Production method of semiconductor discrete device back side metal suitable for screen printing

A backside metal, discrete device technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, metal material coating processes, etc., can solve problems such as Ti/Ni/Ag structure falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

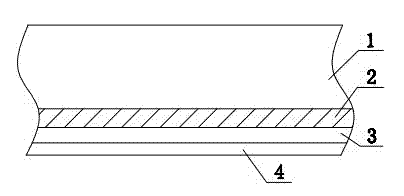

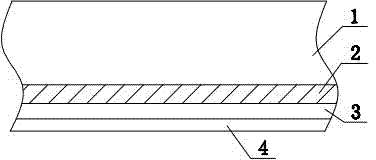

[0028] By evaporating metal on the back of the wafer 1 by the method of the present invention, a multilayer metal structure consisting of wafer 1, Cr2, Ni3 and Ag4 from top to bottom is finally obtained.

[0029] Processing step of the present invention is as follows:

[0030] 1) Film attachment: the wafer with the front structure of the device has been completed, and the UV film is pasted on the front of the wafer to protect the front structure of the wafer from damage during subsequent processing;

[0031] 2) Thinning the wafer by mechanical grinding: first rough grinding, using a 320-mesh grinding wheel to grind off the silicon on the back of the 300um wafer, and then finely grinding, using a 2000-mesh grinding wheel to grind off the silicon on the back of the 30um wafer. The model of the mechanical grinding machine: DFG8540, the manufacturer : DISCO;

[0032] 3) Relieve stress corrosion, remove the mechanical damage caused by step 2, the cleaning steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com