A square head bolt marking device

A technology of square head bolt and marking unit, which is applied in printing devices, typewriters, transportation and packaging, etc., can solve the problems of high production cost and low production efficiency, and achieve the goal of improving production efficiency, ensuring orientation and avoiding position deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

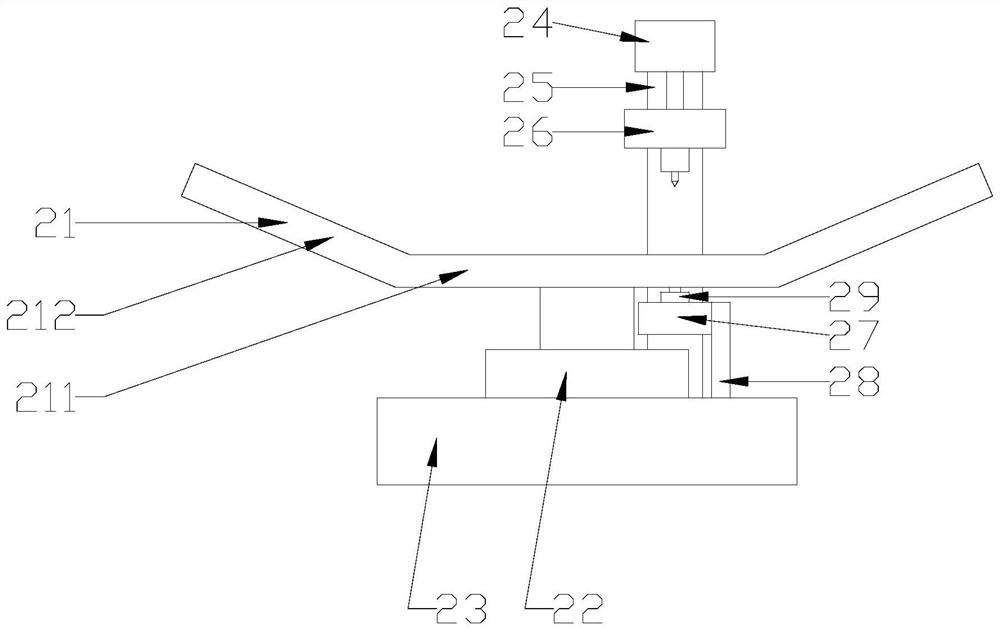

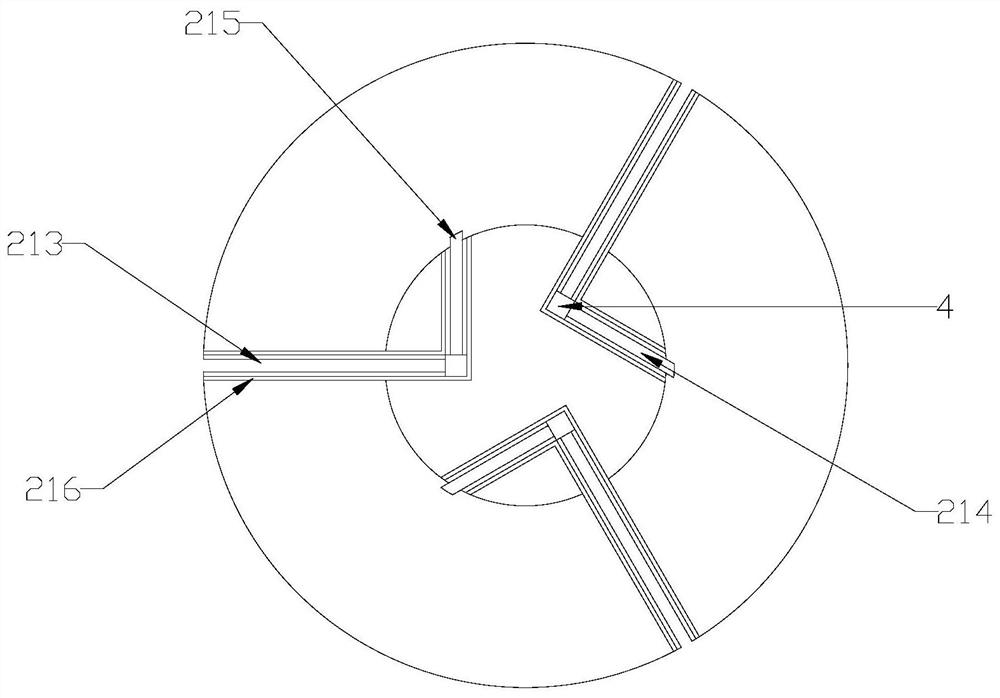

[0013] refer to figure 1 with figure 2 , a lag bolt marking device of the present invention includes a turntable 21, a motor 22, a base 23, a marking unit and an ejection unit, the motor 22 is fixed on the base 23 and drives the turntable 21 to rotate through a rotating shaft, and the turntable 21 includes an inner plate 211 and a side wing 212 that is located at the edge of the inner plate 211 and is turned over to the top in a ring shape. The turntable 21 is provided with several first passages 213 extending from the outer edge of the side wing 212 to the inner plate 211. The connection between the inner plate 211 and the side wings 212 is provided with several outlets 215, and the first channel 213 is located between one end of the inner plate 211 and the outlet 215, and a second channel 214 is provided between the first channel 213 and the second channel 214. An electromagnet is provided at the junction of the first channel 213 and the second channel 214, and a side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com