Pumping unit for delivery of liquid medium from a vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

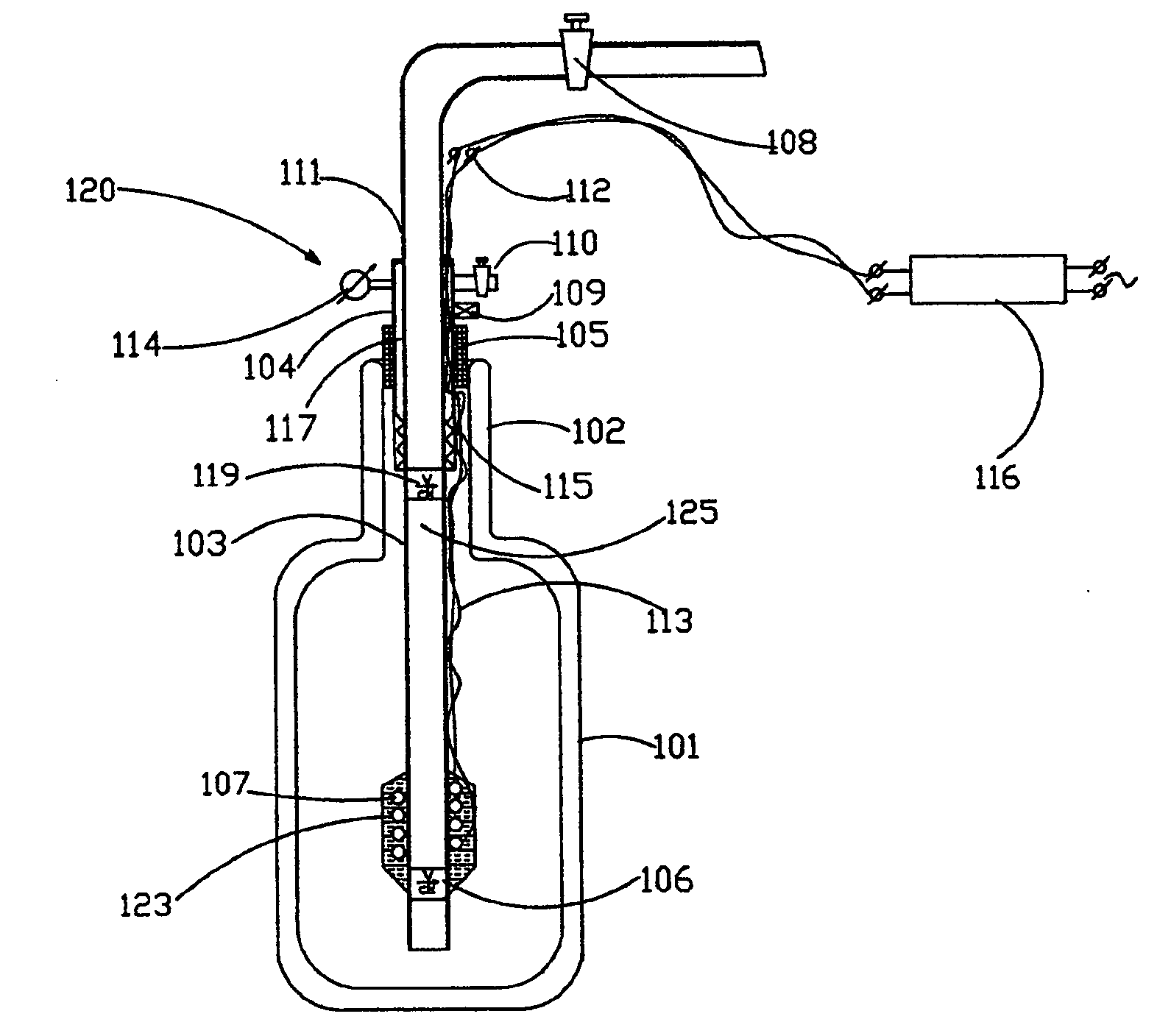

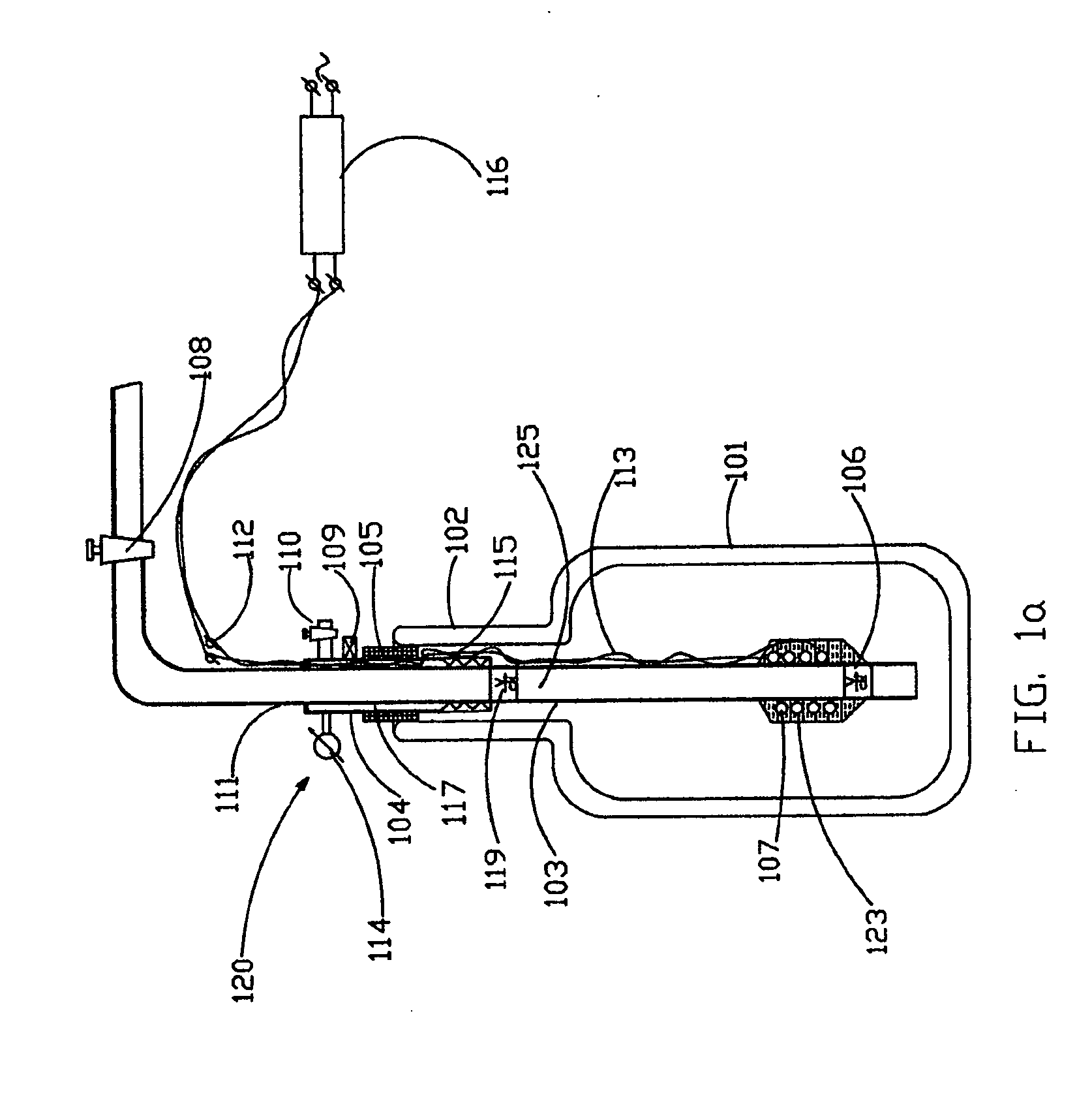

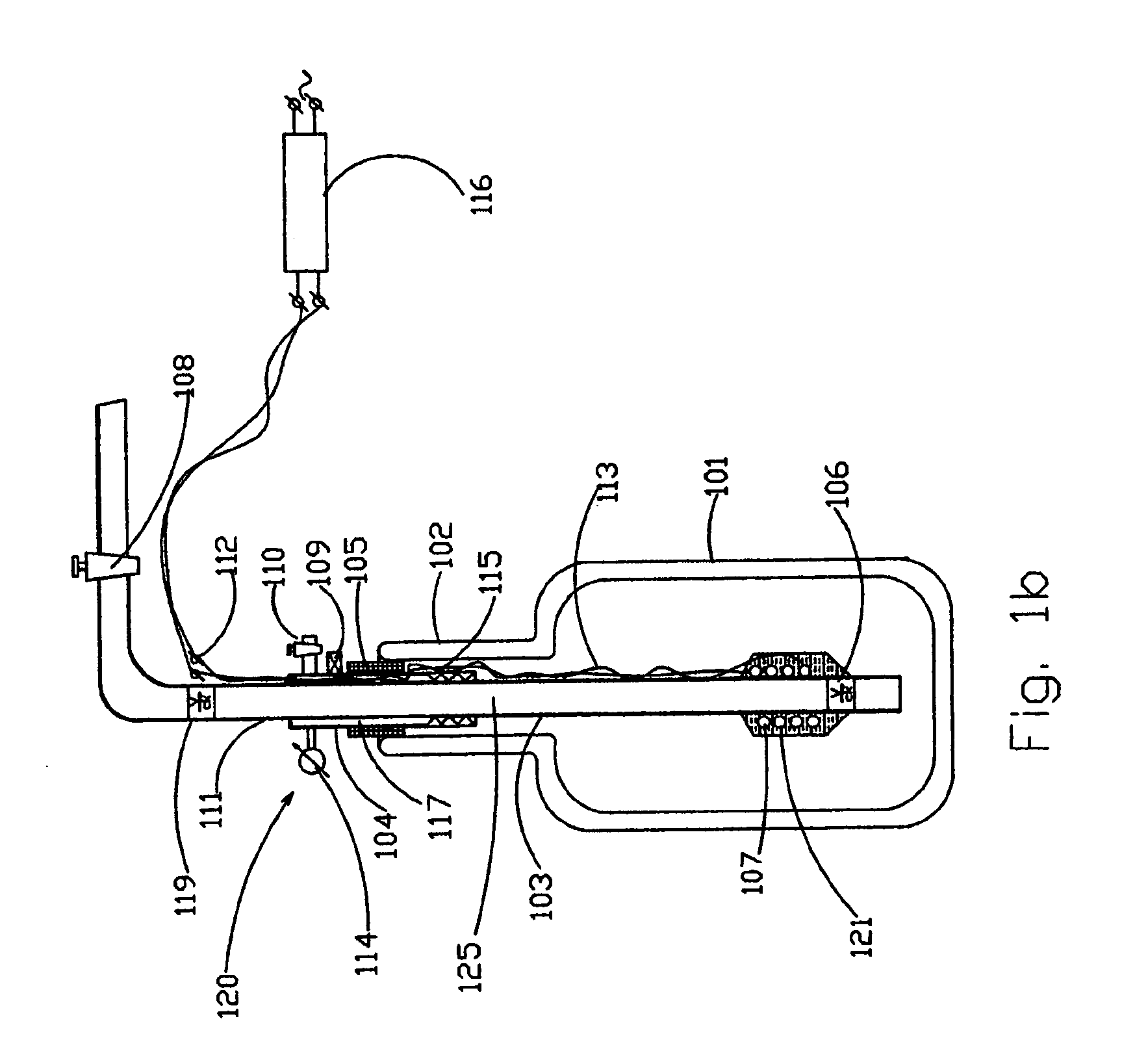

[0050]FIG. 1a shows a Dewar flask 101 with neck 102, which is intended to be filled with a liquid cryogen to be supplied by the pumping unit 120. Pumping unit 120 comprises a central feeding conduit 103 for supplying the liquid cryogen to an external location, and jacket 104 surrounding the central feeding conduit 103 with gap 117 formed between them. The central feeding conduit 103 comprises an external section 111. The upper edge of jacket 104 is sealed with the central feeding conduit 103 as shown. An annular rubber ring 105 is installed on jacket 104 and inserted partially into neck 102, for holding pumping unit 120 in Dewar flask 101 and for sealing jacket 104 to the Dewar flask 101. Also, preferably a shut-off valve 108 is installed on the external section 111 of the central feeding conduit 103. The shut-off valve 108 ensures control of the supply of the liquid cryogen.

[0051]In a preferred embodiment, preferably safety and relief valves 109 and 110 are installed on ports of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com