Producing method of suspension board with circuit

一种制造方法、悬挂基板的技术,应用在印刷电路制造、金属芯电路制造、印刷电路等方向,能够解决连接可靠性降低、花费劳力和时间、蚀刻时间长等问题,达到防止过蚀刻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

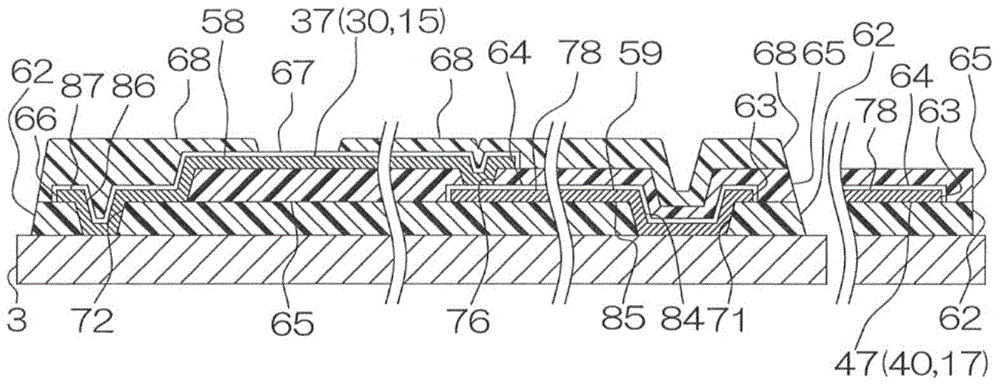

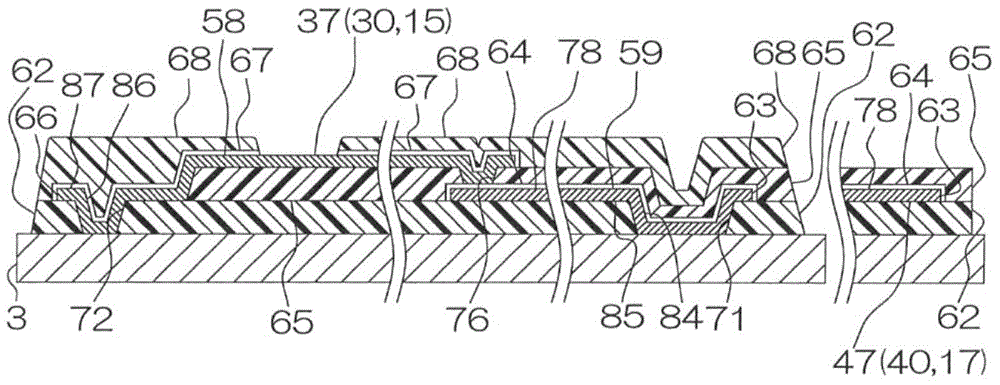

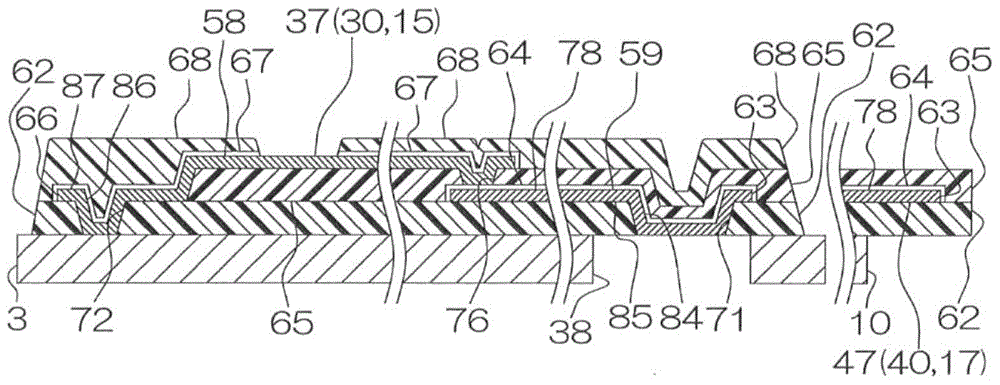

[0057] Structure of this embodiment

[0058] in figure 1 In this case, the upper side of the paper is the front side (one side in the first direction), the lower side of the paper is the back side (the other side in the first direction), and the left side of the paper is the left side (in the first direction). The side in the second direction perpendicular to the width direction), the right side of the paper is the right side (the other side in the second direction, the other side in the width direction), and the paper thickness of the paper The direction near the front side is the upper side (the side in the third direction orthogonal to the first and second directions, that is, the side in the thickness direction), and the deep side of the paper in the paper thickness direction is the lower side (the third direction , The other side in the thickness direction). figure 2 The directions of the subsequent figures are figure 1 The direction of the reference.

[0059] in Figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com