Method for preparing metal-PDMS (Polydimethylsiloxane) composite material

A composite material and metal technology, which is applied in the field of preparing metal-PDMS composite materials, can solve problems such as the difficulty of introducing biomolecules and limit the application of PDMS, and achieve the effects of low cost, high integration and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of platinum-PDMS sheet composite material

[0034] (1) Preparation of PDMS sheet: Inject commercialized PDMS raw materials into a sheet profile mold, and cure for a certain period of time according to the product instructions to obtain the desired sheet. (For example: WACKER company, RT 601 product, raw materials include A and B two components. According to the instructions, the two components A and B are uniformly mixed in a volume ratio of 9:1, then injected into the sheet profile mold, and cured at 70°C for 20 minutes to obtain a PDMS sheet. )

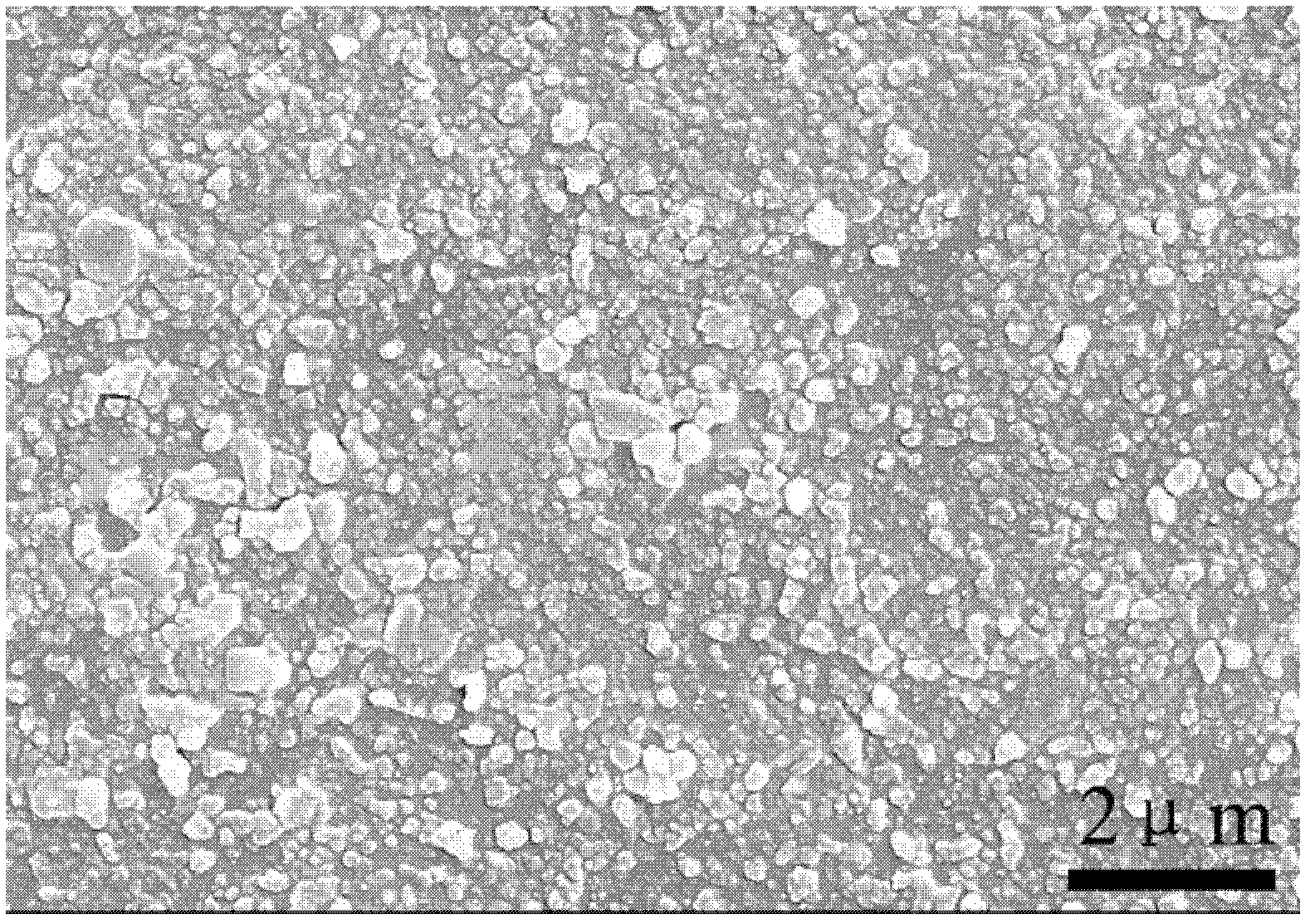

[0035] (2) Prepare a chloroplatinic acid solution with a concentration of 5mmol / L, soak the PDMS sheet in the chloroplatinic acid solution for 60 minutes, and use the silane compound additive in PDMS as a reducing agent to reduce the platinum in the chloroplatinic acid solution Ion, generate nano-platinum particles on the surface of the PDMS sheet, then take out the PDMS sheet and rinse it with deionized ...

Embodiment 2

[0039] Example 2: Preparation of gold-PDMS sheet composite material

[0040] (1) Prepare a PDMS sheet according to the method of Example 1.

[0041] (2) Prepare a chloroauric acid aqueous solution with a concentration of 10mmol / L, soak the PDMS sheet in the chloroauric acid solution for 30 minutes, and use the silane compound additive in PDMS as a reducing agent to reduce the gold in the chloroauric acid solution Ion, generate nano-gold particles on the surface of the PDMS sheet, then take out the PDMS sheet and rinse it with deionized water.

[0042] (3) Prepare amplification solution: take 7.5ml deionized water, add 1mL, 2% (g / 100ml) sodium citrate aqueous solution, 30μL, 50mmol / L chloroauric acid aqueous solution, 10μL, 0.1mol / L ascorbic acid aqueous solution to it .

[0043] (4) Immerse the PDMS sheet with gold nanoparticles on the surface into the amplification solution, and after reacting at room temperature for 10 minutes, take out the PDMS sheet and rinse with deionized water...

Embodiment 3

[0044] Example 3: Preparation of patterned silver-PDMS composite material

[0045] (1) Prepare a PDMS chip with patterned channels.

[0046] (2) Configure a silver nitrate aqueous solution with a concentration of 10 mmol / L, fill the channel of the PDMS chip with the solution through a syringe pump, react for 1 hour, and then use a syringe pump to inject deionized water into the channel to remove the silver nitrate aqueous solution in the channel.

[0047] (3) Prepare amplification solution: take 7.5ml deionized water, add 2ml, 2% (g / 100ml) trisodium citrate aqueous solution, 30μL, 50mmol / L silver nitrate aqueous solution, 10μL, 0.1mol / L ascorbic acid aqueous solution to it .

[0048] (4) Use a syringe pump to inject the amplification solution into the PDMS chip channel to amplify the nano-silver particles formed in the channel. After 30 minutes of reaction, inject deionized water into the channel to rinse the channel, and the channel area contains the silver film layer. The silver-PD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com