Method for producing film metal fine device on PDMS surface

A micro-device and thin-film technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., to achieve the effect of simple process, low cost and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Fabricate a thin-film integrated gold film micro-device on the surface of a PDMS sheet

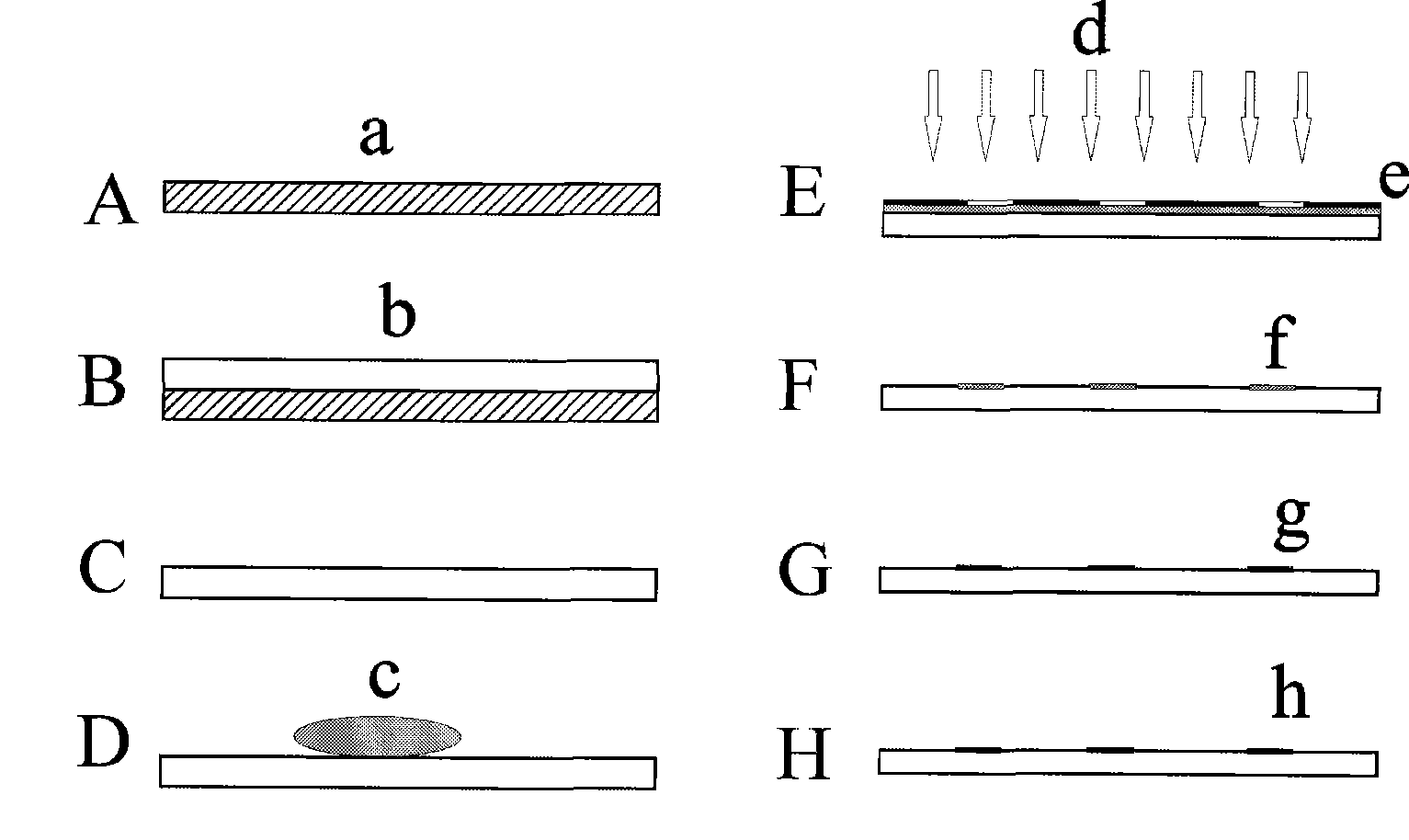

[0034] see figure 1 , A is the positive mold of the desired shape; B is the cast PDMS sheet; C is the PDMS sheet formed after the PDMS is cured and released from the mold, and the sheet is soaked in benzophenone solution; D is the adsorbed benzophenone The grafting solution containing AA monomer was added dropwise on the PDMS sheet; E is the photochemical polymerization of the monomer by ultraviolet light after covering the mask; F is the PDMS sheet grafted with PAA in the surface illuminated area; G is the PDMS grafted with PAA slices for amination, HAuCl 4 Treatment, NaBH 4Reduction and other pretreatment reactions form a nano-gold particle catalytic center in the irradiated area; after H is electroless gold plating, a gold thin film device with a mask pattern is formed in the ultraviolet irradiated area.

[0035] Among them, a. positive mold; b. PDMS; c. grafting ...

Embodiment 2

[0044] Example 2 Selective electroless gold-plated film on the inner surface of the PDMS microfluidic chip channel

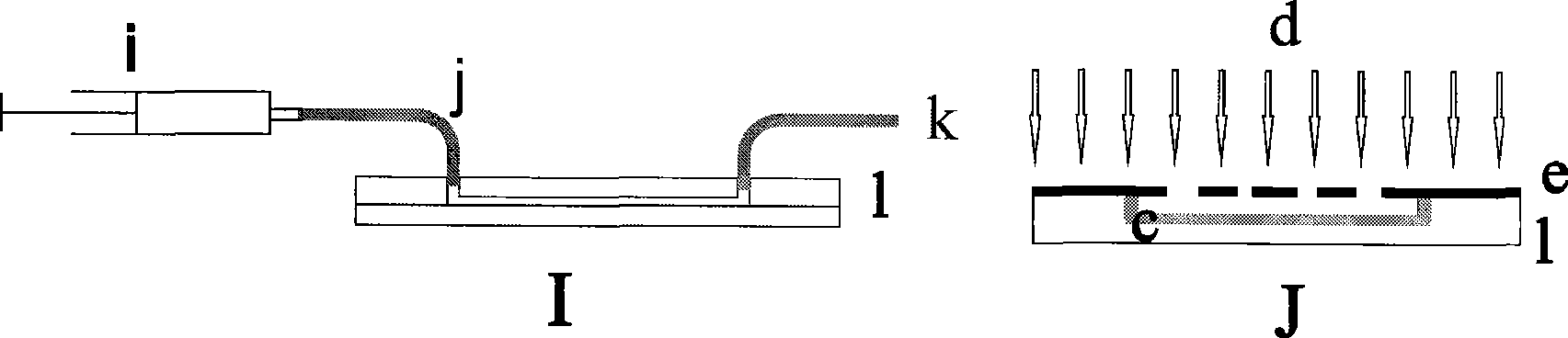

[0045] See attached figure 2 , figure 2 I is a schematic diagram of a solution processing device in a PDMS channel; i. a syringe pump; j. a polytetrafluoroethylene tube connected to the channel inlet; k. a solution outlet; 1. a PDMS chip with a channel.

[0046] figure 2 J is a schematic diagram of the device for the regioselective grafting process induced by ultraviolet light on the inner wall of the PDMS channel.

[0047] Wherein, c. grafting solution for grafting PAA; d. 365nm ultraviolet light; e. ultraviolet lithography mask; 1. PDMS chip with channels.

[0048] (1) Fabricate a PDMS chip with a channel according to a conventional method.

[0049] (2) Prepare a 10% (wt) benzophenone solution, wherein the solvent composition is acetone:water=65:35. Use a syringe pump to fill the prepared benzophenone solution through the connecting tube to fill the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com