Electronic equipment and method of manufacturing the electronic equipment

一种电子设备、连接设备的技术,应用在接触件盒/底座的制造、电路、电气元件等方向,能够解决连接可靠性下降、应力残留等问题,达到防止连接可靠性降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

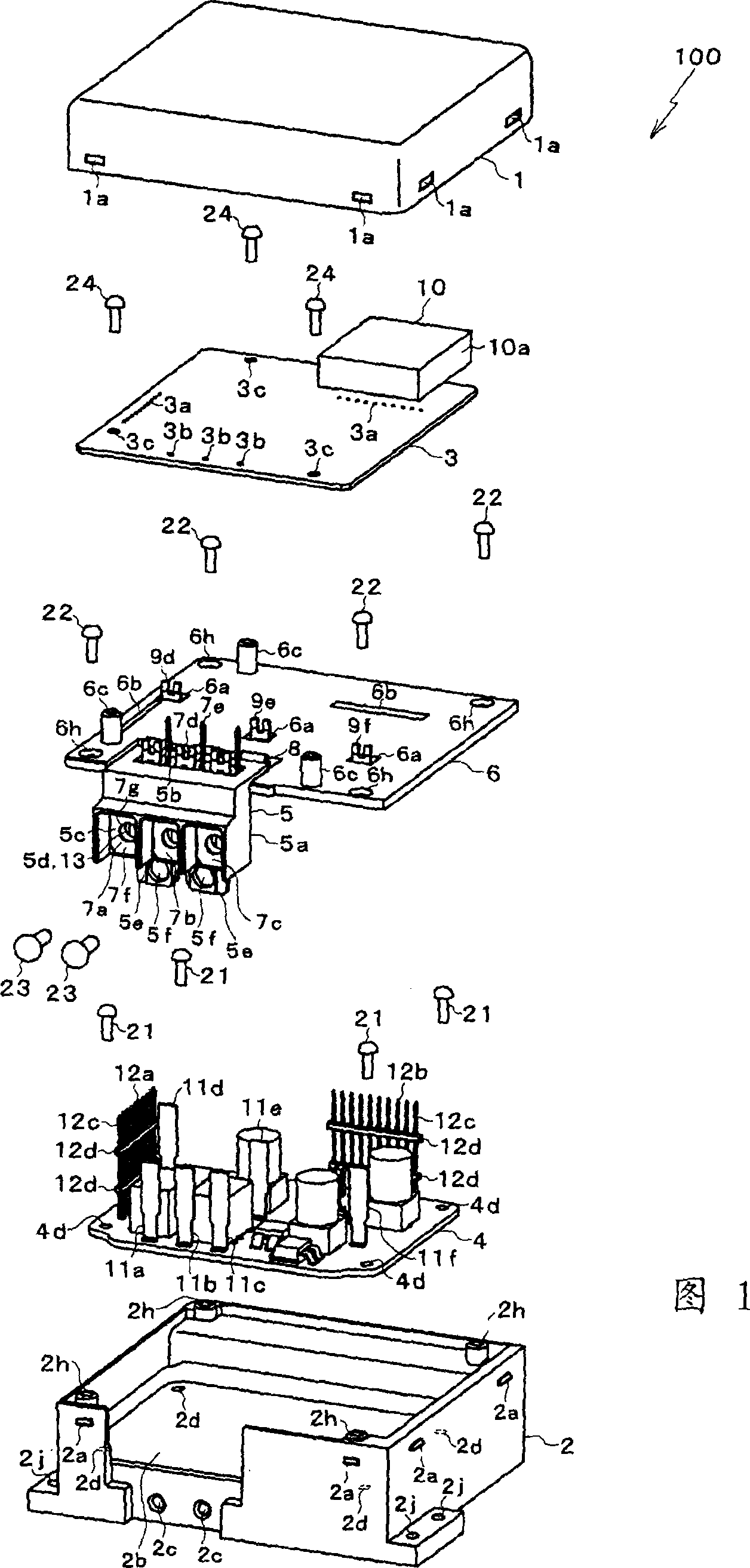

[0053] FIG. 1 is an exploded view of an electronic device 100 according to an embodiment of the present invention. The electronic device 100 is an electronic control device (also referred to as ECU: Electronic Control Unit) of an electric power steering device mounted on an automobile. The electric power steering system is composed of the electronic device 100 and a three-phase motor 90 (shown in FIG. 12 ) that generates a steering assist torque corresponding to the operation of a handle with respect to a steering shaft of an automobile (not shown). The electronic device 100 is mechanically and electrically connected to the motor 90 and controls the driving of the motor 90 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com