V-shaped conveying type spring conveying and chamfering equipment and using method

A kind of equipment and chamfering technology, which is applied in the field of spring processing, can solve the problems of affecting the spring chamfering process, the inability to adjust the spring size and head screening, and the labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

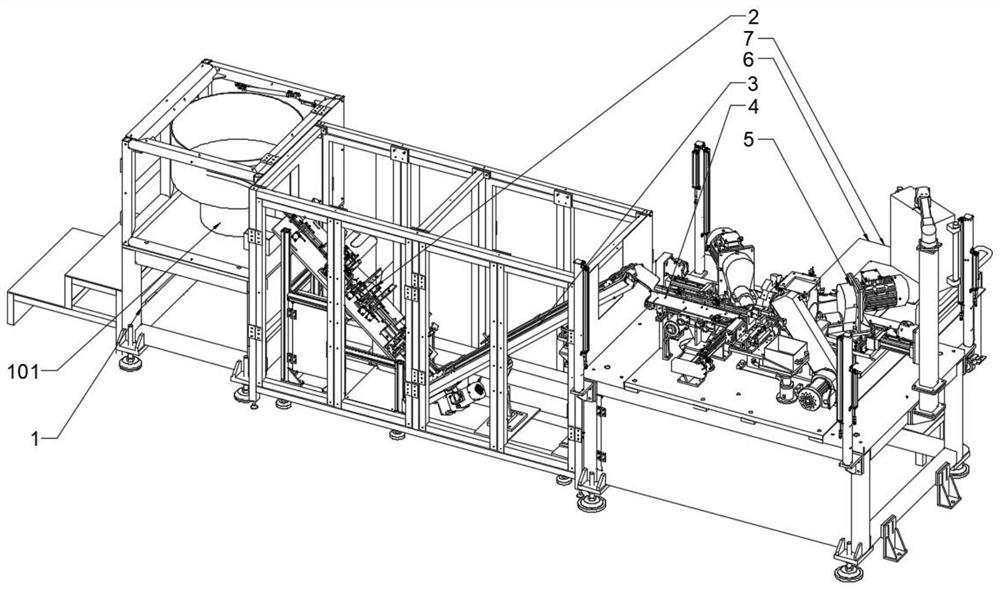

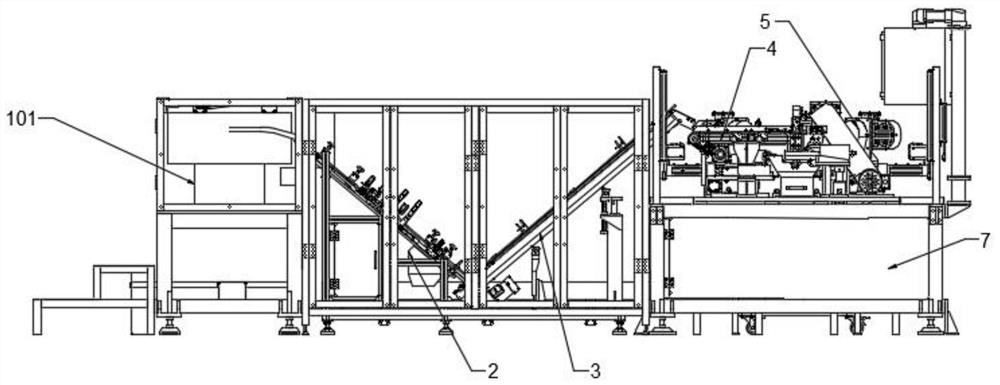

[0084] like Figures 1 to 10 As shown, a conveying spring chamfering device for V-shaped conveying includes a frame 1. According to the conveying route of the spring, a feeding vibrating plate, a V-shaped conveying line and a grinding unit 5 are sequentially arranged on the frame 1. The grinding unit 5 The tail is connected with a receiving box 6;

[0085] The vibrating plate 101 is installed on the frame 1 through the protective frame, the top of the vibrating plate 101 is open, and the vibrating plate 101 is connected to the top of the first guide rail 2021 of the slide unit 2;

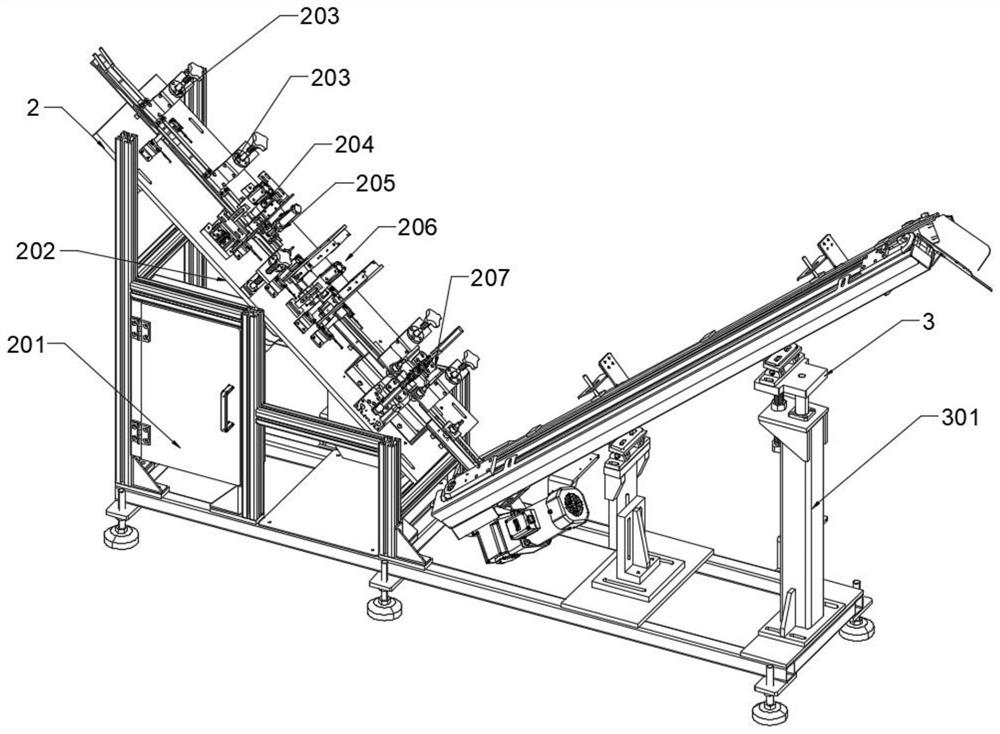

[0086] The V-shaped conveying line includes a landslide unit 2 and a climbing unit 3. The landslide unit 2 is installed on the frame 1 through a landslide mounting seat 201; The top of the climbing unit 3 is connected to the grinding unit 5, and the climbing unit 3 is installed on the frame 1 through the climbing mounting seat;

[0087] The slide unit 2 includes a slide mounting plate 202, a first...

Embodiment 2

[0106] like Figure 1-10 As shown, a V-shaped conveying spring chamfering equipment includes a frame 1, and a feeding vibrating plate, a V-shaped conveying line and a grinding unit 5 are sequentially arranged on the frame 1 according to the conveying route of the spring;

[0107] The vibrating plate 101 is installed on the frame 1 through the protective frame, the top of the vibrating plate 101 is open, and the vibrating plate 101 is connected to the top of the first guide rail 2021 of the slide unit 2;

[0108] The V-shaped conveying line includes a landslide unit 2 and a climbing unit 3. The landslide unit 2 is installed on the frame 1 through a landslide mounting seat 201; The top of the climbing unit 3 is connected to the grinding unit 5, and the climbing unit 3 is installed on the frame 1 through the climbing mounting seat;

[0109] The slide unit 2 includes a slide mounting plate 202, a first guide rail 2021 installed on the upper surface of the slide mounting plate 202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com