Patents

Literature

30results about How to "Ensure consistent orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

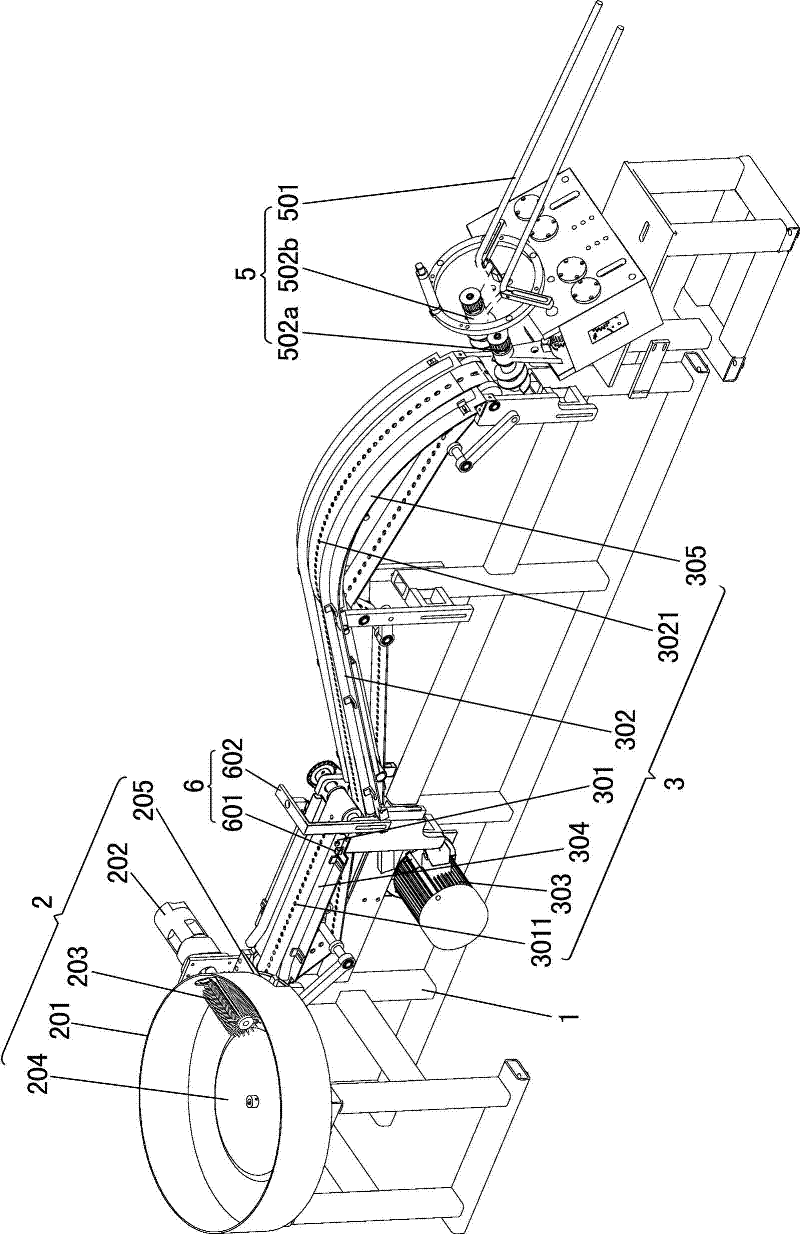

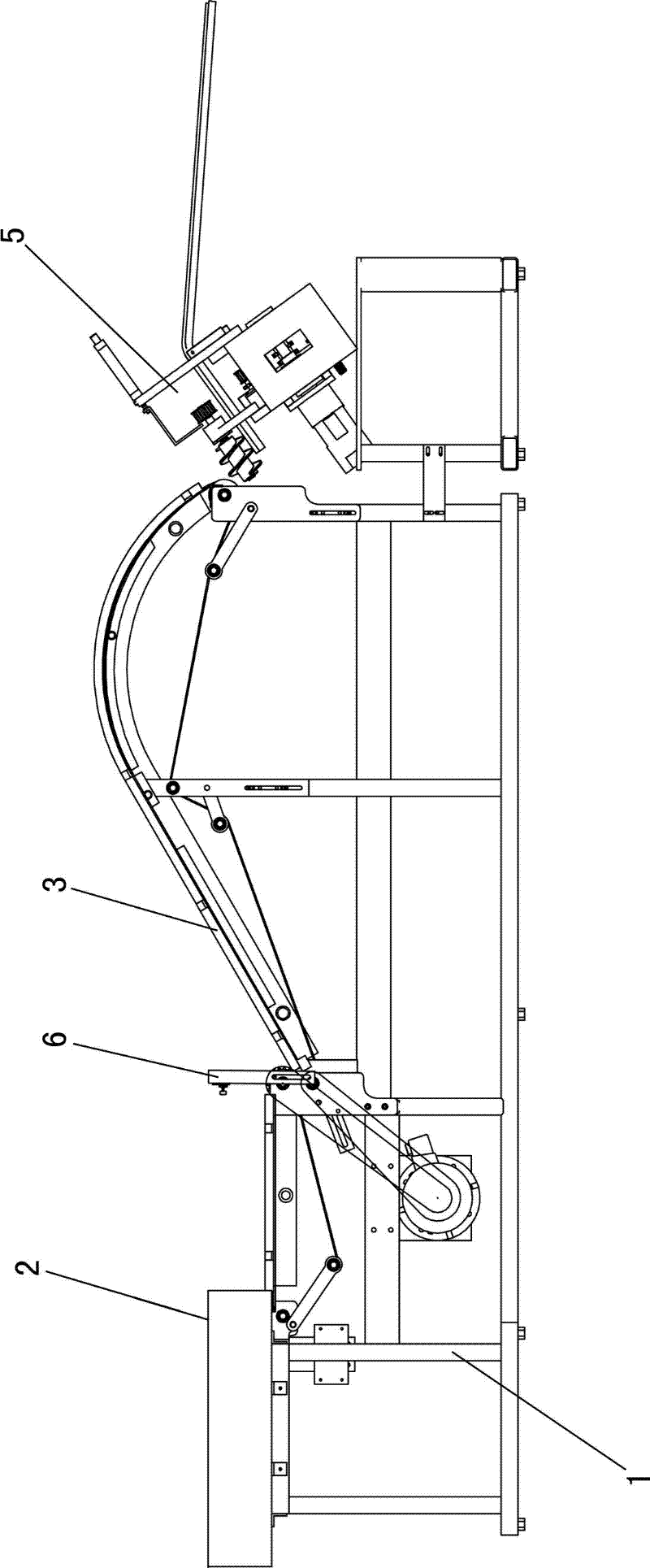

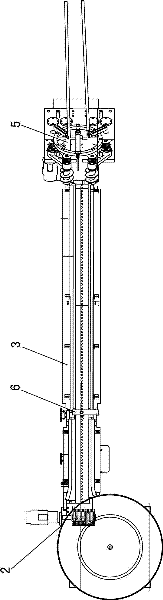

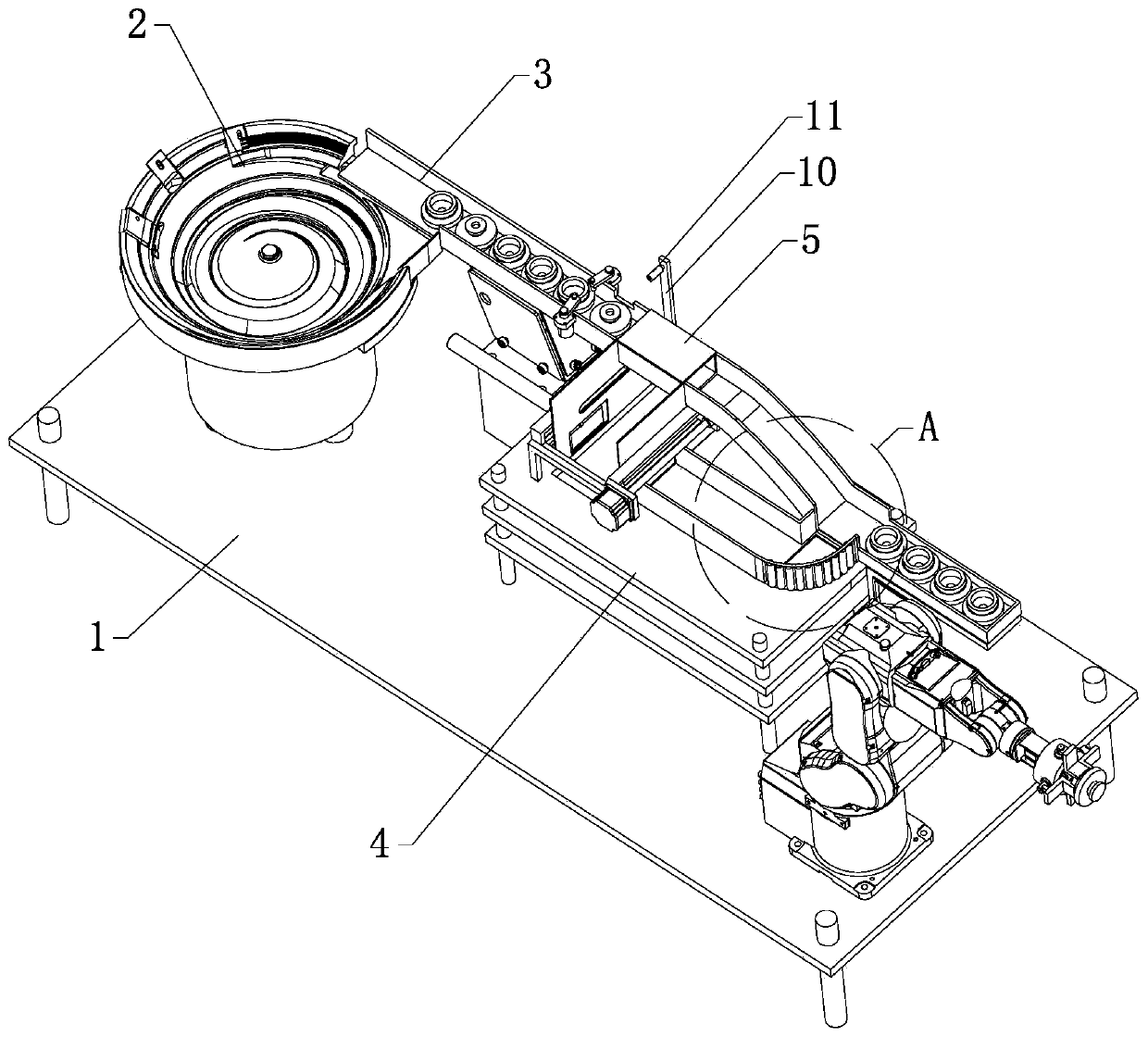

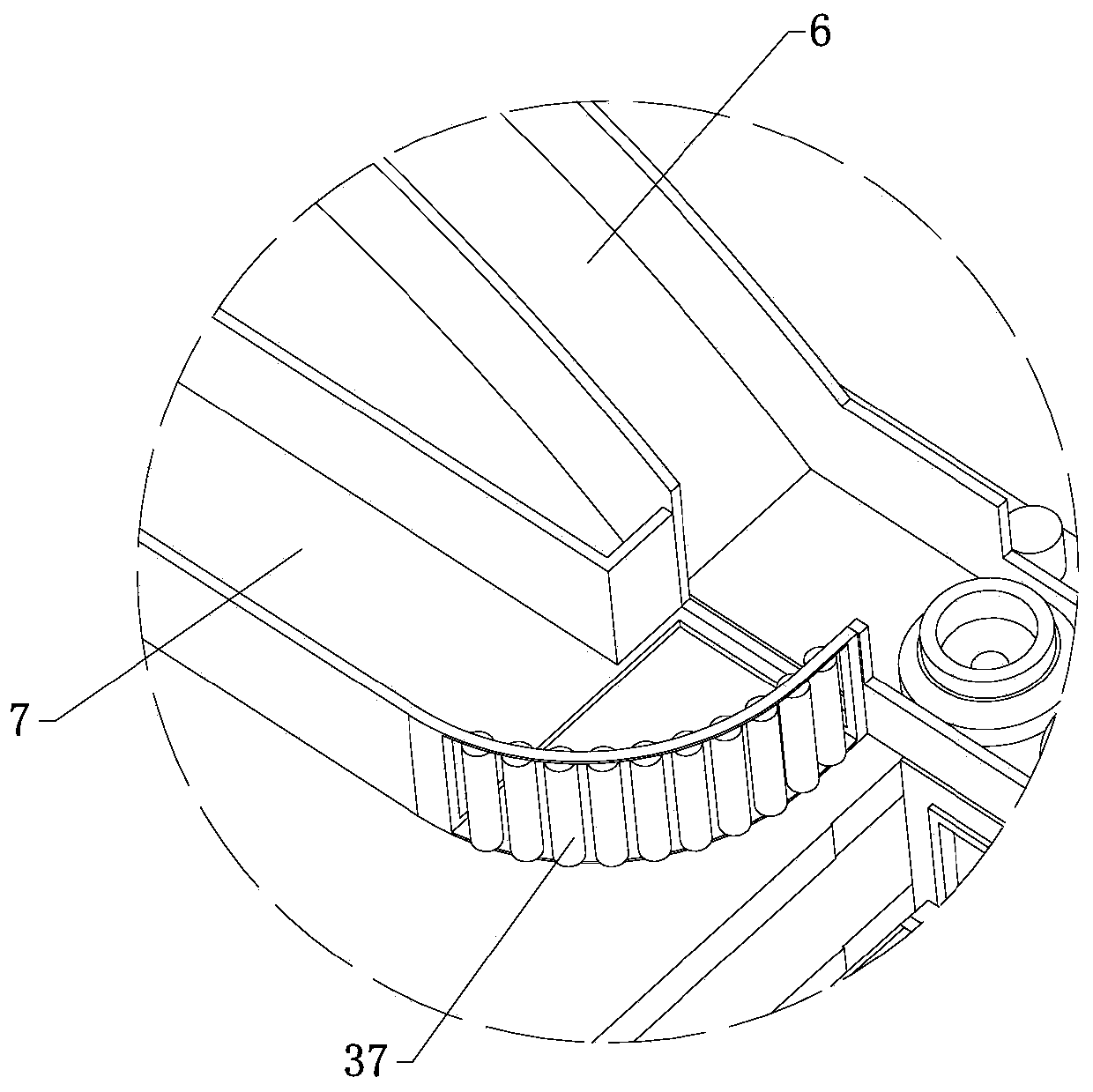

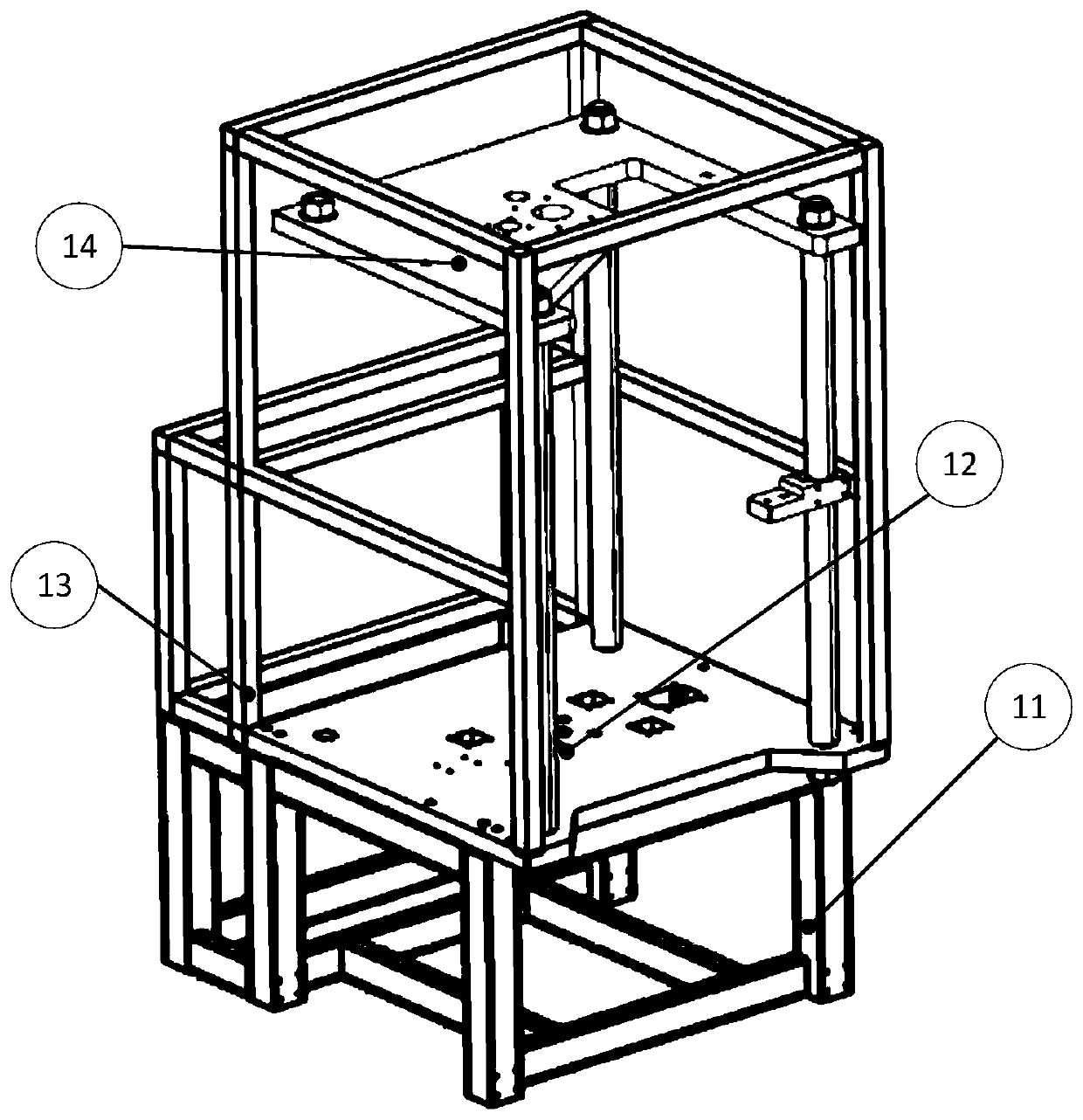

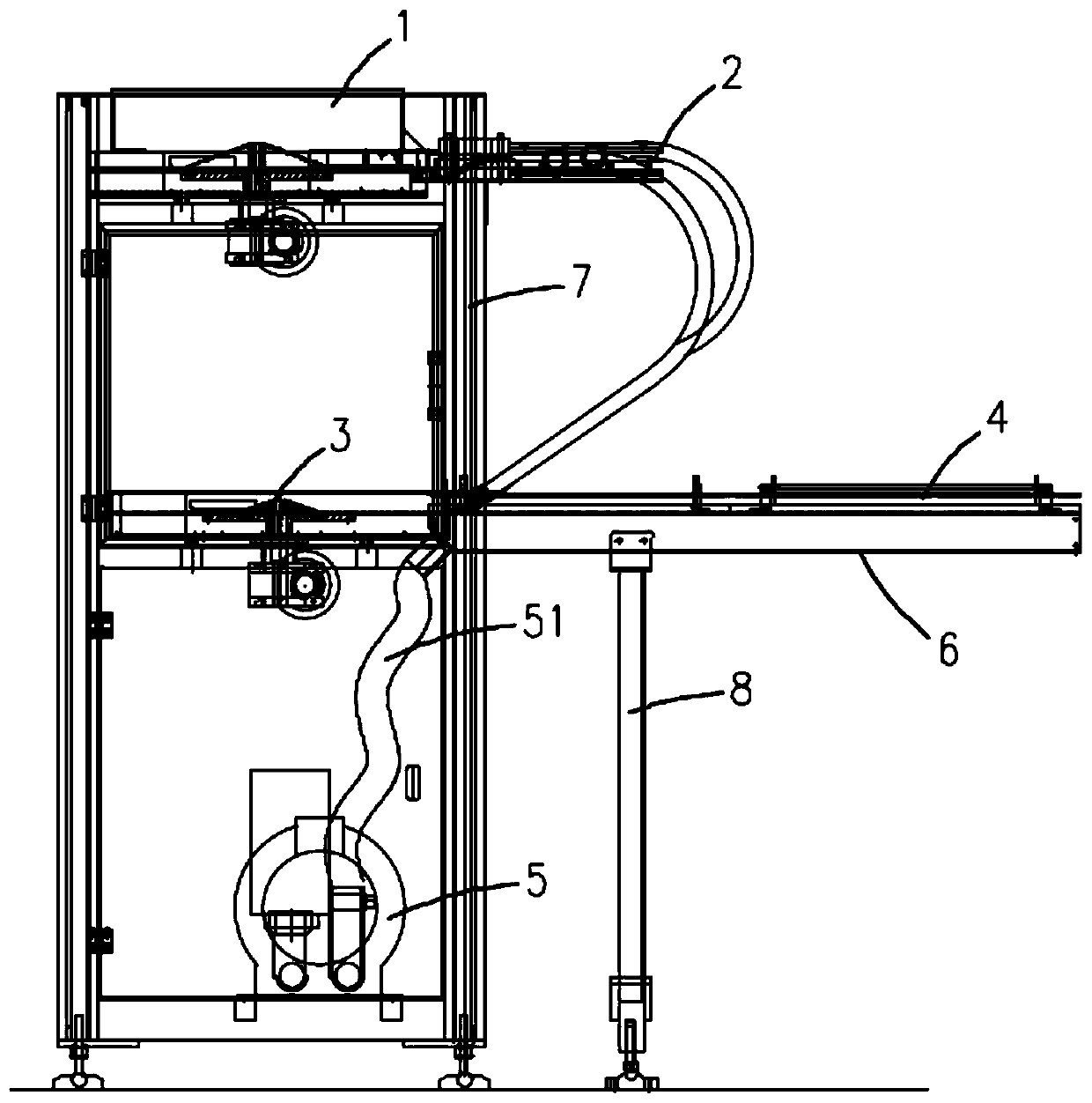

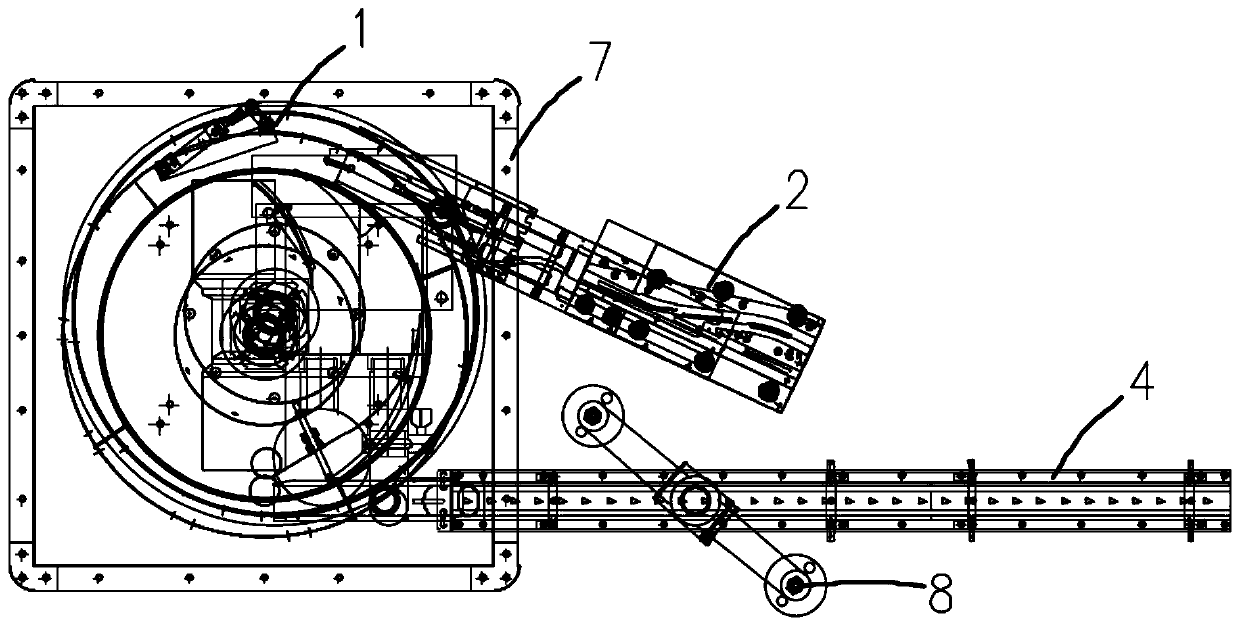

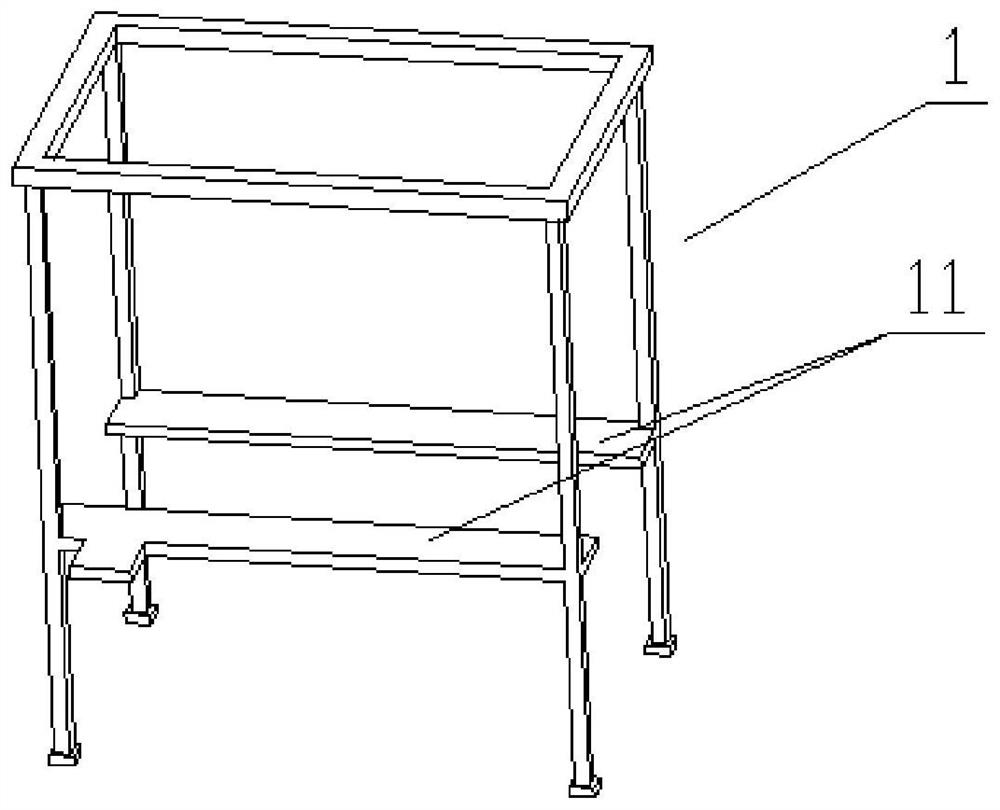

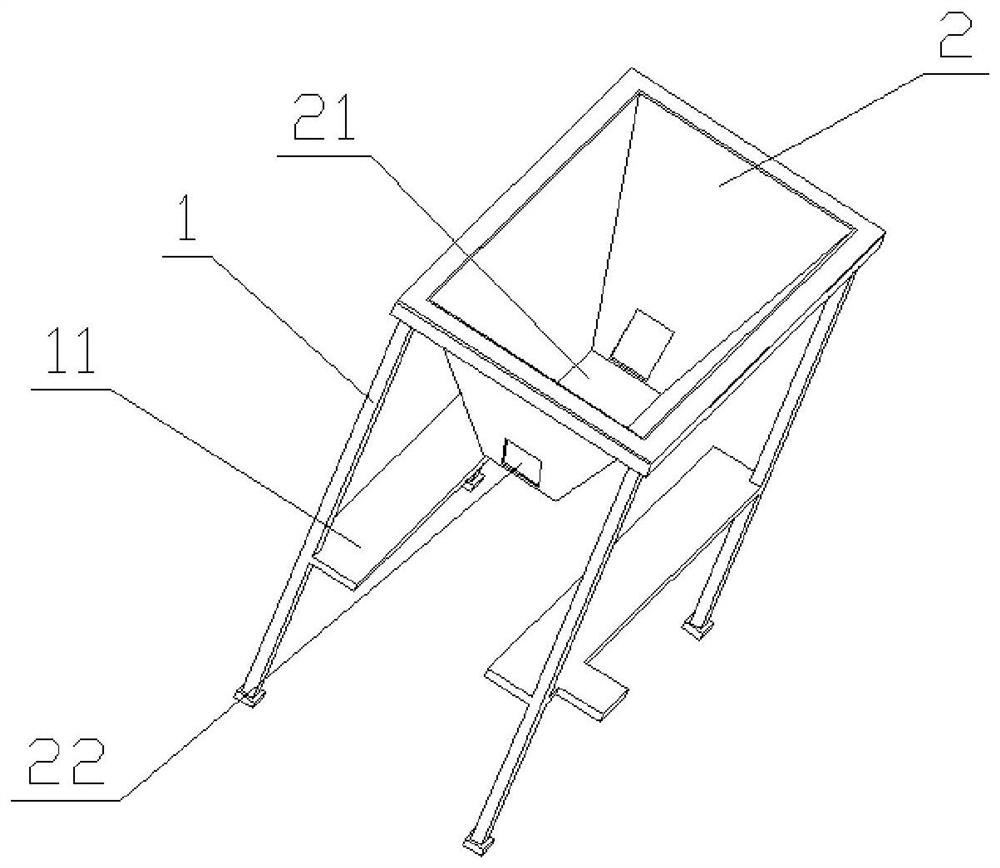

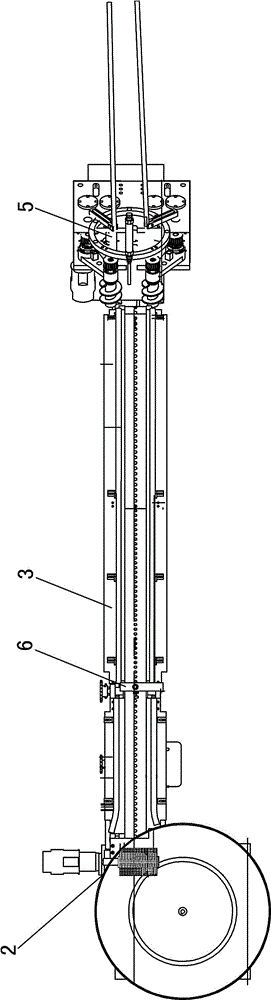

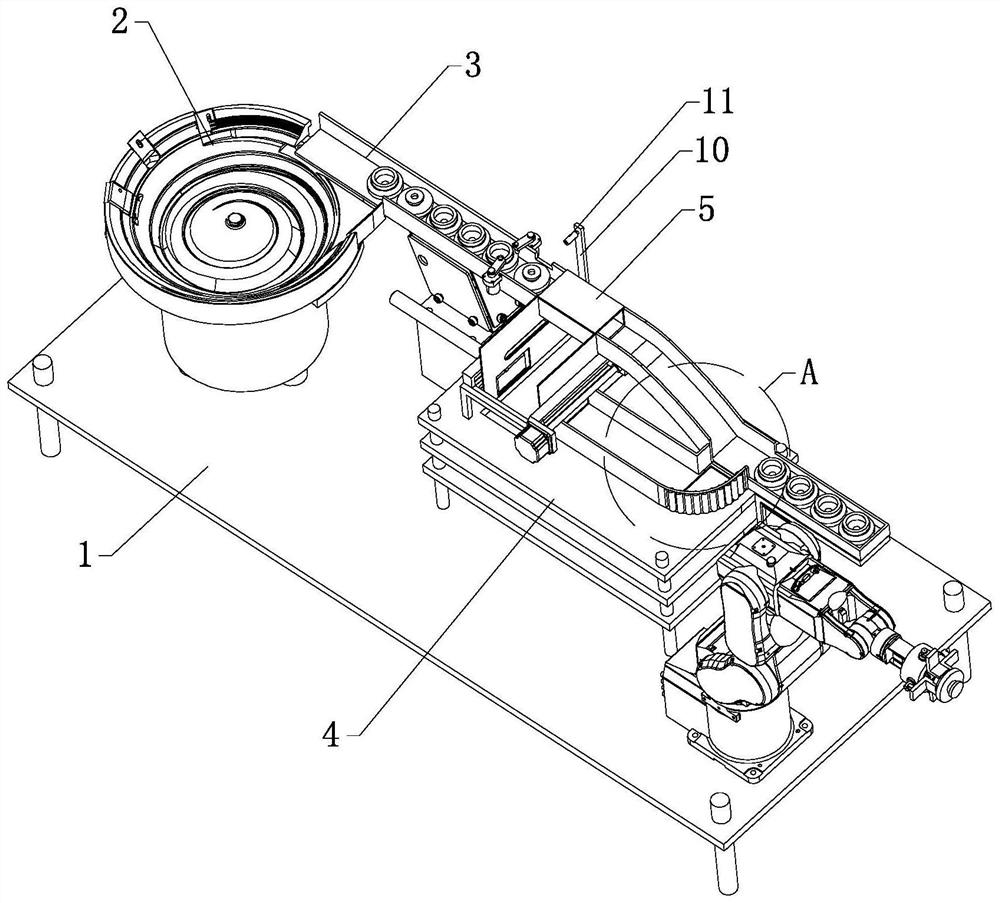

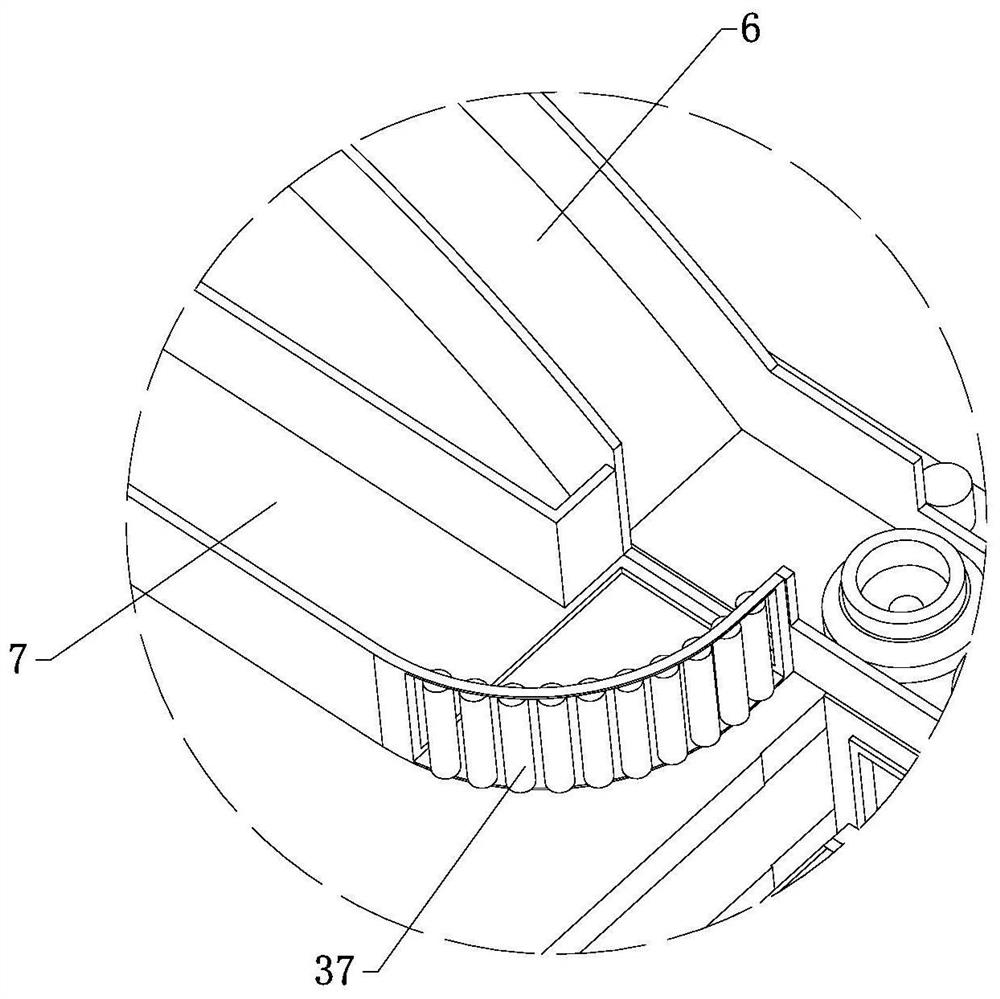

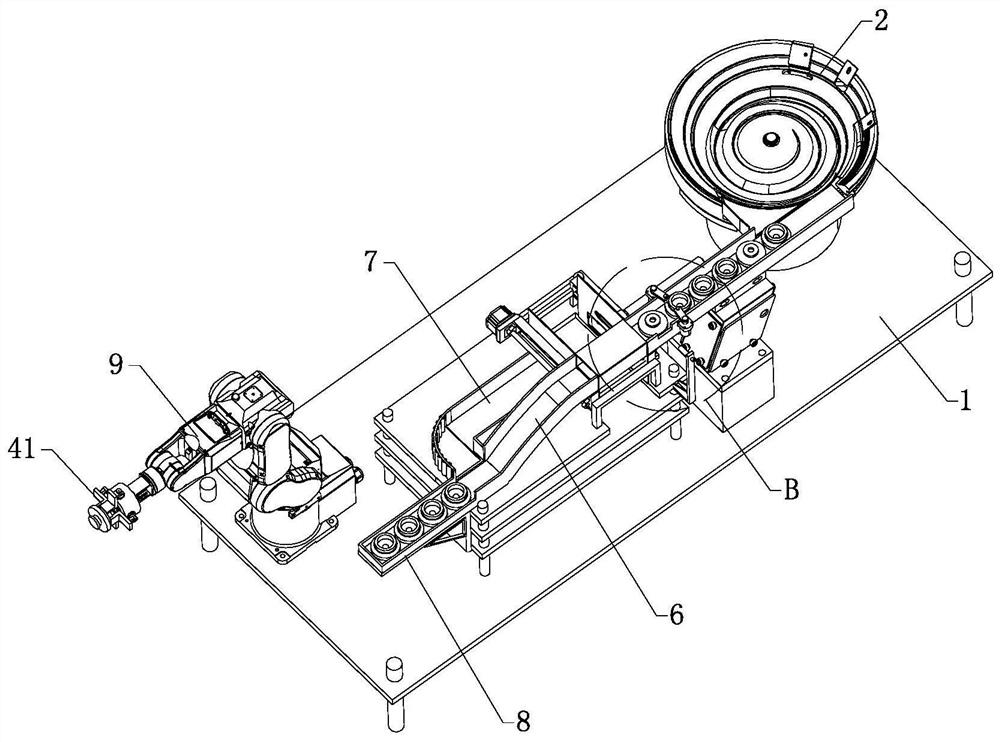

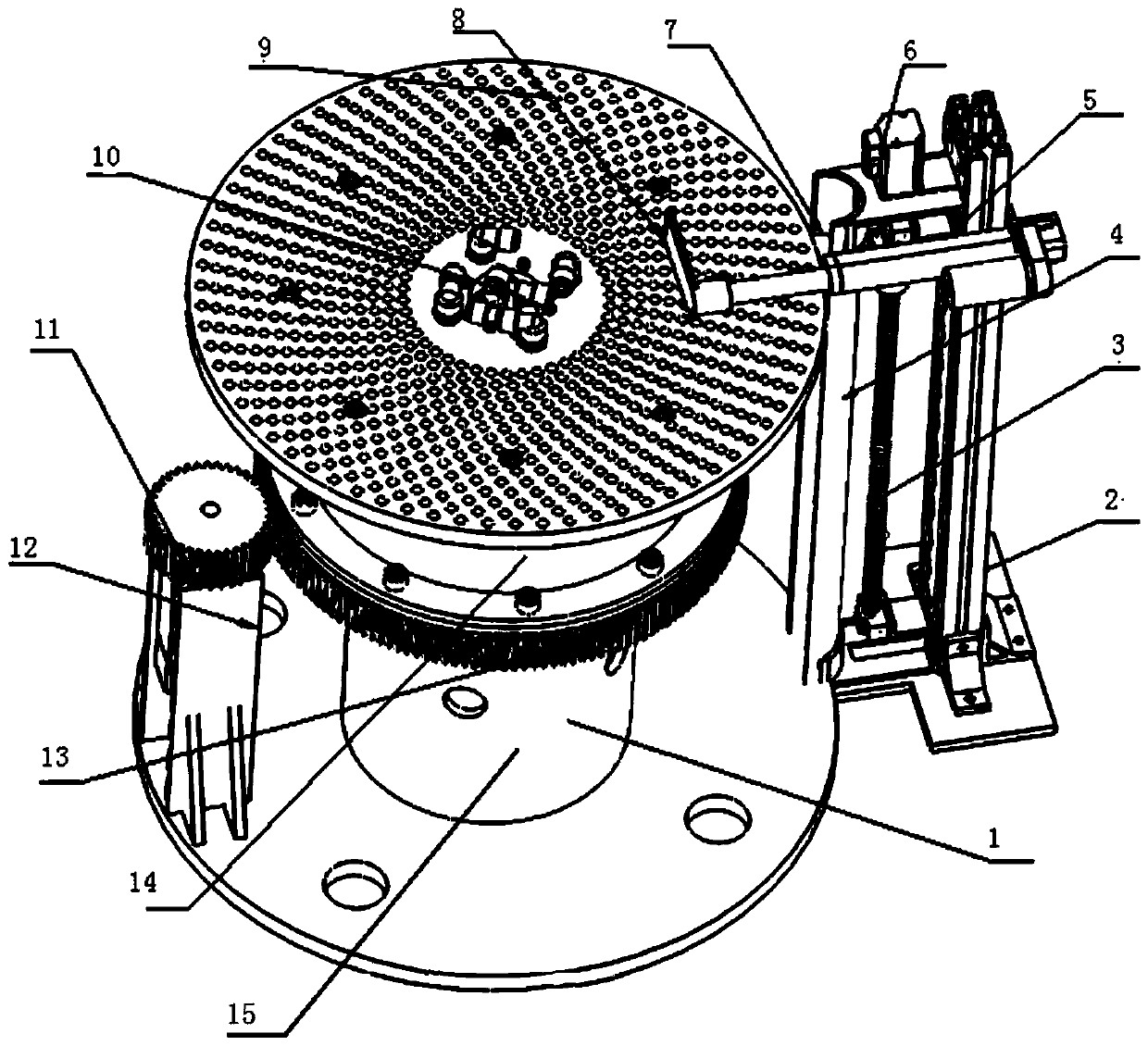

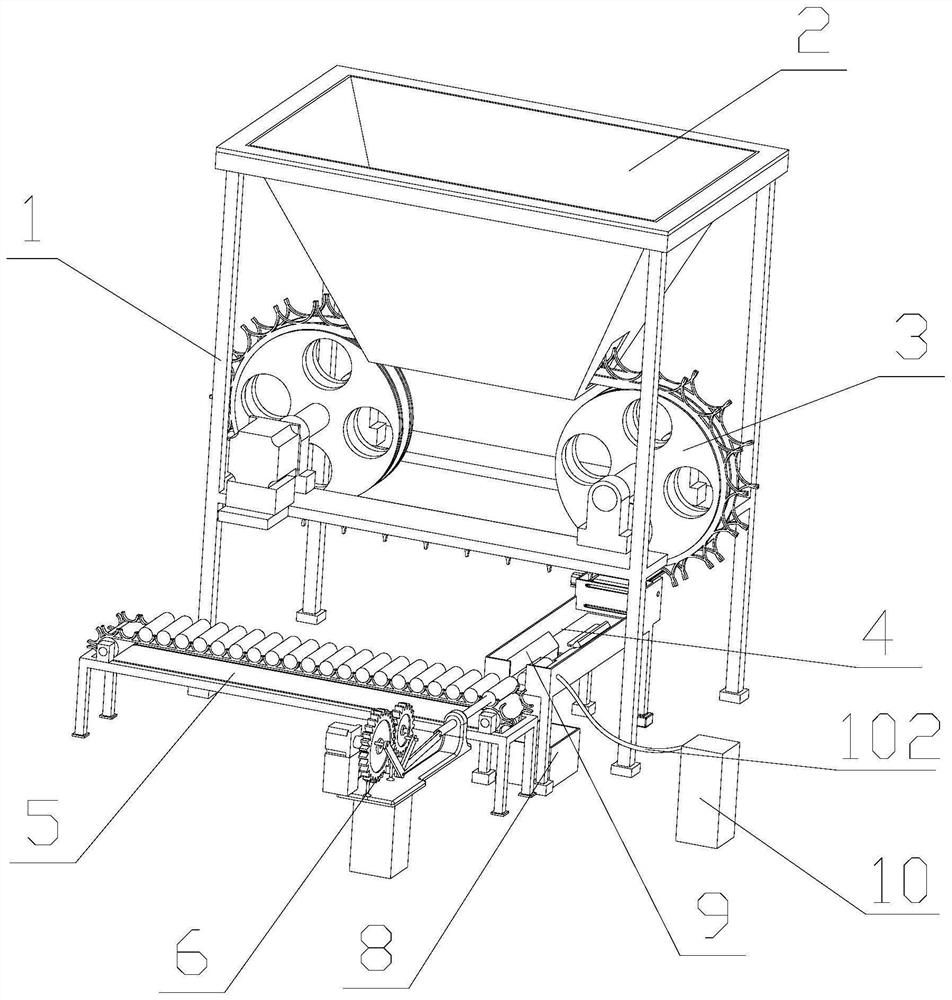

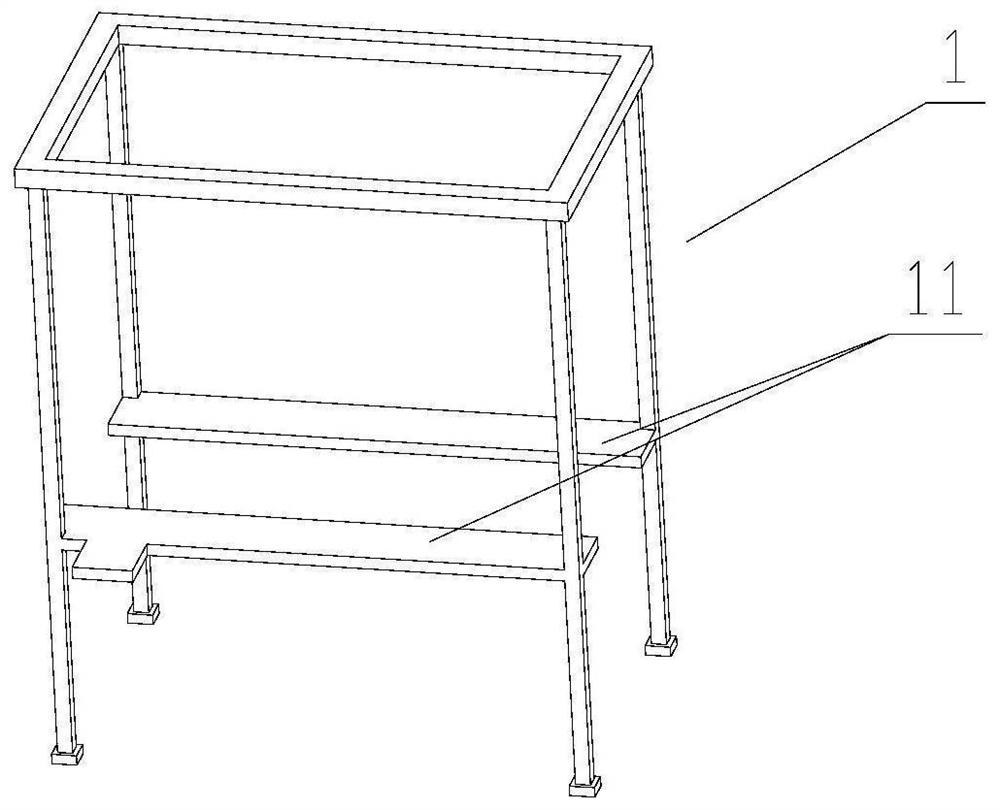

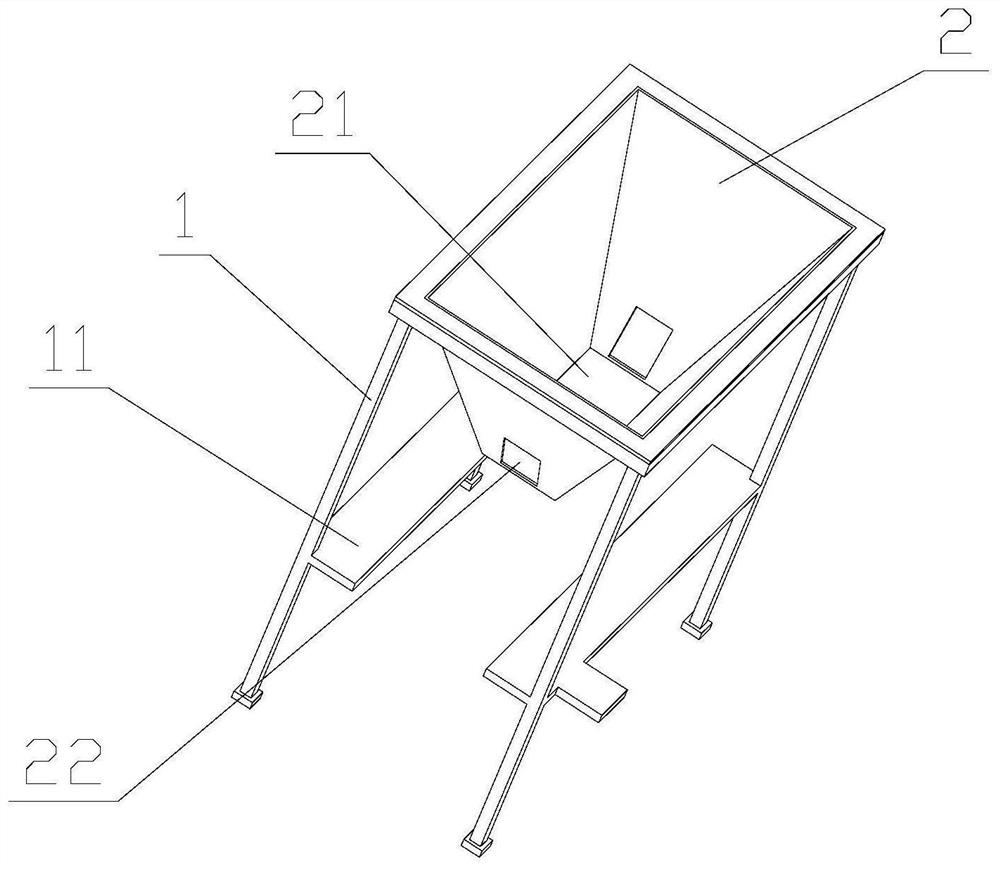

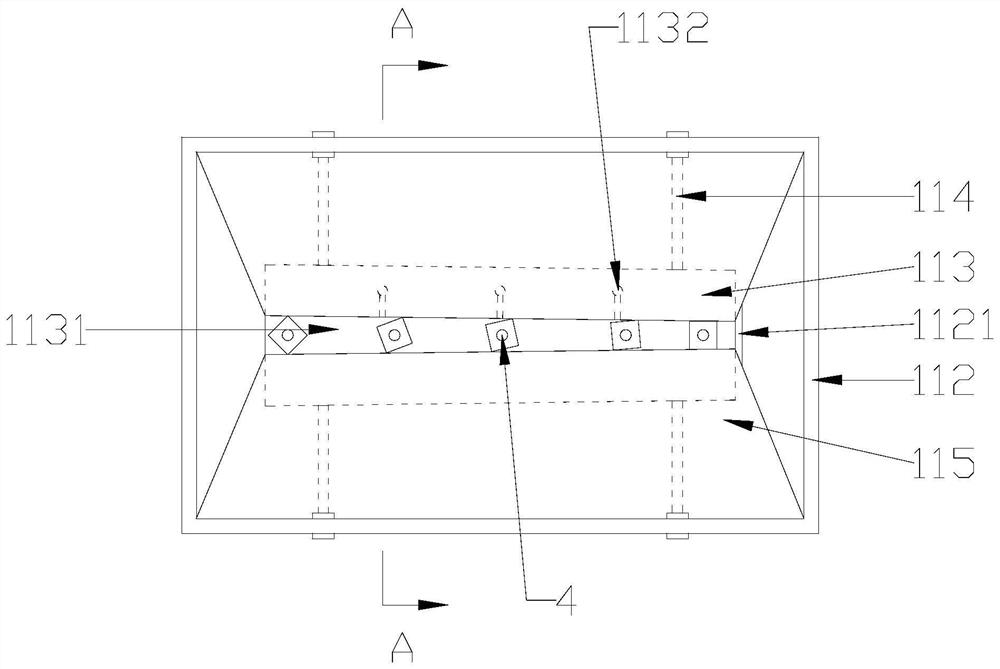

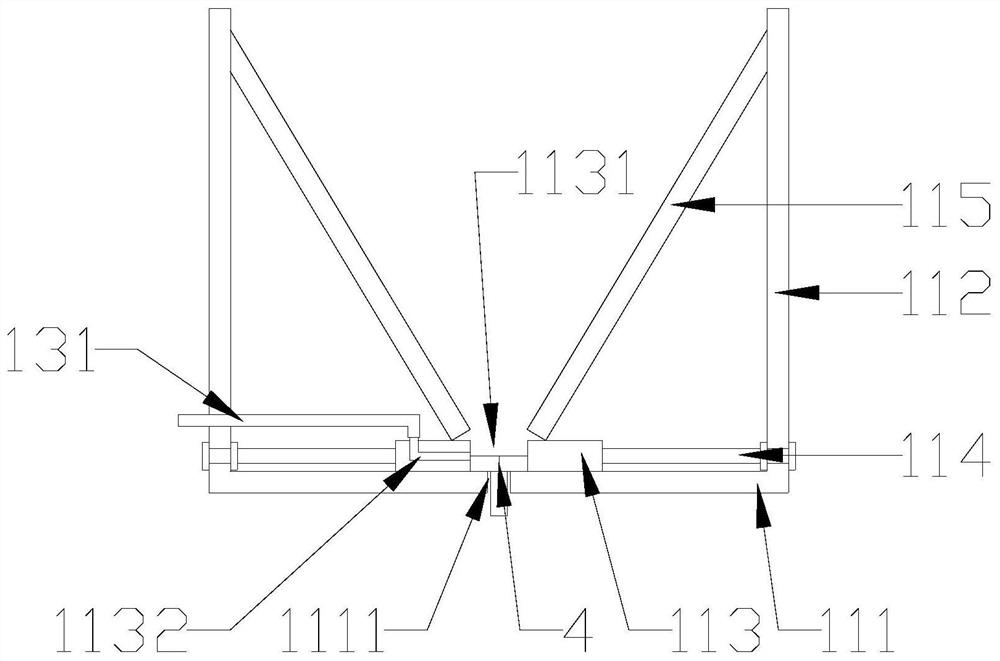

Automatic cover finishing machine

ActiveCN102390699AEnsure consistent orientationOrganize fastStacking articlesConveyor partsAgricultural engineeringEngineering

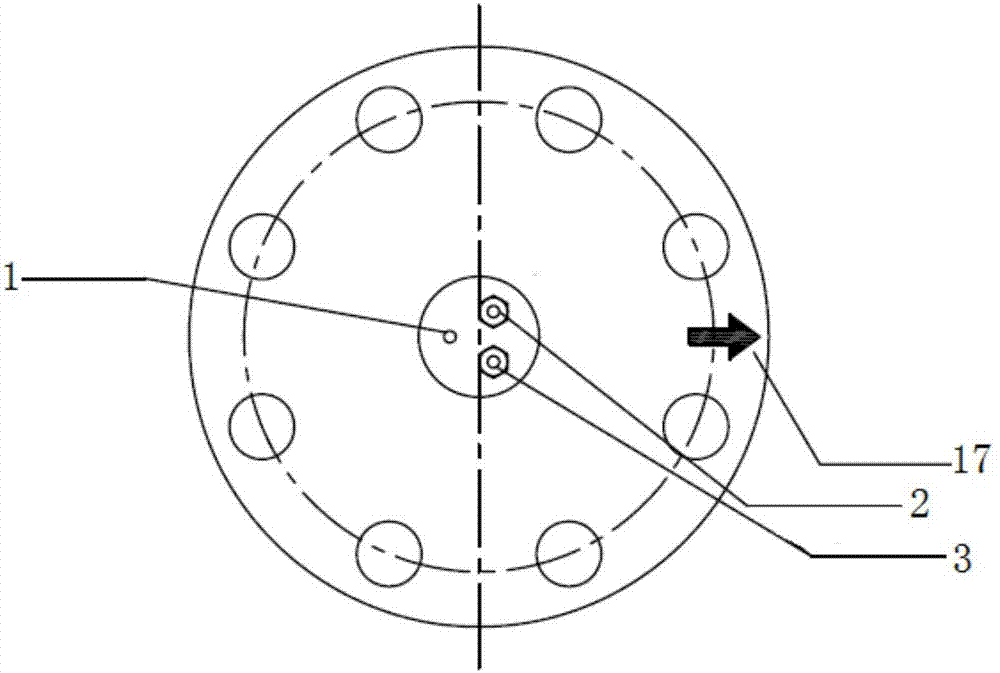

The invention relates to an automatic cover finishing machine which comprises a frame, a cover distributing mechanism and a cover conveying mechanism, wherein the cover distributing mechanism and the cover conveying mechanism are fixed on the frame respectively; the cover distributing mechanism comprises a cover storage groove, a motor, a distributing bush, a centrifuged turntable and a turntable driving mechanism; the cover storage groove is round; a cover outlet is formed on the bottom end of side surface of the cover storage groove; the inlet of the cover conveying mechanism is connected with the cover outlet; the centrifuged turntable is rotatably fixed on the bottom surface of the cover storage groove; the turntable driving mechanism is connected with the centrifuged turntable; the motor is fixed on the frame; the output shaft of the motor is parallel with the bottom surface of the cover storage groove; the distributing bush is fixed on the output shaft of the motor, extends into the cover storage groove and is positioned at the rear side of the cover outlet. In addition, the machine also comprises a cover detection and turning mechanism and a cover stacking mechanism. The machine can automatically finish the covers, and the finishing speed is fast and the machine is particular suitable for the industrial production in large scale.

Owner:GUANGDONG HUASHENG PLASTIC

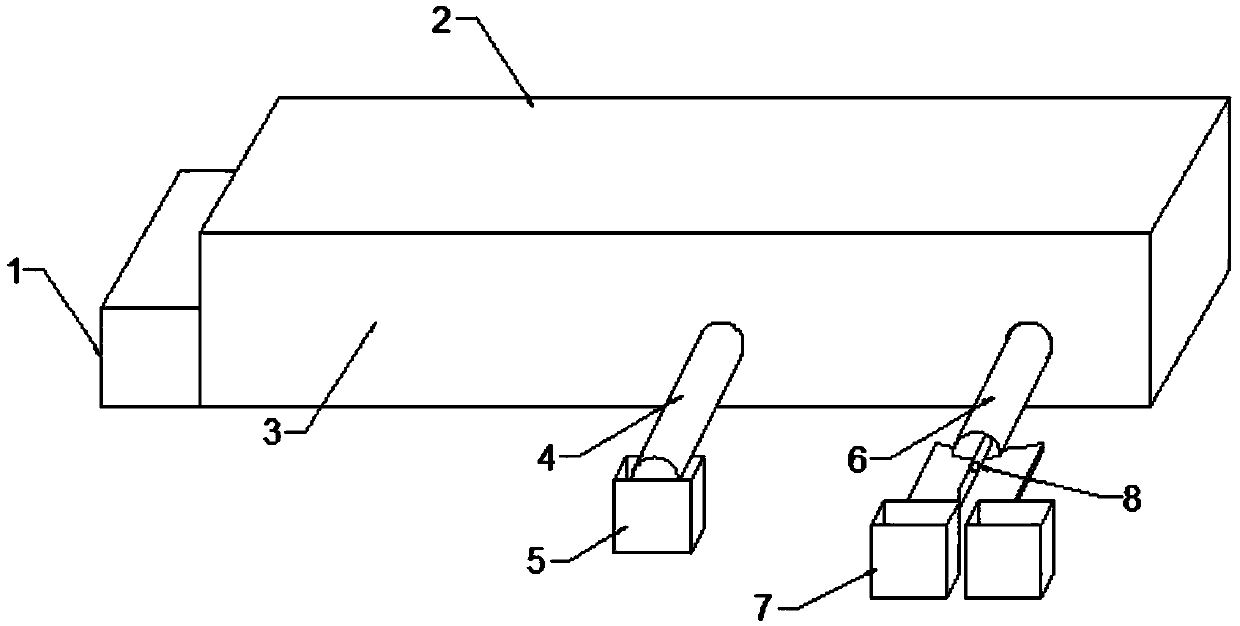

Method and device for turning over bamboo chips used for summer sleeping mat

InactiveCN103056929AEnsure consistent orientationEasy to machine weaveMulti-purpose machinesVeneer manufactureEngineeringBuoyant force

The invention discloses a method and device for turning over bamboo chips so as to ensure that green surface or yellow surface of each bamboo chip faces towards the same direction absolutely. The method and the device are characterized in that decoration and drilled or knitted bamboo chips are placed in a container filled with liquid; the liquid is in a stationary or flowing state; the specific gravity of the liquid is larger than that of bamboo chips; the bamboo chips are raised to the surface of the liquid under the effect of buoyant force; the specific gravities of the green surface and the yellow surface of the bamboo chip are different, and the bamboo is turned over in the raising process, so that the yellow surface of the bamboo chip floating on the surface of the liquid faces upwards, and the green surface faces downwards. The method is unique and simple, easy to implement, low in cost and high in efficiency, and the same orientation of green surface or yellow surface of each bamboo chip can be ensured absolutely so as to facilitate decoration and drilling of bamboo chip and mechanical knitting of mahjong summer sleeping mats.

Owner:YIYANG HUAYU MACHINERY CO LTD

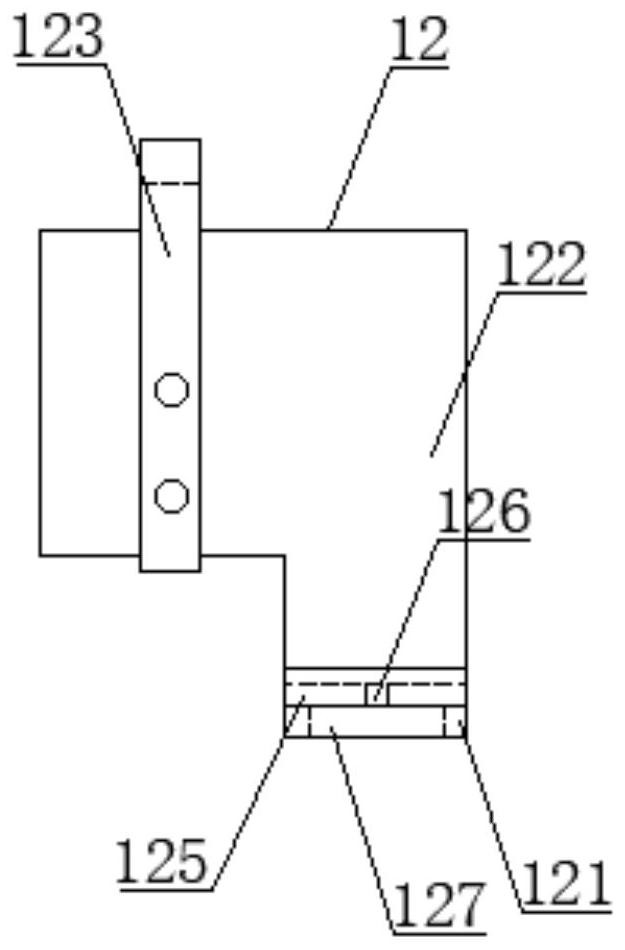

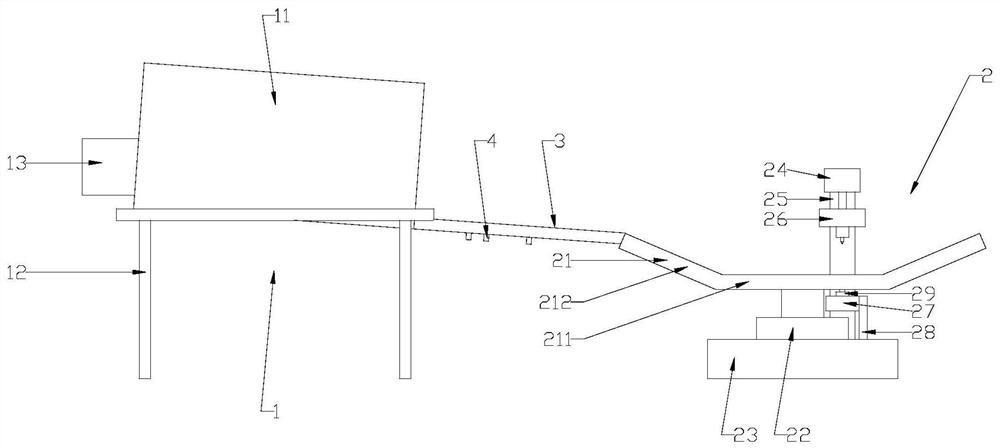

Automatic feeding transfer robot of boss kit

ActiveCN111573208AAutomatically correct orientationOrientationConveyor partsSteering wheelRobot hand

The invention relates to the technical field of automobile part machining, in particular to an automatic feeding transfer robot of a boss kit. The robot comprises a base, a conveying mechanism, a correction turnover mechanism, a guiding mechanism and a transfer mechanism. The conveying mechanism comprises a vibration disc and a vibration sliding way. A detection stopping mechanism is arranged at the outer side of the end, away from the vibration disc, of the vibration sliding way. The correction turnover mechanism comprises a supporting table and a turnover assembly. The turnover assembly comprises a storage box which is in butt joint with one end of the vibration sliding way and can be turned over. The guiding mechanism comprises an inclined sliding way, a correction guiding sliding way and a reclaiming table which are installed on the supporting table. The transfer mechanism comprises a mechanical hand. The output end of the mechanical hand is provided with a clamping jaw capable ofgrabbing a workpiece on a reclaiming sliding way. According to the technical scheme, a boss kit can be automatically transferred and automatically corrected in the transfer process, and the transfer efficiency is improved.

Owner:DONGGUAN POLYTECHNIC

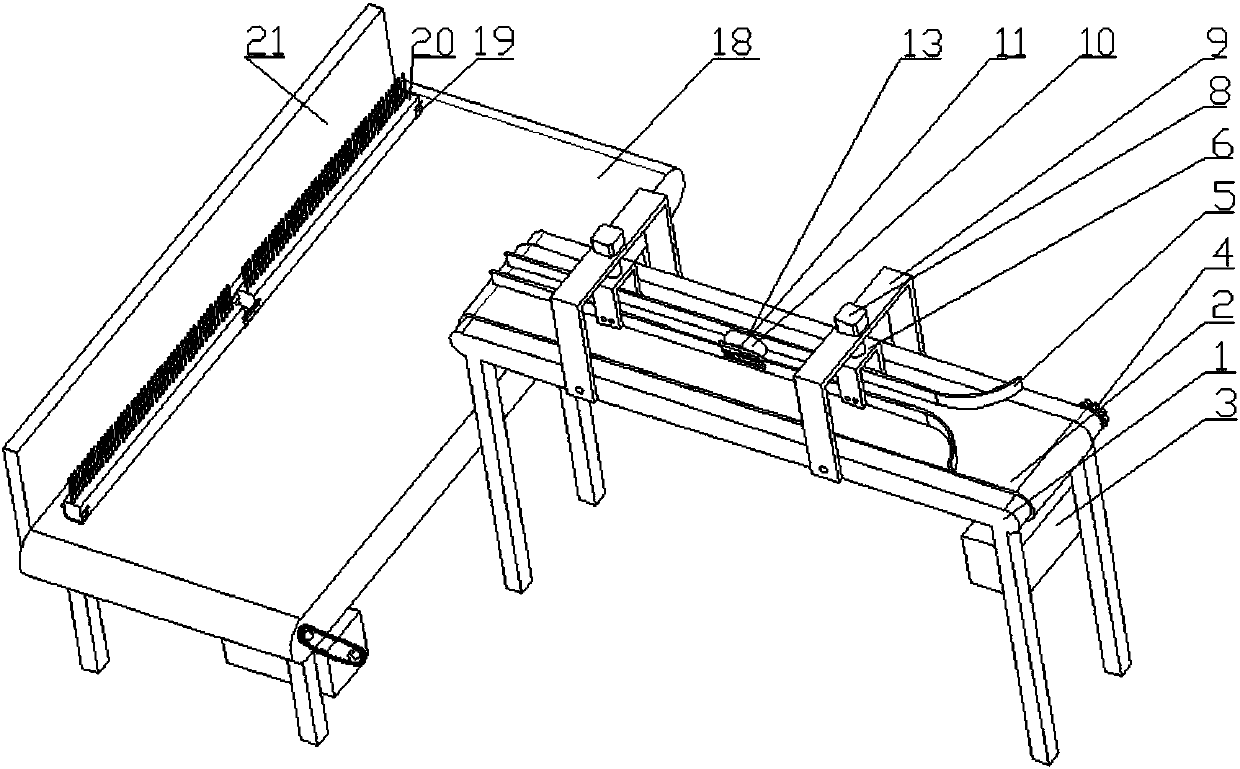

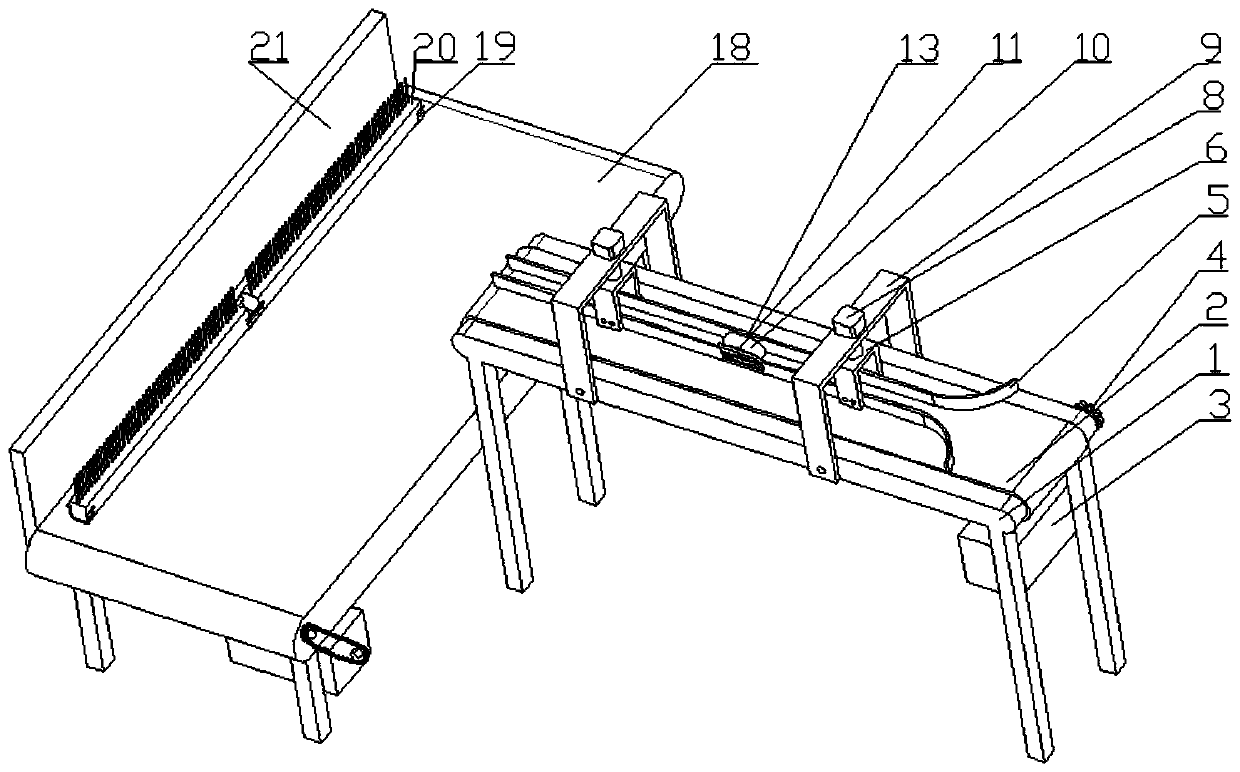

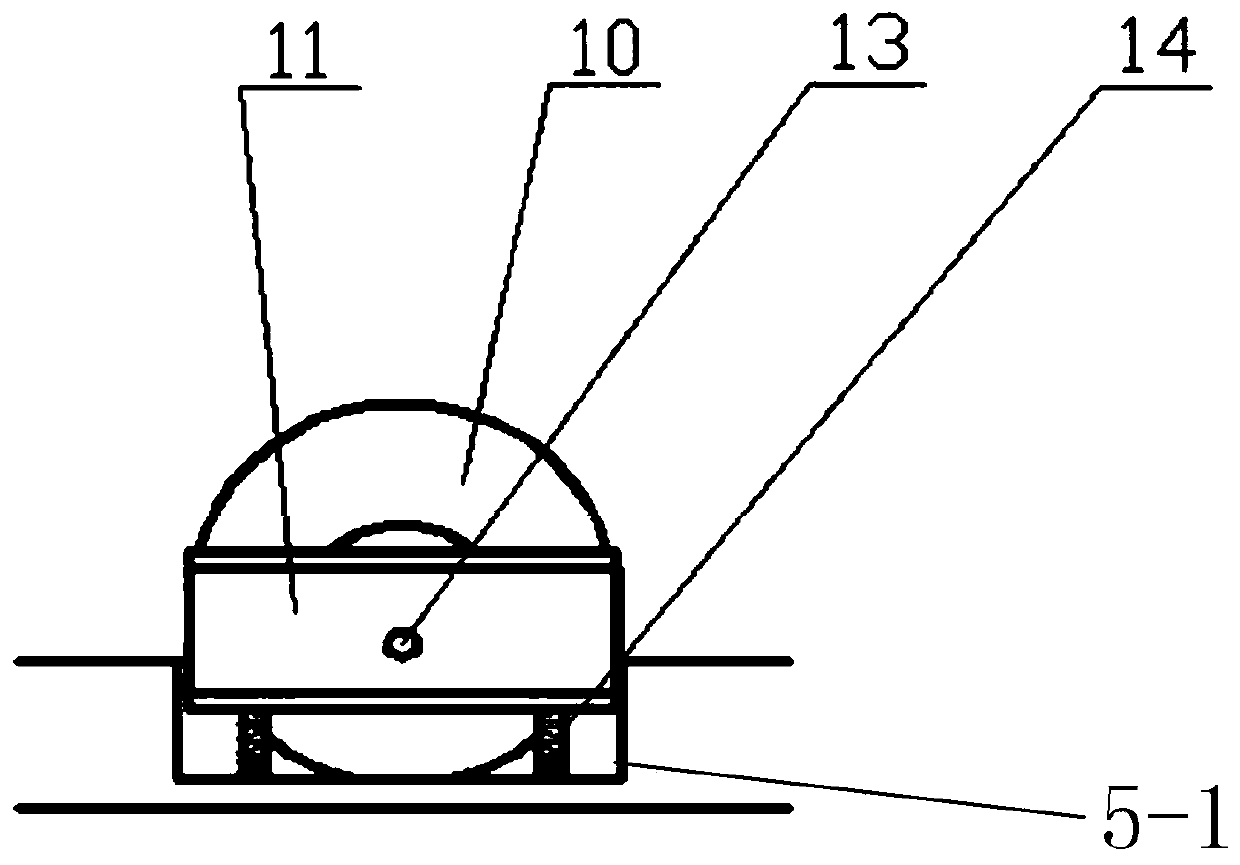

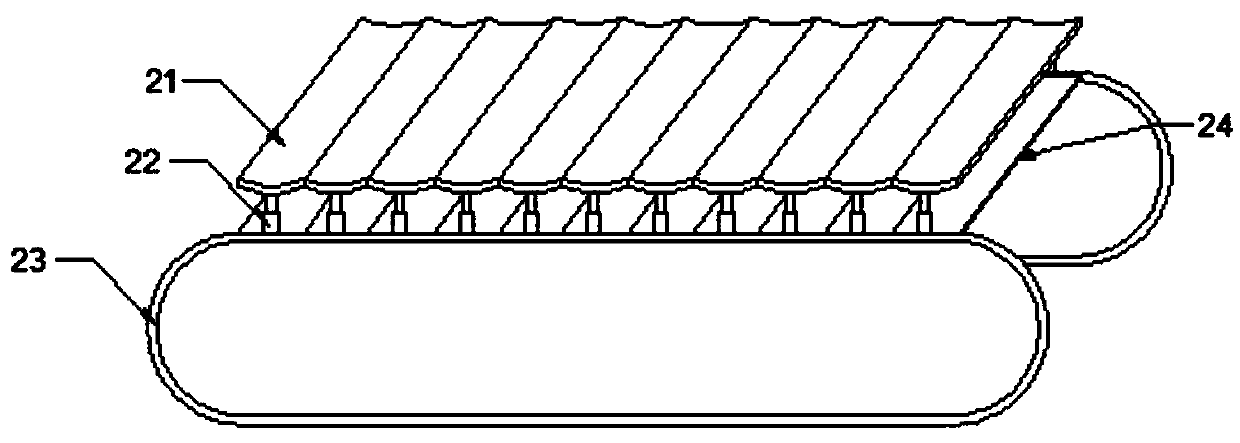

Fresh tobacco leaf stalk sectioning and orderly-clamping device and sectioning and clamping method thereof

The invention discloses a fresh tobacco leaf stalk sectioning and orderly-clamping device and a sectioning and clamping method thereof. Leaf stalks and tobacco leaves are different in flue-curing degree, and accordingly the flue-curing quality is affected. The fresh tobacco leaf stalk sectioning and orderly-clamping device comprises a positioning adjusting assembly, a first belt conveying mechanism, guiding plates, a compressing contour wheel, a Y-shaped cutter, a photoelectric sensor, a second belt conveying mechanism, a fastener, a tobacco clamp and a baffle. The Y-shaped cutter begins to cut main veins from the end faces of tobacco leaf stalks, and the compressing contour wheel is adjusted through a spring to adapt to the different height situations at different positions of the tobaccoleaf main veins. Sectioned tobacco leaves are throwed and conveyed through the first belt conveying mechanism, and leaf stalks fall between two adjacent clamping columns of the tobacco clamp after being in contact with the baffle; when n tobacco leaves are stacked between the two adjacent clamping columns, the tobacco clamp is stepped for one station; when the tobacco clamp is full of tobacco leaves, a motor is driven to stop rotating, the tobacco clamp is taken down and put in a flue-curing room, then a new tobacco clamp is clamped on two fasteners located at an upper tobacco leaf clamping station. The fresh tobacco leaf stalk sectioning and orderly-clamping device achieves automatic and orderly clamping of fresh tobacco leaves and makes the leaf stalk flue-curing time approximate to leaf flue-curing time.

Owner:西安智财全技术转移中心有限公司

Bottle opening steering and arranging equipment for wine bottle recycling

ActiveCN113120569AEasy to recycle and transportEnsure consistent orientationConveyorsConveyor partsWine bottleIndustrial engineering

The invention relates to the field of wine bottle recycling, in particular to bottle opening steering and arranging equipment for wine bottle recycling. The bottle opening steering and arranging equipment comprises a supporting frame, a containing plate, a guide conveying mechanism, a conveying mechanism and the like. The containing plate is fixedly connected to the supporting frame, the guide conveying mechanism is arranged on the containing plate, and the conveying mechanism is rotationally connected to the supporting frame. Through a clamping steering mechanism, a rotating shaft drive a connecting plate and a clamping block to move downwards, the clamping block clamps a bottle body of a wine bottle with the bottle bottom facing the direction of a first straight gear, it can be known according to the tooth number of a second rack that the connecting plate drives the clamping block to rotate by 180 degrees, the clamping block drives the wine bottle to rotate by 180 degrees, and a bottle opening of the wine bottle faces the direction of the first straight gear, so that it is guaranteed that openings of all wine bottles face the same direction, and follow-up workers can conveniently put the arranged wine bottles into a recycling basket to be transported and recycled.

Owner:HUBEI JINGBO HAILONG GLASSWARE

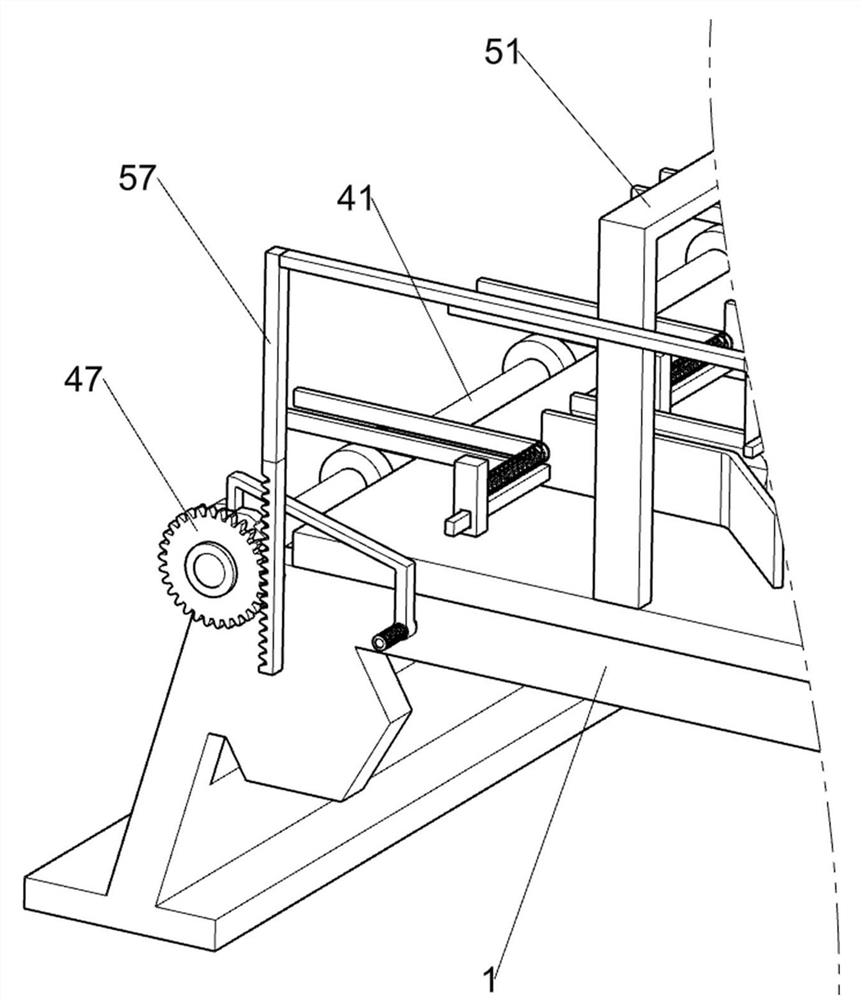

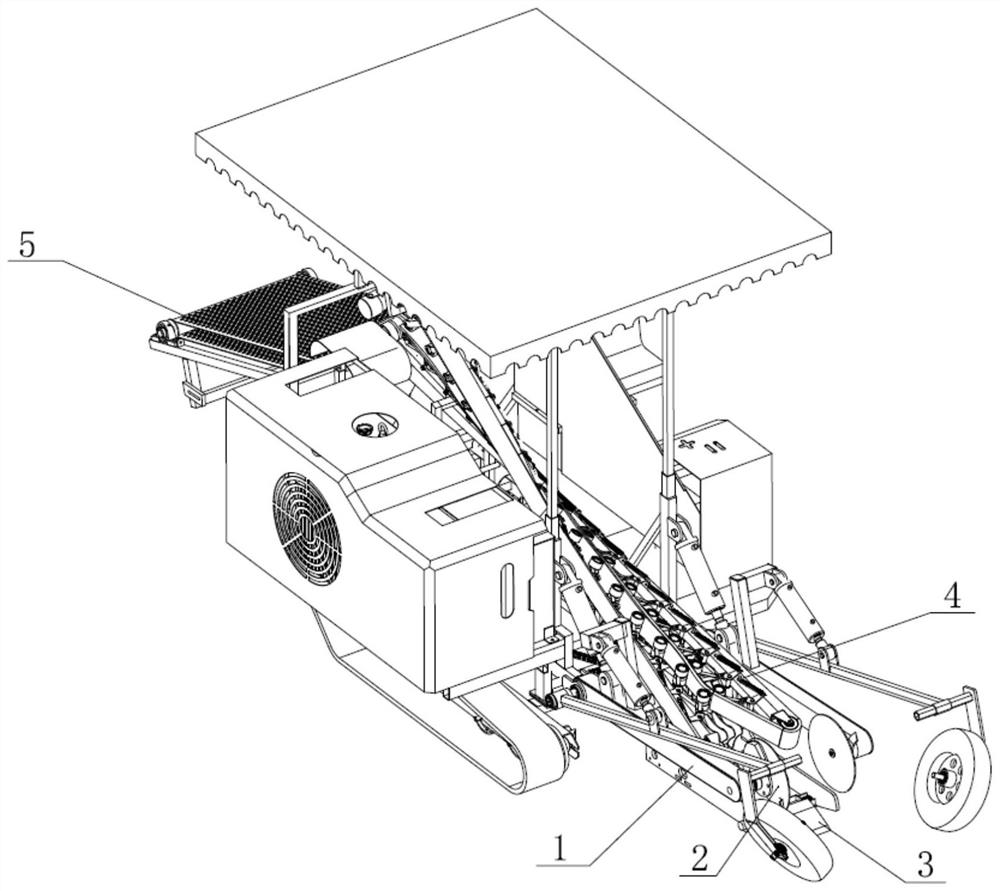

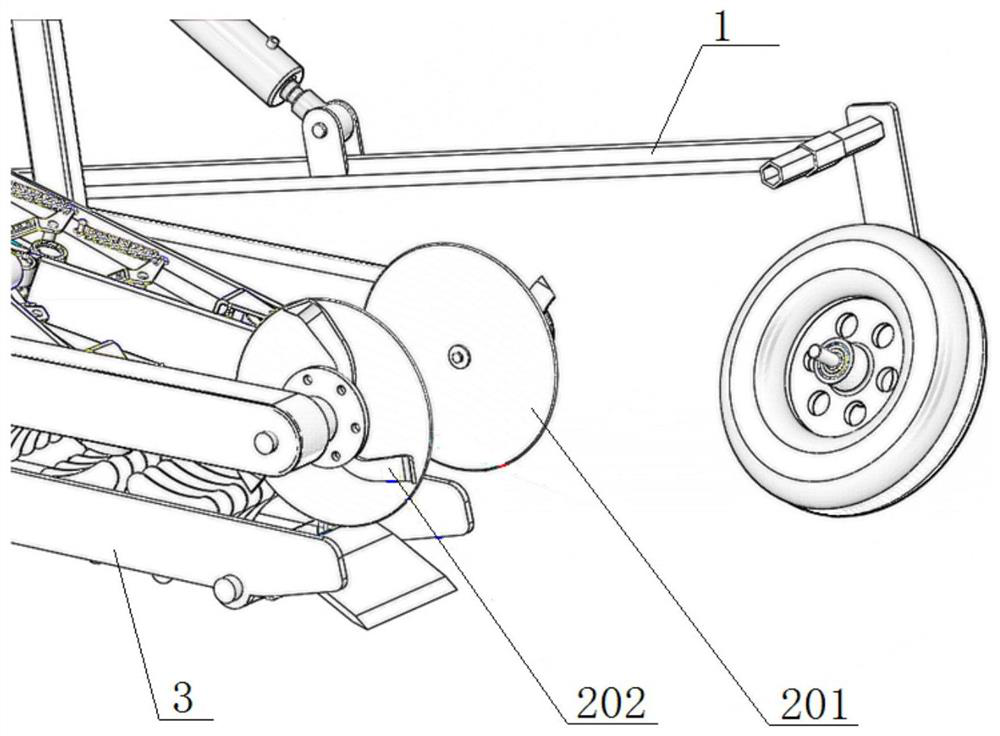

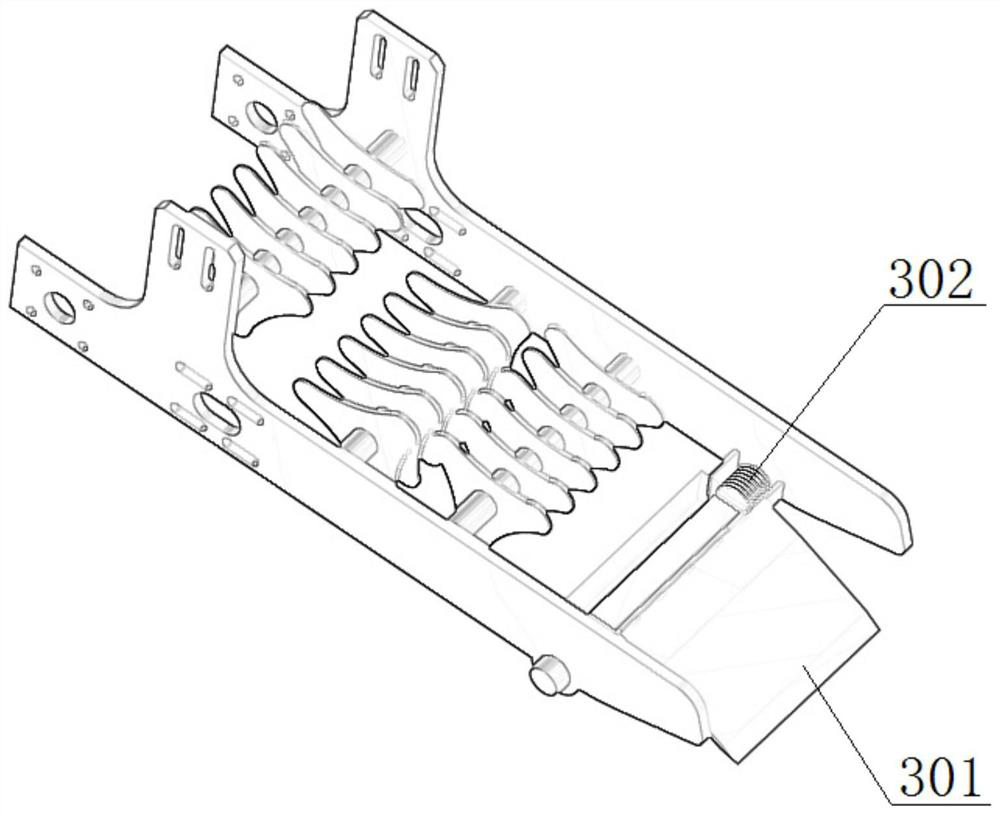

Self-propelled green Chinese onion combine harvester

InactiveCN112753350ASolve congestionReduce digging resistanceLiftersDiggersAgricultural scienceAgricultural engineering

The invention relates to agricultural machinery, in particular to a self-propelled green Chinese onion combine harvester. The self-propelled green Chinese onion combine harvester comprises a rack, a soil separating mechanism, a vibration excavating mechanism, a forming torsion mechanism and a quantitative laying mechanism, wherein the soil separating mechanism, the vibration excavating mechanism, the forming torsion mechanism and the quantitative laying mechanism are sequentially arranged on the rack from front to back; the vibration excavating mechanism is located below the soil separating mechanism; the digging mechanism comprises a digging shovel, a spring I, a permanent magnet, a coil and a sliding shaft; the rear end of the digging shovel is fixedly connected with the permanent magnet; the front end of the digging shovel faces the soil separating mechanism; the sliding shaft is sleeved with the spring I, the permanent magnet and the coil; the permanent magnet is located between the spring I and the coil; the two ends of the permanent magnet are fixedly connected with the spring I and the coil respectively; and the two ends of the sliding shaft are fixedly connected with the rack 1. The resistance in the green Chinese onion digging process is reduced, green Chinese onions are conveniently collected, and automatic harvesting of the green Chinese onions is achieved.

Owner:QINGDAO AGRI UNIV

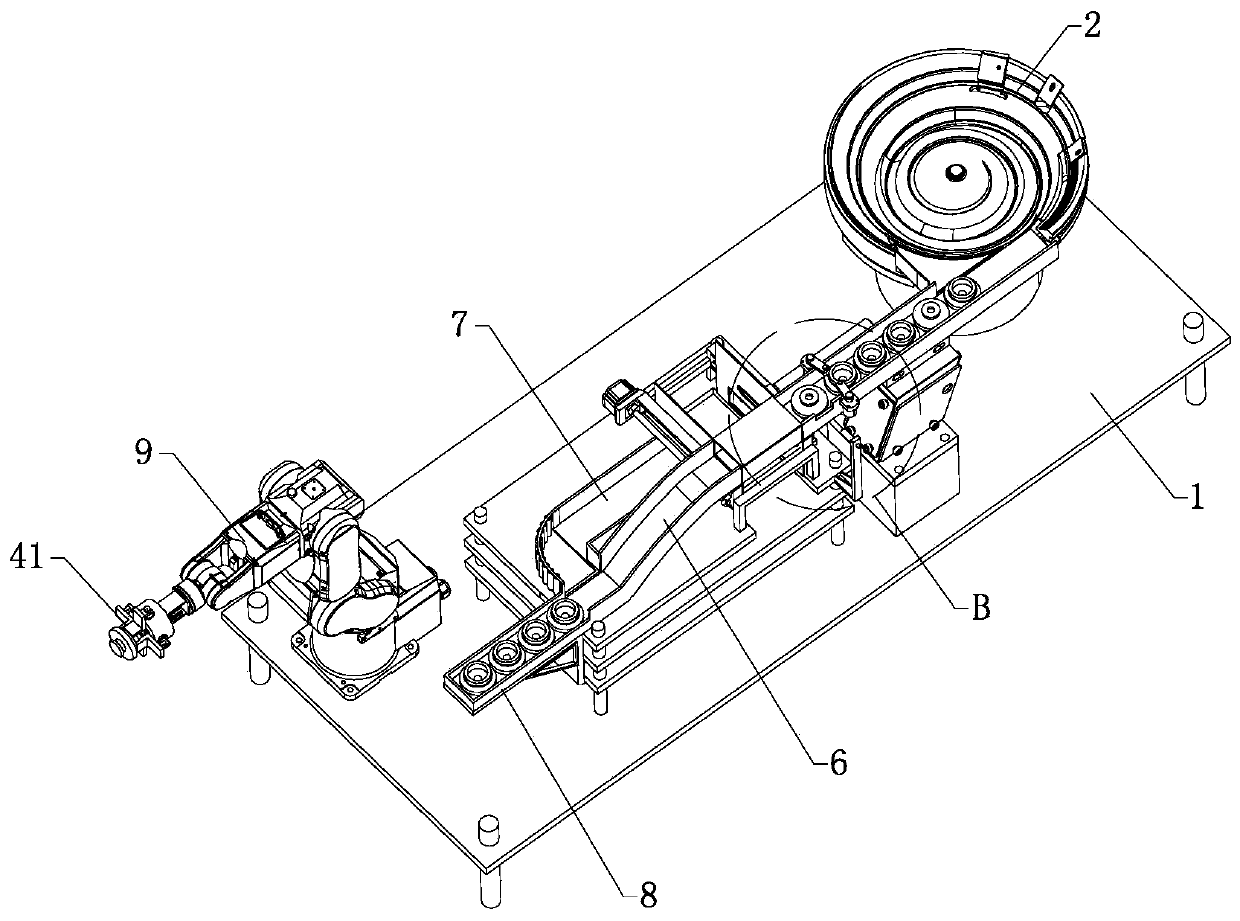

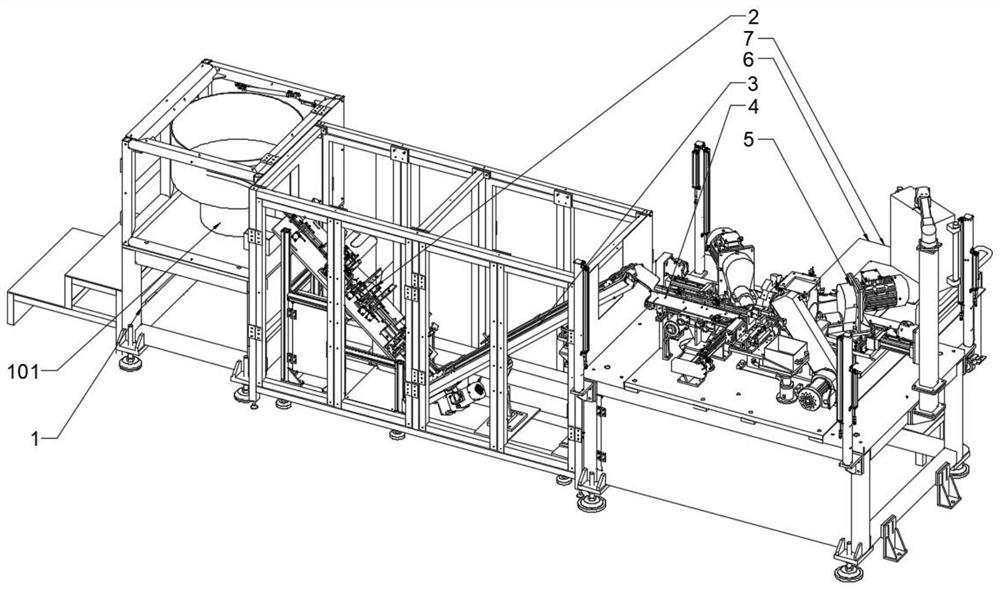

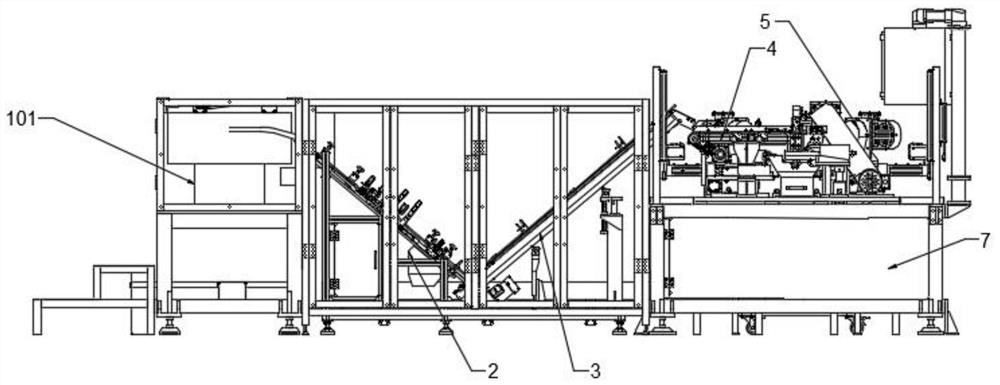

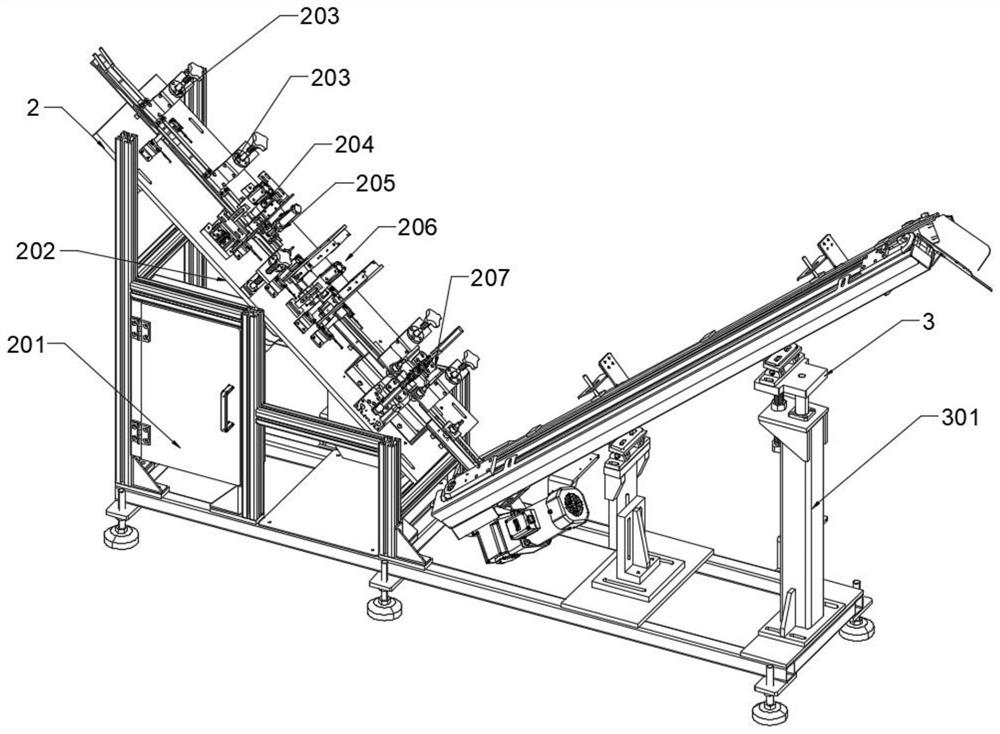

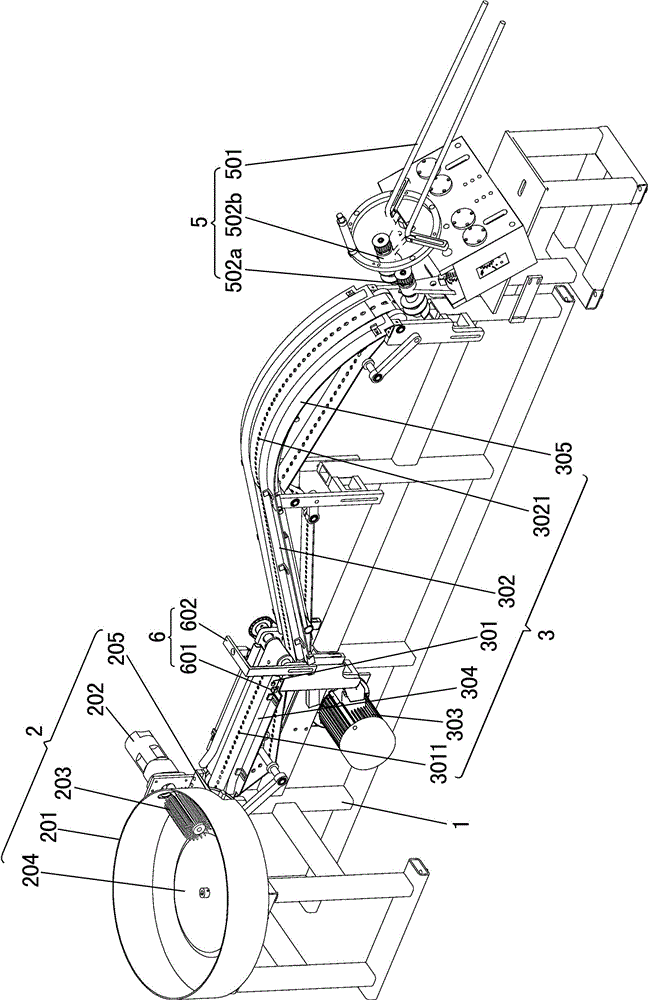

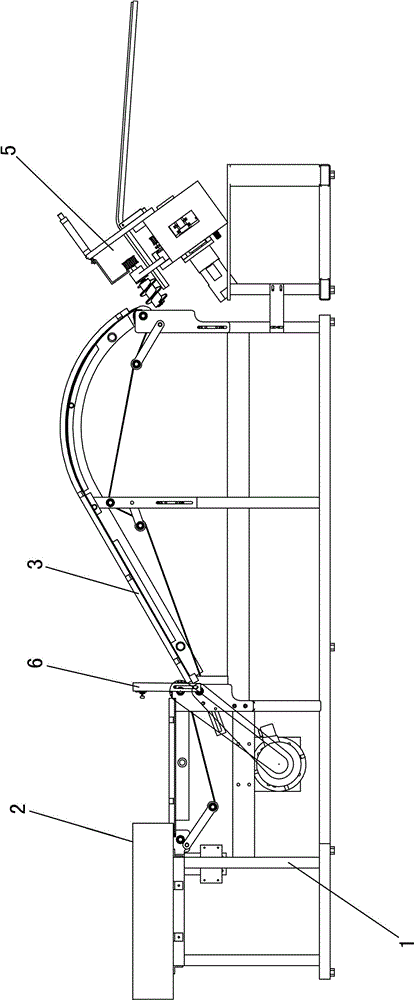

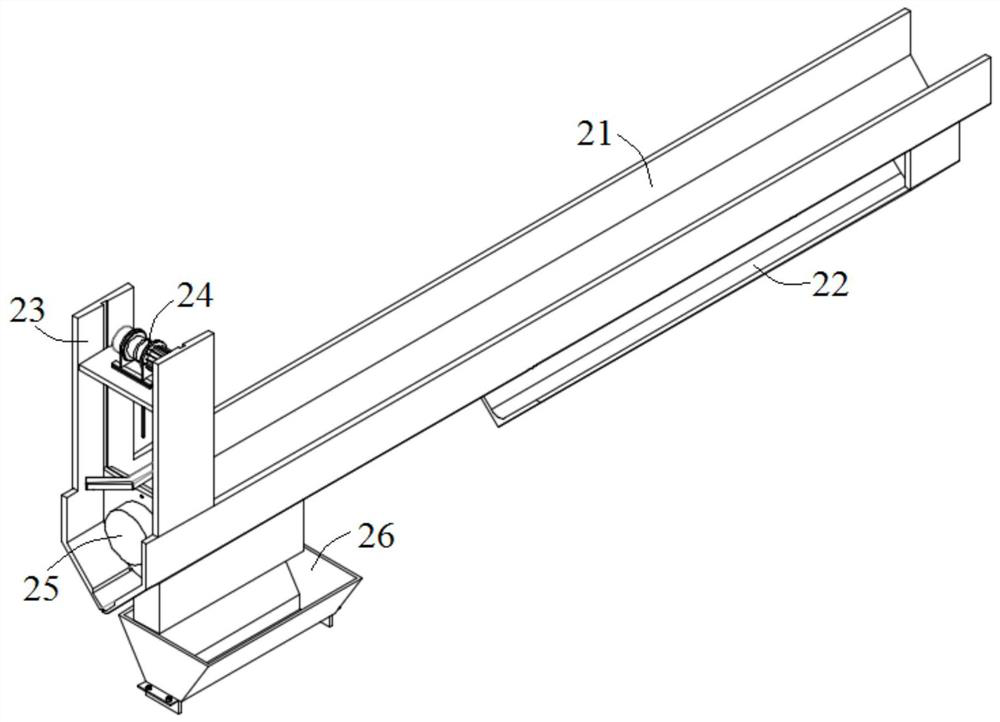

V-shaped conveying type spring conveying and chamfering equipment and using method

InactiveCN112439709AImprove work efficiencyReduce labor costsEdge grinding machinesSortingStructural engineeringMachining

The invention relates to the technical field of spring machining, and particularly provides V-shaped conveying type spring conveying and chamfering equipment. The V-shaped conveying type spring conveying and chamfering equipment comprises a machine frame, a feeding vibration disc, a V-shaped conveying line and a grinding unit are sequentially arranged on the machine frame according to the conveying line of springs, the V-shaped conveying line comprises a sliding slope unit and a climbing slope unit, and the sliding slope unit is further sequentially provided with a large end and small end detecting and discharging mechanism and a wire diameter detecting assembly from top to bottom. The V-shaped conveying type spring conveying and chamfering equipment solves the problems that in the springfeeding process of existing spring machining equipment, the springs need to be manually placed on a conveying belt one by one, so that the labor intensity of workers is high; and when the springs aretransported, screening and adjusting cannot be carried out on the large ends and the small ends of the springs, rejecting, screening and adjusting on a detection line with specific machining requirements for the diameters of the springs cannot be carried out, and unqualified springs cannot be automatically removed through screening when the springs are transported. The invention further provides ausing method of the V-shaped conveying type spring conveying and chamfering equipment. The using method is used for improving the spring chamfering efficiency.

Owner:佛山协航智能装备制造有限公司

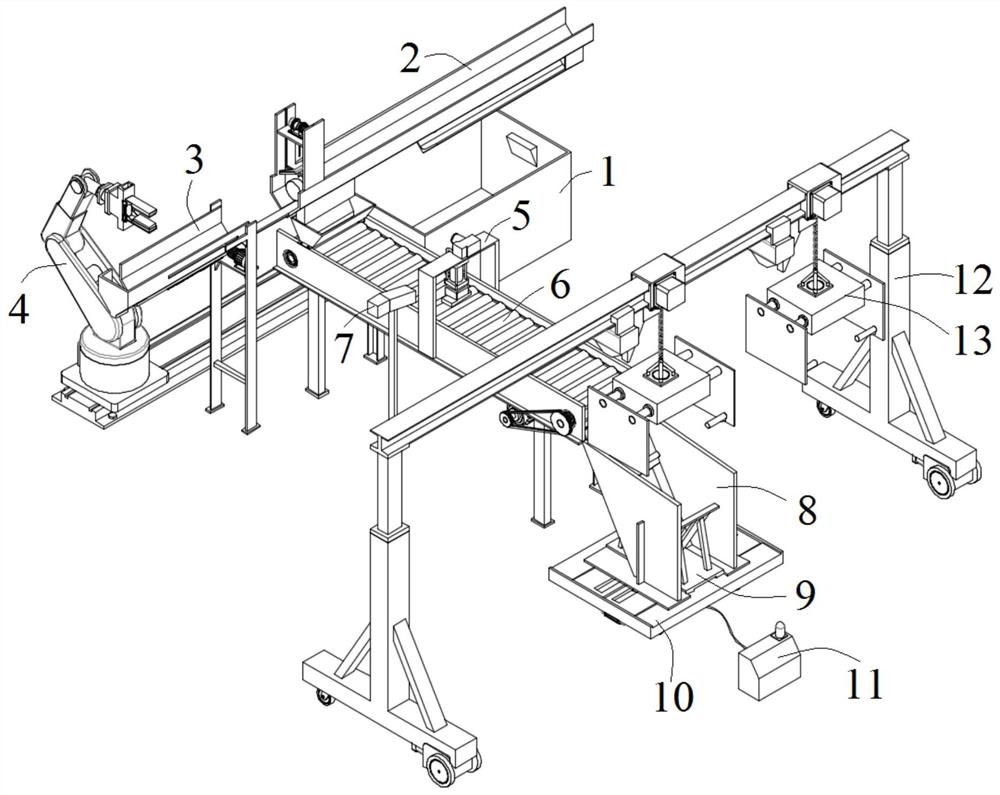

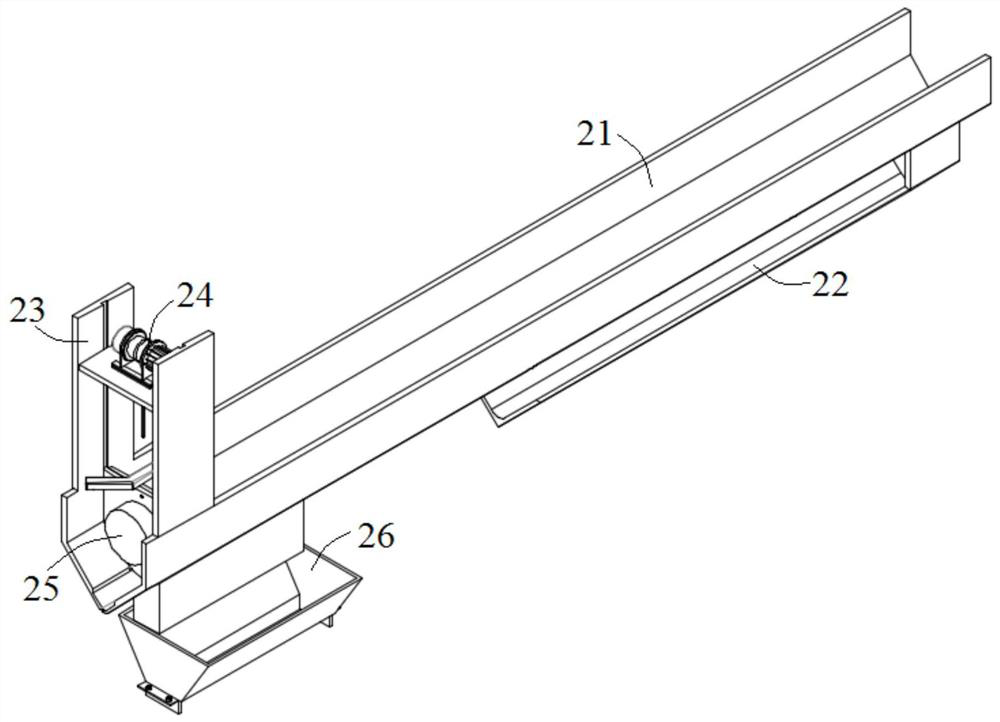

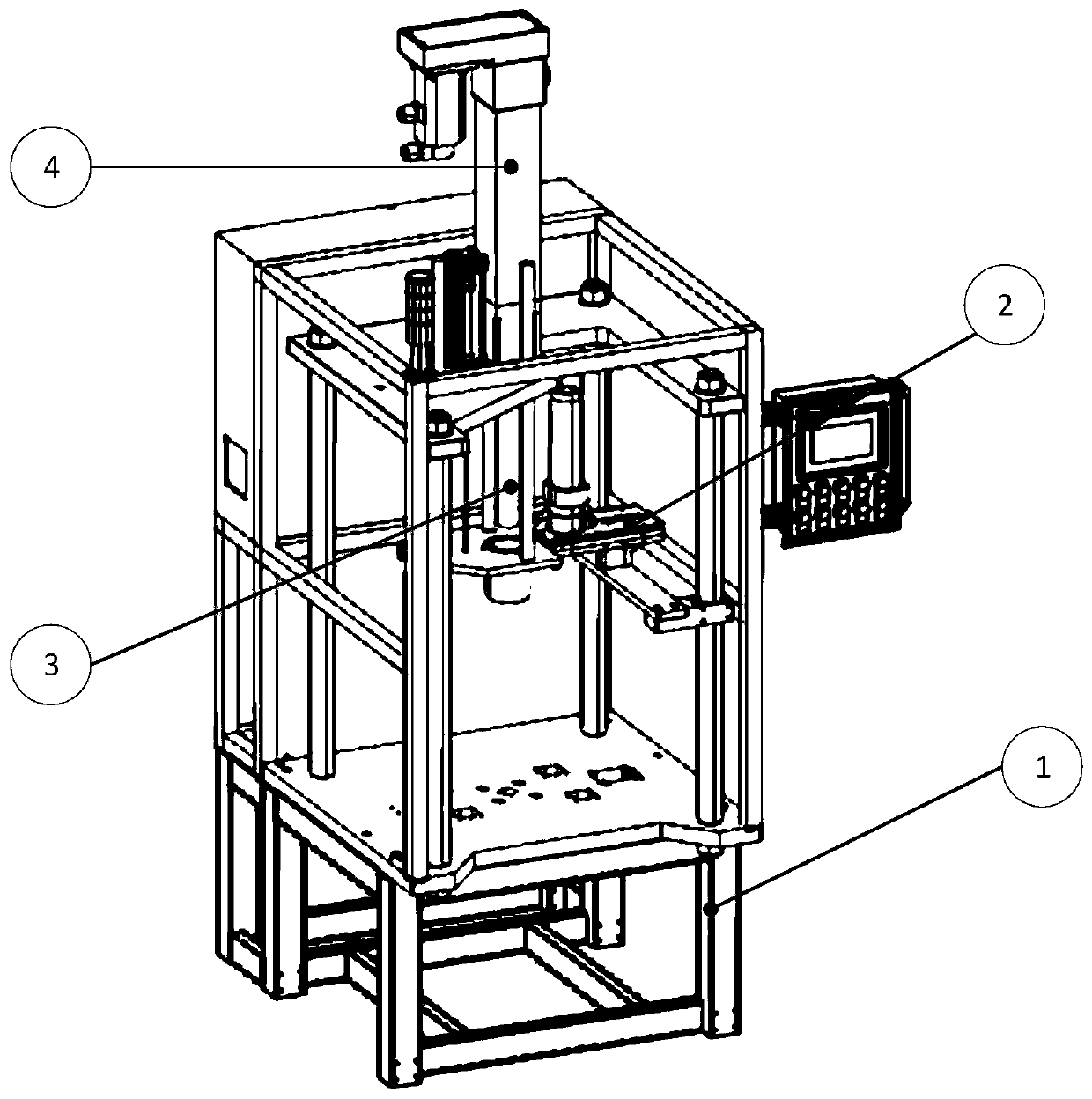

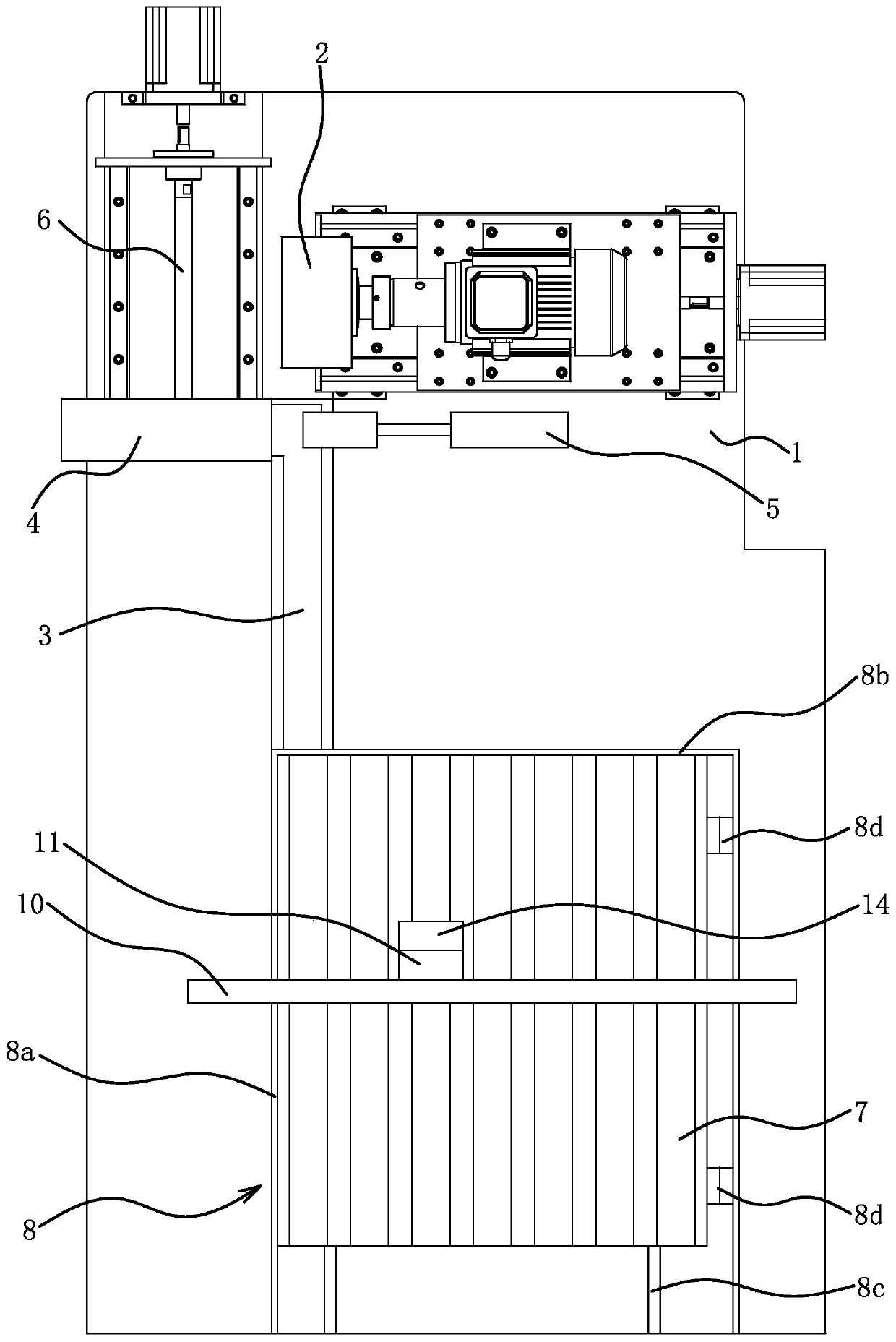

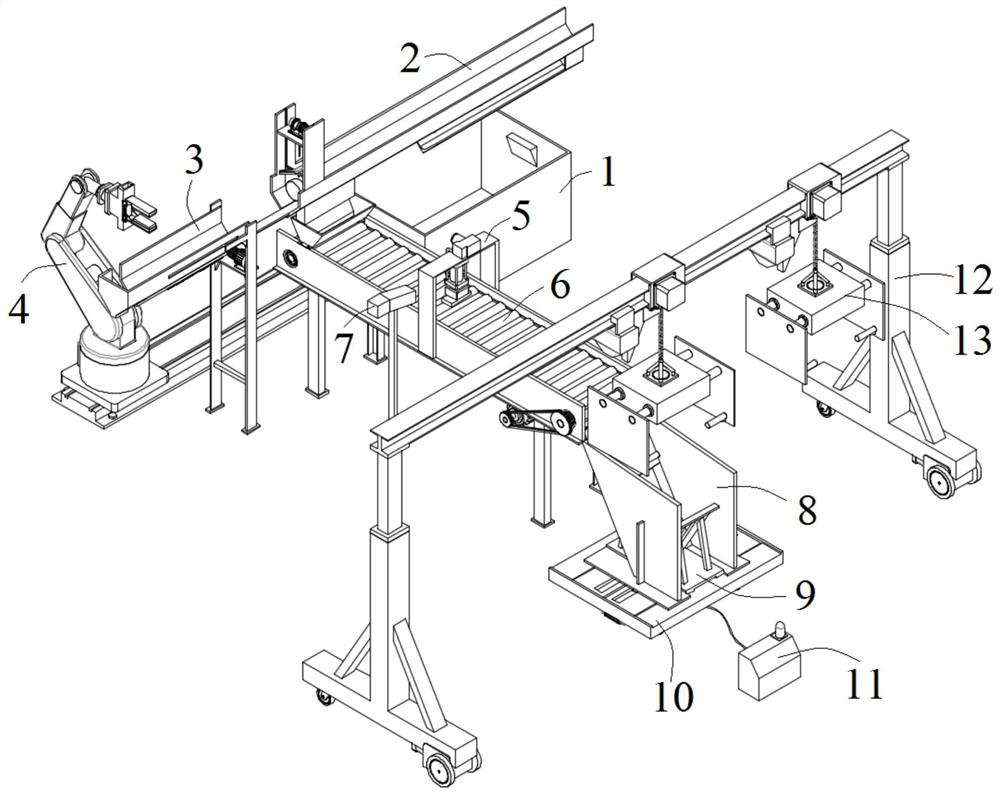

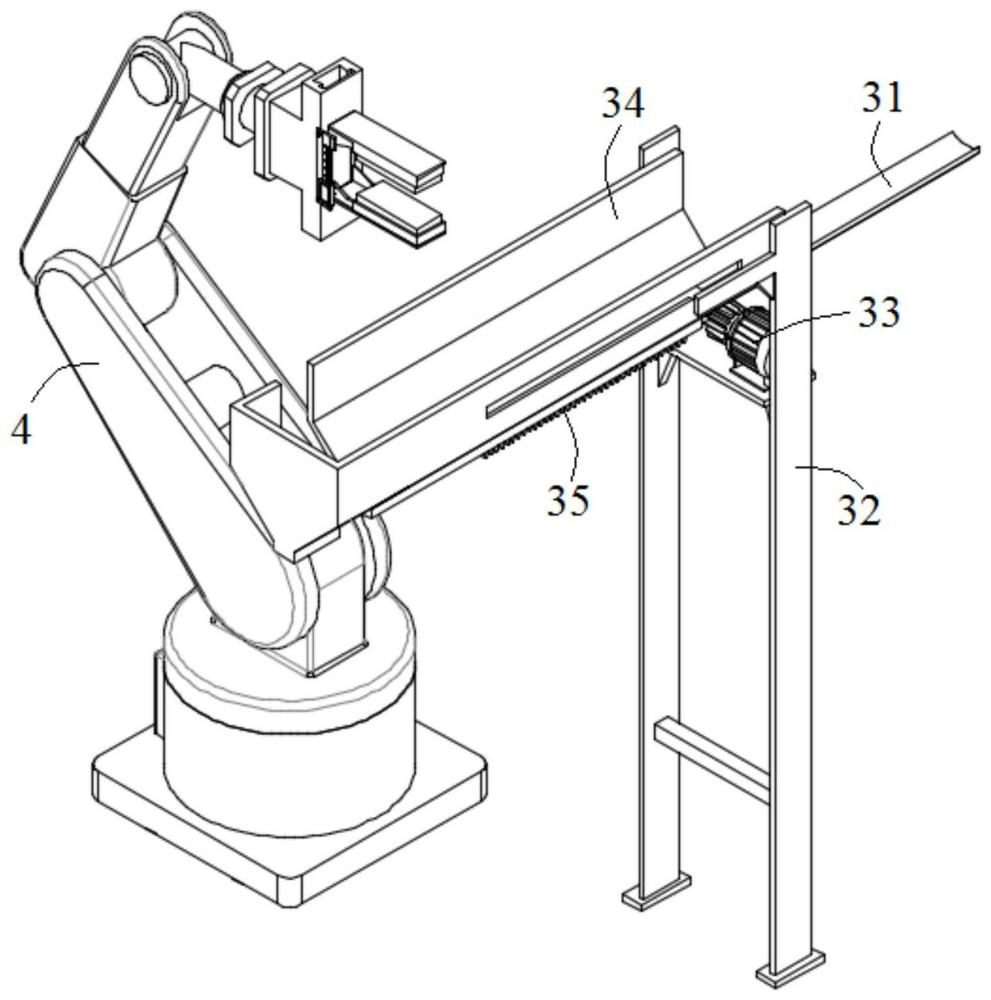

Automatic detecting, stacking and storing integrated production line and method for machine tool discharging drill bits

ActiveCN112173712AAdjust in timeLow costStacking articlesDe-stacking articlesProduction lineRobot hand

The invention discloses an automatic detecting, stacking and storing integrated production line and method for machine tool discharging drill bits, and belongs to the technical field of drill bit machining. The production line comprises a discharge chute, a mechanical arm, an adjusting mechanism, a conveying mechanism, a monitoring mechanism and a triangular frame; one end of the discharge chute is connected with an outlet of a drill bit production machine, and the other end is provided with the mechanical arm for conducting sampling inspection on the drill bits; the conveying mechanism is connected with an outlet of the discharge chute, the monitoring mechanism monitors the orientation of the heads of the drill bits, and the adjusting mechanism adjusts the drill bits of which the head orientation is wrong; and the triangular frame is arranged at an outlet of the conveying mechanism and used for stacking of the drill bits. According to the invention, the drill bits are conveyed to thetriangular frame through a conveying belt to be automatically stacked without manual stacking; and meanwhile, the monitoring mechanism is used for monitoring the orientation of the heads of the drillbits, the drill bits with wrong head orientation are grabbed by a magnet of the adjusting mechanism, a rotating motor rotates, thus, the orientation of the drill bits is adjusted correctly, and consistent orientation after drill bit stacking is guaranteed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

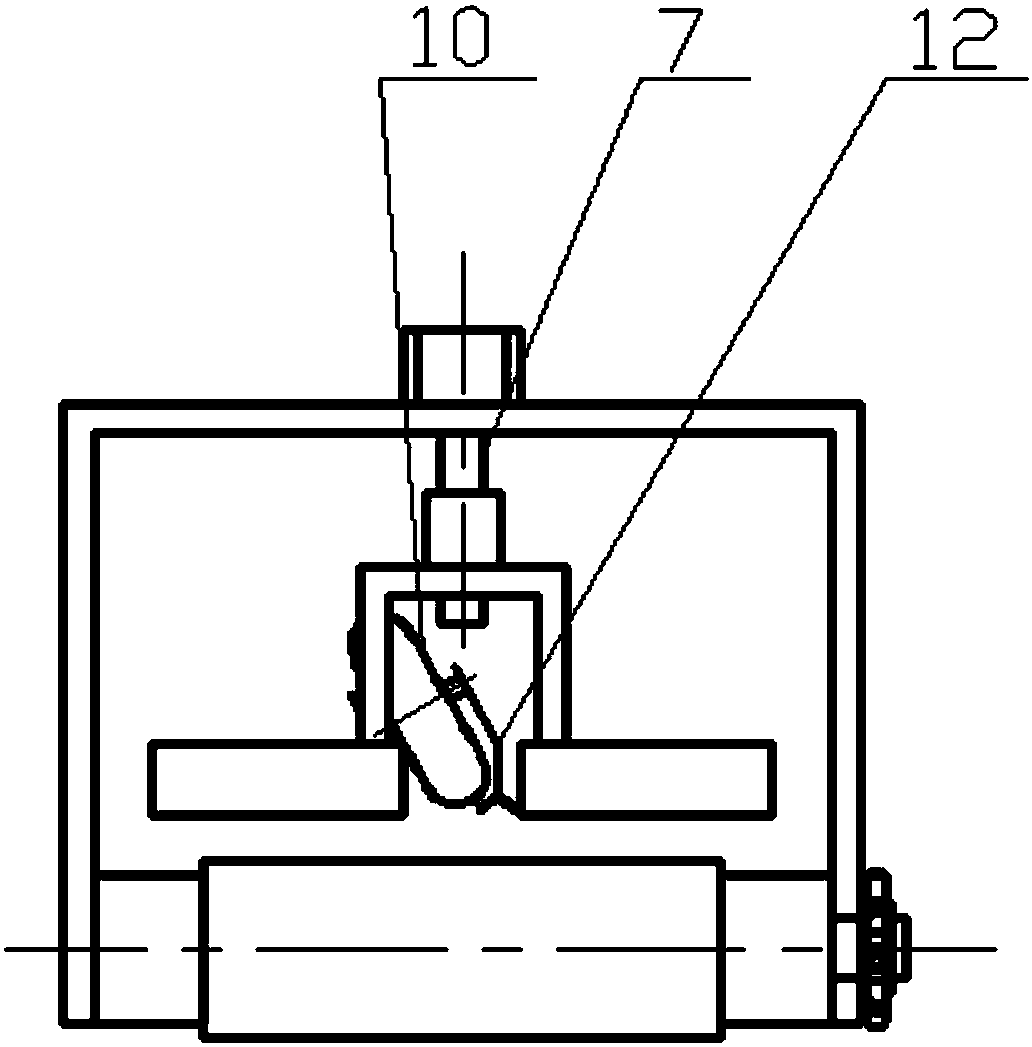

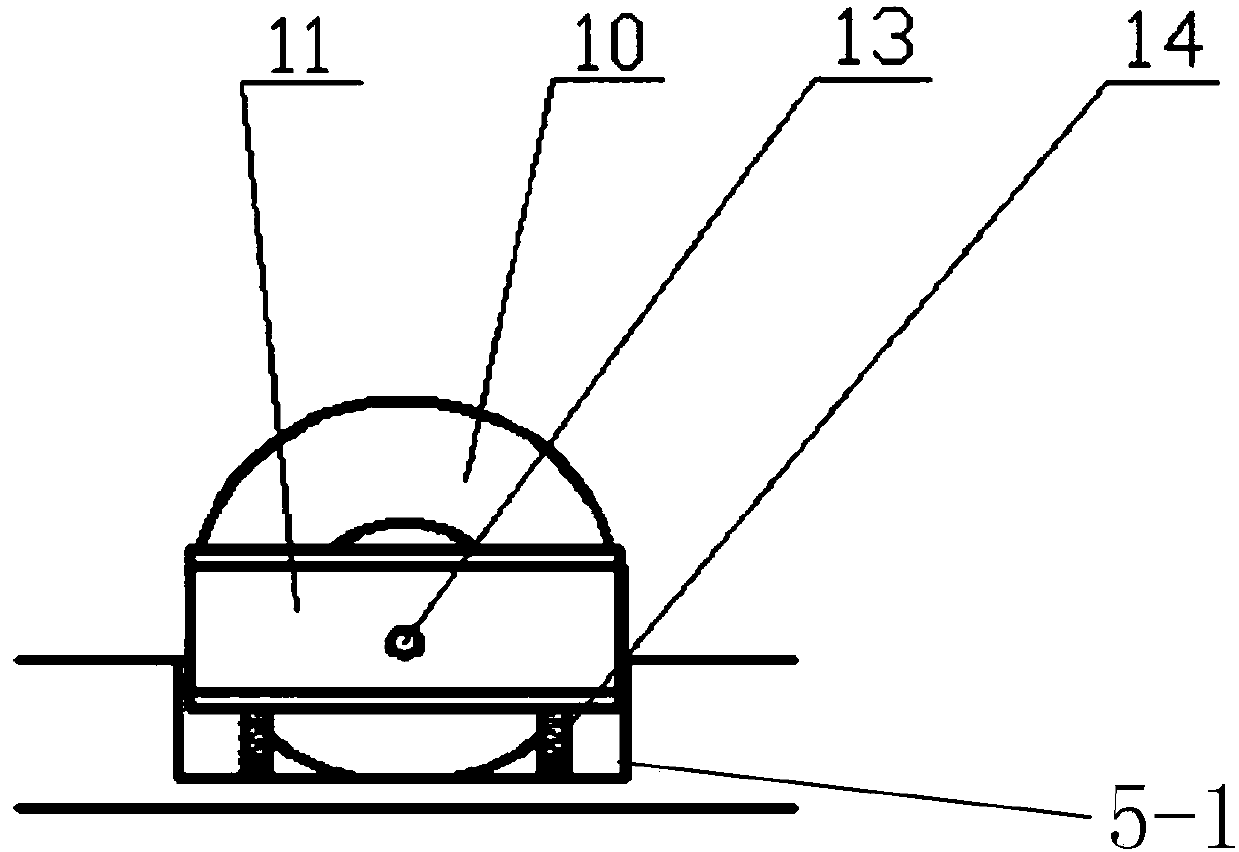

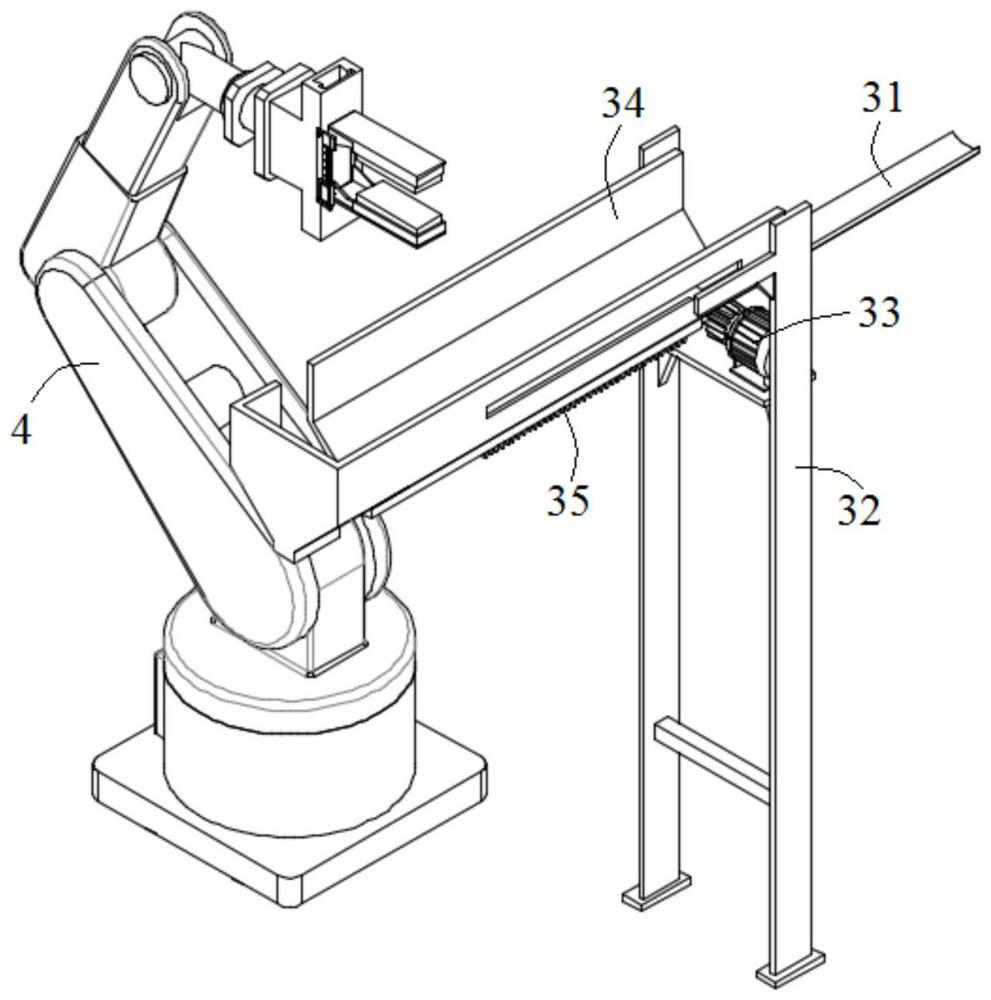

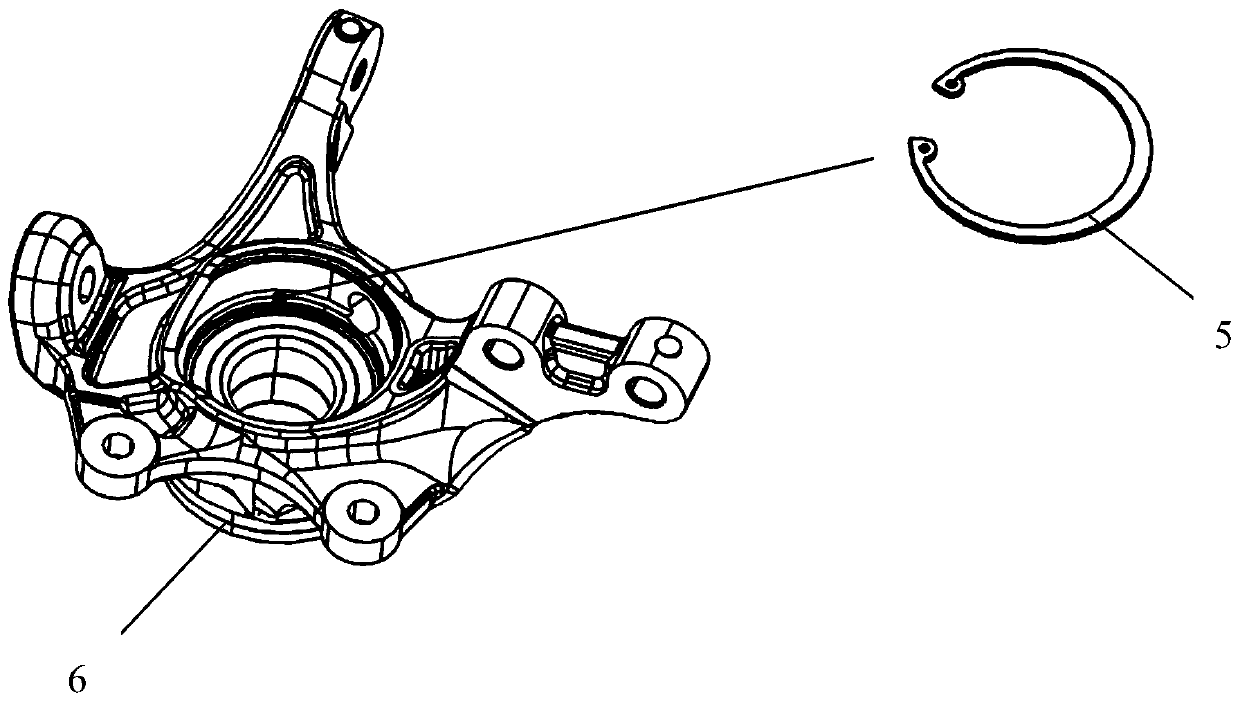

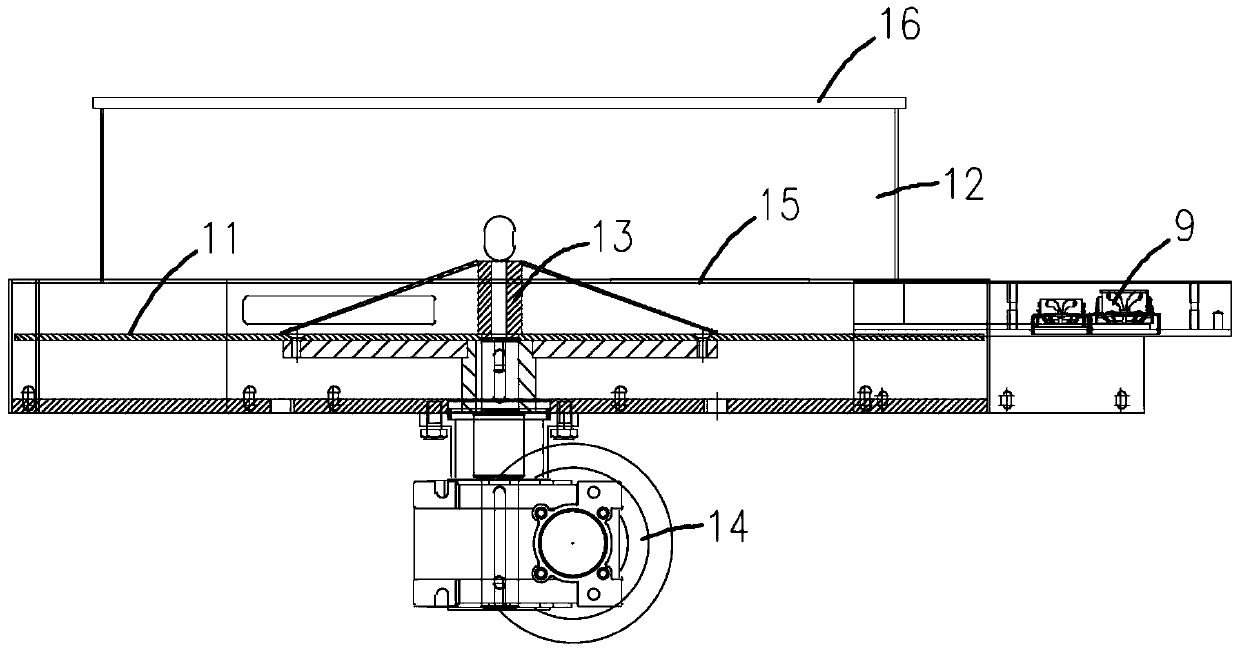

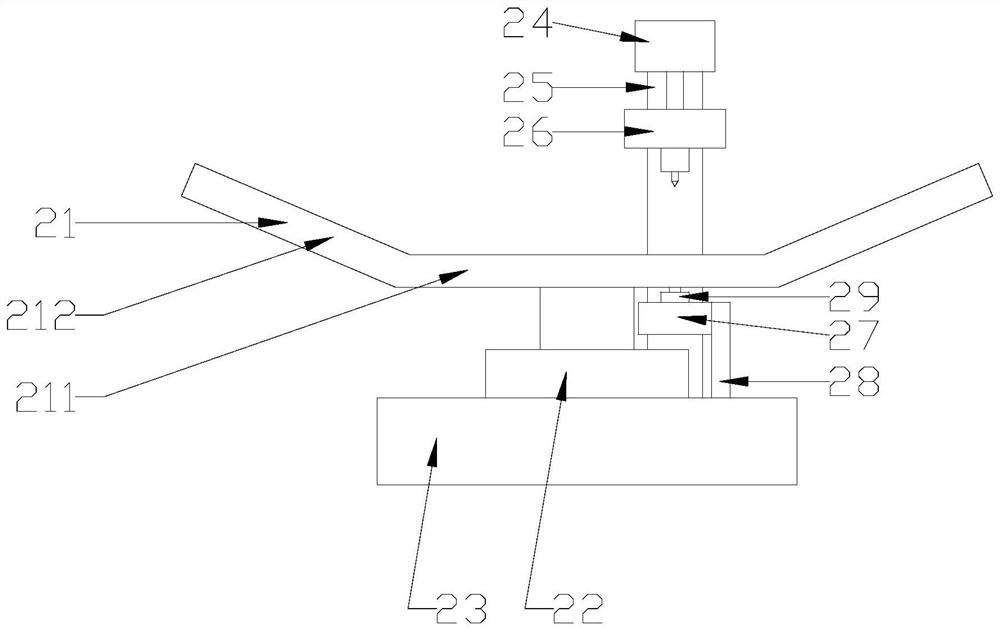

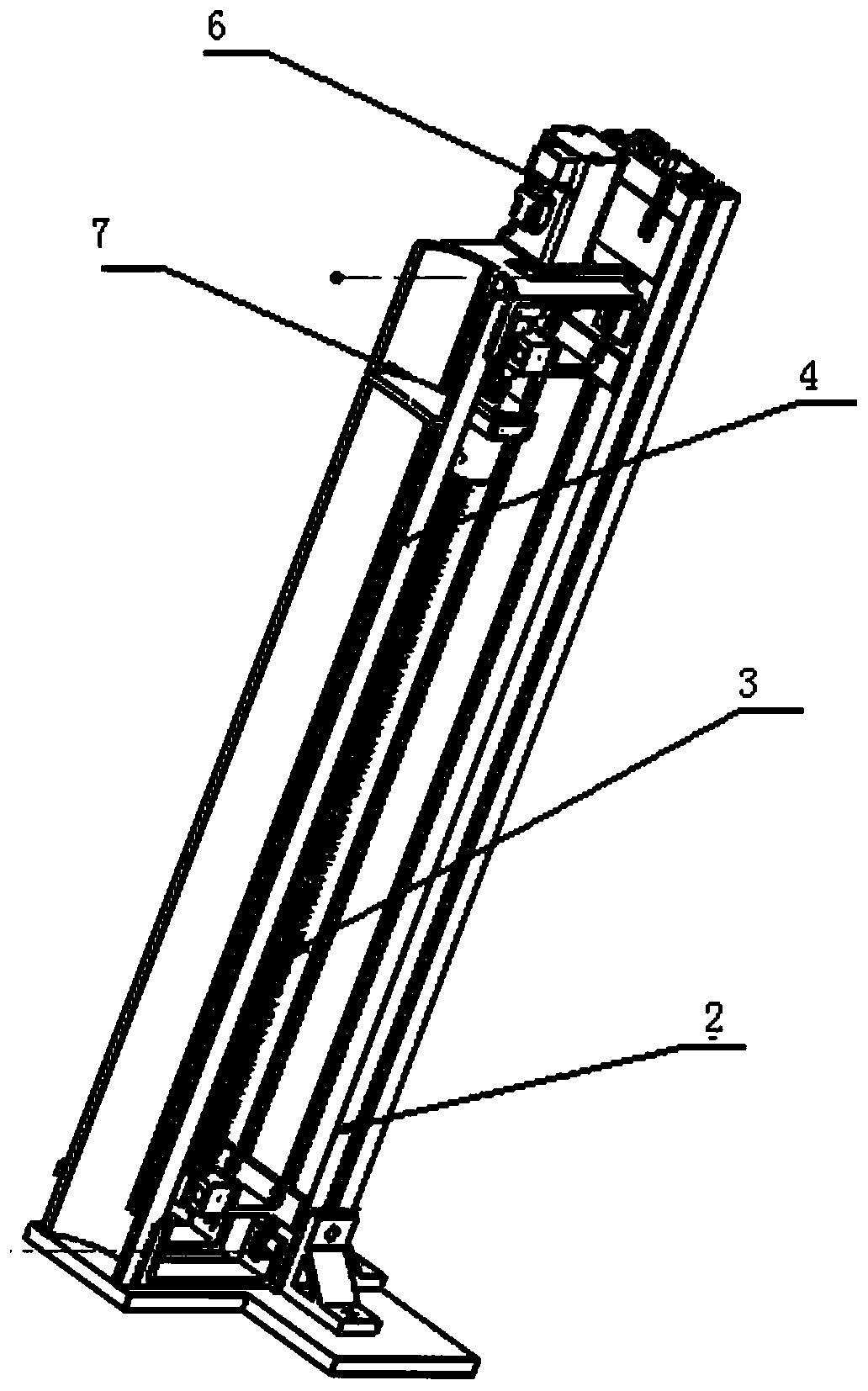

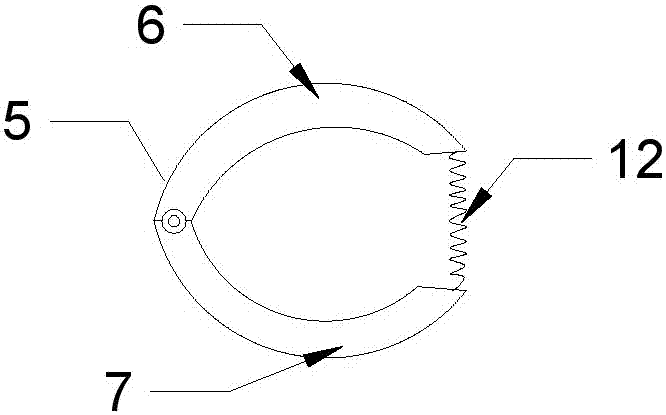

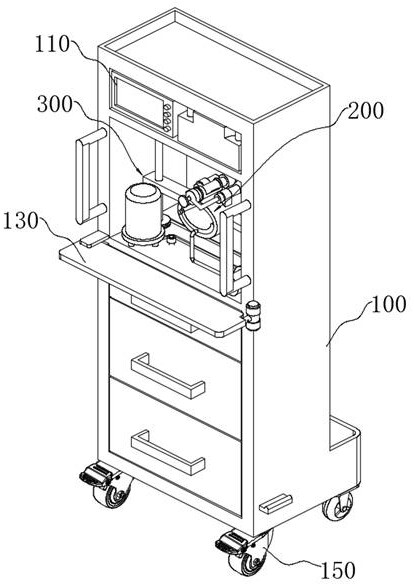

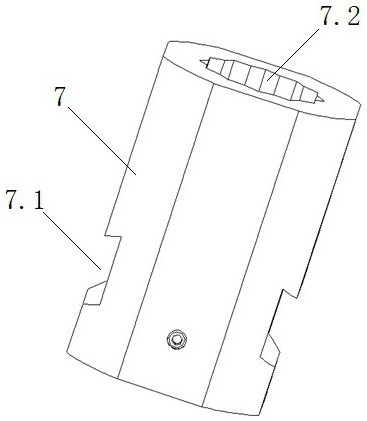

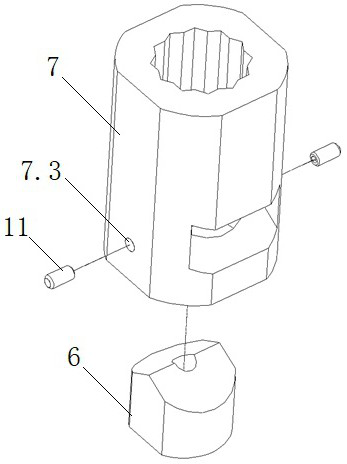

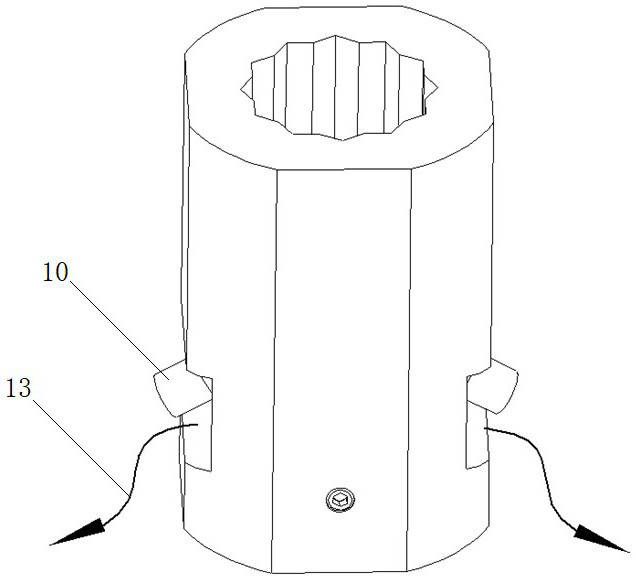

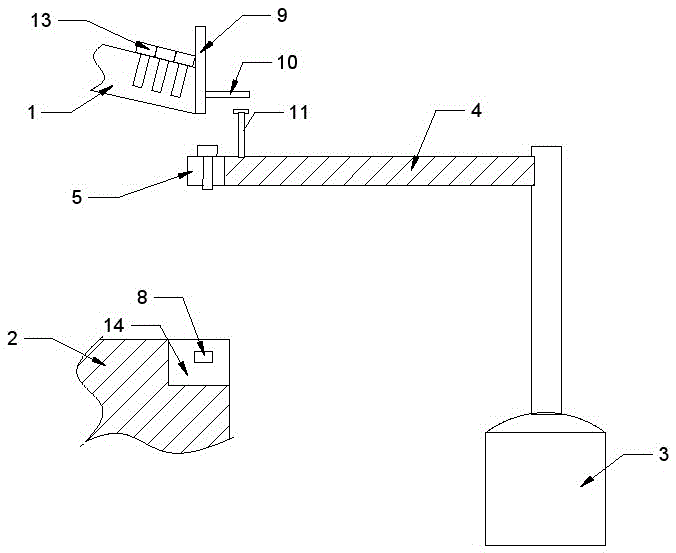

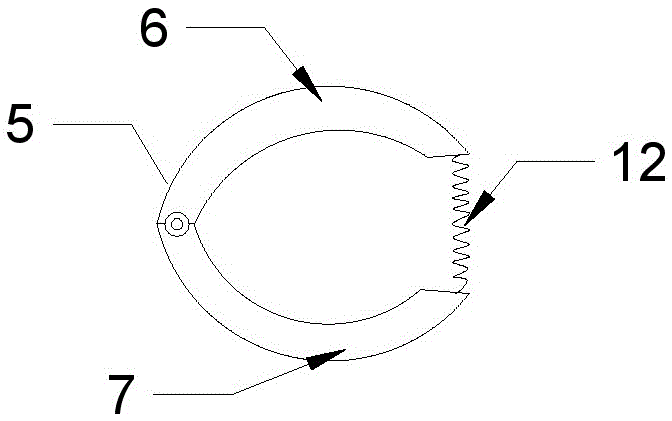

Automatic loading mechanism for hole circlip for automobile front axle brake assembly

PendingCN110000541ASolve the leakage problemSolve the problem of not being fully pressed into the shaft grooveVehicle componentsMetal working apparatusCirclipAutomotive engineering

The invention relates to an automatic loading mechanism for a hole circlip for an automobile front axle brake assembly. The automatic loading mechanism for the hole circlip for the automobile front axle brake assembly mainly comprises a framework, a feeding device, a guide device and a pressing-fitting device, wherein the feeding device, the guide device and the pressing-fitting device are installed on the framework. The automatic loading mechanism for the hole circlip for the automobile front axle brake assembly has the following beneficial effects: through the structure, alarming prompt is carried out with regard to the cases of abnormal pressing force data and unreasonable displacement data, so that the problems that the pressure of the hole circlip is leaked and the hole circlip is incompletely pressed into a shaft groove, are solved; and the consistent orientation of the hole circlip in a pressing-fitting process is ensured, and the hole circlip installed in the opposite directionis extremely easily found, so that the installation accuracy of the hole circlip is improved, and the working of people is replaced by a machine, so that the human participation degree in an assembling process for an automobile brake is lowered, and the installation quality problems of the hole circlip, which are caused due to human factors, are reduced, and then the product assembling quality ofthe automobile brake is improved, and an enterprise has higher competitiveness.

Owner:ZHEJIANG WANXIANG SYST +1

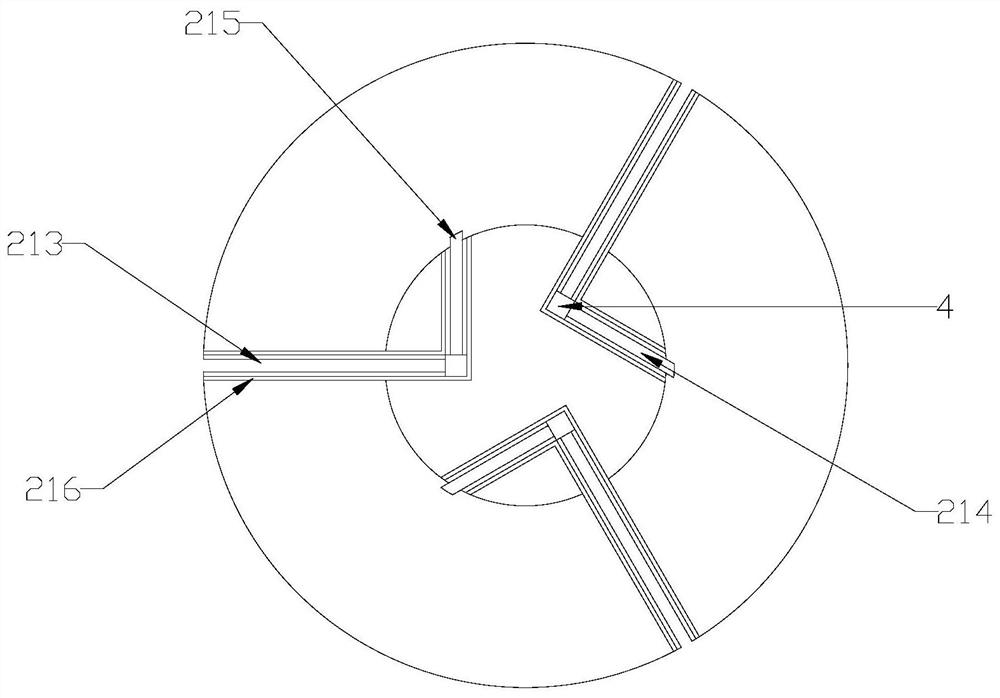

High-yield cap arranging machine

PendingCN110294302ASmall footprintIncrease output yieldSortingConveyor partsRolling resistanceEngineering

The invention provides a high-yield cap arranging machine. The high-yield cap arranging machine is characterized in that a horizontally-placed bottle caps are screened out through an upper-layer cap arranging mechanism, then the bottle caps are input into a rotating channel, the bottle cap are erected through a turning trajectory in the rotating channel; by using a shape characteristic that the bottle caps are round, the bottle caps are changed into a form of rolling friction to transfer, so that the damage to the bottle caps is reduced; due to the bottle caps are provided with two orientations, the bottle caps facing the opposite direction are separated into a first rotating guide rail and a second rotating guide rail which are opposite in rotation direction through a cap dividing channel, so that the bottle caps facing the opposite direction are changed into facing same direction, then the bottle caps are input into a lower-layer cap arranging mechanism for temporary storage, so thatthe bottle caps with two orientations can meet the requirements of output, the procedure of removing the bottle cap with one orientation and rearranging the caps is avoided, and the production efficiency is improved.

Owner:广州市博仕机电工贸有限公司

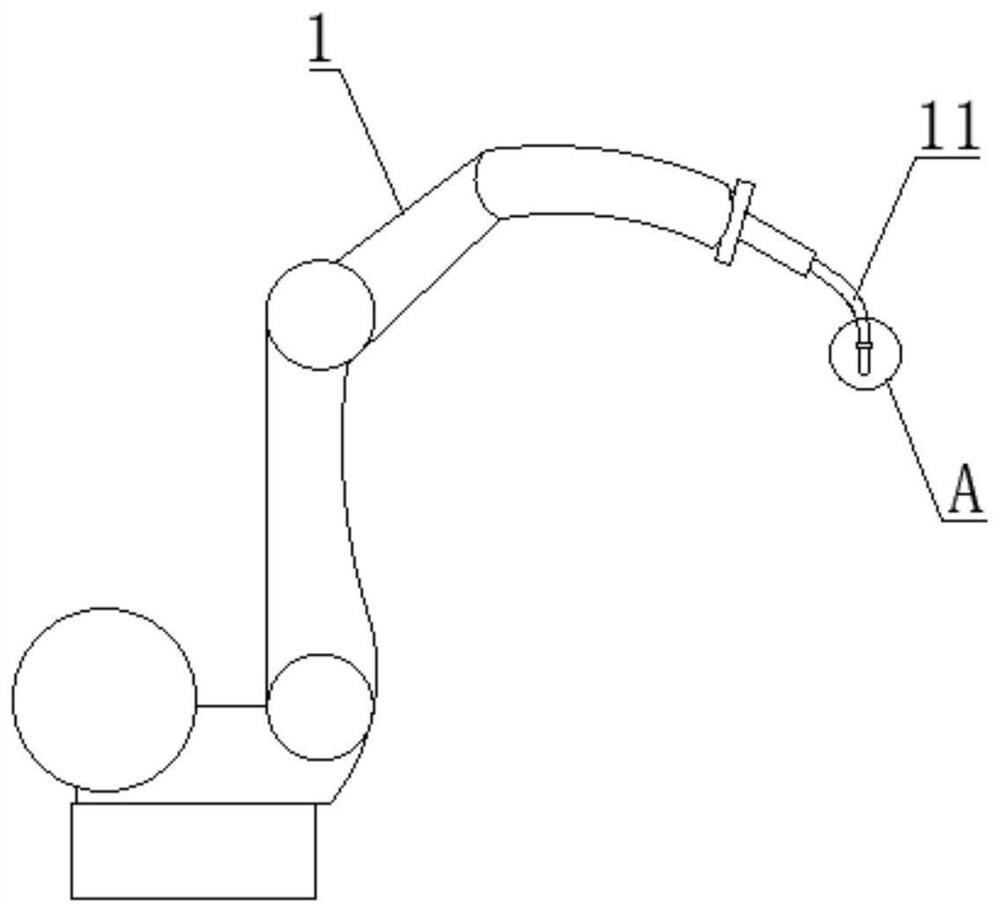

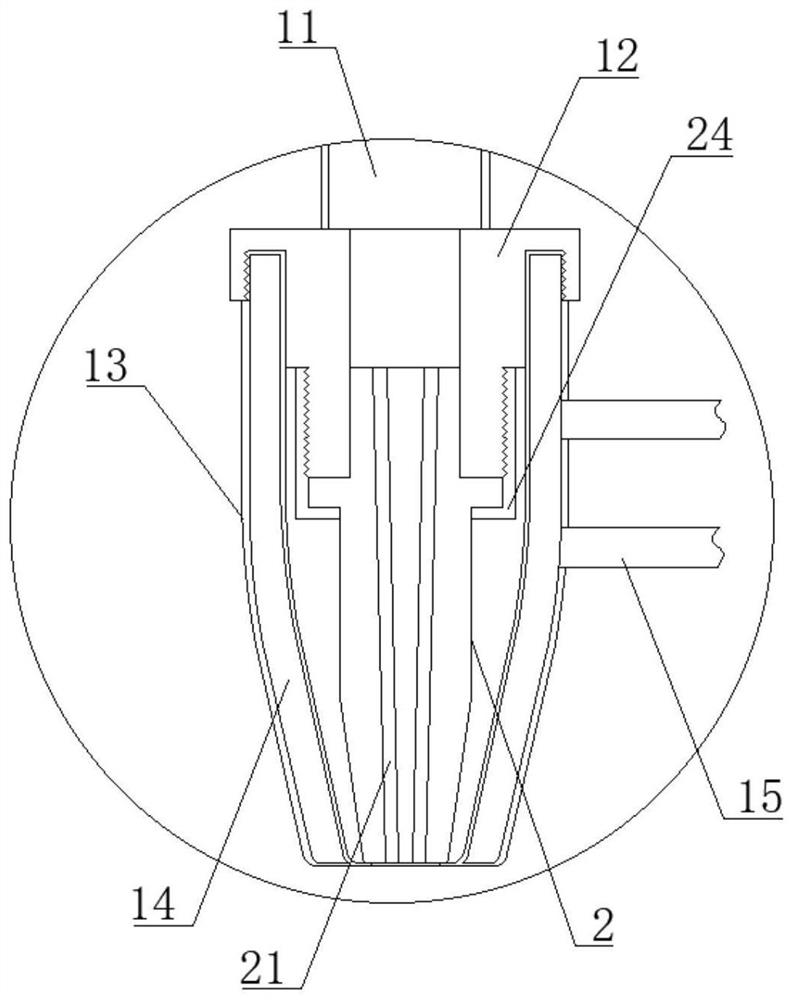

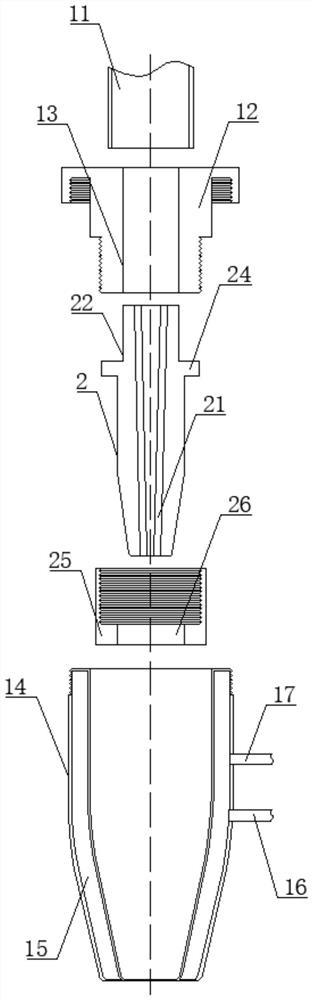

Welding robot and welding method thereof

PendingCN113305863AIncrease current densityReduce arc disturbanceProgramme-controlled manipulatorGripping headsThick plateEngineering

The invention discloses a welding robot and a welding method thereof. The welding robot comprises a body, wherein an elbow is arranged on the body, a connecting rod is arranged at the tail end of the elbow, a nozzle is formed in the connecting rod, a contact tube connected with the connecting rod is arranged in the nozzle, and at least two welding wire holes are formed in the contact tube. The welding method comprises the steps of workpiece fixing, welding robot assembling, welding robot operation program editing, welding operation and the like. According to the invention, at least two or more welding wire holes are formed in the same contact tube, so that interference between two arcs can be avoided during existing double-wire double-arc welding, and the stability of the welding quality is ensured; and when the welding robot is used for welding, the welding robot is used for welding common workpieces and is flexible in operation and better in penetration performance while welding thick plates, and therefore the welding quality is ensured.

Owner:广西焊杰机器人技术有限公司

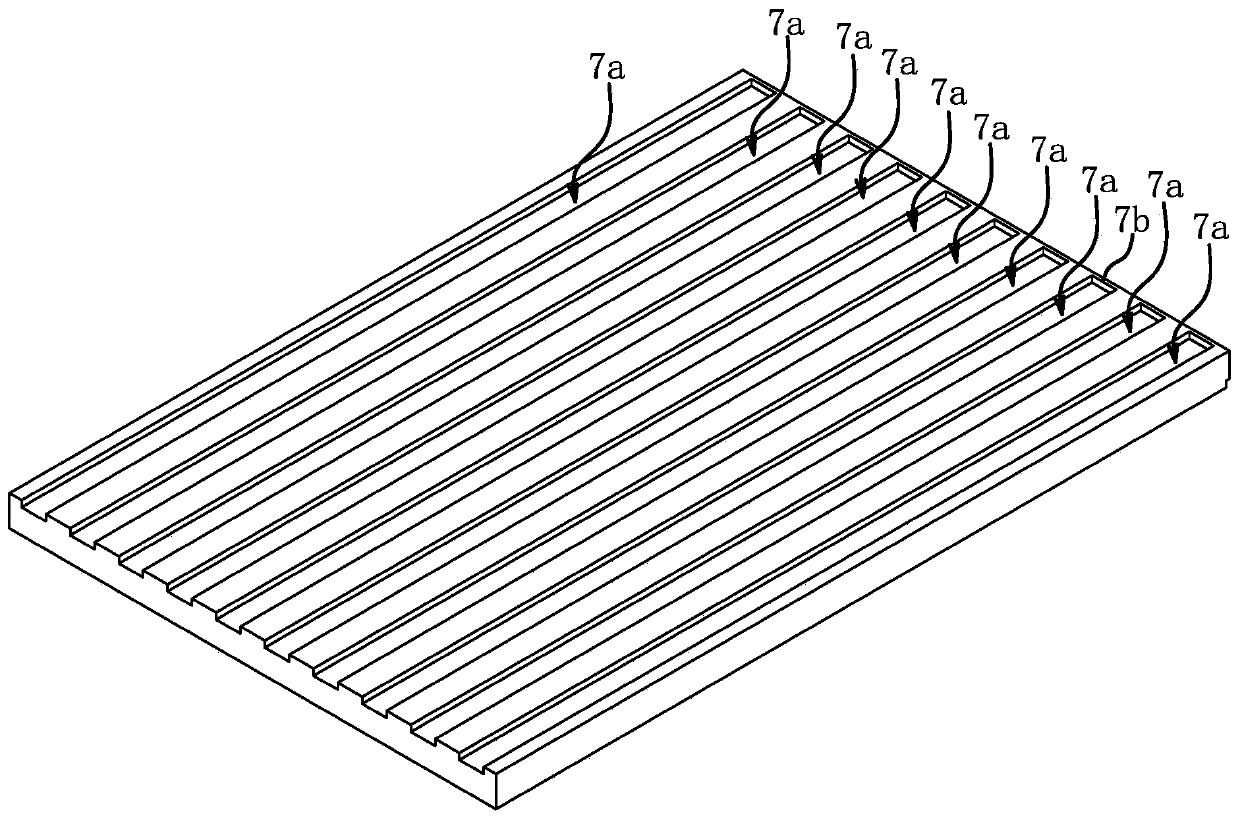

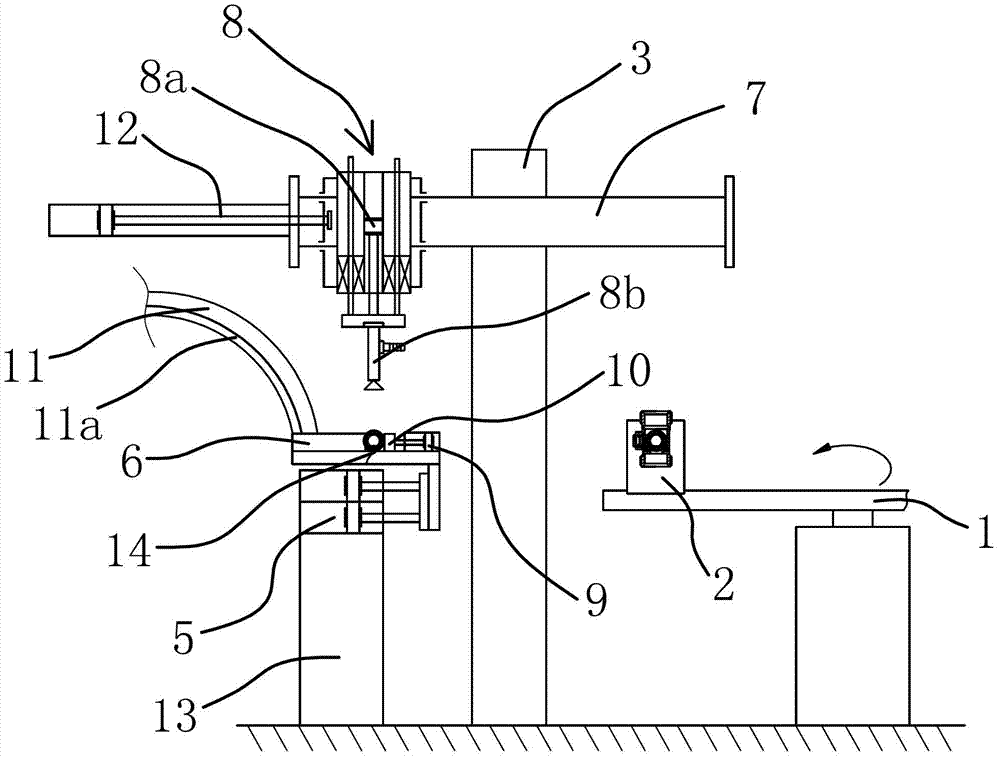

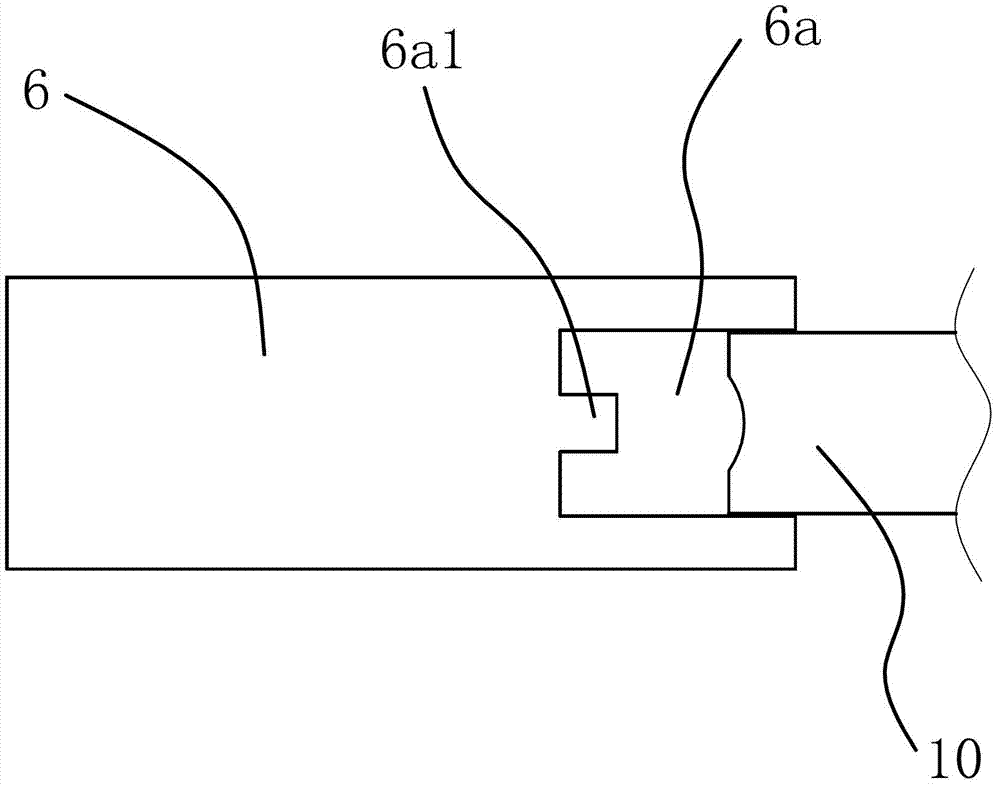

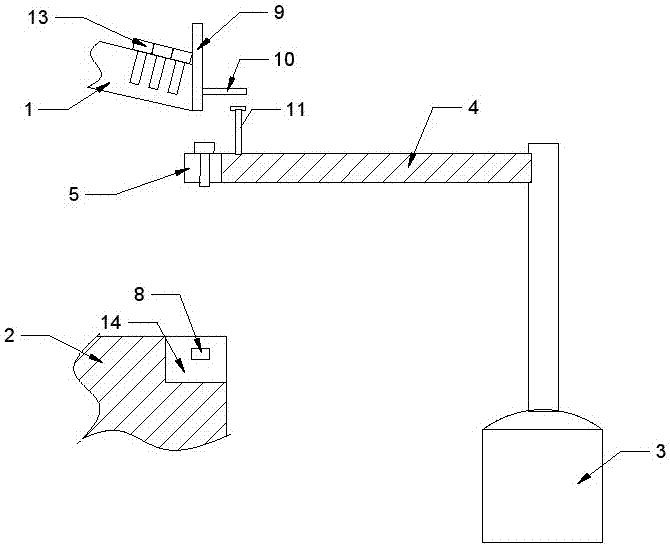

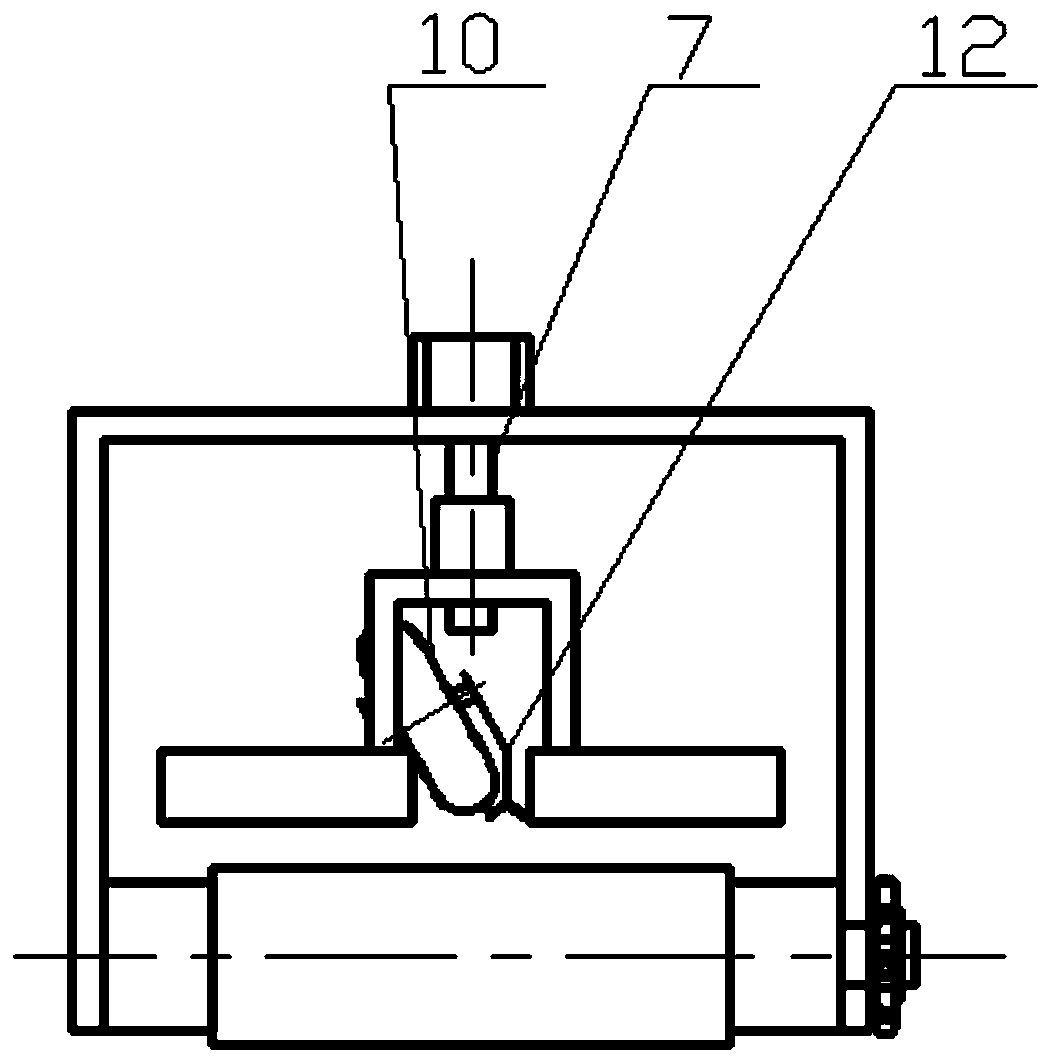

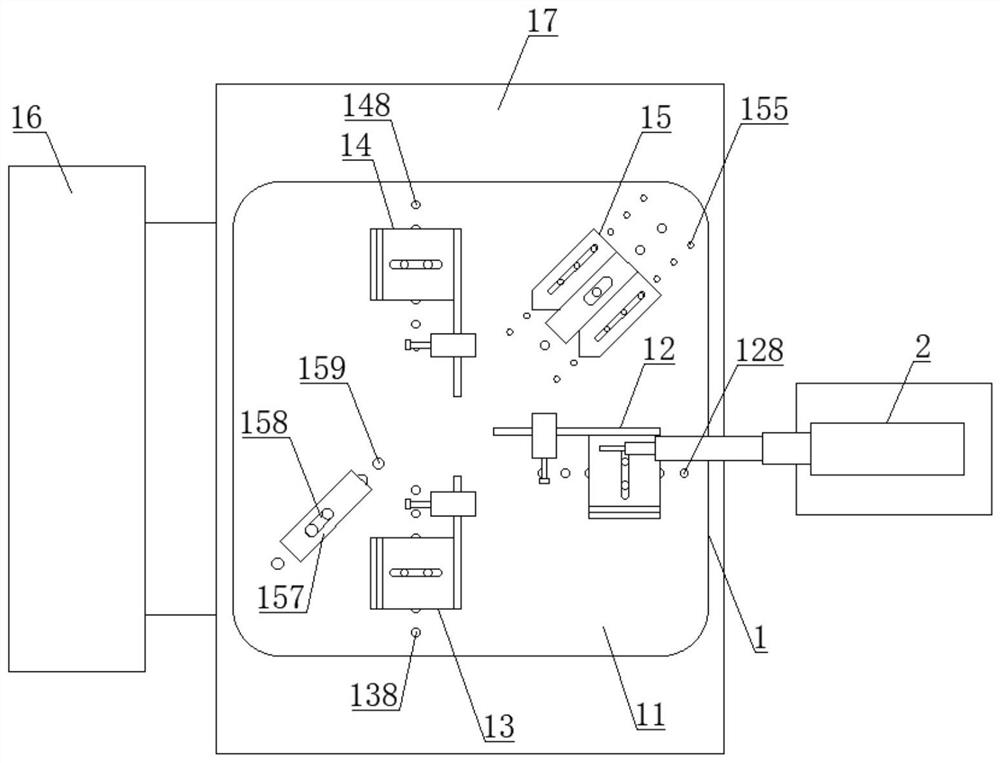

Automatic feeder and diamond tip bottom grinder

ActiveCN106826418BEnsure consistent orientationAchieve grindingDrilling toolsGrinding work supportsDiamond cuttingSurface grinding

The invention provides an automatic feeding device and a diamond cutter head bottom surface grinding machine and belongs to the technical field of grinding. The problem that the manufacturing cost of diamond cutting heads is high, and the qualities of the diamond cutting heads are insufficient due to an existing diamond cutter head bottom surface grinding machine is solved. The automatic feeding device of the diamond cutter head bottom surface grinding machine comprises a tray provided with a plurality of cutter head placing grooves. A rack is provided with a tray seat on which the tray can be positioned horizontally and the cutter head placing grooves are formed upwards. A clamp is arranged on the tray seat. A clamp moving and driving mechanism is arranged between the clamp and the rack, wherein the clamp moving and driving mechanism enables the clamp to move to the position above the cutter head placing grooves to realize clamping diamond cutter heads in the cutter head placing grooves and enables the clamp to move to the position above a cutter head transferring piece. By adjusting the structure of the automatic feeding device, the knife surface and the bottom surface are distinguished by workers, and the diamond cutter heads are placed on the tray, so that the grinding machine is suitable for machining diamond cutter heads with longer burrs, and the manufacturing cost of the diamond cutter heads is reduced and the qualities of the diamond cutter heads are improved.

Owner:项俊俊

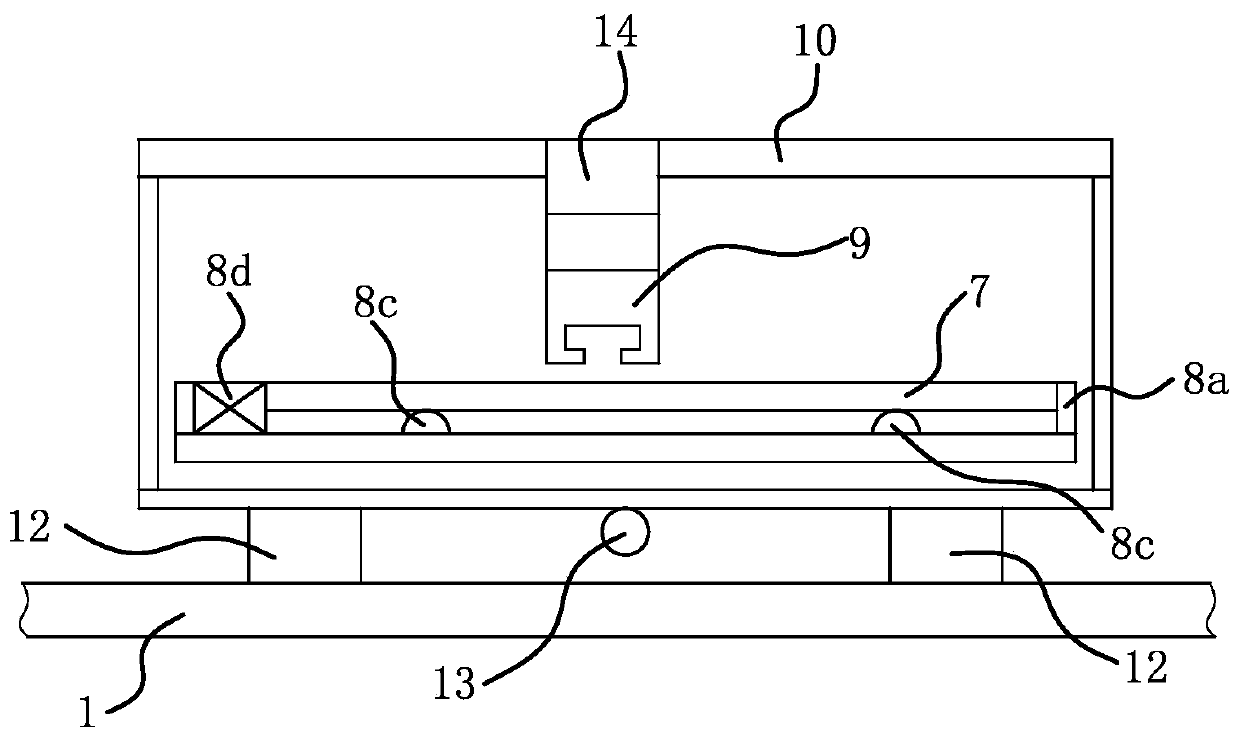

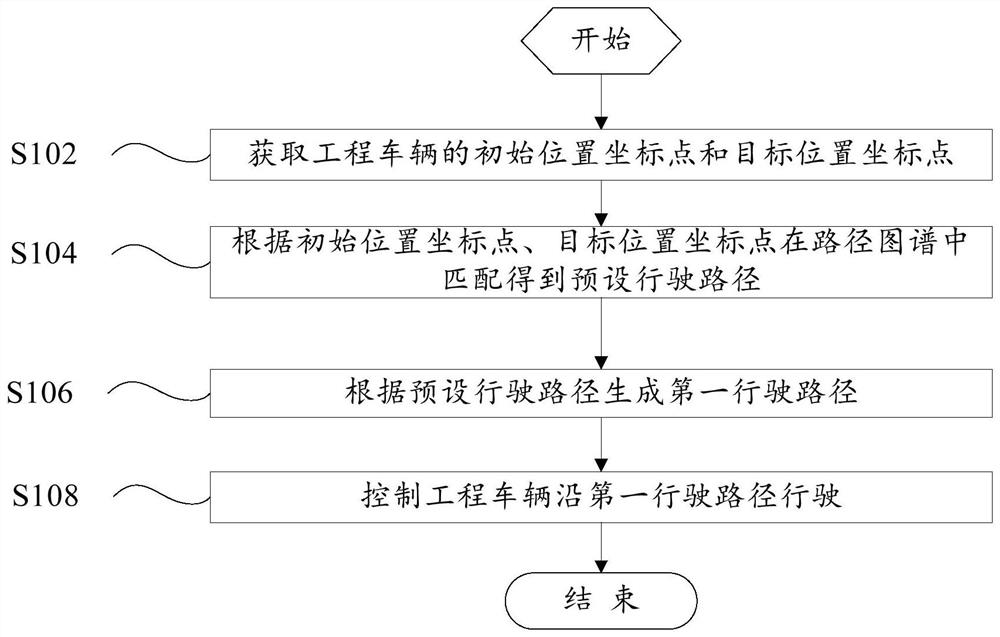

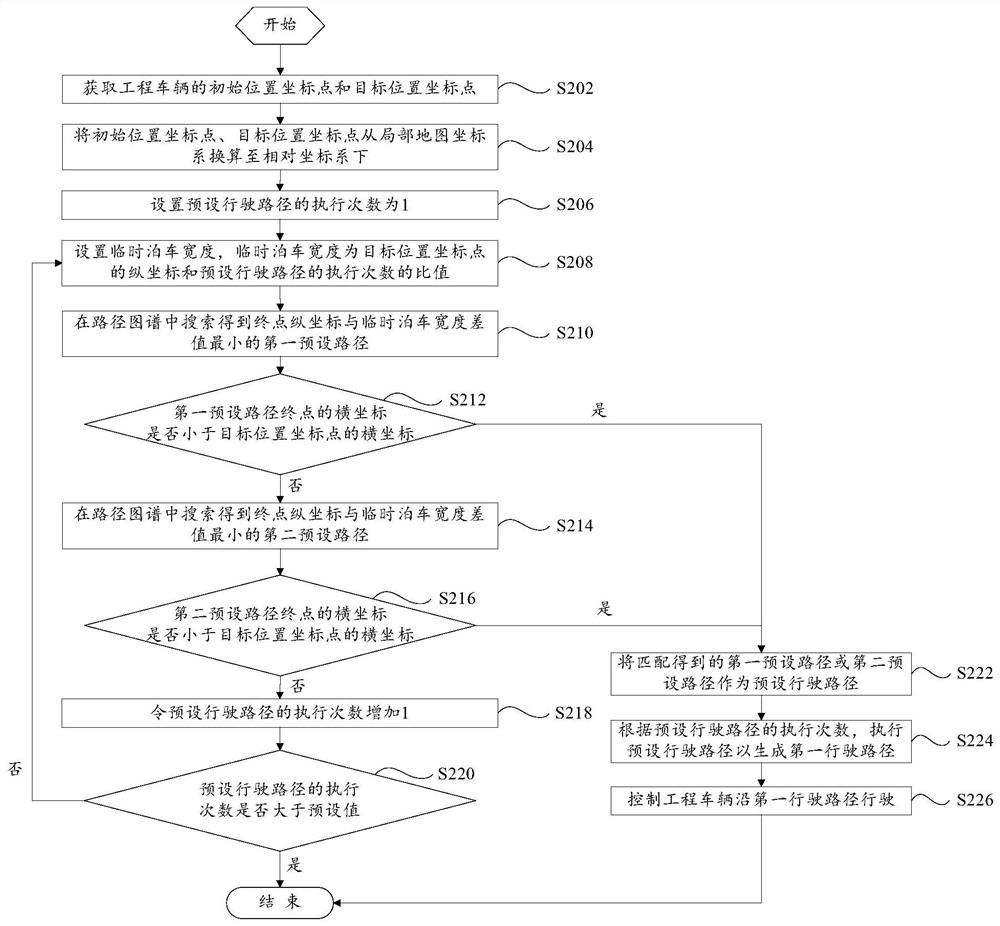

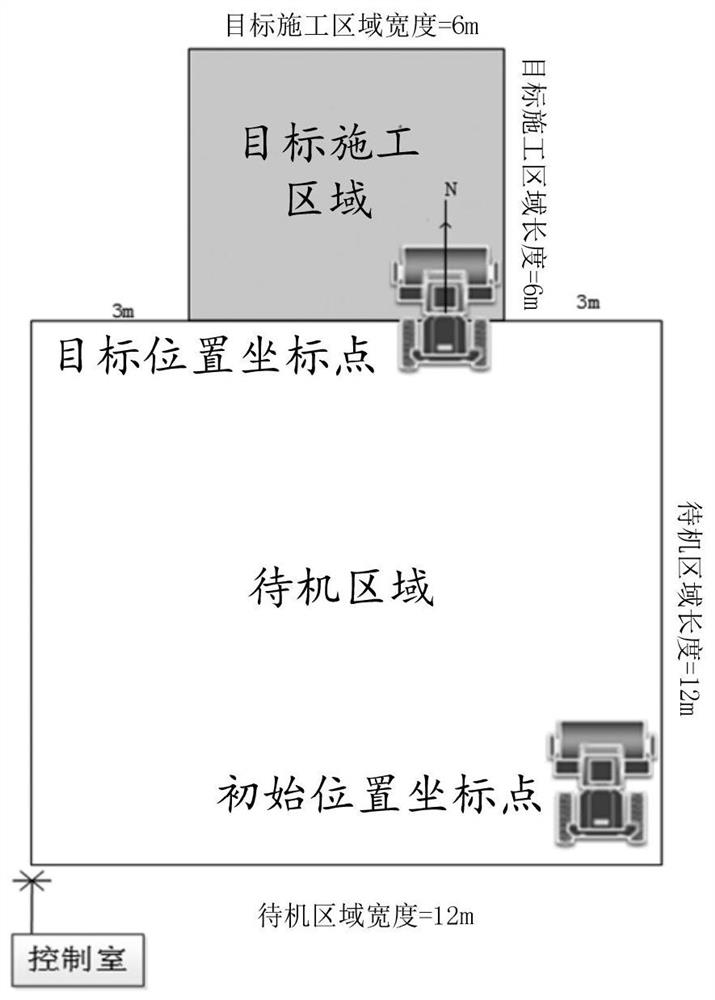

Control method, control system and engineering vehicle for parallel positioning of construction vehicles

ActiveCN112389421BEnsure consistent orientationFast placementControl devicesControl systemControl engineering

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP

A square head bolt marking device

ActiveCN110654825BEasy to slidePrevent rotationTypewritersOther printing apparatusElectric machineStructural engineering

Owner:海盐巨龙标准件有限公司

Shuttlecock collecting device for shuttlecock training ground

PendingCN111659091AGuaranteed lateral dropSame directionBall sportsRacket sportsSports equipmentStructural engineering

The invention provides a shuttlecock collecting device for a shuttlecock training ground, and belongs to the technical field of sports equipment. The device comprises a bracket, a storage box is arranged at the top of the bracket, a conveying mechanism is arranged at the bottom of the bracket, a steering mechanism is arranged at the bottom of the conveying mechanism, the steering mechanism realizes the consistent direction of the shuttlecock head, the conveying mechanism is arranged on one side of the steering mechanism, a storage barrel is arranged on the conveying mechanism, an ejection mechanism is arranged on one side of the conveying mechanism, the ejection mechanism pushes the storage barrel to the steering mechanism, an opening and closing mechanism is arranged on the steering mechanism, and the storage barrel full of badminton balls falls into the collecting box from the steering mechanism through the opening and closing mechanism. The storage barrel has the beneficial effectsthat the storage barrel is adopted for containing badminton balls, the problem that the badminton balls are damaged due to extrusion is solved, meanwhile, the problem that the badminton balls cannot fall off when moved out of the storage box can be solved, it can be guaranteed that the orientations of ball heads of the badminton balls are consistent, and the empty storage barrel can be rapidly replaced.

Owner:长沙德知信息咨询有限公司

Automatic cover finishing machine

ActiveCN102390699BEnsure consistent orientationOrganize fastStacking articlesConveyor partsAgricultural engineering

Owner:GUANGDONG HUASHENG PLASTIC

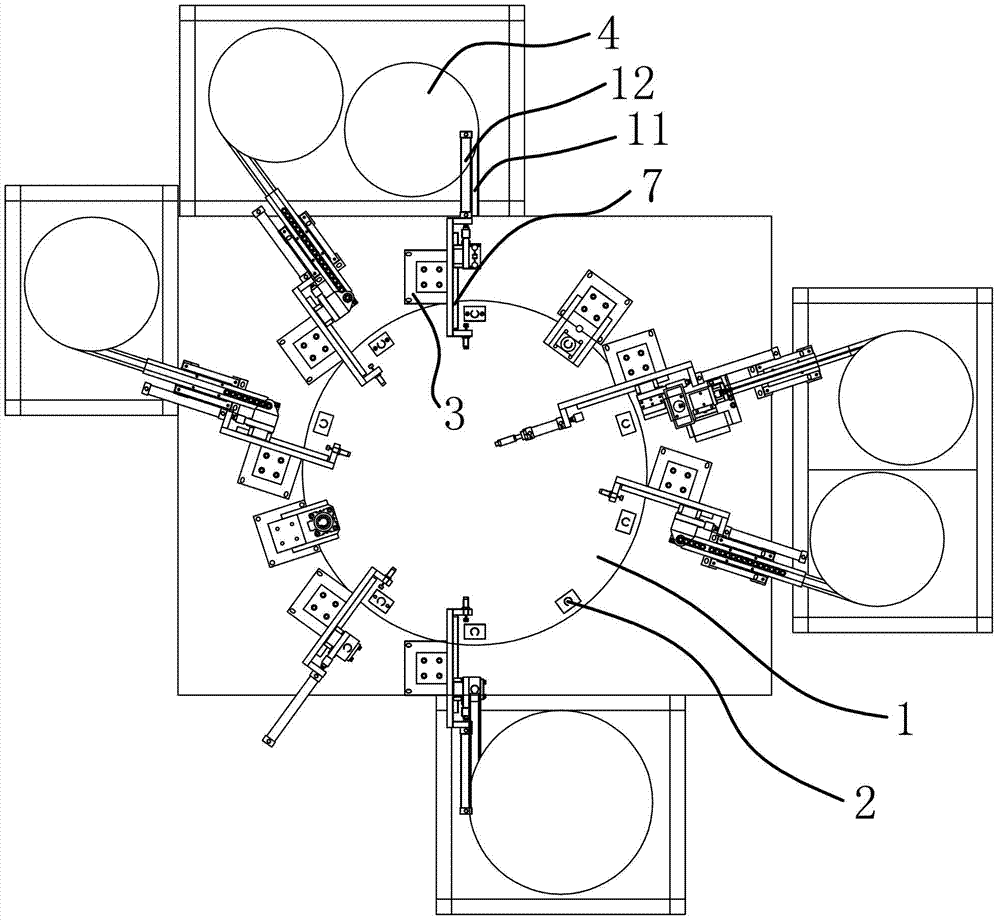

Valve ball loading device of a ball valve automatic assembly machine

InactiveCN103223594BQuick installationEasy to installAssembly machinesMetal working apparatusAutomatic balancing valvesEngineering

The invention provides a valve ball loading device of an automatic ball valve assembling machine, belonging to the technical field of machinery, and solving the problems that the traditional ball valve is assembled by the hands, the assembling efficiency is low, the labor cost is high and the like. The automatic ball valve assembling machine comprises a worktable, wherein the worktable is fixedly connected with a die holder, the die holder moves together with the worktable, and the valve ball loading device is arranged on the side edge of the worktable and comprises a support, a vibration tray, a sliding-table air cylinder and a positioning bar, wherein the upper part of the support is fixedly connected with a horizontal guide rail, the horizontal guide rail is movably connected with a mechanical hand, the sliding-table air cylinder is positioned in the middle of the support, the positioning bar is fixed on a sliding table of the sliding-table air cylinder, one end of the positioning bar is provided with a positioning groove, the positioning groove is formed in a discharging port of the vibration tray, and a valve ball in the positioning groove can be moved by the mechanical hand into a valve body on the die holder. The valve ball loading device has the advantages of high automation degree, high ball valve assembling efficiency, and the like.

Owner:ZHEJIANG VALOGIN TECH

A steering wheel connector automatic loading transfer robot

ActiveCN111573208BAutomatically correct orientationOrientationConveyor partsSteering wheelRobot hand

The invention relates to the technical field of automobile part machining, in particular to an automatic feeding transfer robot of a boss kit. The robot comprises a base, a conveying mechanism, a correction turnover mechanism, a guiding mechanism and a transfer mechanism. The conveying mechanism comprises a vibration disc and a vibration sliding way. A detection stopping mechanism is arranged at the outer side of the end, away from the vibration disc, of the vibration sliding way. The correction turnover mechanism comprises a supporting table and a turnover assembly. The turnover assembly comprises a storage box which is in butt joint with one end of the vibration sliding way and can be turned over. The guiding mechanism comprises an inclined sliding way, a correction guiding sliding way and a reclaiming table which are installed on the supporting table. The transfer mechanism comprises a mechanical hand. The output end of the mechanical hand is provided with a clamping jaw capable ofgrabbing a workpiece on a reclaiming sliding way. According to the technical scheme, a boss kit can be automatically transferred and automatically corrected in the transfer process, and the transfer efficiency is improved.

Owner:DONGGUAN POLYTECHNIC

An integrated production line and production method of automatic detection, palletizing and stacking of machine tool discharging drill bits

ActiveCN112173712BNo need for manual palletizingEnsure consistent orientationStacking articlesDe-stacking articlesProduction lineRobot hand

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A thrust plate automatic stacking device and a thrust plate stacking method

ActiveCN107931475BEnsure consistent orientationPrevent reboundMetal-working feeding devicesPositioning devicesBall screwCoupling

The invention discloses an automatic stacking device for thrust plates. The automatic stacking device comprises a rotating sucker mechanism, a shifting mechanism and a collecting mechanism. The rotating sucker mechanism comprises a base. A driving motor is installed at the edge of the base. The output end of the driving motor is provided with a driving gear. The driving gear is in linkage with a revolving support through a meshing structure. The top of a lower supporting column is provided with an upper supporting column and a revolving sucker. The revolving sucker is used for transmitting thethrust plates to a working position of the shifting mechanism under driving of the driving motor. The shifting mechanism comprises a bracket. An electric pushing rod is installed on the bracket. Theelectric pushing rod is connected with a shifting head and can drive the shifting head to shift the thrust plates into the collecting mechanism. The collecting mechanism comprises a stepper motor. Theoutput end of the stepper motor is connected with a ball screw shaft through a coupling. A tray used for stacking the thrust plates is installed in a collecting groove, and can move up and down alonga sliding groove under driving of the stepper motor.

Owner:SHANGHAI DIANJI UNIV

Badminton ball collecting device for training

PendingCN111659090AIncrease humidityKeep dryBall sportsRacket sportsStructural engineeringMechanical engineering

The invention relates to a badminton ball collecting device. A storage box is arranged at the top of a support, a conveying mechanism is arranged at the bottom of the support, the conveying mechanismpenetrates through the storage box and moves out shuttlecocks in the storage box, a steering mechanism is arranged at the bottom of the conveying mechanism, the steering mechanism is used for realizing consistent directions of badminton heads, a conveying mechanism is arranged on one side of the steering mechanism, a storage cylinder is arranged on the conveying mechanism, an ejection mechanism isarranged on one side of the conveying mechanism and used for pushing the storage cylinder at the tail end of the conveying mechanism to the steering mechanism through a notch, an air inlet hole is formed in the end, close to the ejection mechanism, of the storage cylinder, an air conveying pipeline is arranged at an air outlet of a steam generator, and the air conveying pipeline penetrates through a penetrating hole and then is communicated with the air inlet hole. The badminton ball collecting device can guarantee that the badminton ball directions are consistent in the badminton ball collecting process, can solve the problem that collected badminton ball is extruded and damaged, and meanwhile badminton ball steaming operation is carried out in due time.

Owner:长沙德知信息咨询有限公司

Transmission device for motorcycle special pin shaft

ActiveCN105460607BEnsure consistent orientationFacilitate subsequent processingConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a conveying device for special hinge pins of a motorcycle. The conveying device comprises a hinge pin conveying sliding groove, a transferring mechanism and a machining table. The hinge pin conveying sliding groove is arranged obliquely. The output end of the hinge pin conveying sliding groove is slidably connected with a sealing door. The transferring mechanism comprises an air cylinder, a supporting shaft and an iron clamping jaw used for clamping the hinge pins. One end of the supporting shaft is perpendicular to the air cylinder and is connected to a piston rod of the air cylinder. The other end of the supporting shaft is hinged to the clamping jaw. The clamping jaw is located under the output end of the hinge pin conveying sliding groove. The supporting shaft is further provided with a pushing piece used for pushing the sealing door. A through groove used for containing the clamping jaw is formed in the machining table. Magnets used for attracting the clamping jaw are arranged on the two side walls of the through groove. By the adoption of the scheme, the problem that according to an existing hinge pin conveying technique, the labor intensity is high or the equipment cost is high is solved.

Owner:邳州市景鹏创业投资有限公司

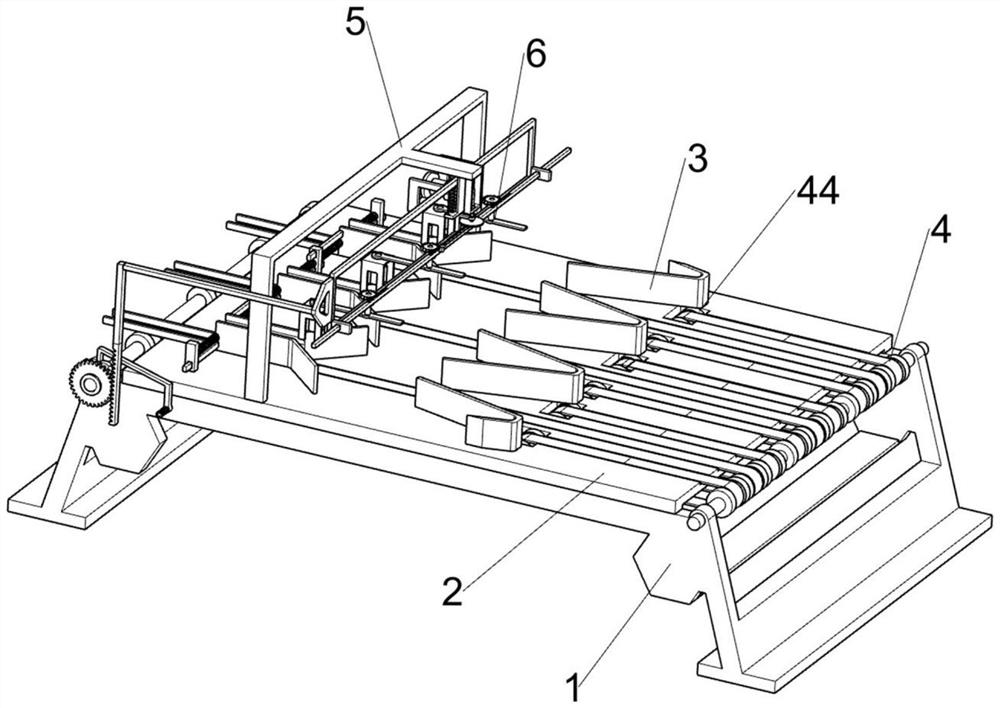

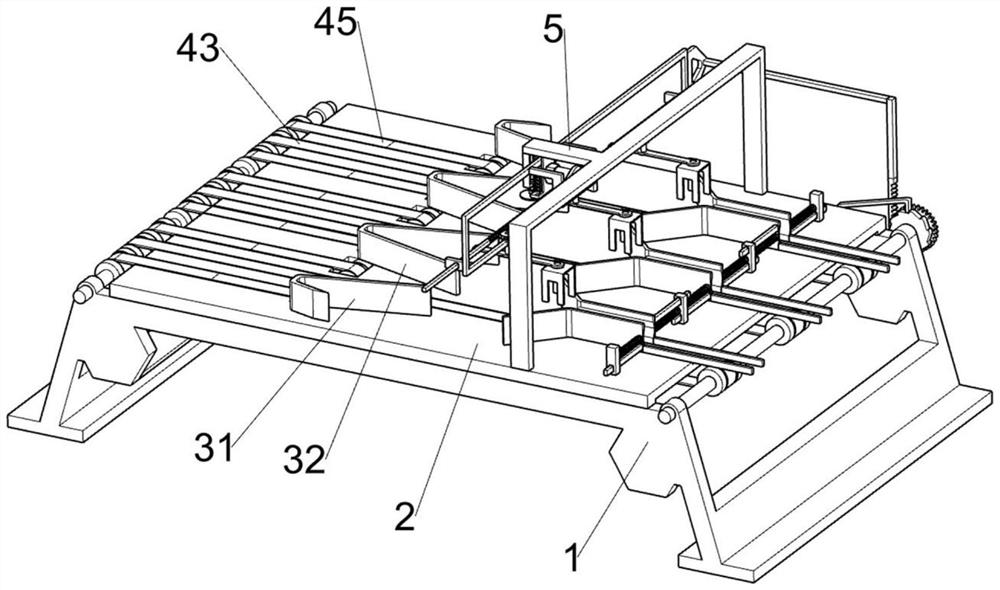

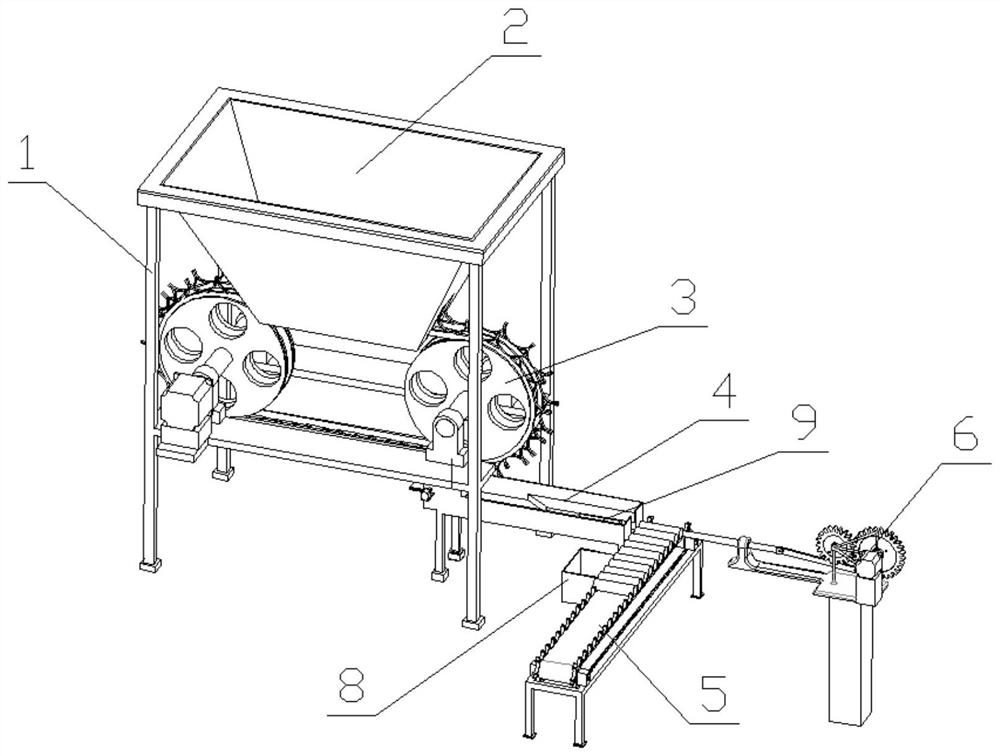

Fresh tobacco leaf petiole sectioning and orderly clamping device and its sectioning and clamping method

ActiveCN107836746BIncrease water evaporation rateReduce consumptionTobacco treatmentEngineeringMechanical engineering

The invention discloses a fresh tobacco leaf stalk sectioning and orderly-clamping device and a sectioning and clamping method thereof. Leaf stalks and tobacco leaves are different in flue-curing degree, and accordingly the flue-curing quality is affected. The fresh tobacco leaf stalk sectioning and orderly-clamping device comprises a positioning adjusting assembly, a first belt conveying mechanism, guiding plates, a compressing contour wheel, a Y-shaped cutter, a photoelectric sensor, a second belt conveying mechanism, a fastener, a tobacco clamp and a baffle. The Y-shaped cutter begins to cut main veins from the end faces of tobacco leaf stalks, and the compressing contour wheel is adjusted through a spring to adapt to the different height situations at different positions of the tobaccoleaf main veins. Sectioned tobacco leaves are throwed and conveyed through the first belt conveying mechanism, and leaf stalks fall between two adjacent clamping columns of the tobacco clamp after being in contact with the baffle; when n tobacco leaves are stacked between the two adjacent clamping columns, the tobacco clamp is stepped for one station; when the tobacco clamp is full of tobacco leaves, a motor is driven to stop rotating, the tobacco clamp is taken down and put in a flue-curing room, then a new tobacco clamp is clamped on two fasteners located at an upper tobacco leaf clamping station. The fresh tobacco leaf stalk sectioning and orderly-clamping device achieves automatic and orderly clamping of fresh tobacco leaves and makes the leaf stalk flue-curing time approximate to leaf flue-curing time.

Owner:西安智财全技术转移中心有限公司

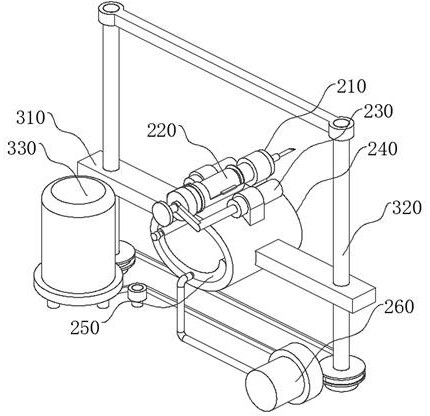

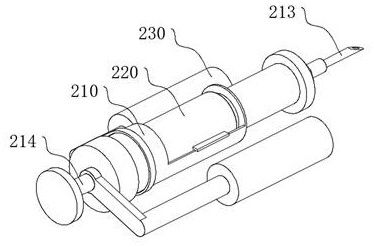

Vehicle-mounted unmanned blood drawing transfer manipulator

PendingCN114748067AAvoid cross infectionReduce work intensitySurgical furnitureSensorsMicrocomputerMicrocontroller

The vehicle-mounted unmanned blood drawing transfer manipulator comprises a transfer vehicle body, an infrared imager and a storage battery, the infrared imager and the storage battery are installed in the top of the transfer vehicle body, and a blood drawing device used for hanging an arm is arranged in the upper half portion of the transfer vehicle body. The blood drawing device comprises a suspended sleeve arm ring, a blood drawing tube moving in the axial direction of the sleeve arm ring, a detachable blood collecting tube arranged in the blood drawing tube and a servo electric cylinder, a single chip microcomputer used for controlling the servo electric cylinder is installed in the infrared imager, and a puncture needle is arranged at the foremost end of the blood drawing tube. Medical articles necessary for blood drawing are loaded on the transfer trolley body, the infrared imager is arranged to display blood vessels of arms of patients, so that blood drawing tubes in the blood drawing device are controlled to be aligned with the blood vessels for automatic puncture and blood drawing, medical staff do not need to time to find the blood vessels and contact different patients, and the work efficiency is improved. And the working intensity in extreme scenes is relieved, cross infection between doctors and patients is also avoided, and practical value is achieved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

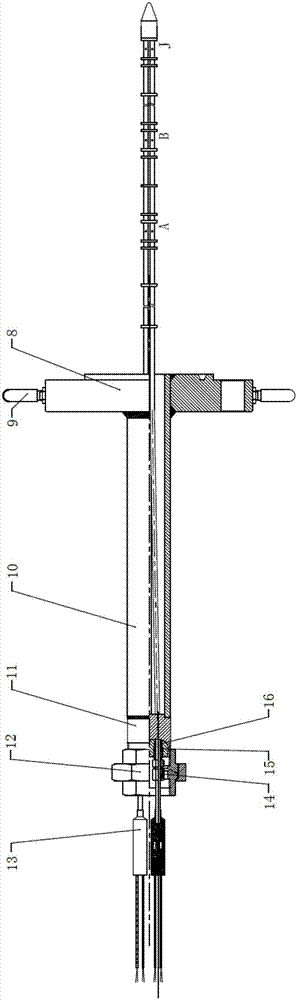

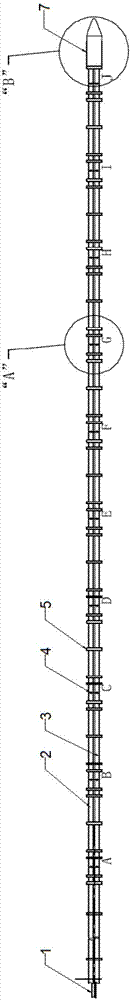

Methanol converter synthetic multipoint thermocouple

ActiveCN106979828AThermal expansion and contractionEasy to adjustThermometer detailsThermometers using electric/magnetic elementsTwo temperatureEngineering

The invention discloses a methanol converter synthetic multipoint thermocouple comprising a first armored core body, a second armored core body, and temperature measuring points. The first armored core body and the second armored core body are both provided with a plurality of temperature measuring points. The number of the temperature measuring points on the first armored core body and the number of the temperature measuring points on the second armored core body are the same and the measuring points on the first armored core body and the temperature measuring points on the second armored core body are disposed correspondingly one to one. The methanol converter synthetic multipoint thermocouple has beneficial effects that the first armored core body and the second armored core body are disposed, that the measuring points on the first armored core body and the temperature measuring points on the second armored core body are disposed correspondingly one to one, namely each same position is provided with two temperature measuring points so that the methanol converter synthetic multipoint thermocouple is improved in measurement accuracy and operation reliability, and that temperature measurement operation is not affected once a temperature measurement point generates a fault.

Owner:TIANJINSHI ZHONGHUAN TEMPERATURE METERS

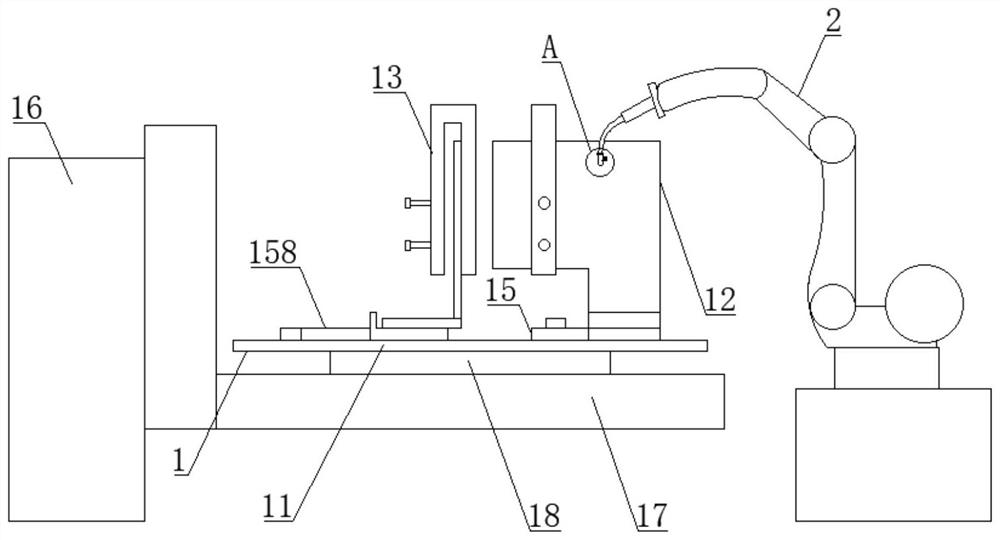

Electric power tower base welding system and welding method thereof

PendingCN113305489AExtended service lifeAvoid melt damageWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric power

The invention discloses an electric power tower base welding system and a welding method thereof. The electric power tower base welding system comprises a welding tool and a welding robot, wherein the welding tool comprises a tool bottom plate, a first fixing assembly is arranged on the tool bottom plate, and a second fixing assembly and a third fixing assembly are arranged at one side of the first fixing assembly separately. The welding method comprises the steps of workpiece fixing, welding robot assembling, welding robot operation program writing, welding operation and the like. By using the welding tool, all workpieces can be stably fixed, so that the welding quality is guaranteed; meanwhile, the workpieces of different specifications can be welded, so that the welding efficiency is increased, and the application range is widened; the welding robot is combined for welding, so that the welding efficiency can be increased, and the welding quality is guaranteed; and in addition, the labor intensity of workers is greatly reduced, and safe and ordered welding operation is guaranteed.

Owner:广西焊杰机器人技术有限公司

A square head bolt direction adjustment and marking integrated device

ActiveCN110775580BPrevent rotationEnsure consistent orientationConveyorsTypewritersGas cylinderElectric machinery

The invention discloses an integrated device for direction adjustment and marking of lag bolts, which comprises a direction adjustment device, a marking device and a track connecting the direction adjustment device and the marking device. body and a gas cylinder on one side of the box body, a first opening is provided in the center of the bottom plate of the box body, clamping plates are respectively fixed on both sides of the first opening, a second opening is formed between the clamping plates and the second The width of the two openings gradually decreases from the high side end of the box body to the low side end of the box body. The marking device includes a turntable, a motor, a base, a marking unit and an ejection unit. The turntable is provided with A plurality of first passages extending from the outer edge of the side wings to the inner panel, a plurality of second outlets are provided at the connection between the inner panel and the side wings, and the first passages are located between one end of the inner panel and the second outlet. There is a second channel, which can realize the direction adjustment and marking of bolts without manual work.

Owner:海盐巨龙标准件有限公司

Drill bushing assembly and novel drill box for automatic anchor protection operation

PendingCN114876535AProblems affecting performanceImprove reliabilityDrilling rodsDrilling casingsDrive shaftRock bolt

The invention provides a drill bushing assembly and a novel drill box for automatic anchor protection operation, and belongs to the technical field of roadway supporting, and the drill box comprises a drill box body, a drill box motor, a motor transmission shaft, a damping piece, a damping type anchor rod, a drill bushing and an abutting column. Wherein the drilling box motor and the liquid distribution plate are mounted on the drilling box body, and the drilling sleeve is connected with the motor transmission shaft to transmit torque; the tray clamping claws are symmetrically assembled on the drilling box body in a detachable mode and can limit the anchor rod tray. The drill bushing is provided with the damping piece disengaging hole in a double-inclined-face mode, the damping piece can be disengaged through the damping piece disengaging hole in the anchoring process, the drill bushing is in a multi-face limiting mode, and therefore the drill rod is more convenient to disassemble. According to the drilling box, the reliability is improved, the service life of the drilling box is prolonged, the working safety and efficiency are improved while the labor intensity of automatic anchor protection operation is reduced, and the automation and standardization progress of the anchor protection operation is promoted.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Conveying device for special hinge pins of motorcycle

ActiveCN105460607AEnsure consistent orientationFacilitate subsequent processingConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a conveying device for special hinge pins of a motorcycle. The conveying device comprises a hinge pin conveying sliding groove, a transferring mechanism and a machining table. The hinge pin conveying sliding groove is arranged obliquely. The output end of the hinge pin conveying sliding groove is slidably connected with a sealing door. The transferring mechanism comprises an air cylinder, a supporting shaft and an iron clamping jaw used for clamping the hinge pins. One end of the supporting shaft is perpendicular to the air cylinder and is connected to a piston rod of the air cylinder. The other end of the supporting shaft is hinged to the clamping jaw. The clamping jaw is located under the output end of the hinge pin conveying sliding groove. The supporting shaft is further provided with a pushing piece used for pushing the sealing door. A through groove used for containing the clamping jaw is formed in the machining table. Magnets used for attracting the clamping jaw are arranged on the two side walls of the through groove. By the adoption of the scheme, the problem that according to an existing hinge pin conveying technique, the labor intensity is high or the equipment cost is high is solved.

Owner:邳州市景鹏创业投资有限公司

An automatic yarn bobbin sorting device

Owner:NANTONG SUZHONG TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com