Boiler device for preparing steam

A boiler equipment and steam technology, which is applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of low steam generation efficiency, slow steam circulation speed, single boiler structure, etc., achieve simple structure, reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

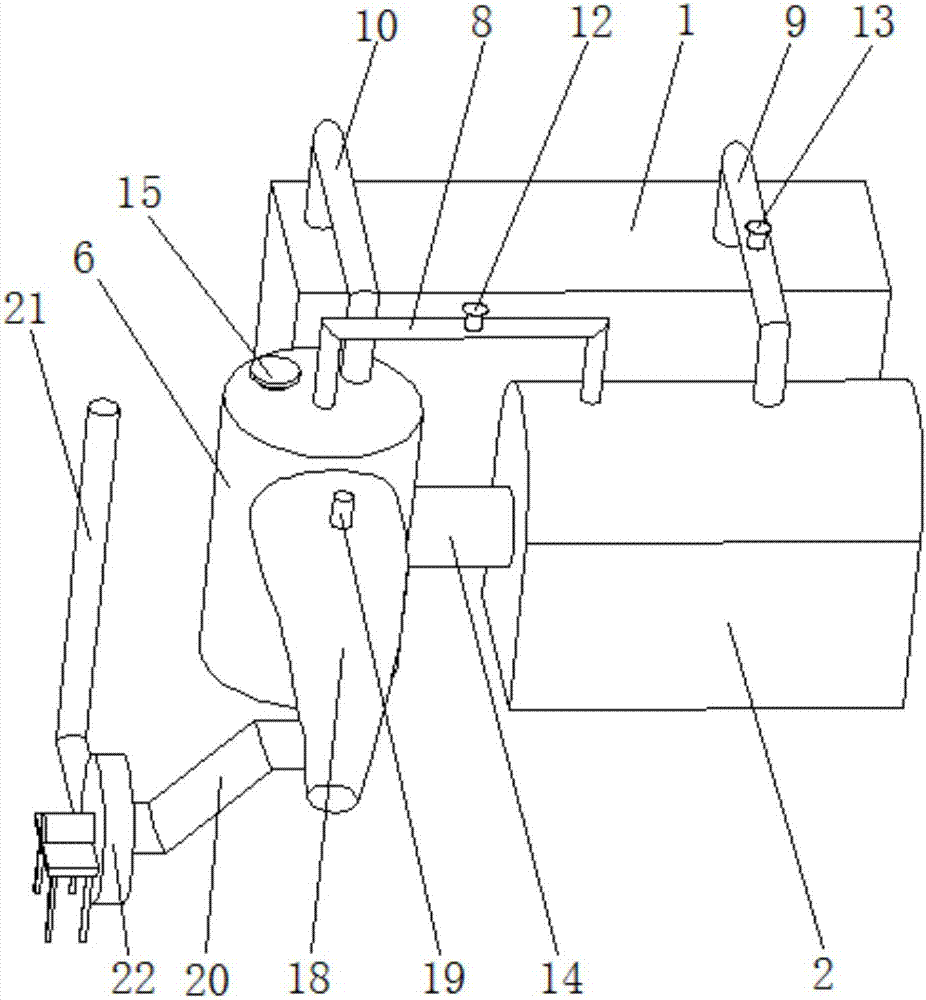

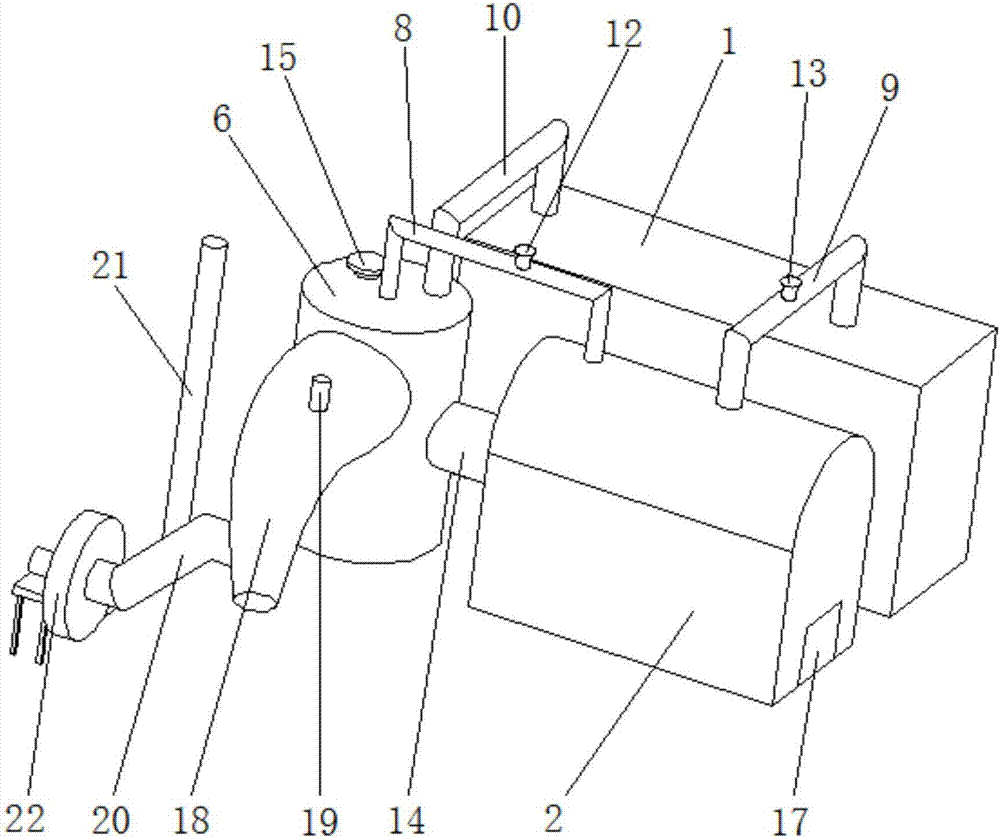

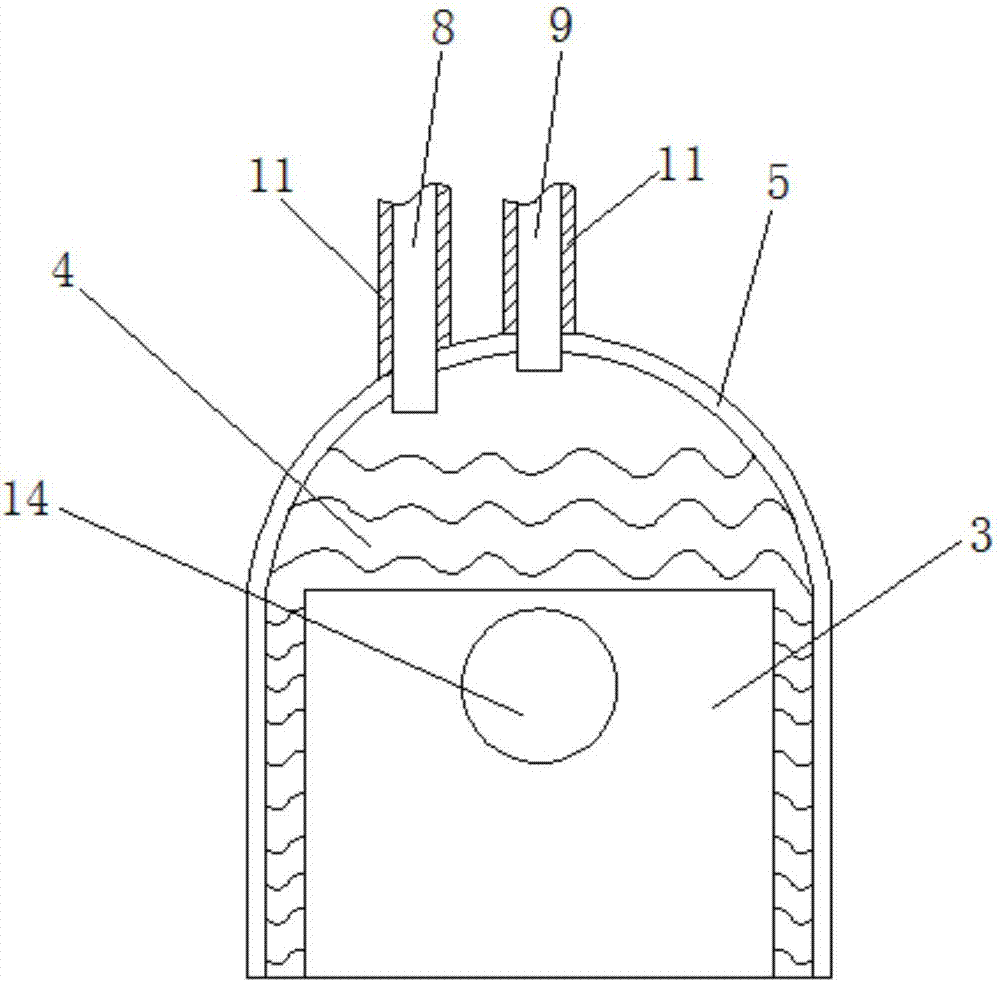

[0023] The present invention will be further described below with reference to the specific embodiments in the accompanying drawings.

[0024] see Figure 1-4 , a boiler equipment for producing steam according to the present invention, including a furnace body 2 located on one side of the drying room 1, which is used to burn firewood to generate steam, and the furnace body 2 is as close as possible to the drying room 1 to avoid heat loss of steam , a combustion chamber 3 for accommodating firewood is provided in the furnace body 2, and a boiling water pool 4 that completely covers the combustion chamber 3 is provided in the furnace body 2 above the combustion chamber 3, and the boiling water pool 4 holds hot water to make the heat The water is in full contact with the outer surface of the combustion chamber 3, and an interlayer 5 covering the boiling water pool 4 is provided between the boiling water pool 4 and the shell of the body of heater 2, that is, the interlayer 5 wraps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com