Welding robot and welding method thereof

A technology of welding robot and welding method, which is applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as difficulty in meeting the welding requirements of high-quality products, insufficient workpiece strength, and affecting welding quality, and achieve good penetration effects and improved Penetration depth and effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

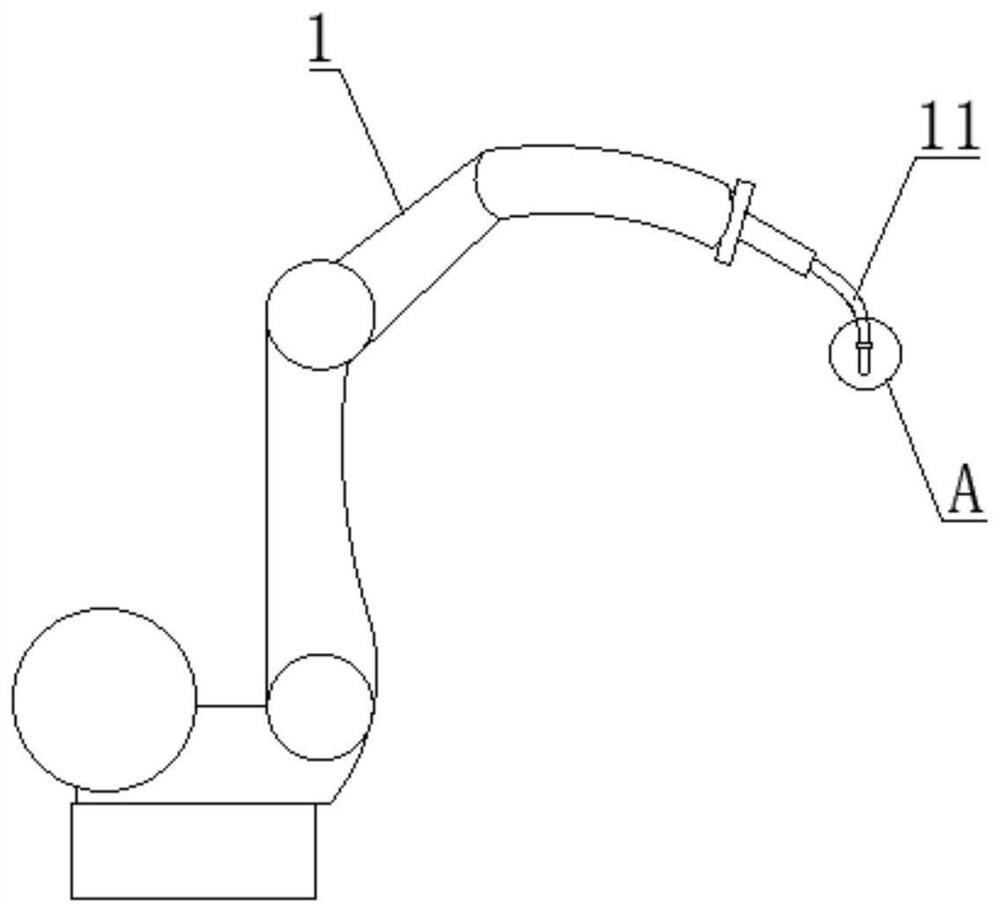

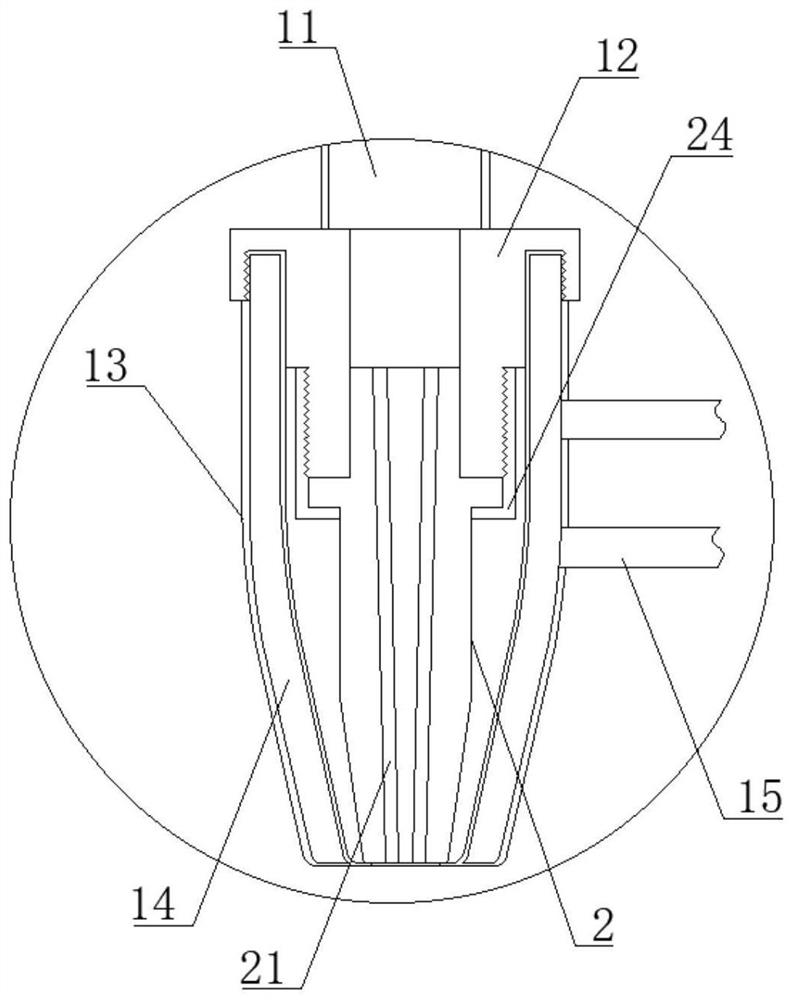

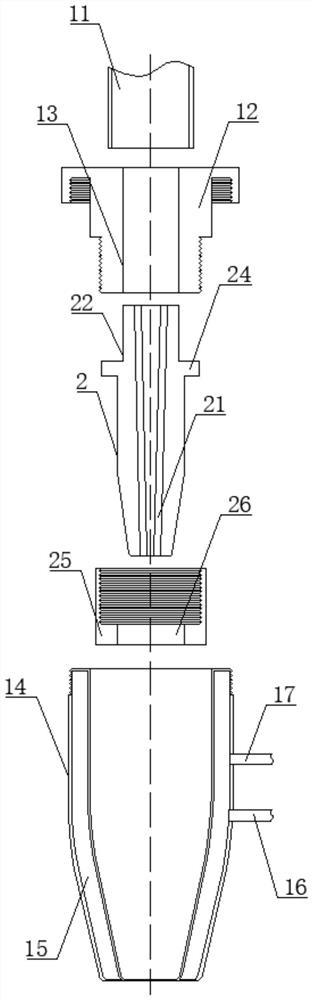

[0036] Welding robot, such as Figure 1-3 As shown, including the body 1, the body 1 is provided with an elbow 11, and the end of the elbow 11 is provided with a link 12, and a nozzle 14 is provided on the link 12. The nozzle 14 is provided with a conductive nozzle 2 connected to the link 12, The conductive nozzle 2 is provided with at least two welding wire holes 21.

[0037] like Figure 2-4 , Figure 5-6 As shown, the number of soldering wire holes 21 is two, and the welding wire hole 21 is arranged as a shaft symmetry in the longitudinal center of the conductive nozzle 2.

[0038] like Figure 2-4 , Figure 5-6 As shown, the vertical distance of the welding wire hole 21 and the conductive nozzle 2 longitudinal mid-length is gradually smaller as the distance is increased from the link 12.

[0039] like Figure 2-4 , Figure 5-6As shown, the center distance between the welding wire holes 21 is from 4.5 to 4.8 mm close to the end of the link 12, and the value of the remote rod 12 is 1.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com