Heat pipe type heat energy recovery device

A heat energy recovery, heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as easy blockage of heat exchange plates, inability to put into production applications, and failure to achieve expected results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

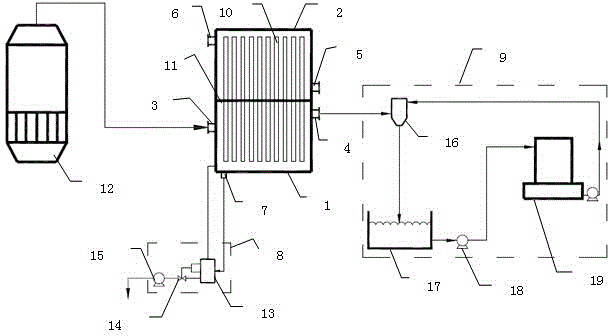

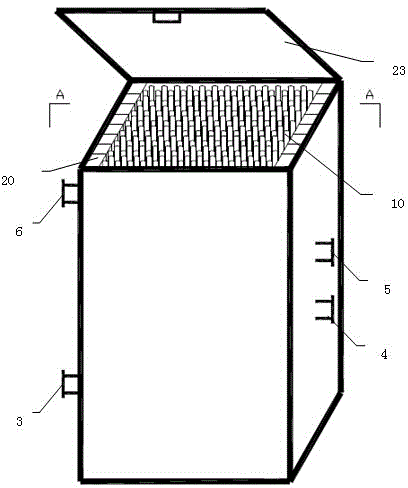

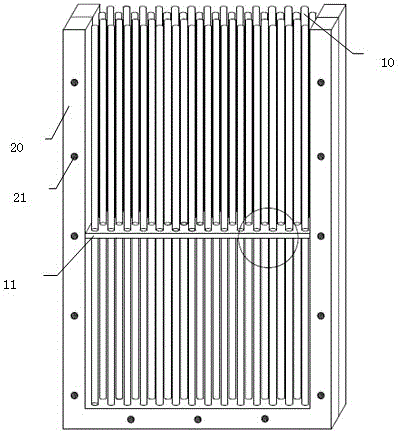

[0022] to combine Figures 1 to 3 , a heat pipe type heat energy recovery device, including a condensation box, a group of heat pipe assemblies 20 are vertically sleeved in the condensation box, and each heat pipe assembly 20 includes a U-shaped outer frame, and a partition arranged transversely on the inner wall of the outer frame 11 and the gravity heat pipe 10 vertically passing through the partition 11, the lower space of the partition 11 is the steam chamber 1, the upper space of the partition 11 is the condensation chamber 2, and the side wall of the steam chamber 1 has a lower inlet 3 , the lower outlet 4 and the drain 7, the side wall of the condensation chamber 2 has an upper inlet 5 and an upper outlet 6; the lower inlet 3 is connected to the final effect evaporation tank 12, and the lower outlet 4 is connected to the cooling system 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com