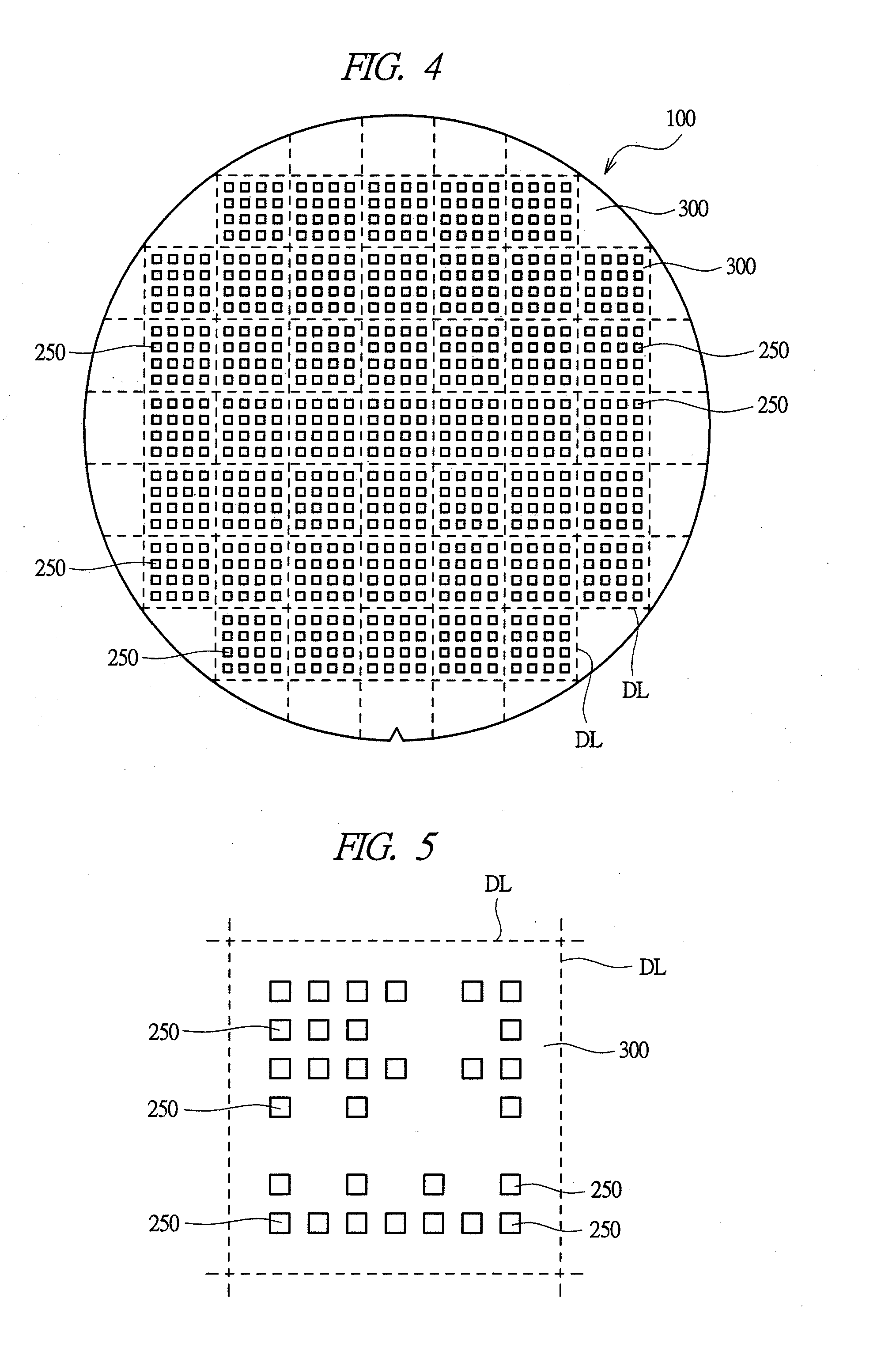

Printed wiring board and method for manufacturing the same

ActiveUS8866027B2Improve the immunityFirmly connectedPrinted circuit aspectsNon-conductive material with dispersed conductive materialConductive pasteOptoelectronics

The printed wiring board 1 includes the metallic substrate 2, the insulating layer 3 provided on the surface of the metallic substrate 2, and the conductive layer 4 formed on the surface of the insulating layer 3. The conductive layer 4 is electrically connected to the metallic substrate 2. A bottomed via hole or a through hole 6 is formed in the insulating layer 3 and the conducive layer 4. The via hole has a bottom in the metallic substrate 2, and has a wall surface in the insulating layer 3 and in the conductive layer 4. The through hole 6 extends through the insulating layer 3, the conductive layer 4, and the metallic substrate 2. Conductive paste 7 fills the bottomed via hole or the through hole 6 to electrically connect the metallic substrate 2 and the conductive layer 4 with each other. The printed wiring board 1 is subjected to a process in which current is applied to the interface between the metallic substrate 2 and the conductive paste 7.

Owner:SUMITOMO ELECTRIC IND LTD +1

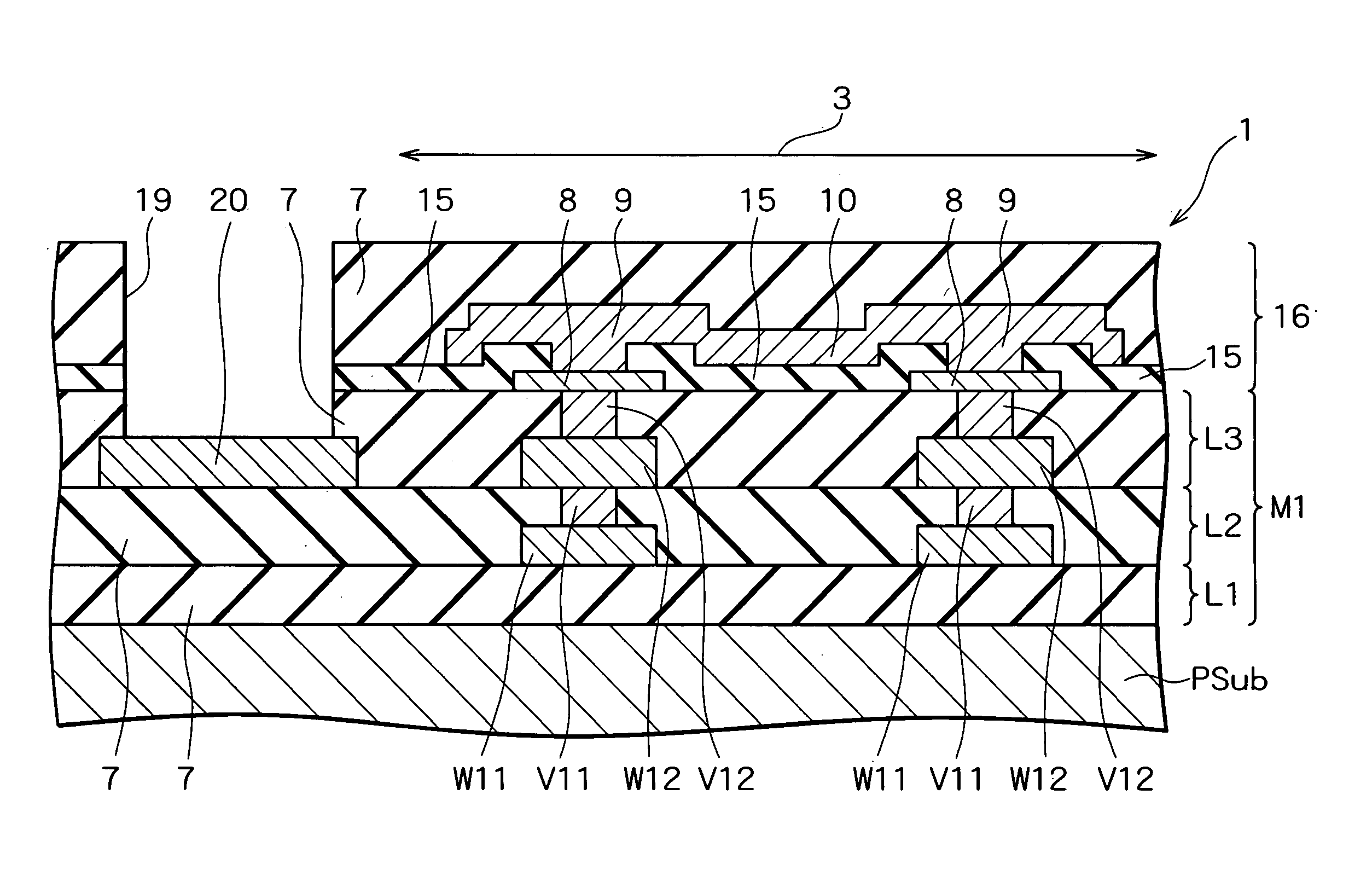

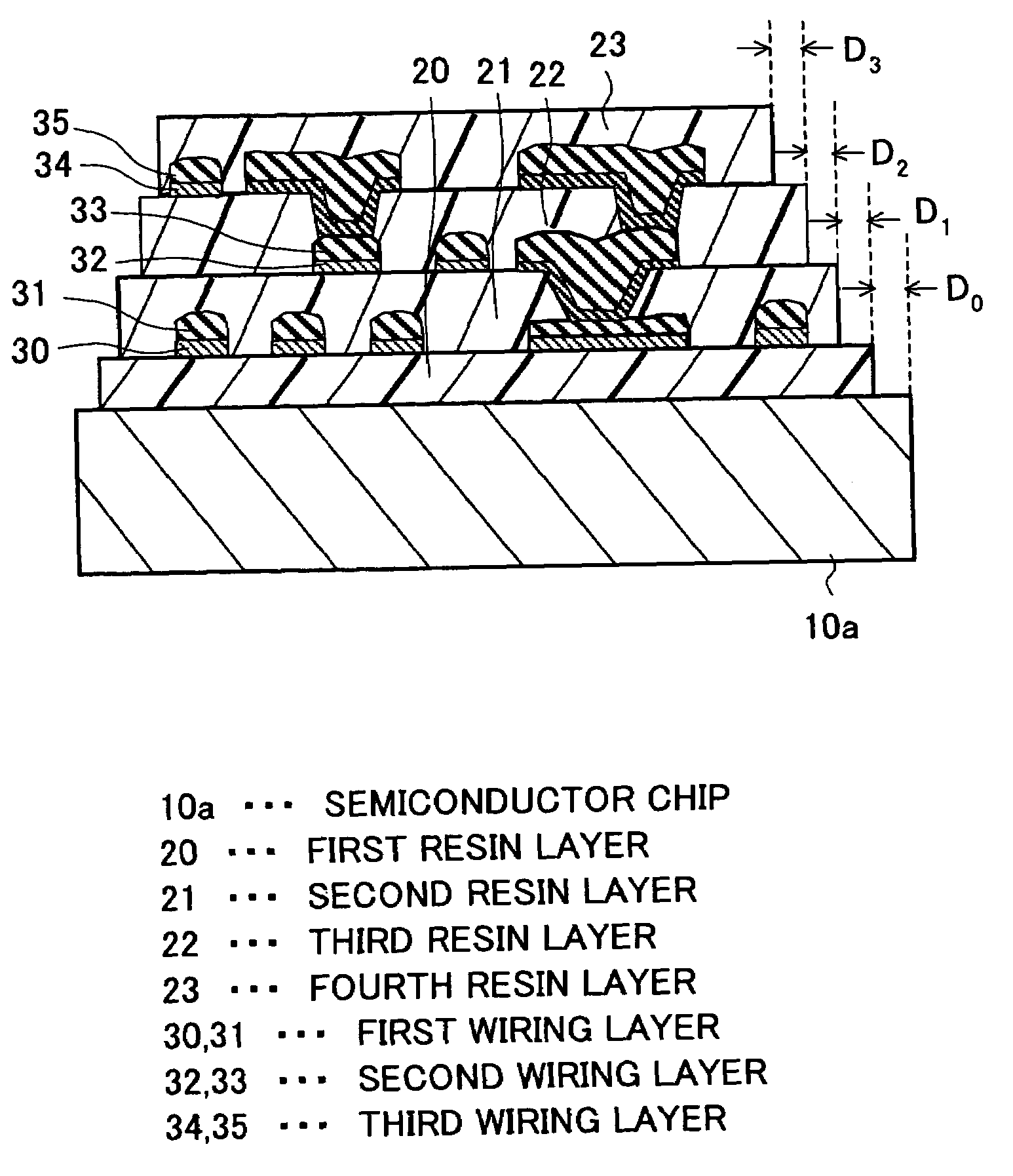

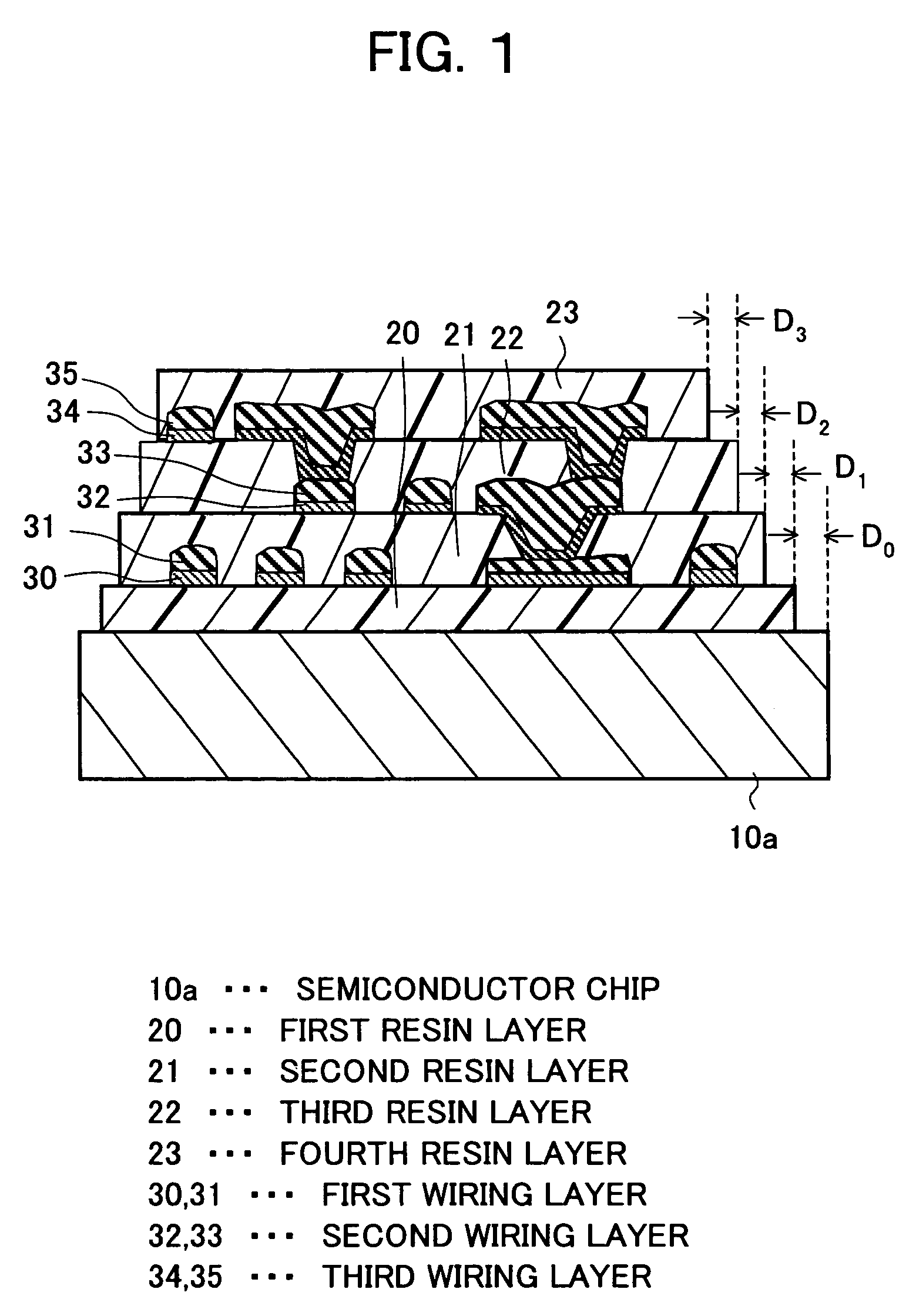

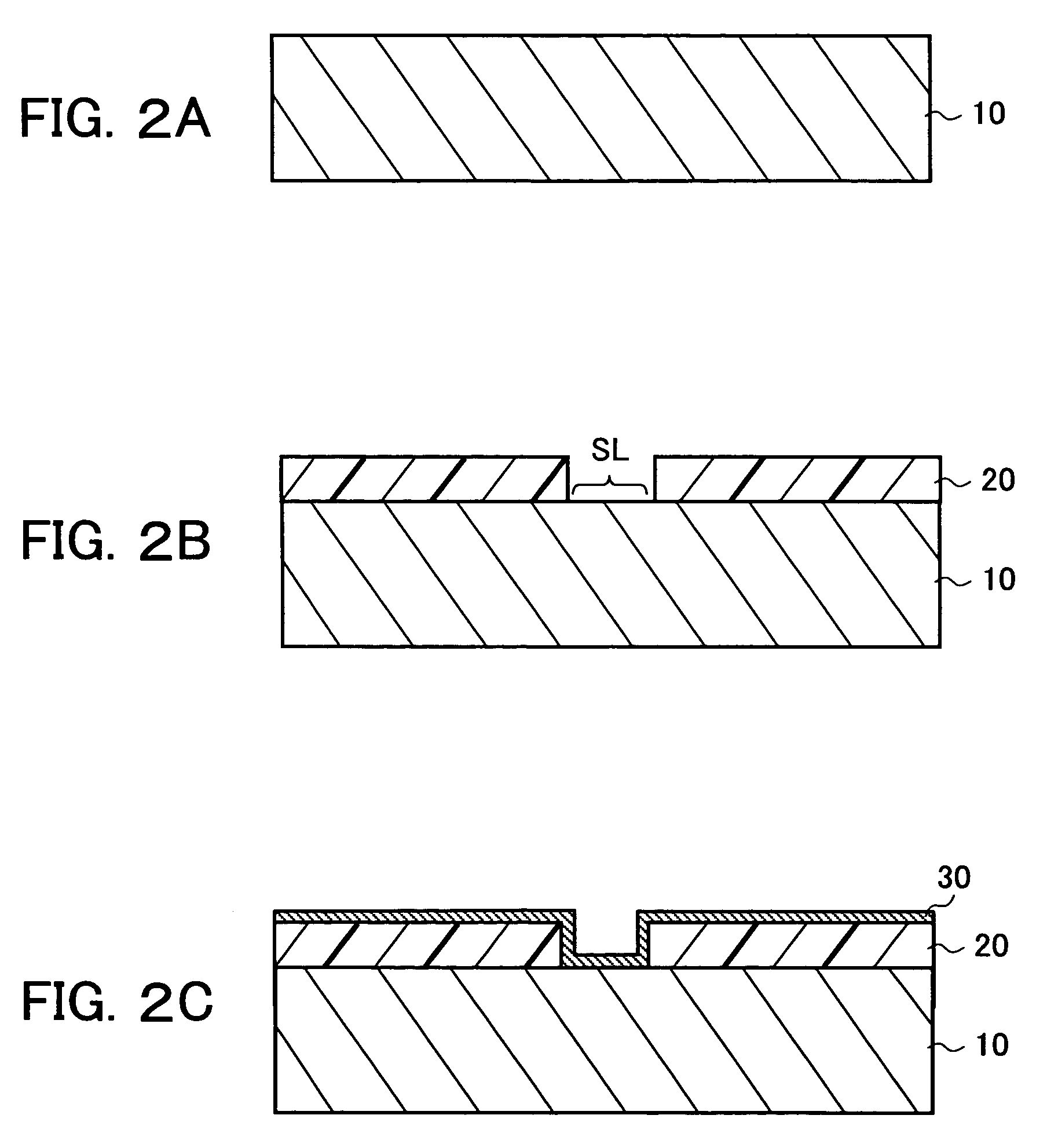

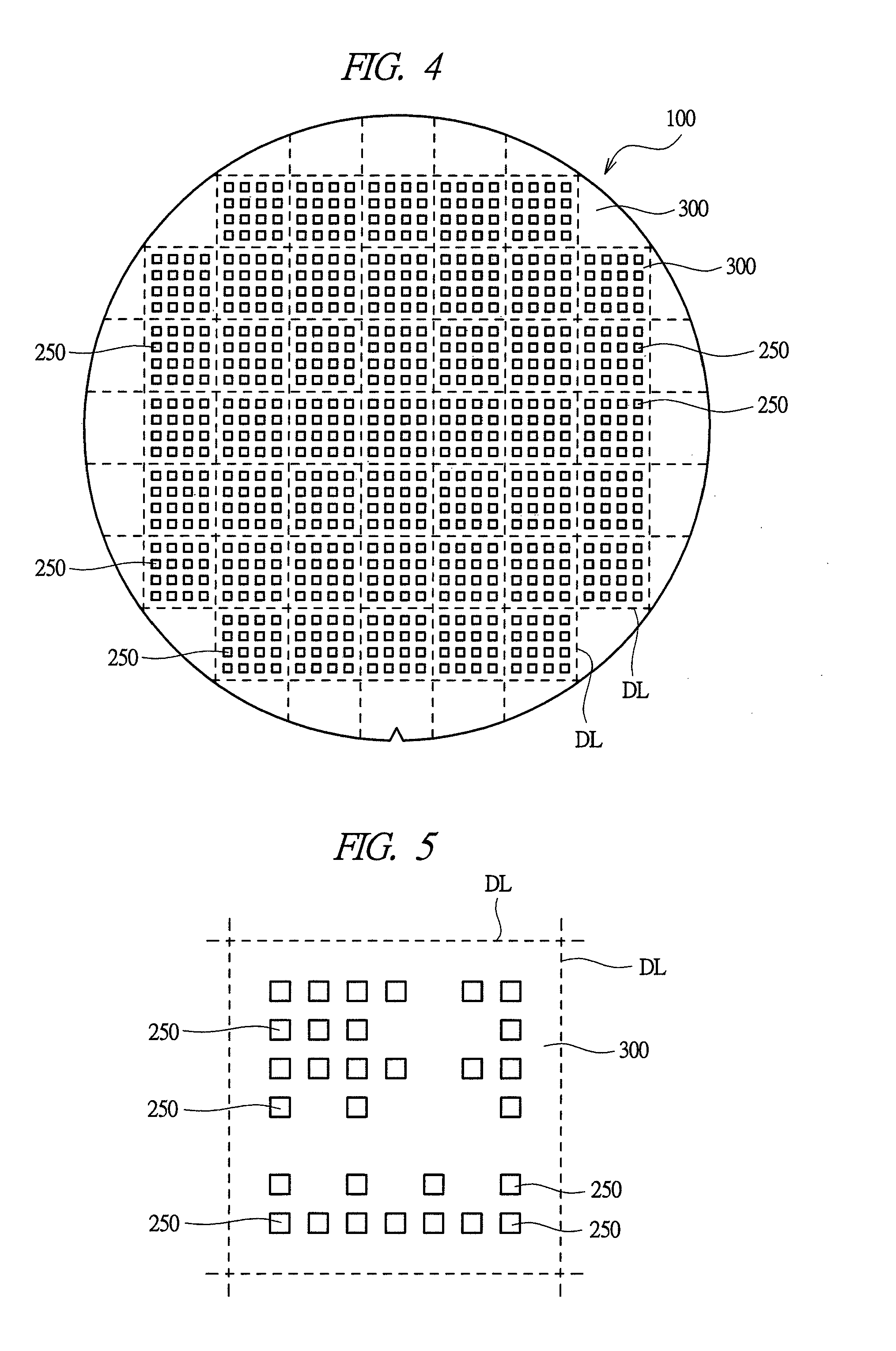

Semiconductor device and production method thereof

ActiveUS7170175B2Reduce yieldReduced connection reliabilityTransistorThyristorSemiconductor chipEngineering

A semiconductor device and a production method thereof capable of reducing warps of a semiconductor wafer when packaging at a wafer level in a SiP type semiconductor device, is configured that an insulating layer is formed by stacking a plurality of resin layers on a semiconductor chip formed with an electronic circuit, wiring layers are buried in the insulating layer and electrically connected to electrodes, and formation areas of the plurality of resin layers become gradually smaller from an area of an upper surface of the semiconductor chip as they get farther from the semiconductor chip, so that a side surface and an upper surface of each of the resin layers and the upper surface of the semiconductor chip form a stepwise shape.

Owner:SONY CORP

Adhesive and connecting structure using the same

ActiveCN101821352AReduced connection reliabilityHigh bonding strengthPrinted circuit assemblingSolid-state devicesChemistrySolid-state

Provided is an adhesive containing (a) a thermoplastic resin, (b) a radical polymerizable compound and (c) a radical polymerization initiator. The radical polymerizable compound is in a solid-state at a temperature of 30 DEG C or below.

Owner:RESONAC CORP

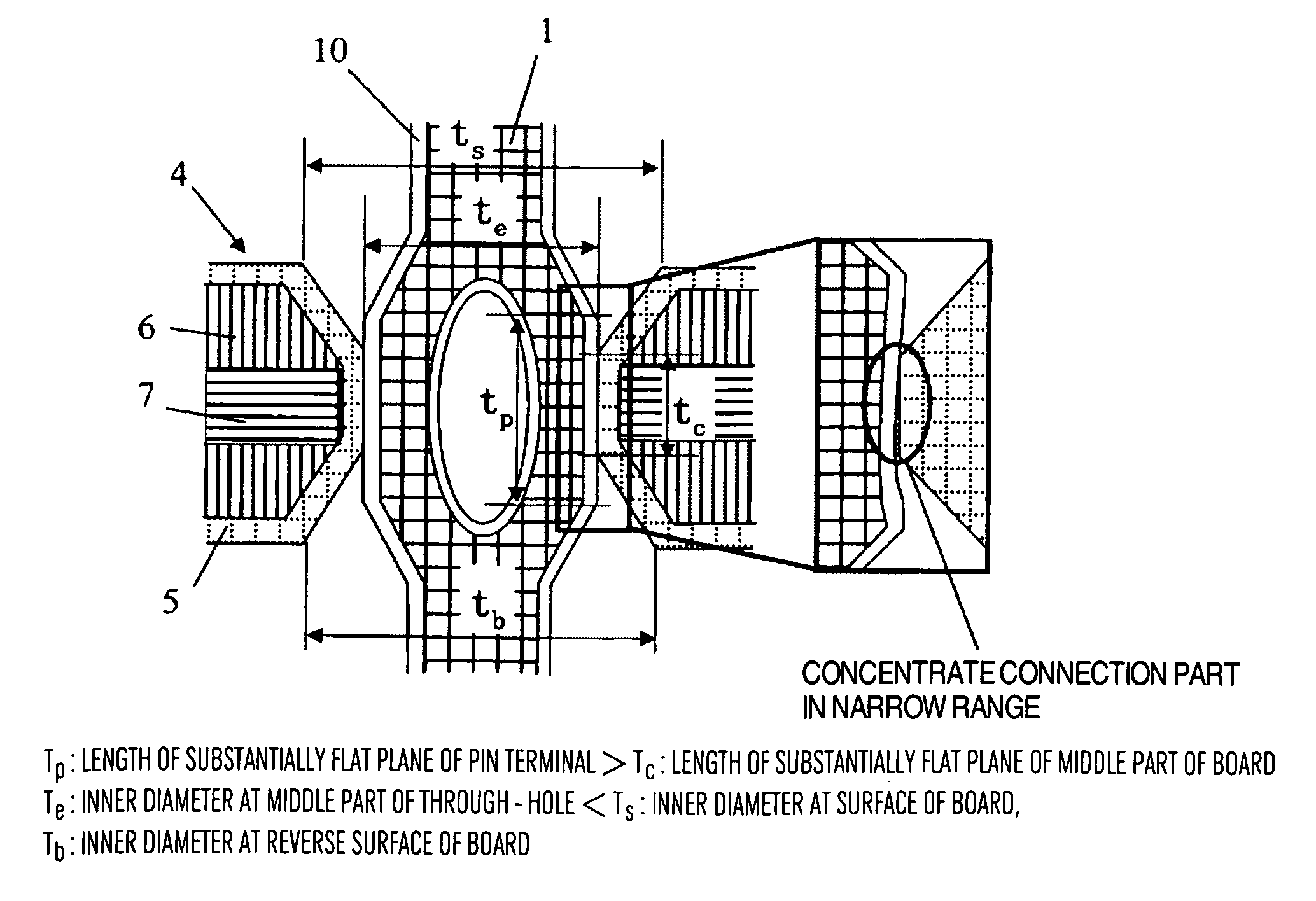

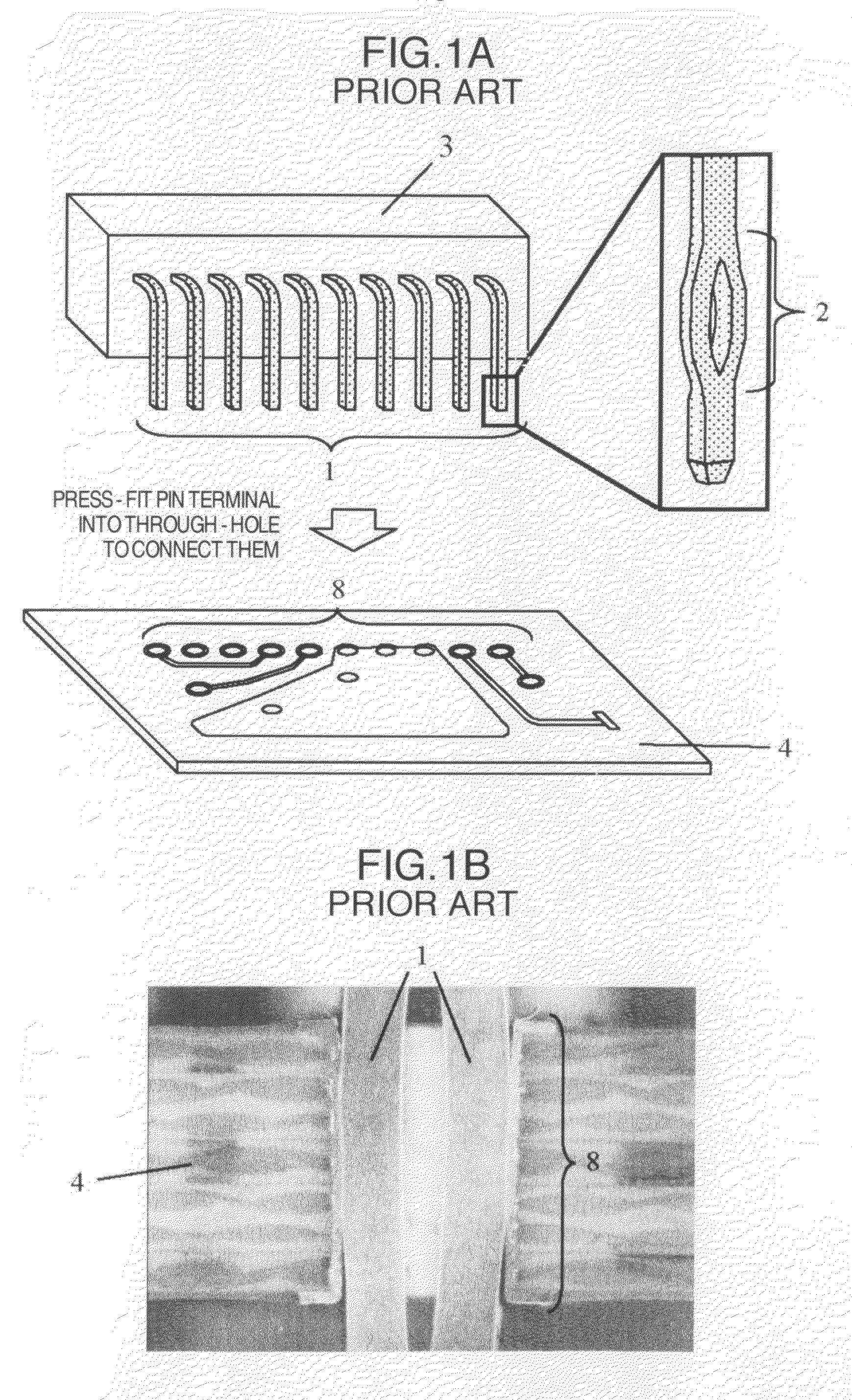

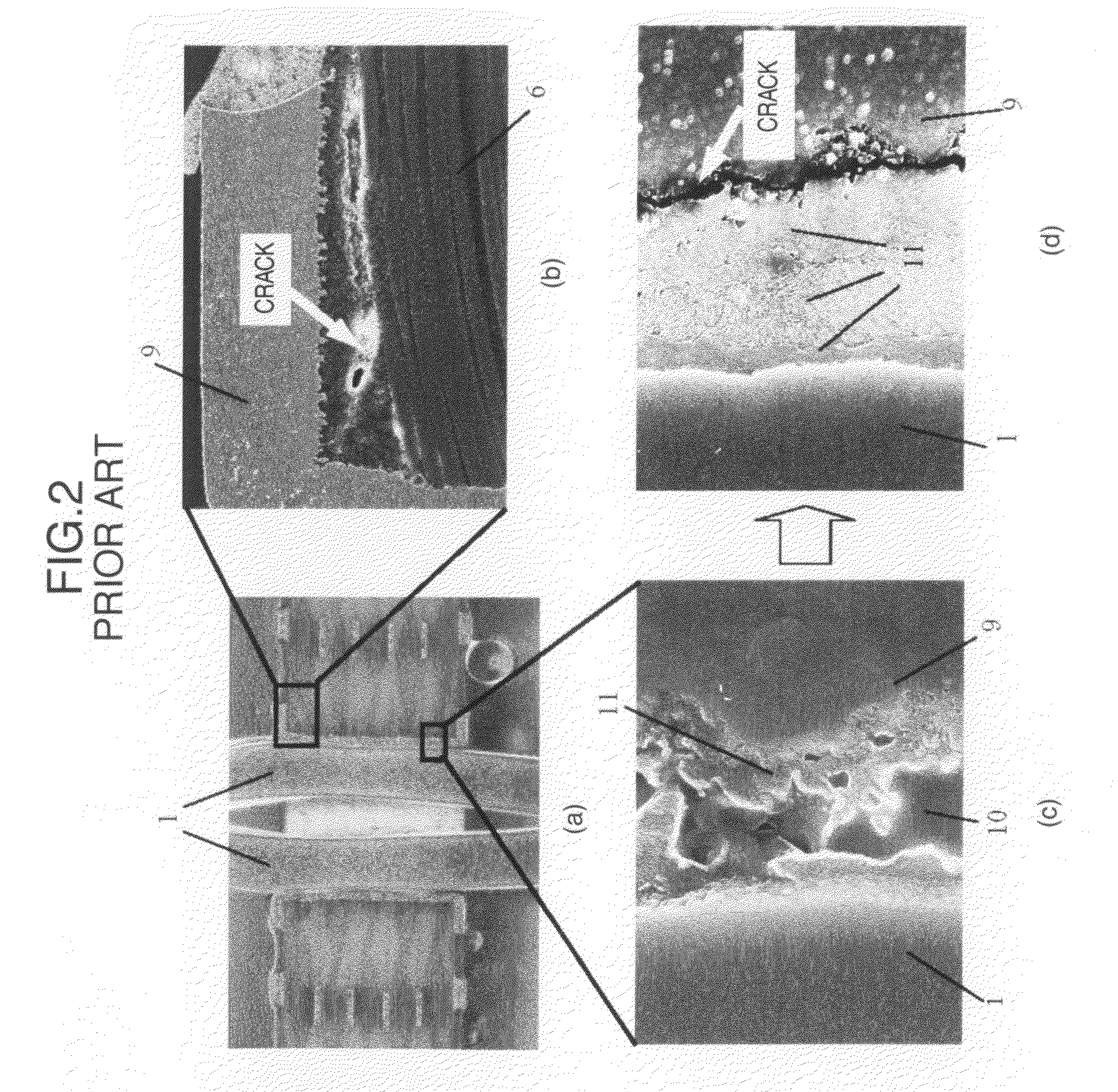

Electronic device and on-vehicle module

InactiveUS20090233468A1Improve reliabilityReduced connection reliabilityPrinted circuit aspectsSecuring/insulating coupling contact membersComputer modulePlane parallel

In a module, press-fit connection using a pin terminal including a connection part separated into two parts and a flat plane parallel to the lengthwise direction in the separation part and perpendicular to the separation direction of the pin terminal is performed. A through-hole of a board is structured so that an inner diameter of the through-hole at a middle part in the thickness direction of the board is smaller than that at obverse and reverse surfaces of the board and the length of the middle part of the through-hole connected to the pin terminal is shorter than the length of the flat plane of the pin terminal.

Owner:HITACHI LTD

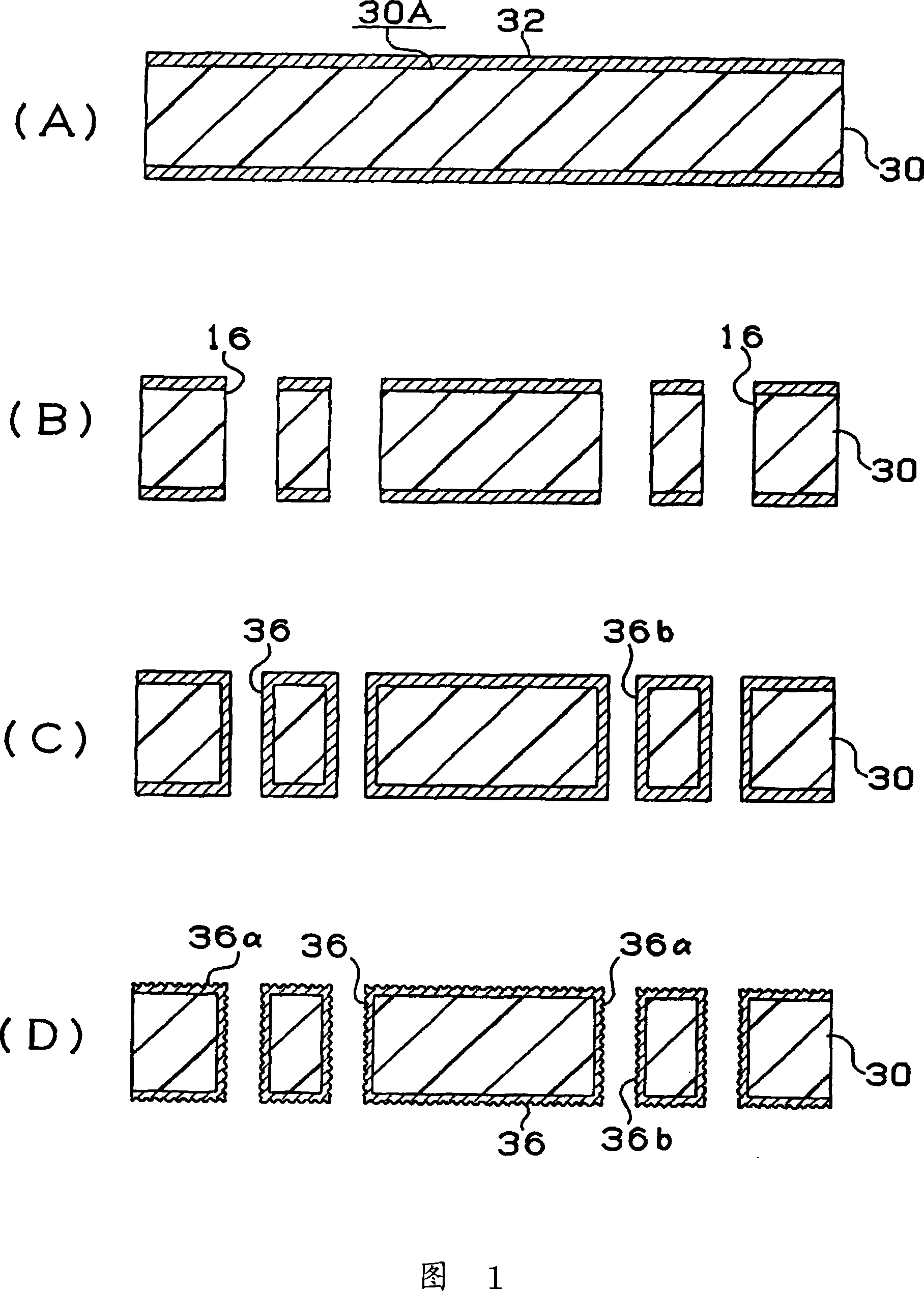

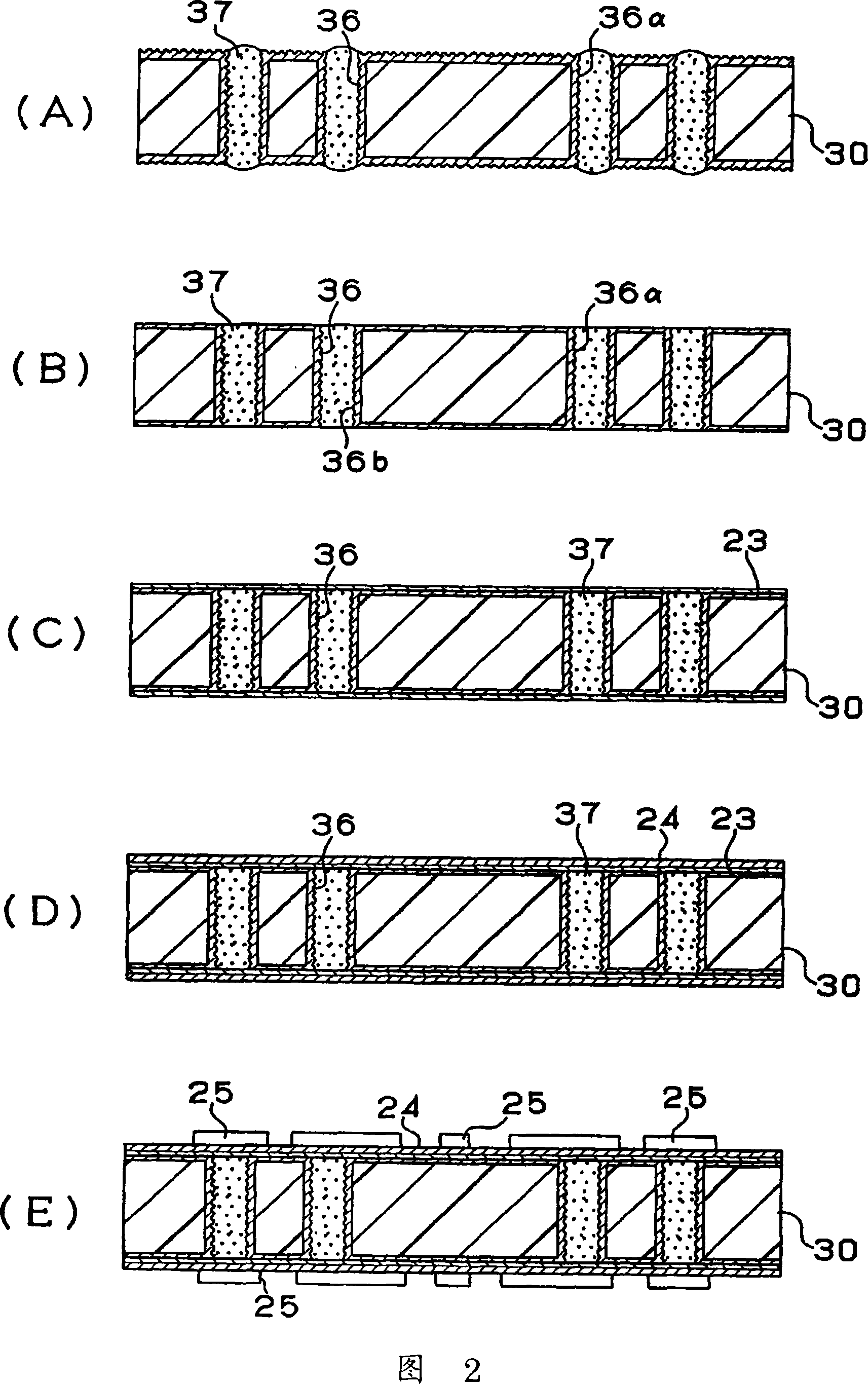

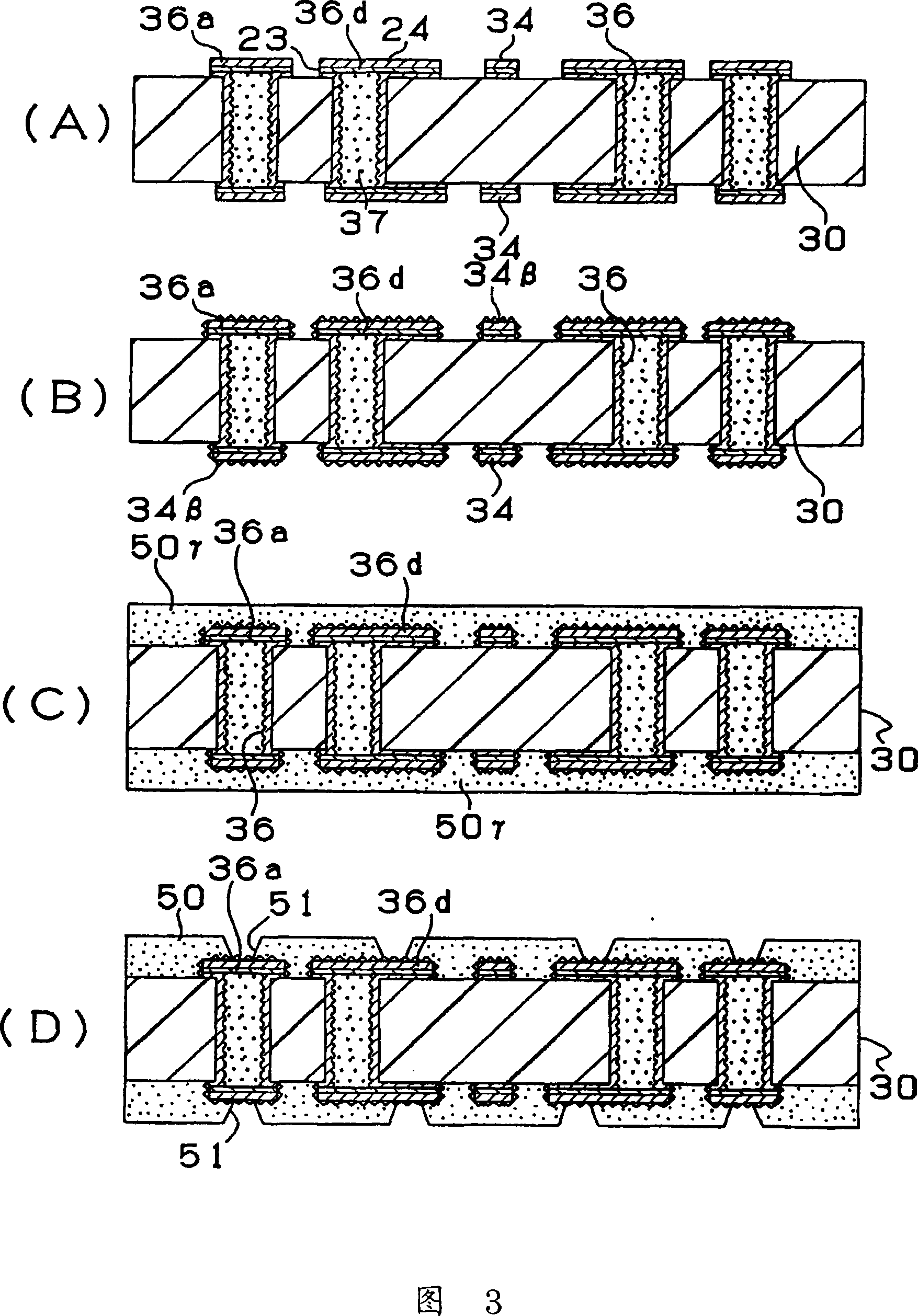

Multi-layer printed wiring board and manufacturing method thereof

InactiveCN101112141ANo loss of connection reliabilityReduced connection reliabilityPrinted circuit aspectsFixed connectionsInsulation layerEngineering

[Problems] To provide a multi-layer printed wiring board without decrease in connection reliability by forming a filled via right above a filled via of a small radius. [Means of Solving the Problems] During a heat cycle, the stress applied to a filled via 60 formed on cover plated layers 36a and 36d is larger than the stress applied to a filled via 160 formed on the second interlayer resin insulation layer 150. Therefore, the bottom diameter d 1 of the filled via 60 is made larger than the bottom diameter d2 of the filled via 160 formed right above the filled via 60.

Owner:IBIDEN CO LTD

Motor cable device and resin component employed thereto

ActiveUS8172601B2Reduced connection reliabilityImprove connection reliabilityAssociation with control/drive circuitsCoupling device detailsElectric machineInverter

The motor cable device which can prevent damage on an inverter-side connecting member of the motor cable device and lowering in a connecting reliability of the inverter-side connecting member is provided. Also, a resin component used in the above-described motor cable device is provided. The motor cable device electrically connects a motor and an inverter and includes an inverter-side protector and a motor-side protector. The inverter-side protector includes a fixed end which is directly or indirectly fixed to the inverter and which supports the inverter-side connecting member. A swinging motion absorbing portion is formed continuously to the fixed end, the swinging motion absorbing portion being arranged to support a cable body at the inverter-side connecting member and absorb the swinging motion generated at the cable body of the motor cable device, is further included.

Owner:YAZAKI CORP

Semiconductor device and method of manufacturing the same

InactiveUS8618667B2Reduce planarityReduced connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialHeat resistance

A bump electrode, a dummy bump, and a heat-resistant polymer film, whose upper-surface heights are uniformed, are formed on each of a first silicon substrate and a second silicon substrate, and then, the first silicon substrate and the second silicon substrate are bonded to each other so that the bump electrodes formed on the respective substrates are electrically connected to each other. At this time, the dummy bump is arranged so as to be bonded to the heat-resistant polymer film on the silicon substrate opposed thereto, so that a semiconductor device having both of good electrical connection between the bump electrodes and bump protection performance obtained by a polymer film with high heat resistance and without voids can be achieved.

Owner:HITACHI LTD

Method for manufacturing a printed circuit board for electronic devices and an electronic device using the same

ActiveUS7604152B2Ensure reliabilityLow reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsSolder pasteMetal

Owner:FUJITSU LTD

Suspension board with circuit

InactiveUS20120193127A1Firmly connectedReduced connection reliabilityElectrical connection between head and armRecord information storageMetalElectrical and Electronics engineering

A suspension board with circuit includes an insulating base layer and a conductive pattern that is laminated on a top surface of the insulating base layer. The conductive pattern includes a wire and a terminal portion that is connected to the wire for being joined by a melted metal. The insulating base layer, in a projected surface when projected in a laminating direction, includes an adjacent region that is adjacent to the terminal portion and a separated region that is separated from the terminal portion so as to sandwich the adjacent region with the terminal portion. The adjacent region is formed to be thinner than the separated region.

Owner:NITTO DENKO CORP

Integrated circuit device

ActiveUS7239002B2Improve connection reliabilityCoefficient is high and stableThermometer detailsSemiconductor/solid-state device detailsSputteringEngineering

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com