An internal boiling activated carbon treatment process

A technology of activated carbon and treatment methods, which is applied in the petroleum industry, other chemical processes, separation methods, etc., and can solve problems affecting the quality of activated carbon and incomplete recovery of activated carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

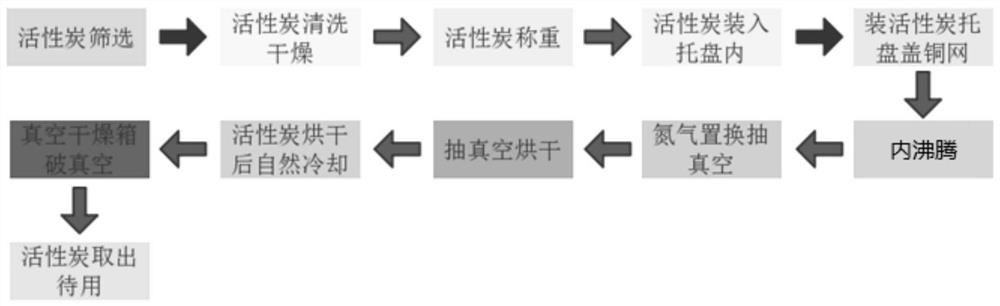

Method used

Image

Examples

Embodiment 1

[0040] Step 1. First, use a 3-mesh sieve to sieve 4.75mm×2.36mm of activated carbon to remove large particles of activated carbon, and then use a 10-14 mesh sieve to sieve 4.75mm×2.36mm of activated carbon to remove small particles activated carbon;

[0041] Step 2. After the activated carbon screening is completed, put it in a 10-14 mesh sieve and rinse it with an alcohol-water mixture (70% alcohol concentration) in a cleaning tank to remove the dust attached to the surface of the activated carbon. Then, the activated carbon and the ethanol aqueous solution were placed in a decompression box, and the pressure was quickly reduced to a slight boiling of the solution, and then the pressure was rapidly increased to atmospheric pressure, repeated 5 times, to make the solution immersed in the internal voids of the activated carbon. The cleaning process should be gentle to prevent the activated carbon from breaking. The activated carbon contained in a single sieve shall not exceed ...

Embodiment 2

[0046] Step 1. First, use a 3-mesh sieve to sieve 4.75mm×2.36mm of activated carbon to remove large particles of activated carbon, and then use a 10-14 mesh sieve to sieve 4.75mm×2.36mm of activated carbon to remove small particles activated carbon;

[0047] Step 2. After the activated carbon screening is completed, put it in a 10-14 mesh sieve and rinse with alcohol-water mixture (alcohol concentration of 75%) in a cleaning tank to remove the dust attached to the surface of the activated carbon. Then, the activated carbon and the ethanol aqueous solution were placed in a decompression box, and the pressure was rapidly reduced until the solution boiled slightly, and then the pressure was rapidly increased to atmospheric pressure, repeated 5 times, so that the solution was immersed in the internal voids of the activated carbon. The cleaning process should be gentle to prevent the activated carbon from breaking. The activated carbon contained in a single sieve shall not exceed ...

Embodiment 3

[0052] Step 1. First, use a 3-mesh sieve to sieve 4.75mm×2.36mm of activated carbon to remove large particles of activated carbon, and then use a 10-14 mesh sieve to sieve 4.75mm×2.36mm of activated carbon to remove small particles activated carbon;

[0053] Step 2. After the activated carbon screening is completed, put it in a 10-14 mesh sieve and rinse with alcohol-water mixture (alcohol concentration of 78%) in a cleaning tank to remove the dust attached to the surface of the activated carbon. Then, the activated carbon and the ethanol aqueous solution were placed in a decompression box, and the pressure was rapidly reduced until the solution boiled slightly, and then the pressure was rapidly increased to atmospheric pressure, repeated 5 times, so that the solution was immersed in the internal voids of the activated carbon. The cleaning process should be gentle to prevent the activated carbon from breaking. The activated carbon contained in a single sieve shall not exceed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com