An automatic yarn bobbin sorting device

A sorting device and yarn bobbin technology, applied in the field of spinning, can solve the problems of low sorting efficiency, low sorting accuracy, large mechanism, etc., and achieve the effects of high sorting efficiency, simple action and speeding up the conveying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

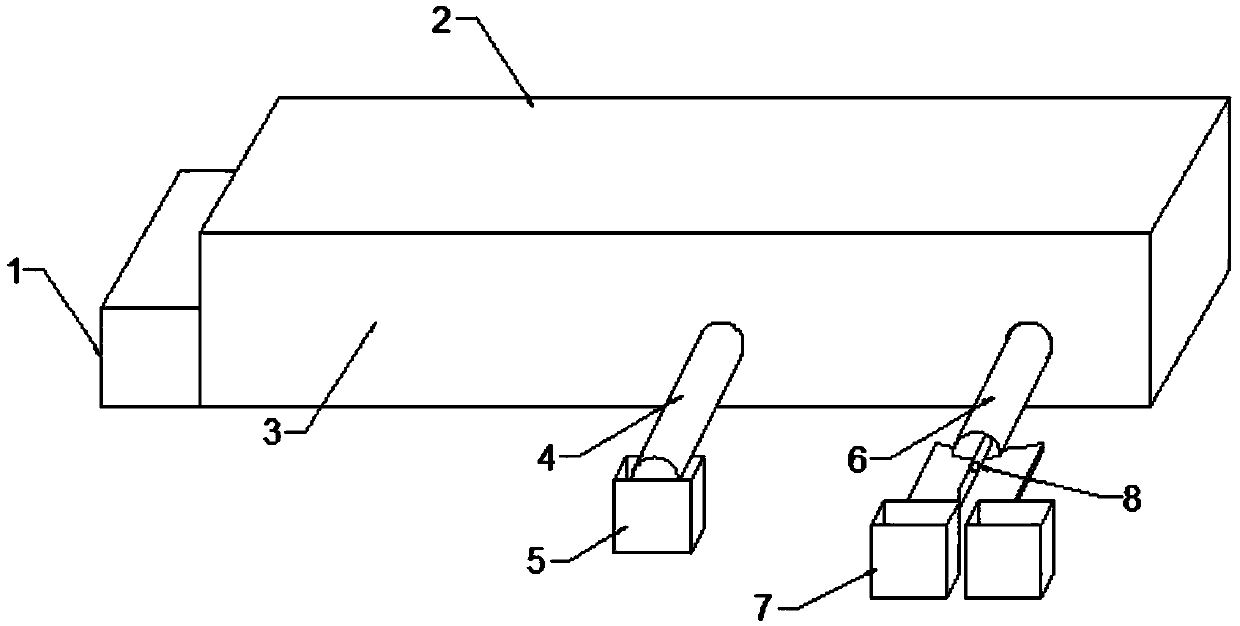

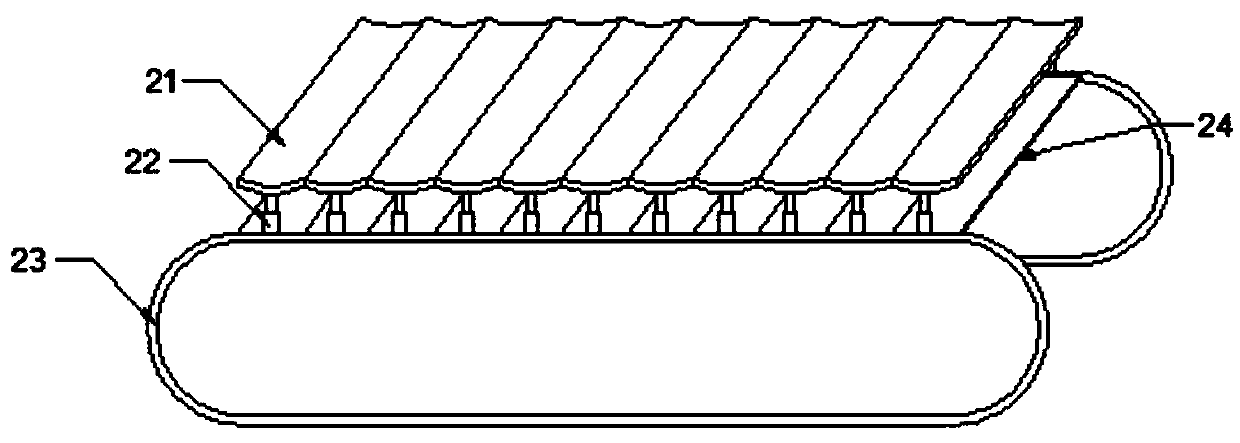

[0025] This embodiment provides an automatic bobbin sorting device, such as figure 1 As shown, the automatic bobbin sorting device includes a conveying device 2, a feeding mechanism 1, an identification mechanism and a control system; above ( figure 1 Not shown in ), the identification mechanism is close to the feeding end of the conveying device 2, the control system is set and any position of the sorting device is controlled to control the action of the conveying device 2, the feeding mechanism 1 and the identifying mechanism.

[0026] As a further preferred embodiment of this embodiment, the feeding mechanism 1 includes a feeding cylinder, a feeding belt and a finishing device, the feeding belt is placed in the feeding cylinder, and several pushing plates are arranged on the feeding belt, The distance between adjacent pusher plates is greater than the thickness of one yarn bobbin and less than the thickness of two yarn bobbins, and the height of the pusher plate is not mor...

Embodiment 2

[0031] The difference between this embodiment and the first embodiment is that in the first embodiment, the yarn bobbins that fall into the finishing barrel 7 from the sorting channel 6 all have the small end facing downward and the big end facing upward; therefore, the finishing barrel 7 Can be combined into the same sorting barrel 7; the sorting channel 6 on one side remains unchanged, and the sorting channel 6 on the other side passes through the bottom of the conveying device 2. A converging channel is arranged between the sorting channel 6 and the sorting barrel 7, and the The output ports of the side sorting channels 6 are all connected to the input ports of the converging channels, and the output ports of the converging channels are connected to the corresponding sorting barrels 7, which reduces the use of the sorting barrels 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com