A cleaning method of a metal film forming mask

A metal film forming and masking technology, which is applied in the field of mask cleaning, can solve the problems of troublesome transportation of the mask, and achieve the effect of eliminating the inconvenience of transportation, improving the cleaning efficiency and simplifying the cleaning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

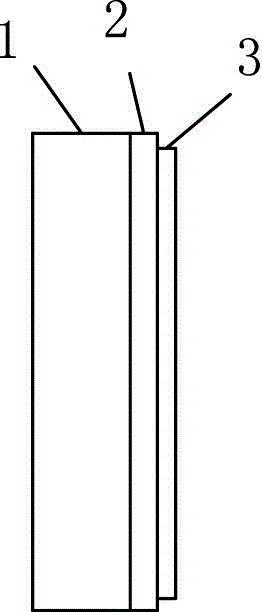

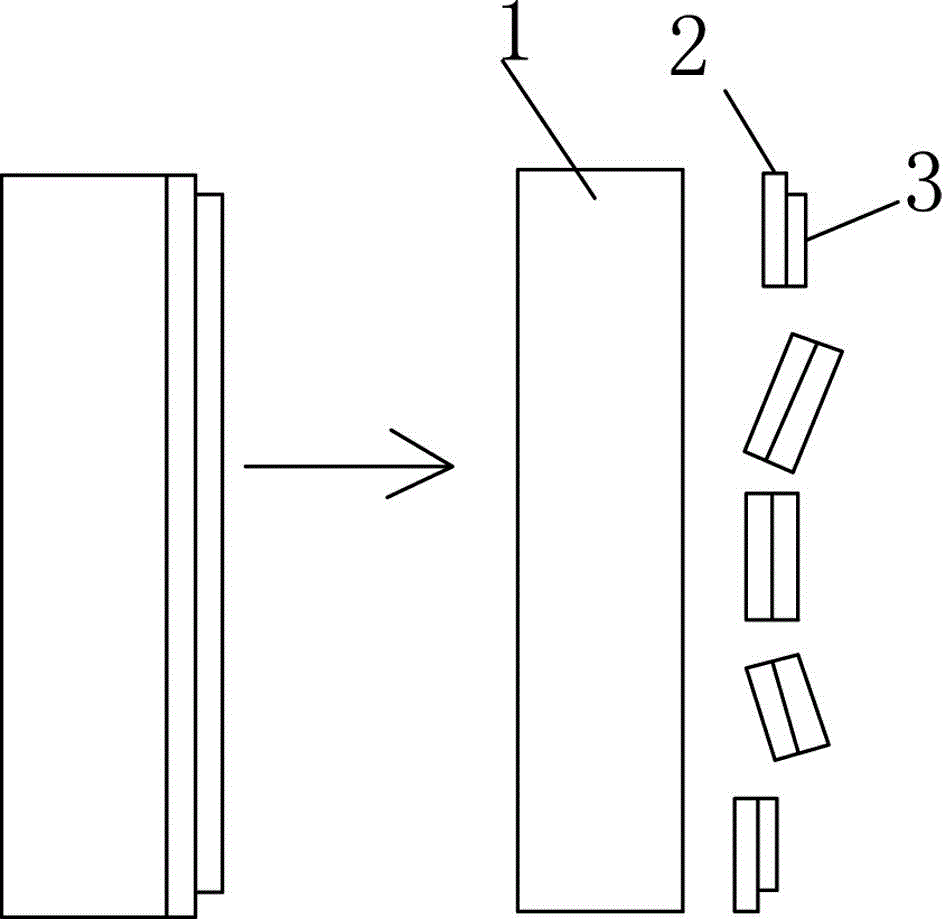

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Referring to the embodiment of the present invention figure 1 As shown, in order to solve the problem of cleaning large-scale metal film-forming masks, the following methods are provided:

[0019] In the first step, the mask plate 1 is put into the organic matter evaporation chamber, and the material of the mask plate is invar36 (Invar alloy), but not limited thereto. Before the evaporation, the organic matter evaporation chamber is evacuated into a high vacuum, and a layer of organic material is evaporated on the entire surface of the mask plate 1 to form an organic layer 2 through a vacuum evaporation of 1 to 2 minutes. The organic layer 2 should be evaporated evenly, and its thickness should be light and thin on the basis of uniform evaporation, so as to prevent the organic layer 2 from being too thick and partially fall off in the later process. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com