Metal evaporation crucible

A crucible and metal technology, applied in the field of vacuum thermal evaporation device, can solve problems such as heating wire 120 alloying, heating circuit short circuit, etc., and achieve the effect of reducing heating instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

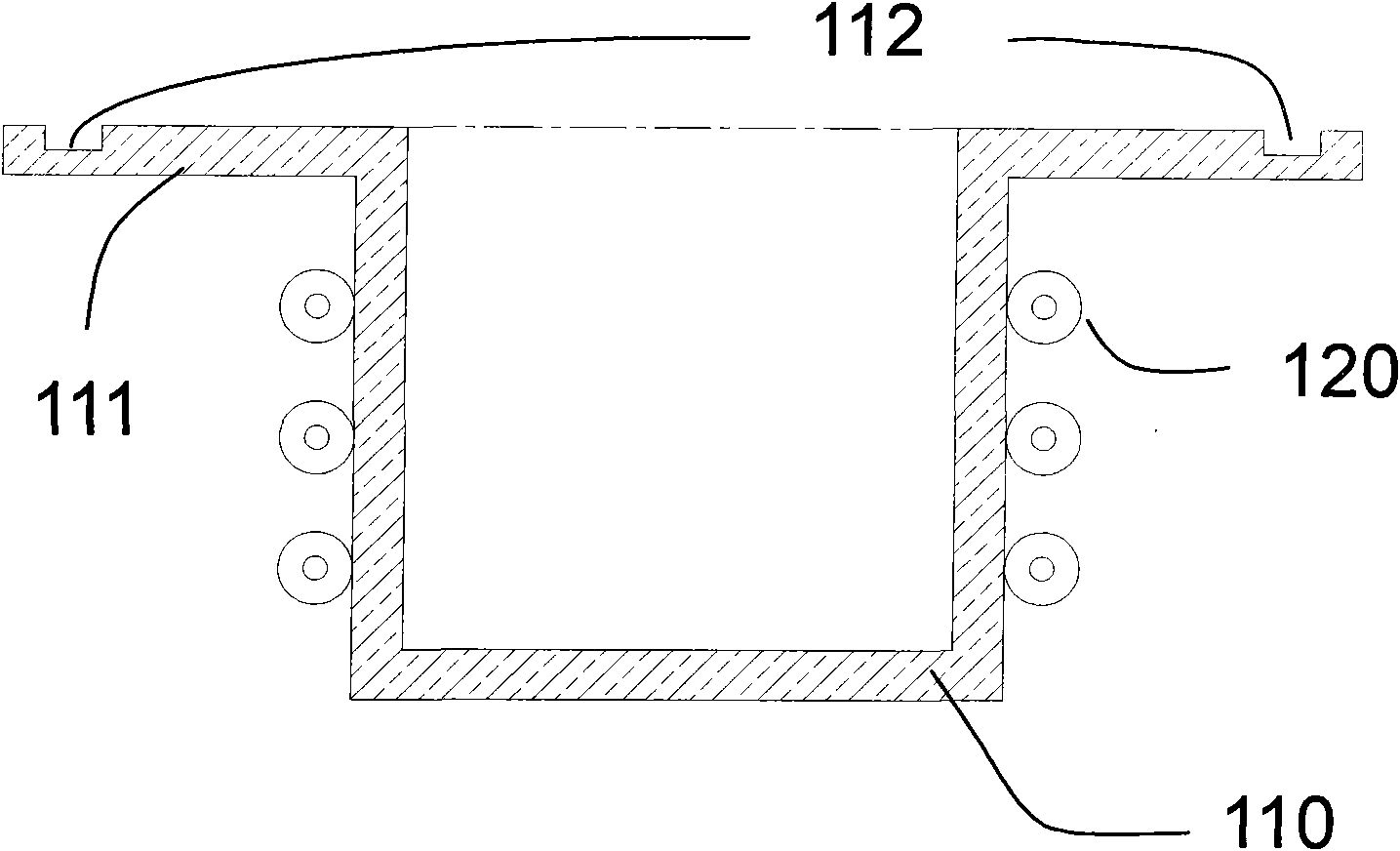

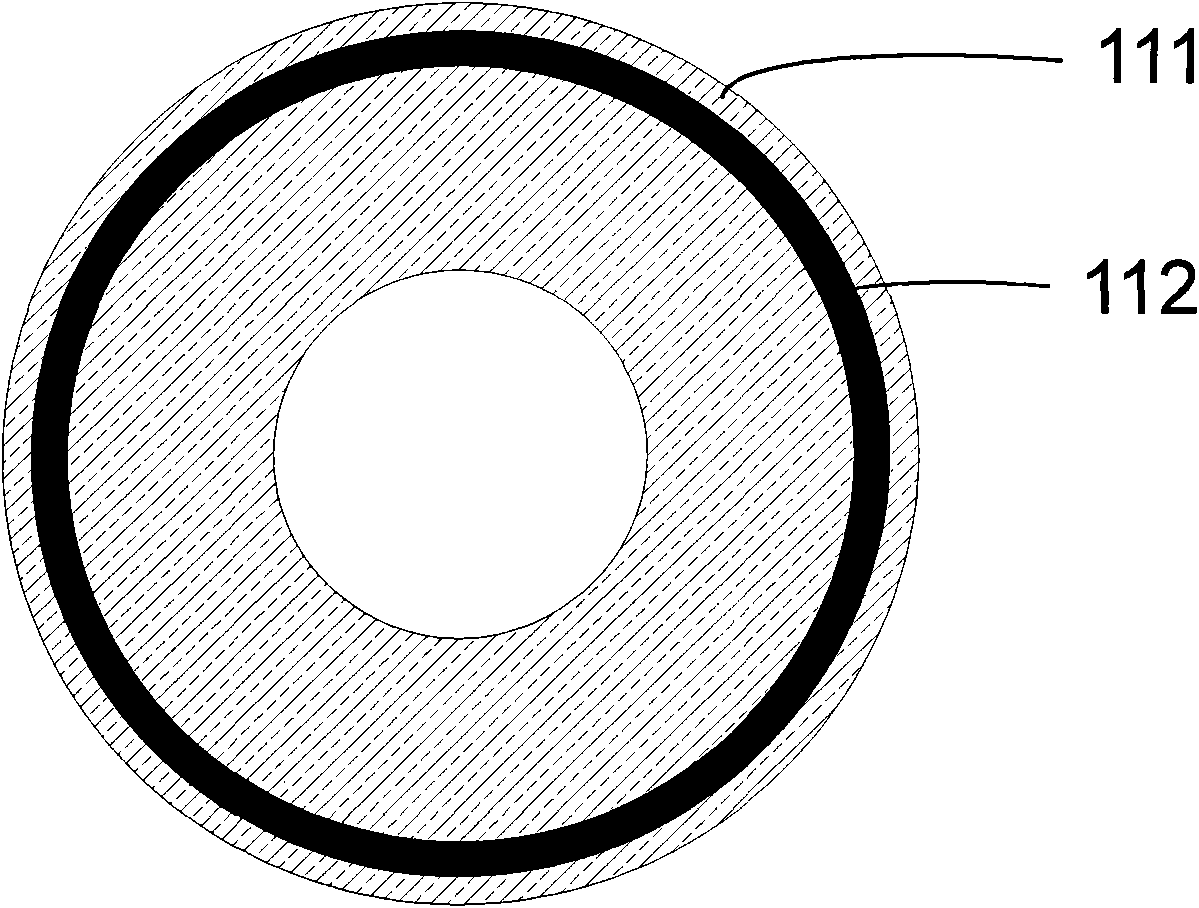

[0018] like figure 1 , as shown in 2, a crucible for evaporating metals includes a crucible container 110, an annular horizontal platform 111 and an annular flow-limiting groove 112 from the inside to the outside, and the crucible wall of the crucible container 110 extends horizontally at the mouth of the crucible, forming An annular horizontal platform 111, the width of the annular horizontal platform 111 is three times or more than the diameter of the heating wire 120, and the outer edge of the annular horizontal platform 111 inwardly does not exceed the width of an annular restricting groove 112 On the top, there is an annular current limiting groove 112, the depth of the annular current limiting groove 112 is about half of the thickness of the horizontal platform, and its width does not exceed the diameter of the heating wire 120. The crucible has a high thermal conductivity and high temperature resistance And it is made of non-metallic materials that do not chemically re...

Embodiment 2

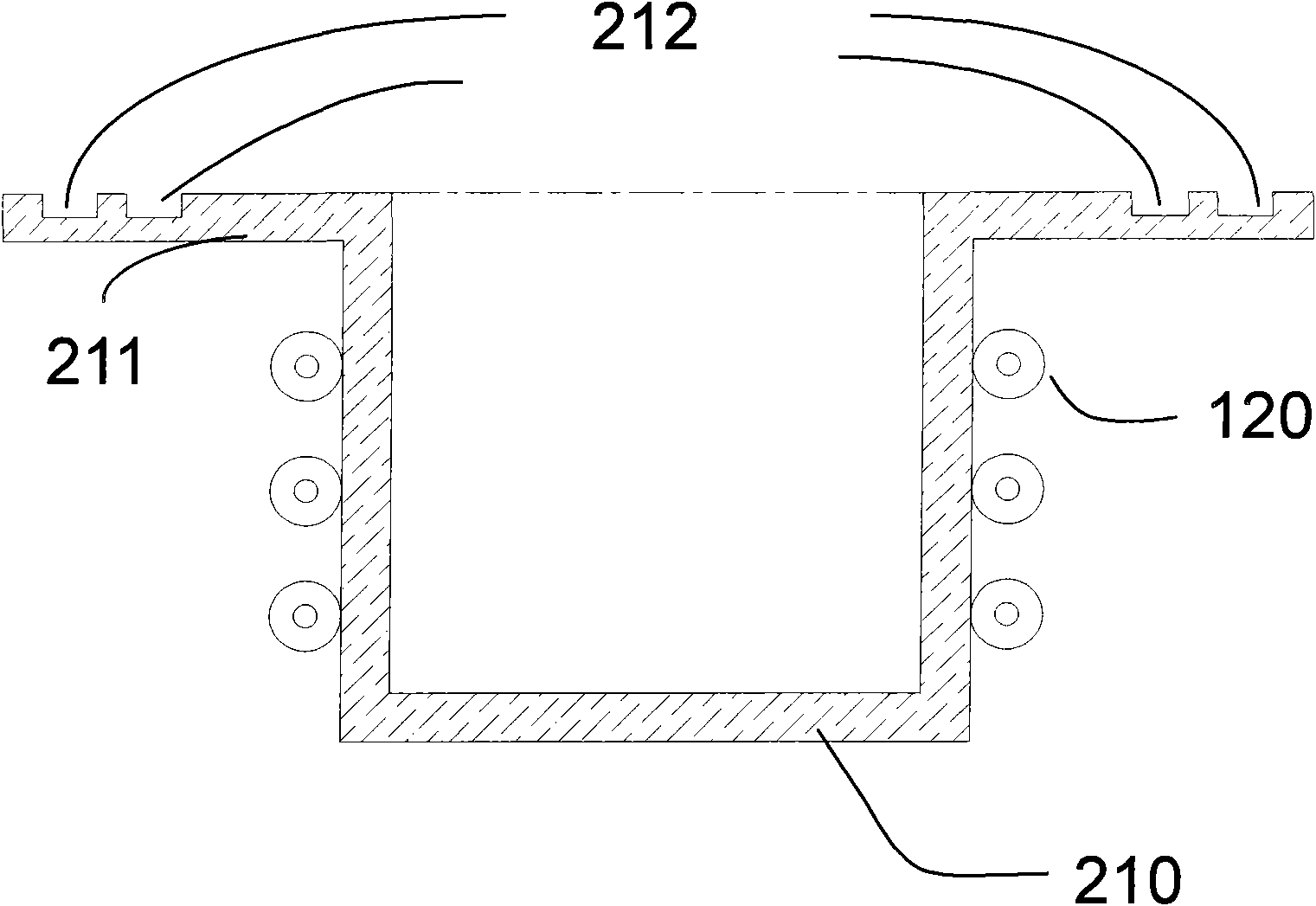

[0021] like image 3 , shown in 4, is another embodiment of the present invention. In this embodiment, the top of the heating body 210 is connected to an annular horizontal platform 211 perpendicular to the side of the main body. The annular horizontal platform 211 is close to the extension and has two flow-limiting grooves 212 distributed therein. Compared with Embodiment 1, the number of flow-limiting grooves is increased, so that when there is a large amount of molten metal overflowing and the overflow speed is too fast, it can effectively prevent the molten metal from flowing out of the platform and affect the vacuum cavity. Therefore, the vapor deposition process of the metal material plays a role of safety protection.

[0022] In the two embodiments of the present invention, the geometric dimensions of the crucible, the thickness of the crucible wall, the width of the horizontal platform and the depth of the restrictor groove are all determined by the shape of the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com