Water-oil integrated water tank

A water tank and integrated technology, applied in the direction of fluid heaters, heat storage heaters, lighting and heating equipment, etc., can solve the problems of affecting the efficiency of heating devices, easily causing scale, uneven heating of water, etc., and achieve compact structure and good silent heating Effect, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

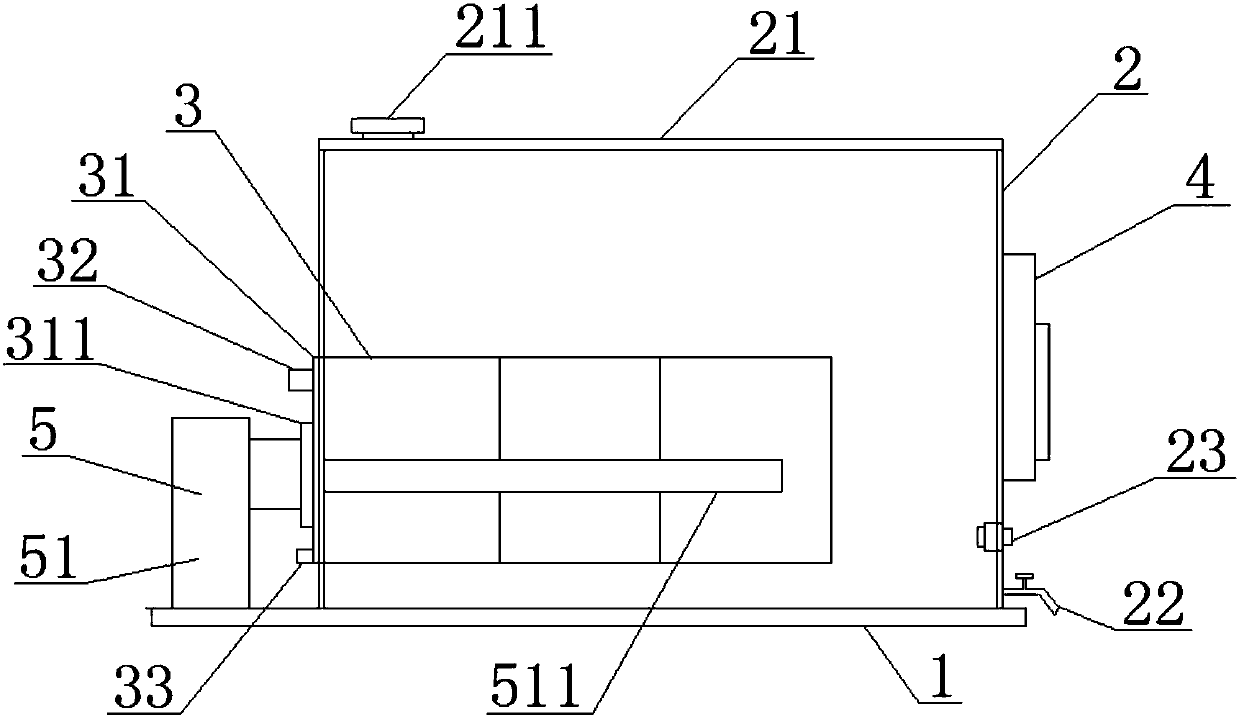

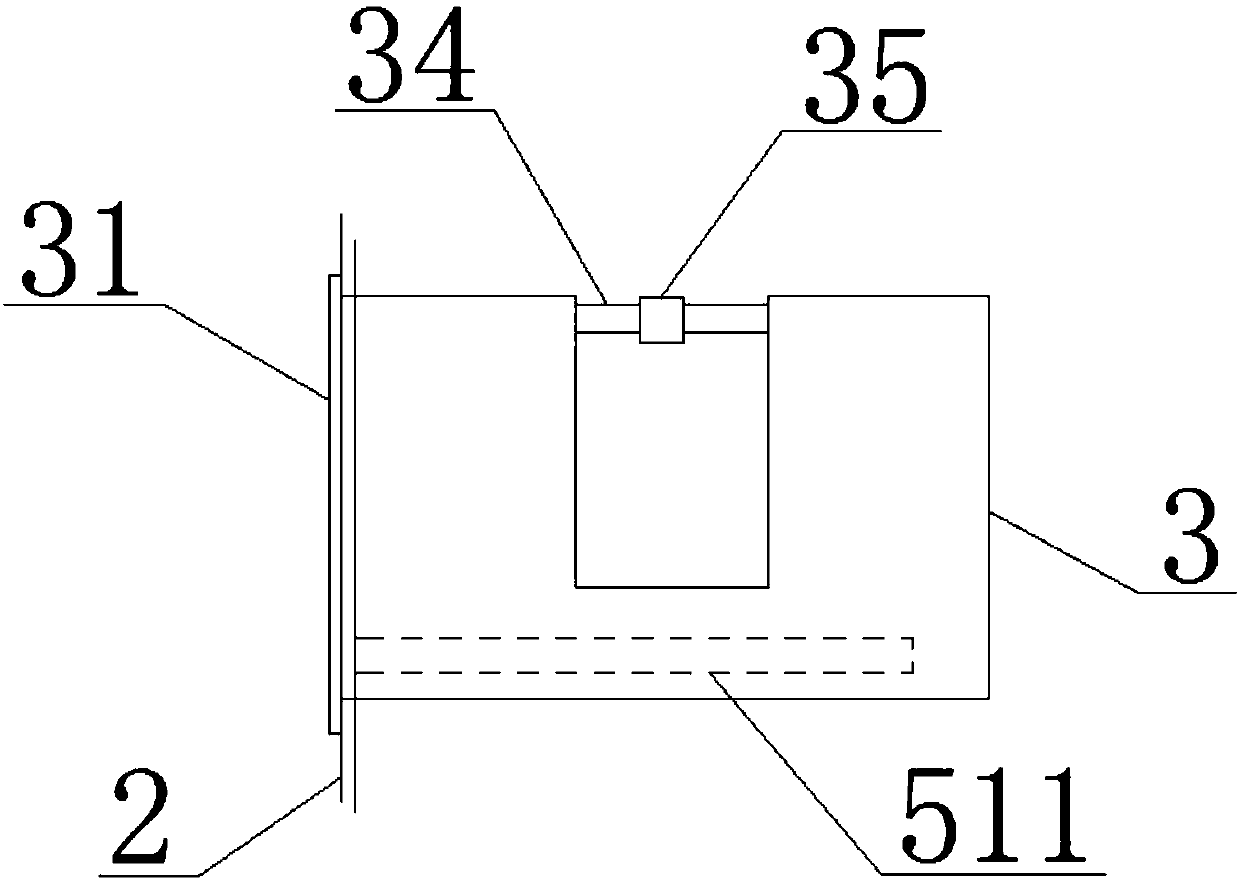

[0015] Figure 1~2 As shown, the water and oil integrated water tank includes a base 1, a water tank 2, a heating oil tank 3, a control box 4 and an electric heating device 5, the water tank 2 is fixedly installed on the base 1, and a tank cover 21 is installed on the top of the water tank 2 , the tank cover 21 can be removed, which is convenient for maintenance personnel to clean and maintain each part of the water tank 2 in time. The tank cover 21 is provided with a water inlet cover 211, and the lower outside of the water tank 2 is provided with a water outlet valve 22 The user can directly obtain heated hot water through the water outlet valve 22. The side of the heating oil tank 3 is provided with a box connecting plate 31, and the box connecting plate 31 is fixedly connected to the side of the water tank 2. The heating oil tank 3 is fixedly installed inside the water tank 2 through the tank connecting plate 31 on its side, and the tank connecting plate 31 is joined toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com