Purifying system and process for 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane

A technology of tert-butyl peroxide and dimethyl peroxide, applied in 2 fields, can solve the problems of long distillation time, unrealizable operation, and high cost of introducing nitrogen, and achieve the effect of shortening the distillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

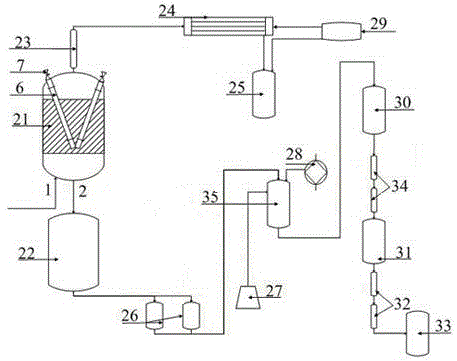

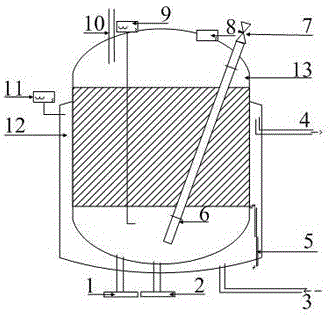

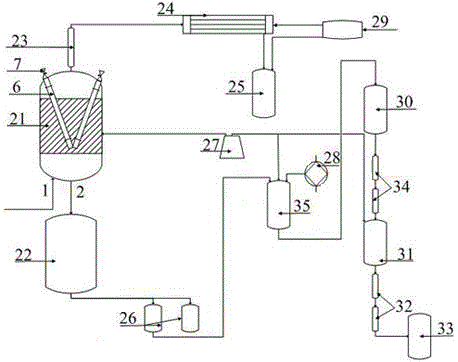

[0050] Such as figure 1 , figure 2 As shown, a purification system of 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane includes still 21 and decolorizing still 22; 22 connection; distillation still 21 comprises housing 13, is provided with air inlet pipe 6 in housing 13, and the bottom distance of one end of air inlet pipe 6 and housing 13 is 10mm, the other end of air inlet pipe 6 and housing 13 Top wall connection.

[0051] The top of the decolorizing kettle 22 is provided with an activated carbon feeding device.

[0052] An air pipe 10 communicating with the inside of the housing 13 is installed on the top wall of the housing 13 .

[0053] The other end of the air inlet pipe 6 is provided with a needle valve 7 .

[0054] The number of 6 air inlet pipes is 2, and they are evenly and symmetrically distributed in the housing 13 with the central axis of the still 21 as the axis.

[0055] The outlet at the bottom of the decolorizing kettle 22 is connected with a suction fil...

Embodiment 2

[0070] In this embodiment, on the basis of Embodiment 1, the distance between one end of the air inlet pipe 6 and the bottom of the housing 13 is set to 100 mm, and the number of 6 air inlet pipes is 3. Other technical features are the same as those in Embodiment 1. The features are the same and will not be repeated here.

[0071] The purified 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane obtained in this example has a purity of 98.1%, a distillation time of 8 hours, and a material consumption of 0.9%.

Embodiment 3

[0073] In this embodiment, on the basis of Embodiment 1, the distance between one end of the air inlet pipe 6 and the bottom of the housing 13 is set to 200 mm, and the number of 6 air inlet pipes is 4. Other technical features are the same as those in Embodiment 1. The features are the same and will not be repeated here.

[0074] The purified 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane obtained in this example has a purity of 98%, a distillation time of 7.5 hours, and a material consumption of 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com