Long-distance concrete sprayer

A concrete spraying machine, long-distance technology, applied in mechanical equipment, earth square drilling, engine components, etc., can solve the problems of seals and cylinders and concrete wear, large dust, short conveying distance, etc., to prevent dust from escaping , reduce dust, ensure the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

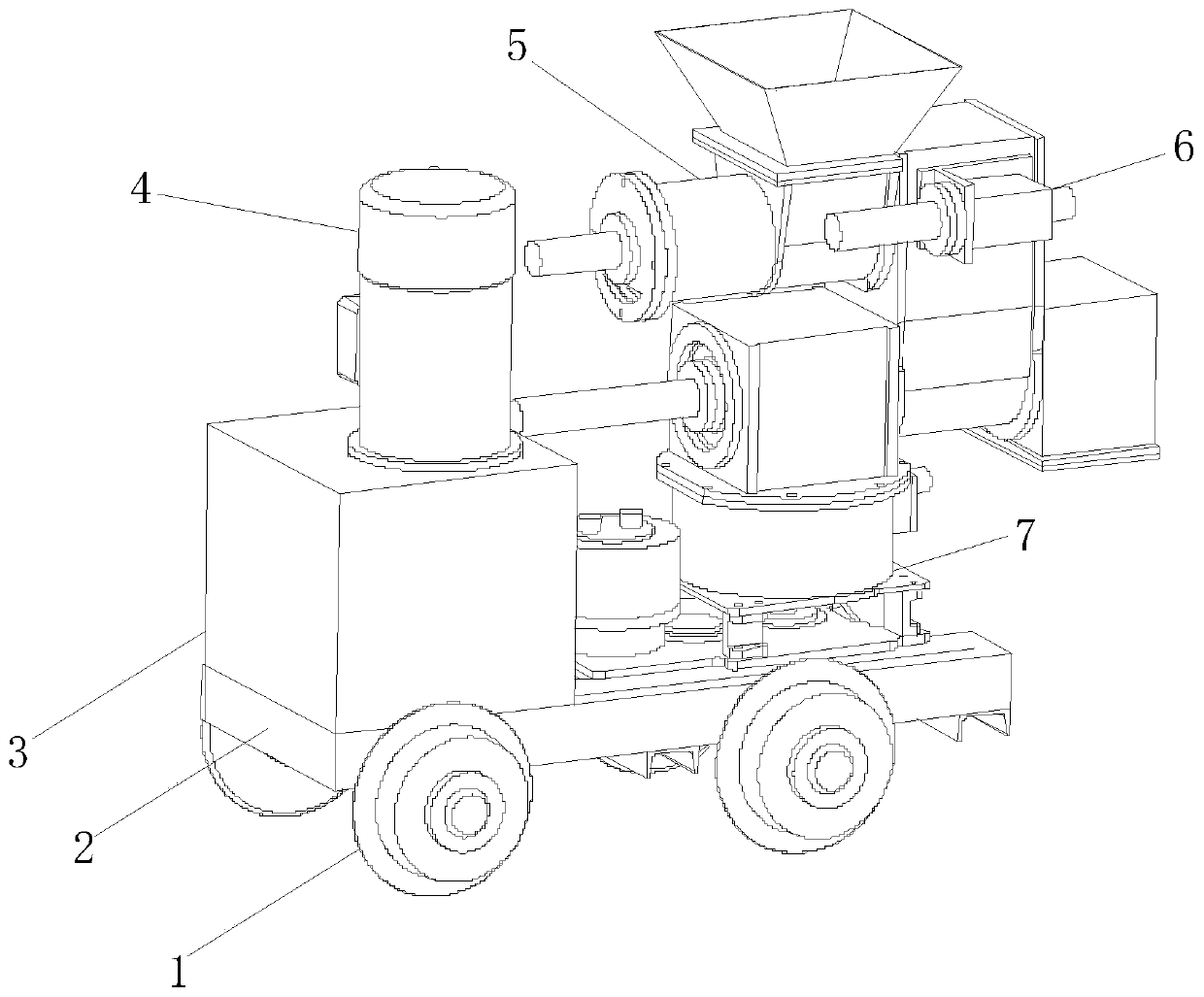

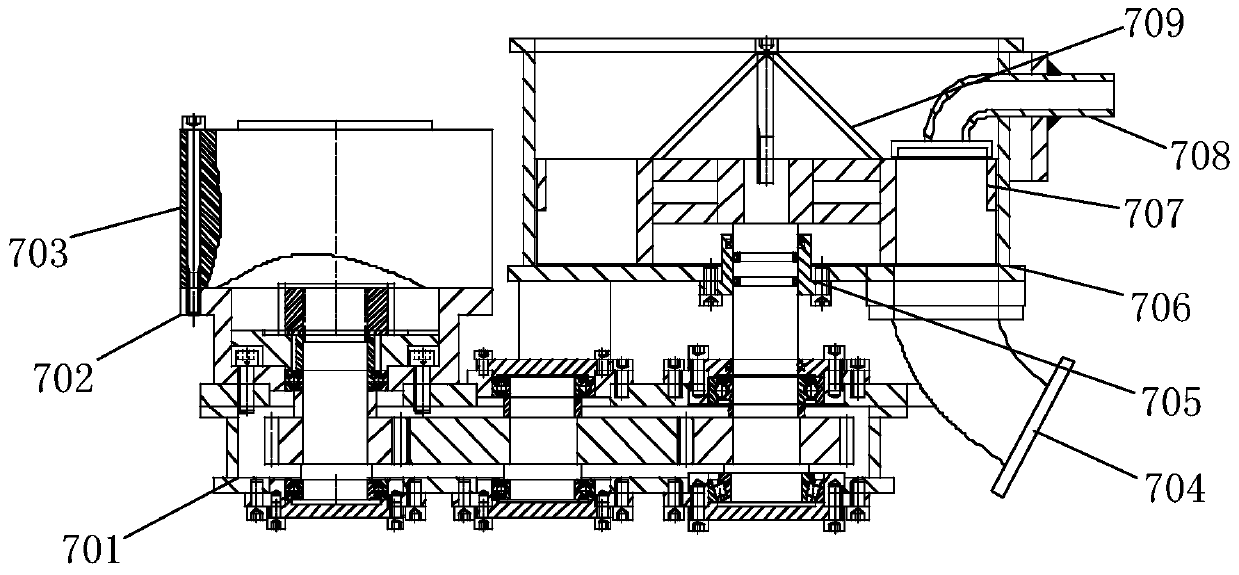

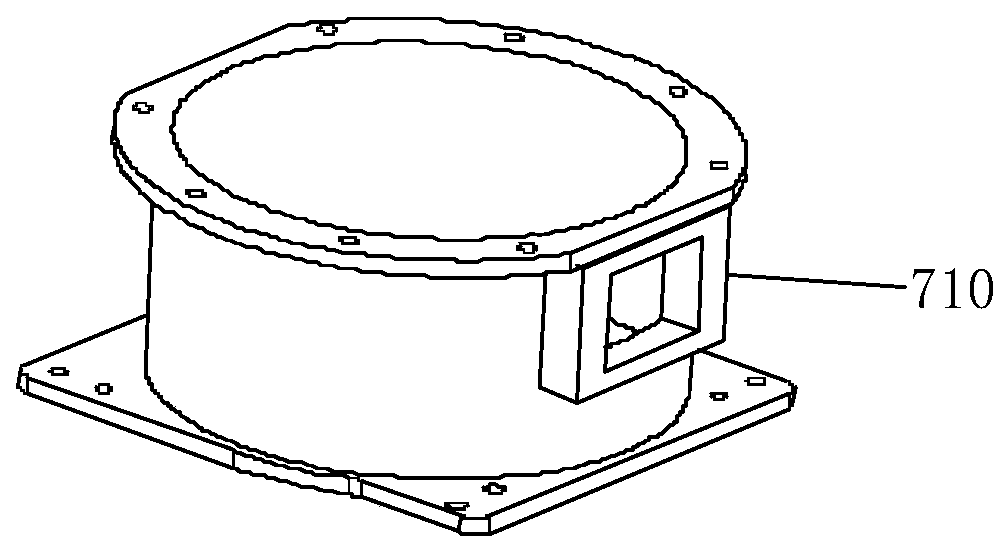

[0033] to combine Figure 1 to Figure 10 As shown, the specific implementation of a short-distance concrete sprayer provided by the present invention is as follows.

[0034] A long-distance concrete sprayer specifically includes an underframe, a cylinder mechanism 5, a rotor mechanism 7 and a hydraulic system. The rotor mechanism is fixed on the bottom frame for spraying concrete, the cylinder barrel mechanism is arranged above the rotor mechanism for conveying concrete, and the hydraulic system realizes hydraulic drive. The motor 4 of the hydraulic system is installed above the hydraulic oil tank 3, the output shaft of the motor is connected with the hydraulic pump through a shaft coupling, and the hydraulic pump is arranged in the hydraulic oil tank. The chassis includes a frame 2 and a walking wheel 1. The walking wheel 1 is set at the bottom of the frame 2. One walking wheel can be installed at each corner of the chassis. Choose the appropriate road wheel structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com