Integrated light-emitting diode array chip and production method thereof

An integrated technology of light-emitting diodes, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of power loss, chip loss, uneven brightness, etc., achieve less heat generation, save packaging costs, current good extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

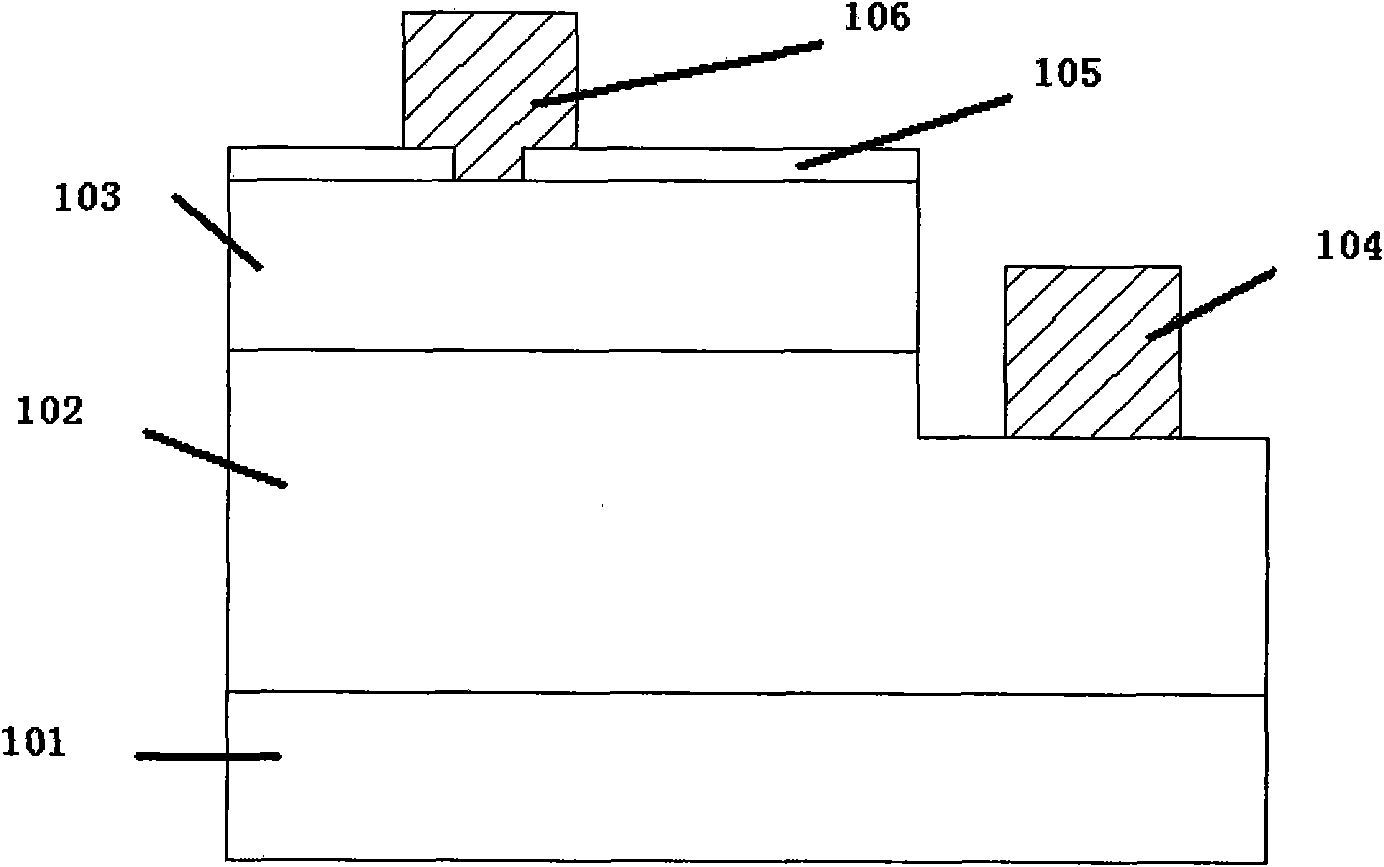

[0037] The manufacturing method of the integrated light emitting diode array chip comprises the following steps:

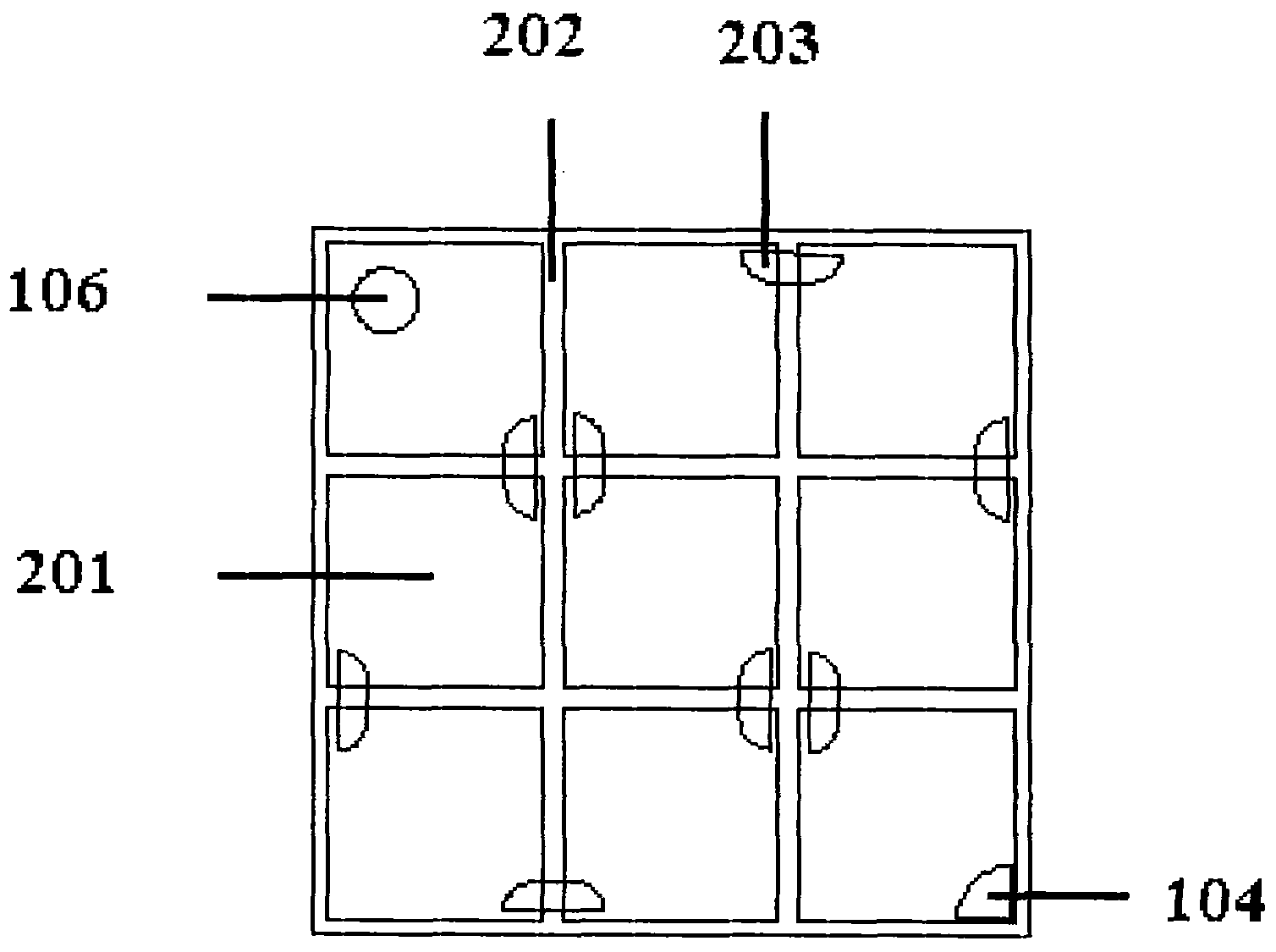

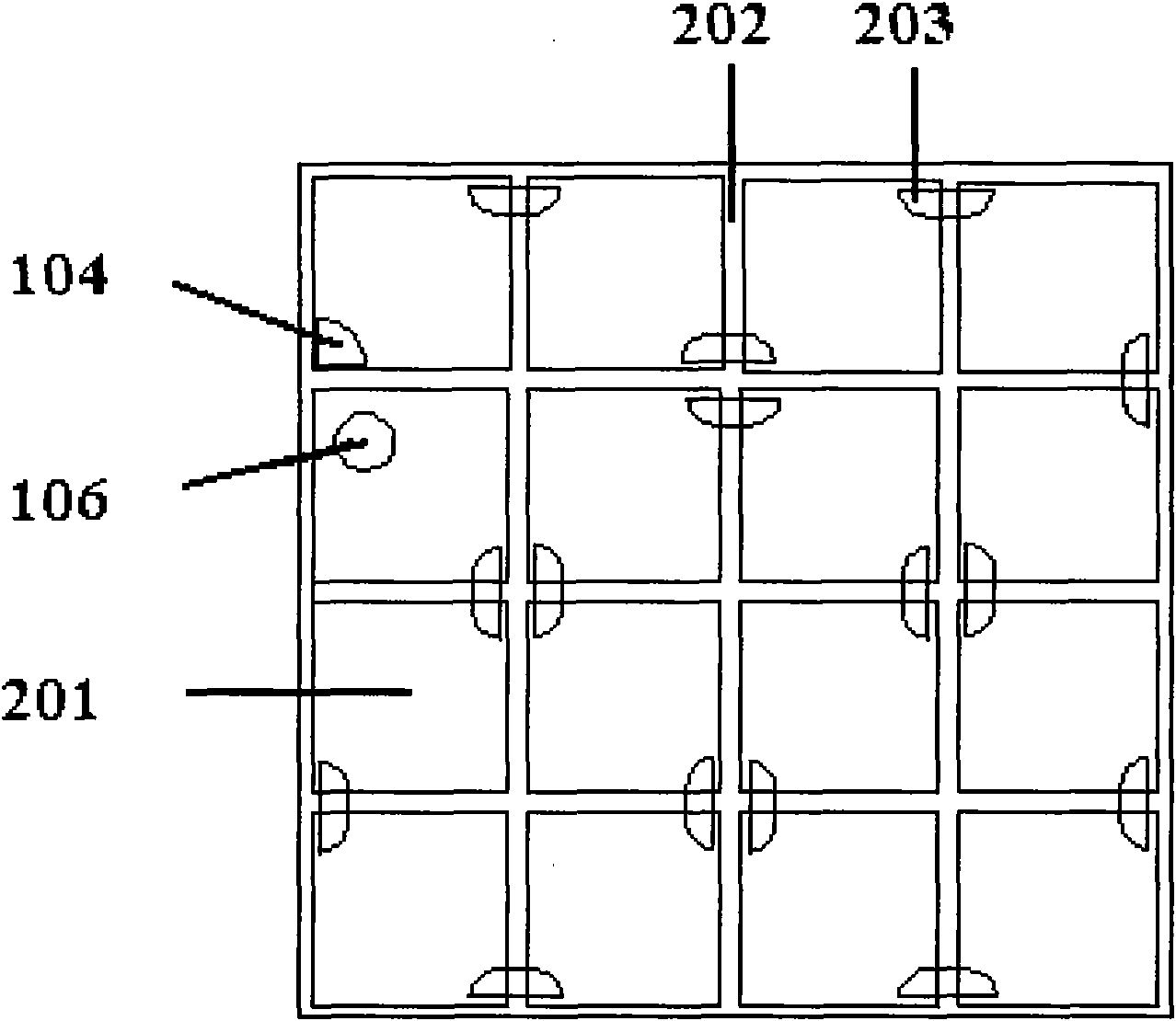

[0038] 1. Evaporate the ITO current spreading layer 105 on the P-type GaN epitaxial layer of the GaN epitaxial wafer by electron beam evaporation, the evaporation environment temperature is 230-250°C, and the thickness is between Then anneal in a suitable environment, the temperature is 250-700 ° C, and the time is 10-60 minutes to form a transparent P-type ohmic contact layer, and then follow the reference figure 2 The designed pattern uses photoresist as a mask, retains the part of the pre-designed transparent electrode layer, uses the method of chemical wet etching, uses ITO etching solution: FeCl3+HCl, soaks at 40 ° C for 5 minutes, and removes the remaining part. ITO current spreading layer.

[0039] 2. Using ICP dry etching, the grown epitaxial wafer is etched according to the pre-designed pattern, and every two light-emitting structures are an integrated...

Embodiment 2

[0046] The manufacturing method of the integrated light emitting diode array chip comprises the following steps:

[0047] 1. Evaporate the ITO current spreading layer 105 on the P-type GaN epitaxial layer of the GaN epitaxial wafer by electron beam evaporation, the evaporation environment temperature is 230-250°C, and the thickness is between Then anneal in a suitable environment, the temperature is 250-700 ° C, and the time is 10-60 minutes to form a transparent P-type ohmic contact layer, and then follow the reference figure 2 The designed pattern uses photoresist as a mask, retains the part of the pre-designed transparent electrode layer, uses the method of chemical wet etching, uses ITO etching solution: FeCl3+HCl, soaks at 40 ° C for 5 minutes, and removes the remaining part. ITO current spreading layer.

[0048] 2. Using ICP dry etching, the grown epitaxial wafer will be etched according to the pre-designed pattern, and every 25 light-emitting structures will be an in...

Embodiment 3

[0055] The manufacturing method of the integrated light emitting diode array chip comprises the following steps:

[0056] 1. Evaporate the ITO current spreading layer 105 on the P-type GaN epitaxial layer of the GaN epitaxial wafer by electron beam evaporation, the evaporation environment temperature is 230-250°C, and the thickness is between Then anneal in a suitable environment, the temperature is 250-700 ° C, and the time is 10-60 minutes to form a transparent P-type ohmic contact layer, and then follow the reference figure 2 The designed pattern uses photoresist as a mask, retains the part of the pre-designed transparent electrode layer, uses the method of chemical wet etching, uses ITO etching solution: FeCl3+HCl, soaks at 40 ° C for 5 minutes, and removes the remaining part. ITO current spreading layer.

[0057] 2. Using ICP dry etching, the grown epitaxial wafer is etched according to the pre-designed pattern, and every 9 light-emitting structures are an integrated u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com