Drill bushing assembly and novel drill box for automatic anchor protection operation

A technology for drill sleeves and drill boxes, which is applied in the direction of drill pipes, casings, and drill pipes. It can solve problems such as the single function of anchoring equipment, the influence of the normal use of the drill box, and the time-consuming replacement process, so as to achieve lifting, maintenance and normal work. High efficiency, reduced labor workload, and convenient disassembly and assembly of drill pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

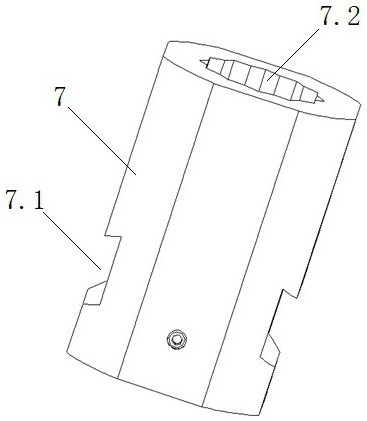

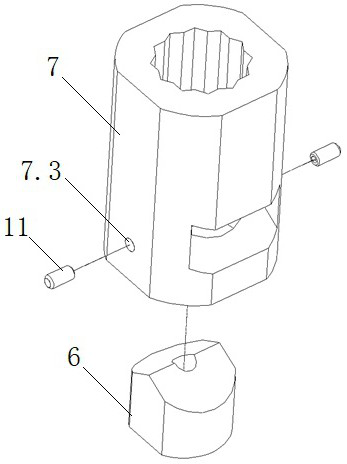

[0034] This embodiment provides a drill sleeve assembly for connecting the motor drive shaft 5 and the damping anchor rod 9, the top end is provided with a limit hole 7.1 for inserting the nut 9.1 at the bottom end of the damping anchor rod 9, and the symmetrical arrangement on both sides is useful The damping element escape hole 7.2 is inserted into the damping element escape hole 7.2 fixedly connected with the nut 9.1 at the bottom end of the damping anchor rod 9 for the damping element 10; the damping element escape hole 7.2 is communicated with the limit hole 7.1, and is provided with a damping element escape inclined surface inclined to the bottom end.

[0035] Further, the above-mentioned drill sleeve assembly includes a drill sleeve 7 and abutting column 6; the limit hole 7.1 and the damping member escape hole 7.2 are both provided on the drill sleeve 7, and the bottom end of the drill sleeve 7 is also provided with the limit hole 7.1 and damping The top surface and the ...

Embodiment 2

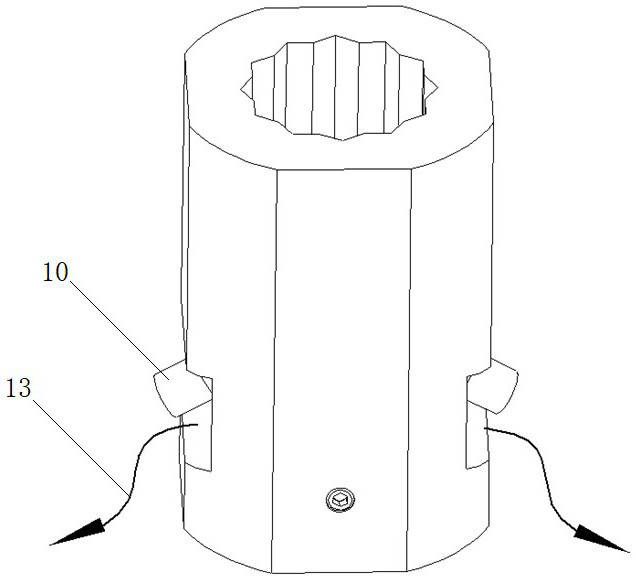

[0039] This embodiment provides a new type of drill box for automatic anchoring operation, including a drill box body 1, a drill box motor 2, a motor drive shaft 5, a damping member 10 and a damped anchor rod 9; a drill box motor 2 and a motor drive shaft 5 is installed on the drill box body 1, and the drill box motor 2 drives the motor drive shaft 5 to rotate; the motor drive shaft 5 and the damping anchor rod 9 are connected through the above drill sleeve assembly, and the serrations of the nut 9.1 on the damping anchor rod are fitted in the In the serration of the limit hole 7.1.

[0040] Further, the nut 9.1 on the damping anchor rod 9 is a hexagonal nut, and the limiting hole 7.1 of the drill sleeve 7 is a dodecahedral serrated hole.

[0041] Further, an anchor rod tray 8 is rotatably installed on the damping anchor rod 9; two tray clamping claws 4 are symmetrically arranged on both sides of the drilling box body 1, and the distance between the two tray clamping claws 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com