Adhesive and connecting structure using the same

A technology for adhesives and connecting terminals, applied in connection, adhesives, conductive connections, etc., can solve problems such as poor bonding strength, achieve excellent bonding strength, excellent operability, and suppress the effect of reducing connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9、 comparative example 1~3

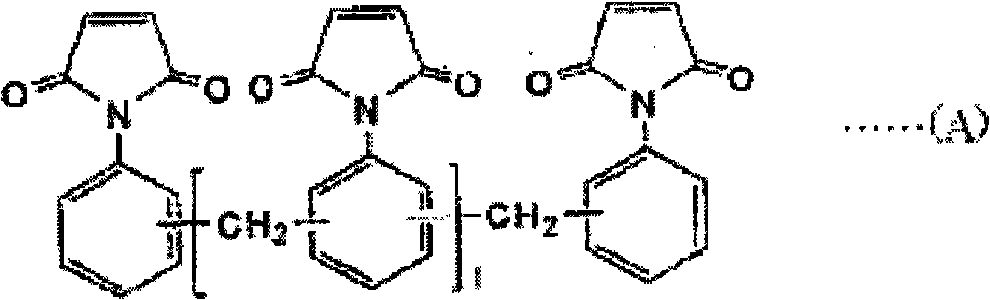

[0129] As the thermoplastic resin, a solution obtained by dissolving the above-mentioned urethane resin in a mixed solvent of methyl ethyl ketone and toluene with a solid content of 30% by weight, and a phenoxy resin (ZX- 1356-2, trade name manufactured by Tohto Kasei Co., Ltd.) or a polyester polyurethane resin (UR-1350, trade name manufactured by Toyobo Co., Ltd.) dissolved in a mixed solvent of methyl ethyl ketone and toluene at a solid content of 40% by weight (UR-1350, trade name manufactured by Toyobo Co., Ltd.) .

[0130] As the radical polymerizable compound, epoxy acrylates (VR-60 and VR-90, trade names manufactured by Showa High Molecular Co., Ltd.) which are solid at 30° C. were used alone, or as a liquid radical polymerizable compound. Isocyanuric acid EO-modified triacrylate (M-215, trade name manufactured by Toagosei Co., Ltd.) and urethane acrylate (UA6100, trade name manufactured by Shin-Nakamura Chemical Co., Ltd.) were used together.

[0131] As the acidic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com