Patents

Literature

54results about How to "Reduce digging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

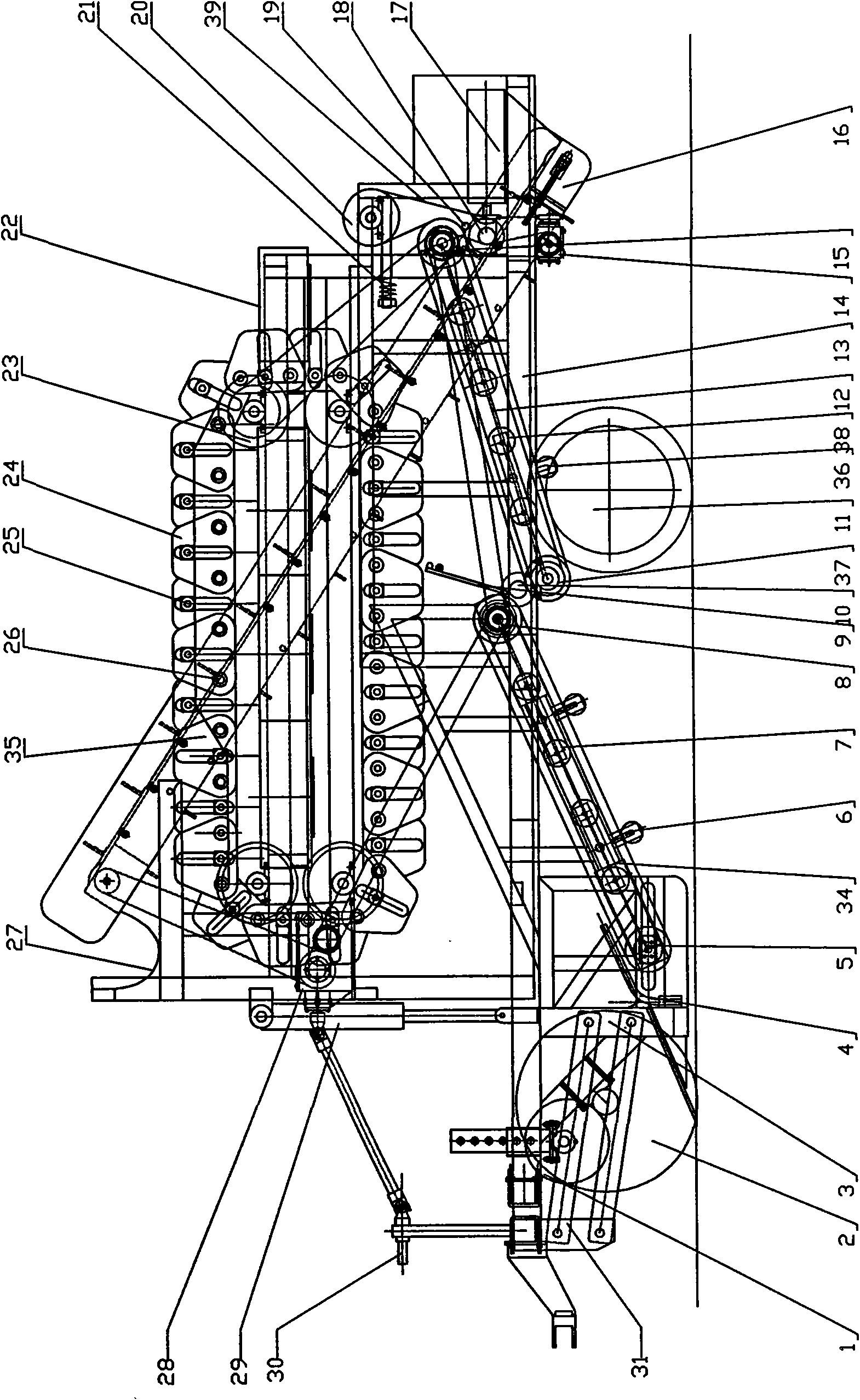

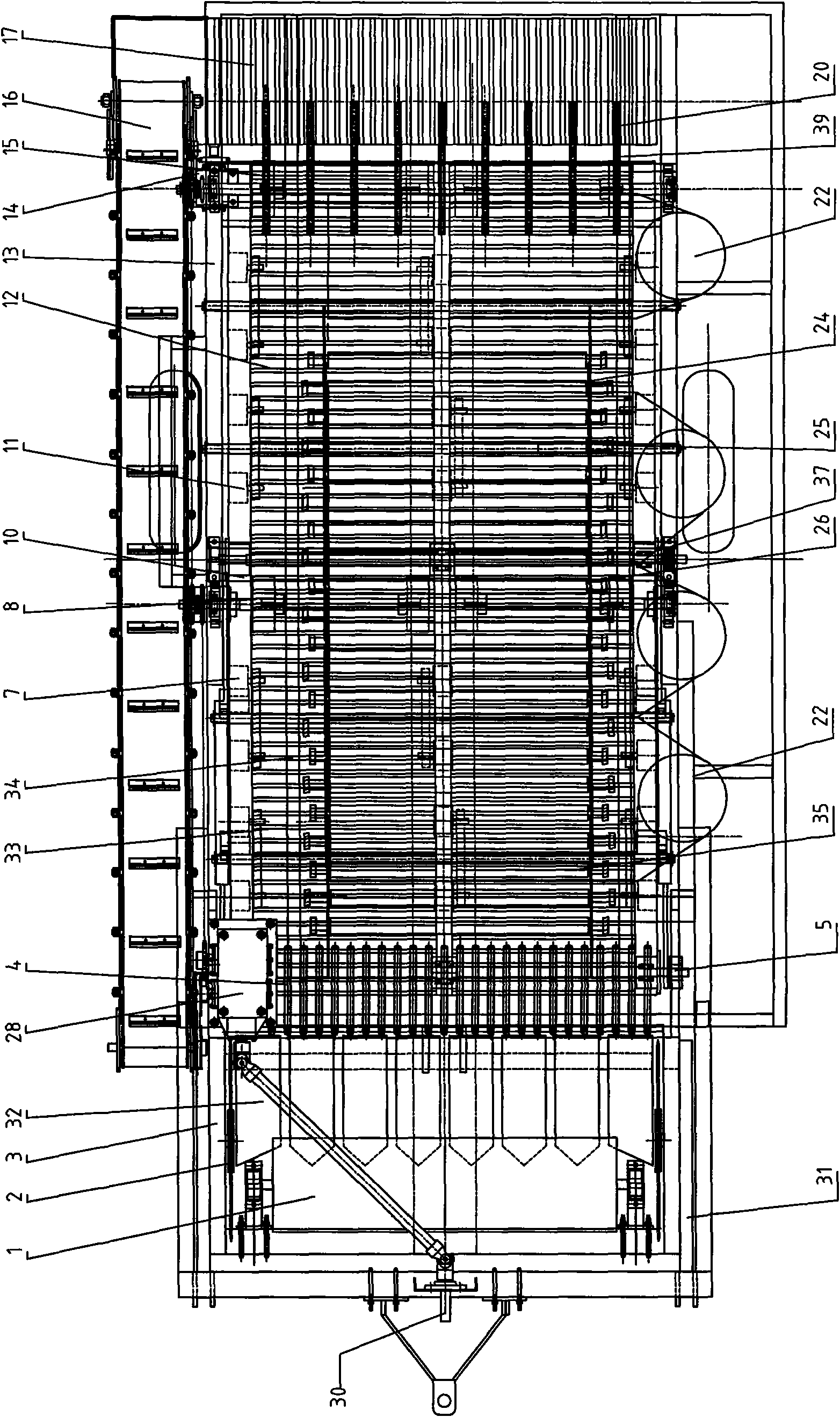

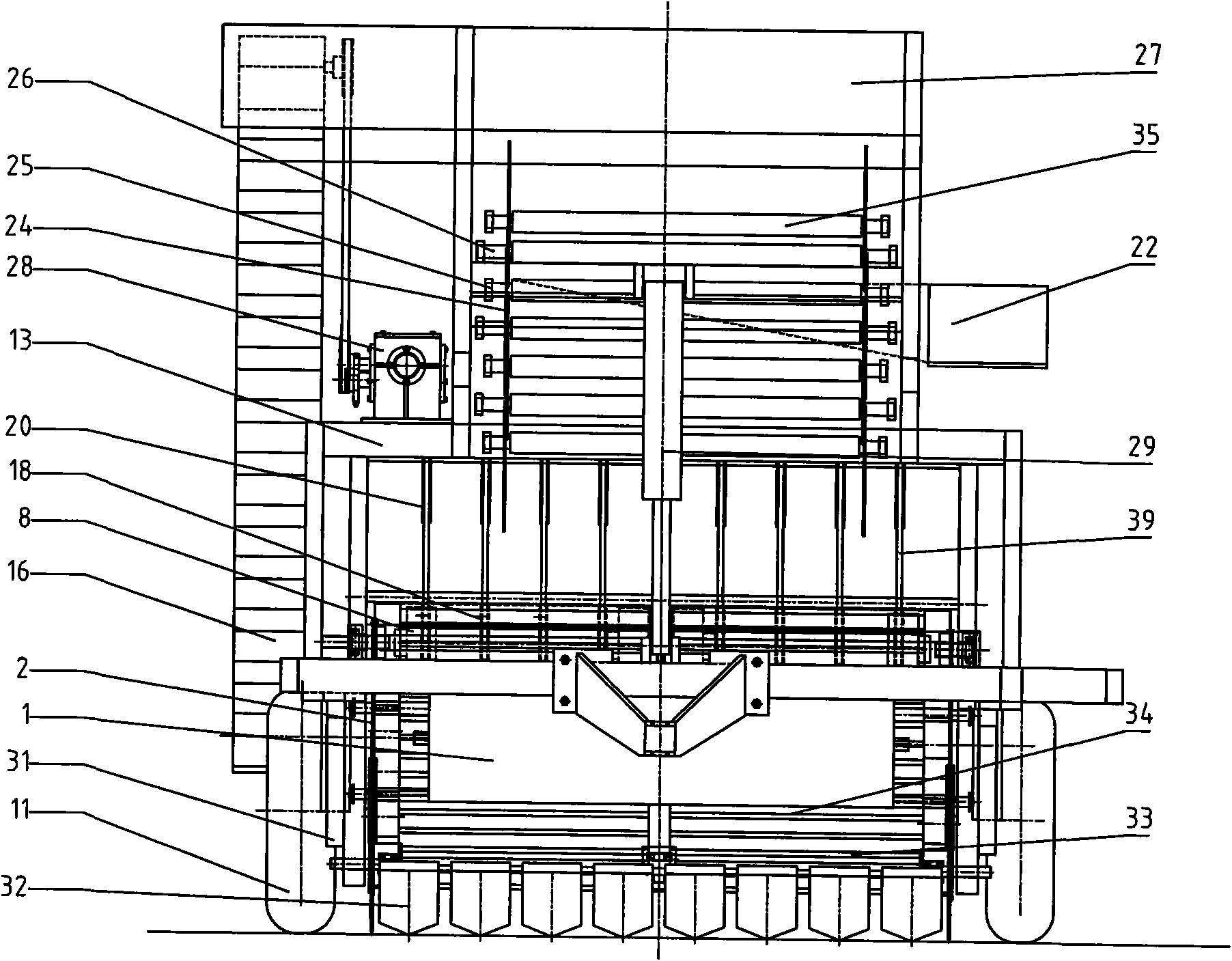

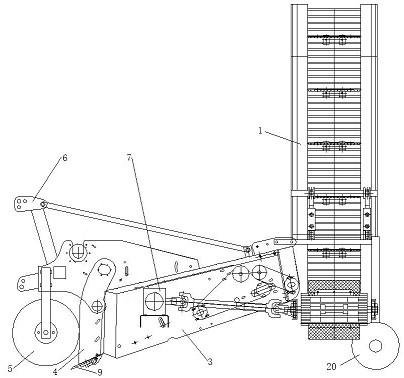

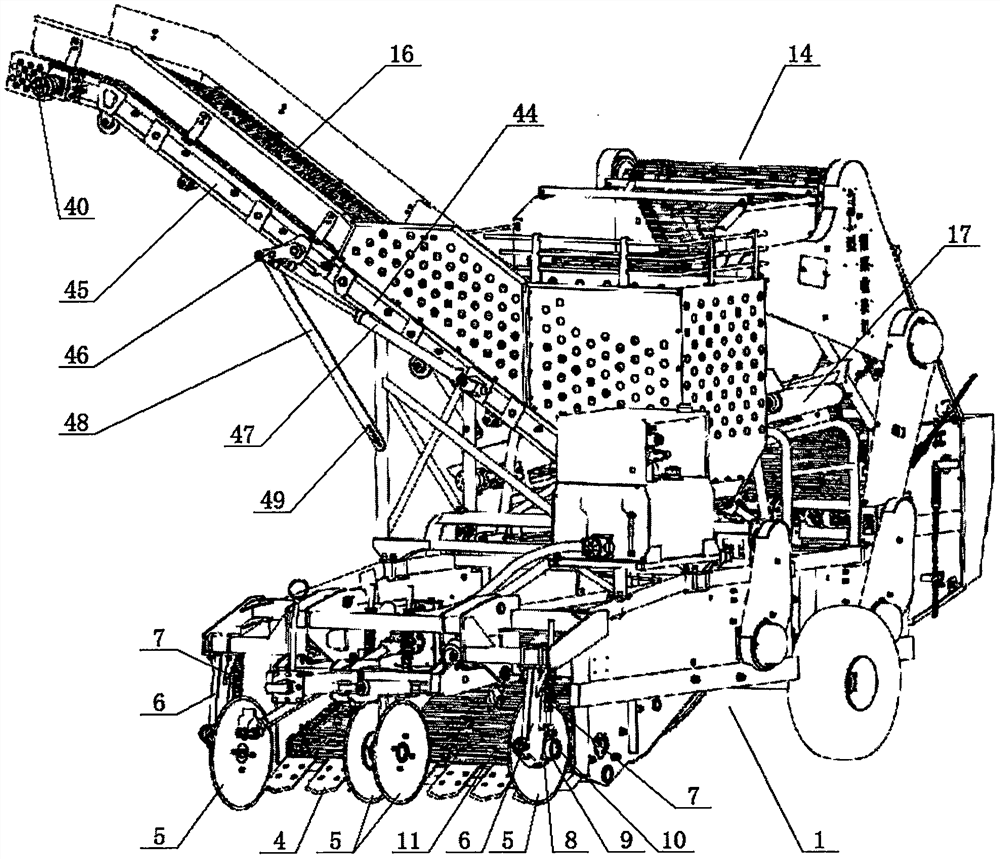

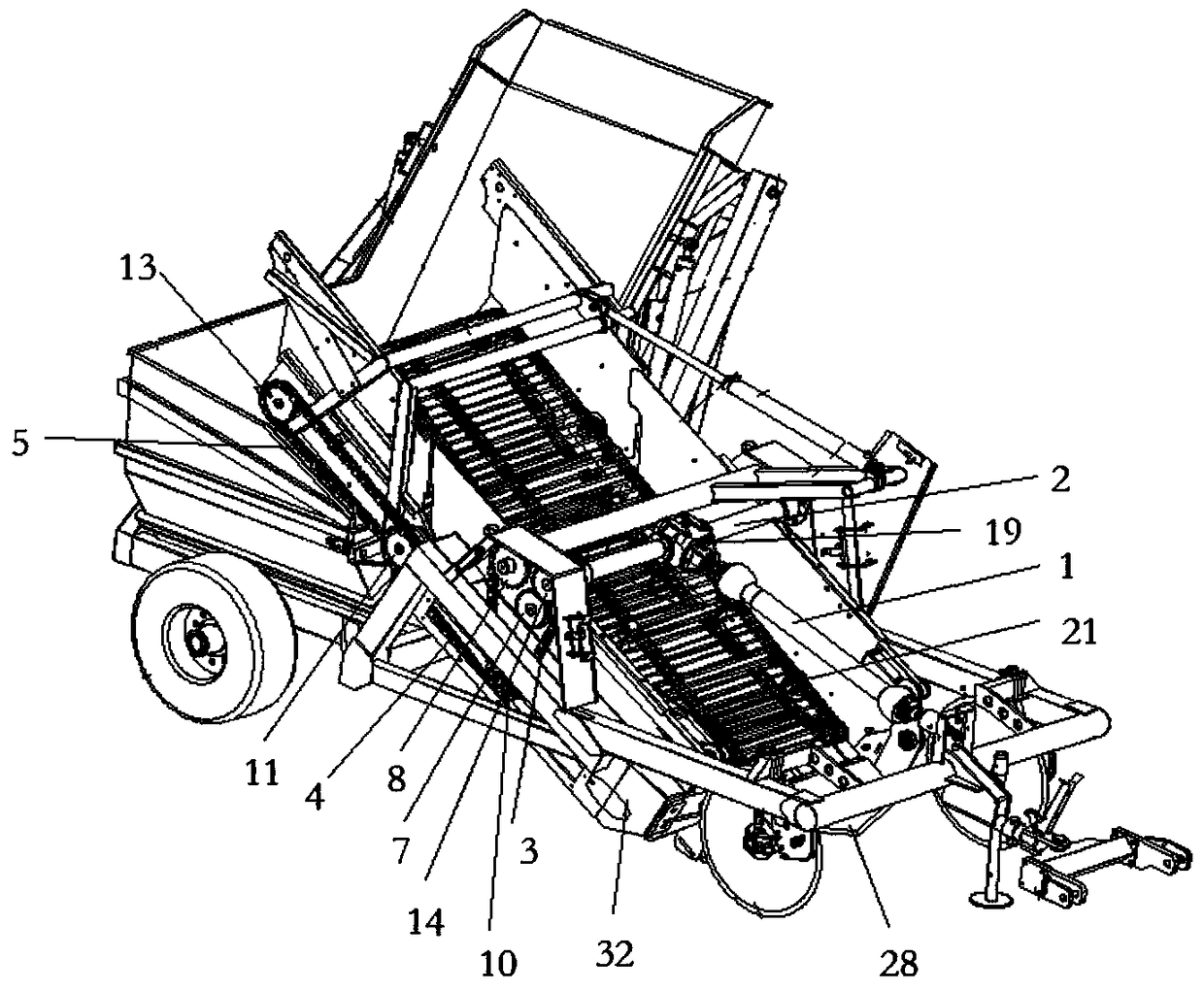

Staged packaging type potato combine harvester

The invention relates to a staged packaging type potato combine harvester. The harvester comprises a rack (13); a roll shaft chain type staging device (35), a first stage soil and potato separation and conveying device (34) and a second stage soil and potato separation and conveying device (12) are arranged on the rack (13); ground wheels (11) are arranged at the lower part of the rack (13); a belt scraper type lifting elevator (16) is arranged on one side; a material receiving and packaging device (22) is arranged on the roll shaft chain type staging device (35); a transverse chain rod type conveyor (17) is arranged at the back end of the second stage soil and potato separation and conveying device (12); an elastic stripper rod pick-roll type two-stage stalk separation device and rubber belt type two-stage stalk separation device are further arranged between the first stage soil and potato separation and conveying device (34) and the second stage soil and potato separation and conveying device (12); a digging shovel frame (3) and the rack (13) are articulated through a traction rod (31); a copying soil breaking roll (1), a soil cutting disk (2), a digging shovel (32) and a soil loosening transition tooth (4) are arranged on the digging shovel frame (3); and the upper part of the digging shovel frame (3) is connected with a lifting rod of a lifting cylinder (29). The harvester is in tractor traction type and can complete the procedures of digging of potato crops, soil and potato separation, separation of stalk, weeds and a ground film, conveying and lifting of potatoes, staging of potatoes, collection, packaging and the like of potato crops.

Owner:GANSU AGRI UNIV

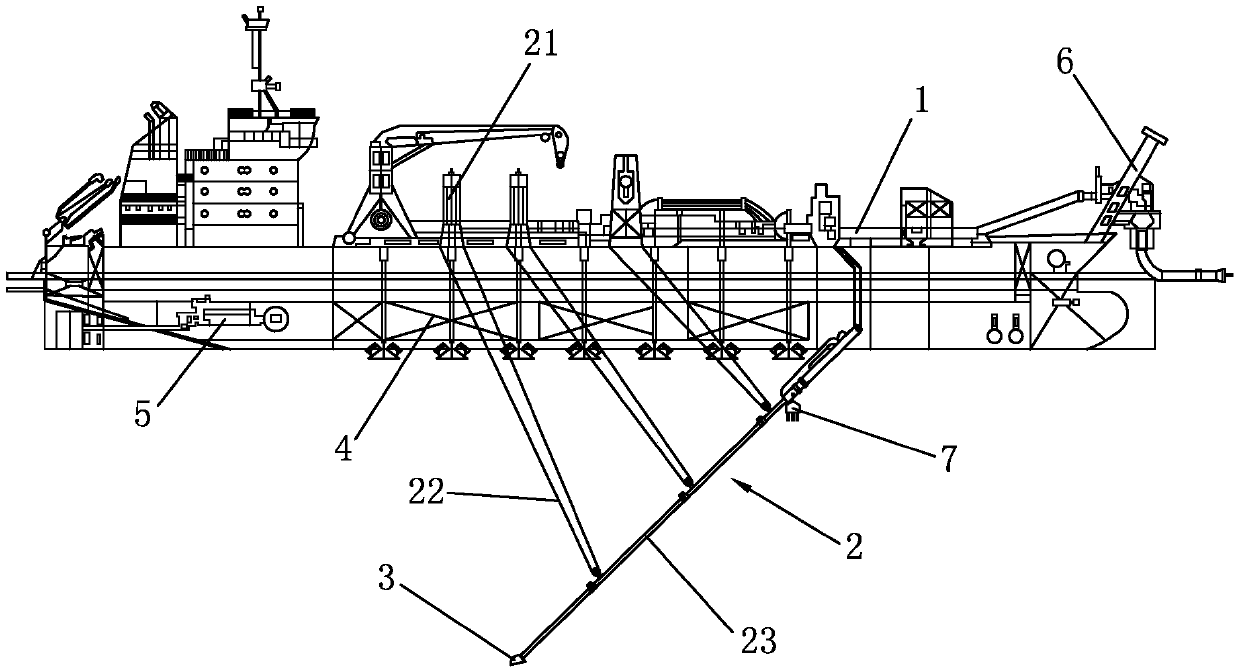

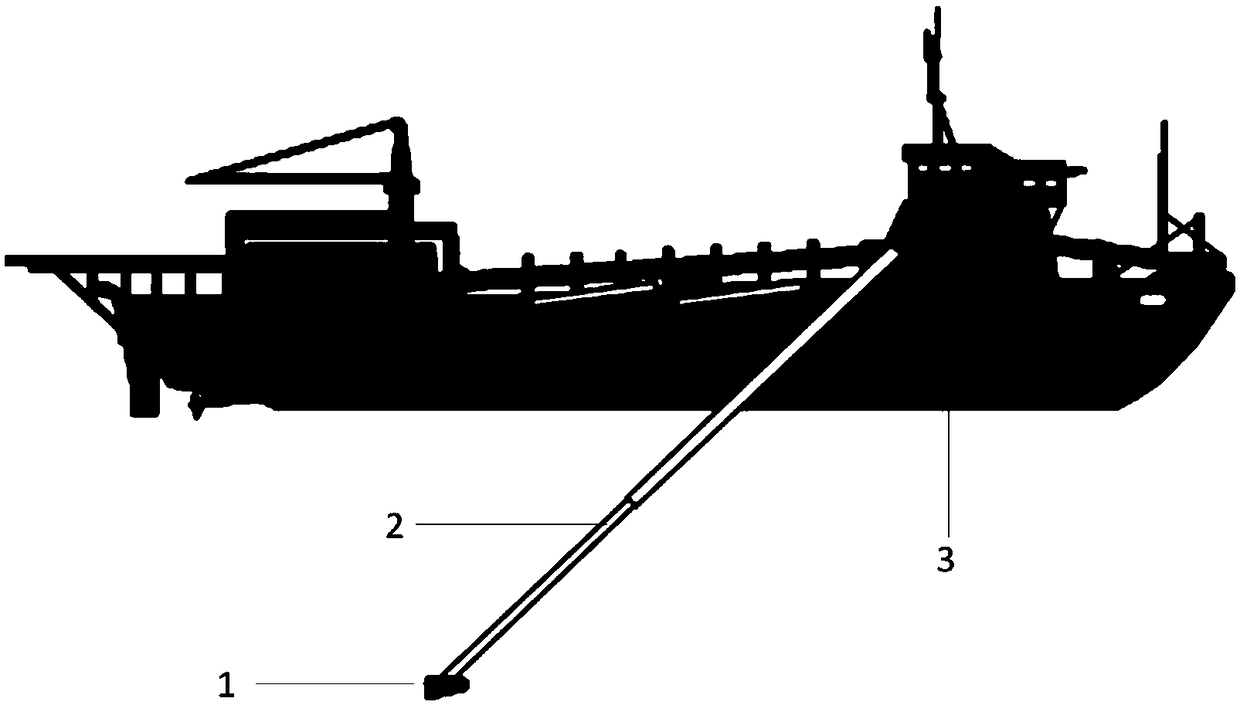

Self-propulsion trailing suction hopper dredger

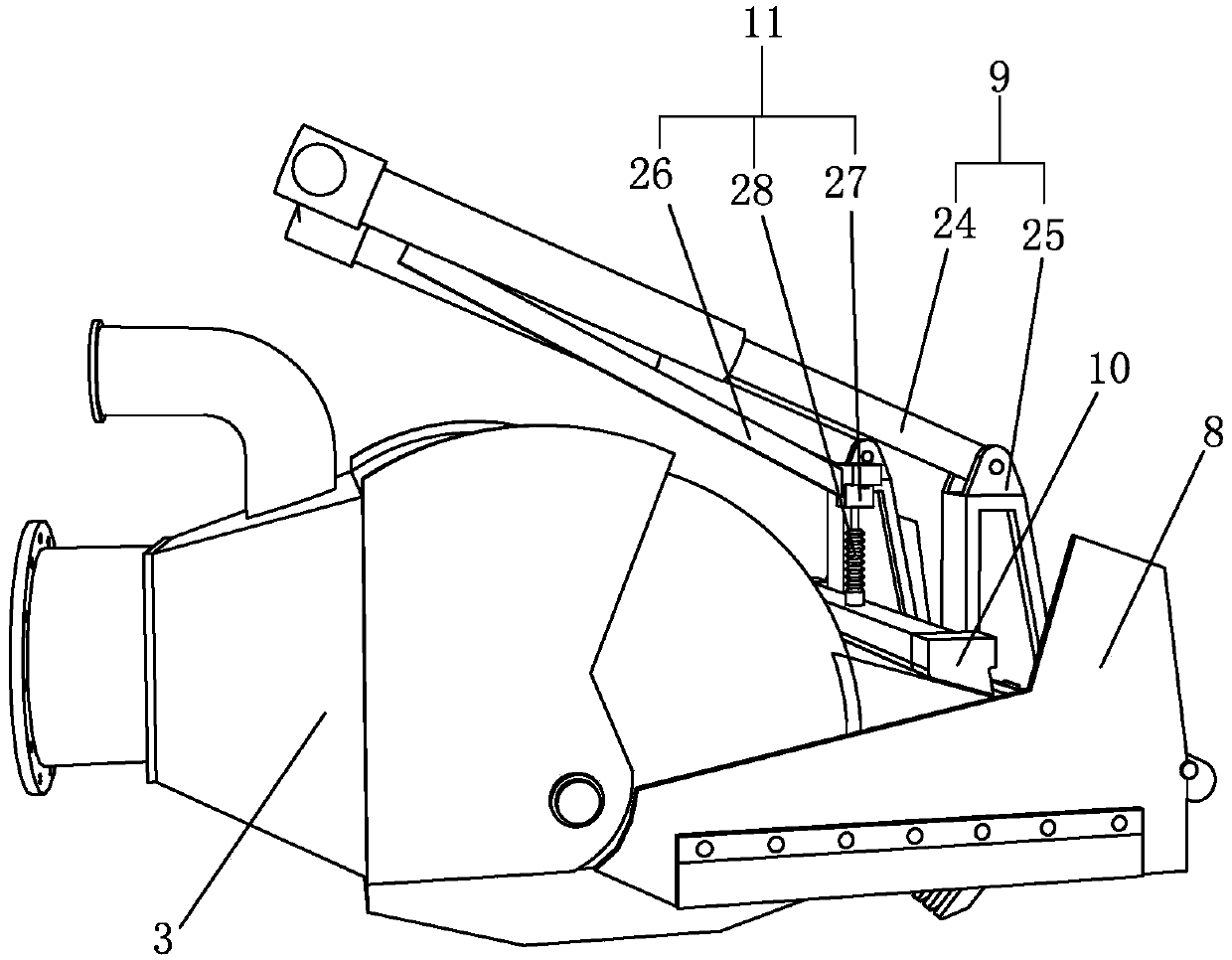

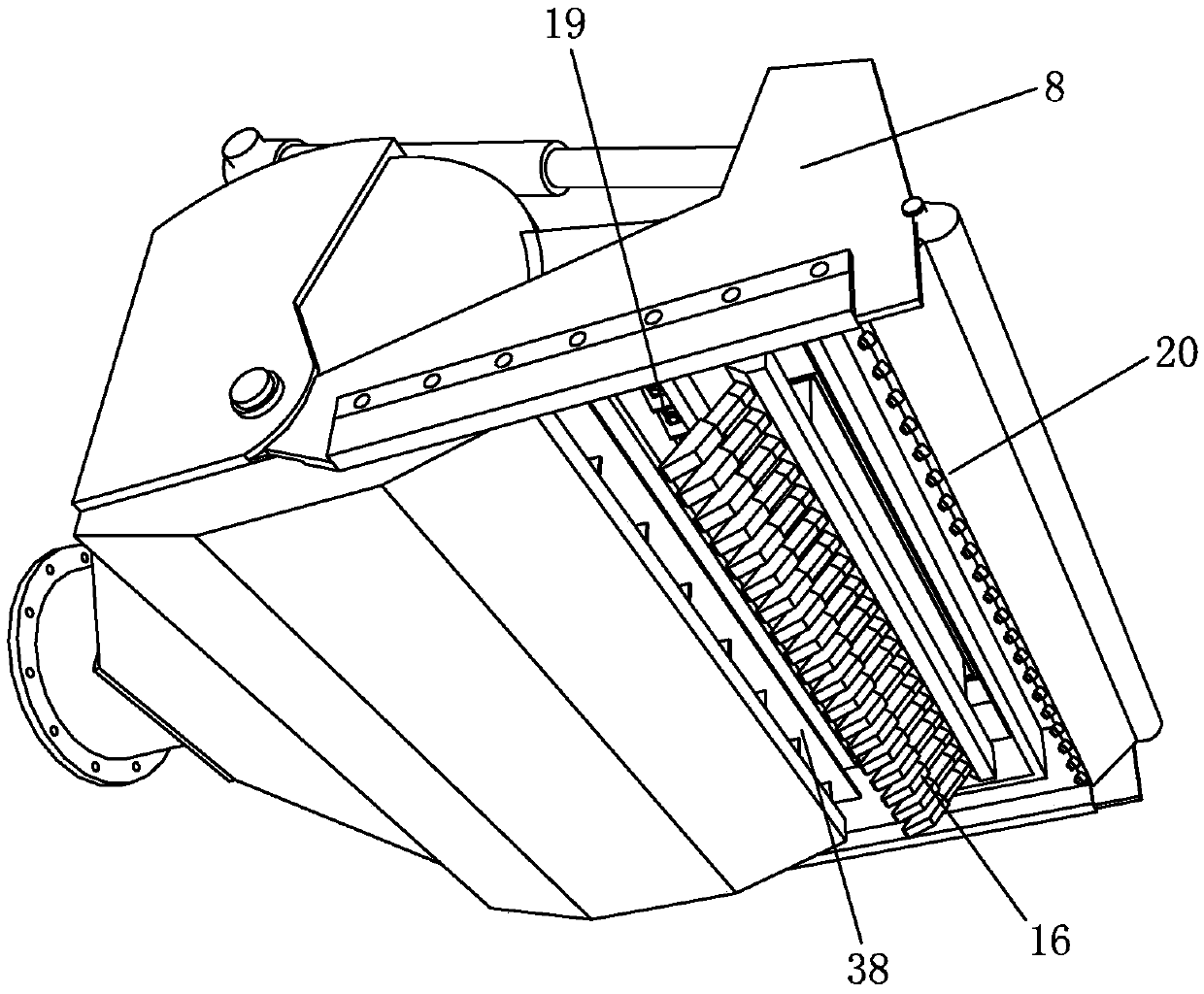

ActiveCN105507355AStrongImprove digging abilityMechanical machines/dredgersSludgeHigh pressure water

The invention discloses a self-propulsion trailing suction hopper dredger. The self-propulsion trailing suction hopper dredger comprises a dredger body; a movable cover is provided with a driving pressing block; a second driving device is arranged at the top of the driving pressing block; the movable cover is internally provided with a translation mechanism; the translation mechanism is provided with a movable through hole; a rake tooth shell is arranged in the movable cover; the rake tooth shell is internally provided with an engagement block; rake teeth are arranged on an inclined plane of the engagement block; a fixed plate is arranged on the top surface of the engagement block; positioning shafts are arranged on the two sides of the fixed plate; a first high-pressure water spraying device is vertically arranged on the inner side of the movable cover; and a second high-pressure water spraying device is obliquely arranged at the outer end of the movable cover. The first high-pressure water spraying device and the second high-pressure water spraying device are matched with each other and spray water to each other, so that underwater soil blocks are loosened; meanwhile, the rake teeth are driven to move up and down; one section of notch is opened underwater, and hard sludge can be conveniently raked when the rake teeth rake the sludge, so that digging resistance of a rake head is reduced, and the digging capability and dredging efficiency of the rake head are improved; and the self-propulsion trailing suction hopper dredger has the effects of high sludge digging efficiency and low production cost.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

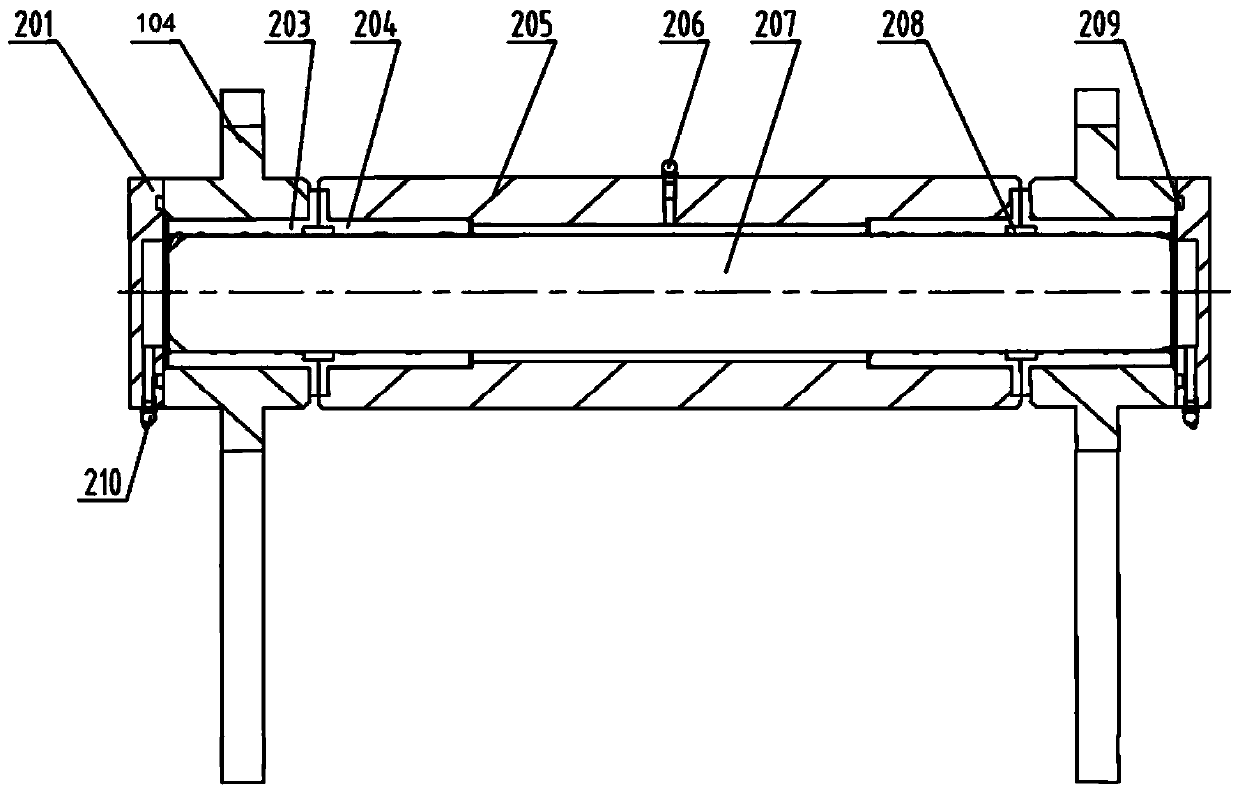

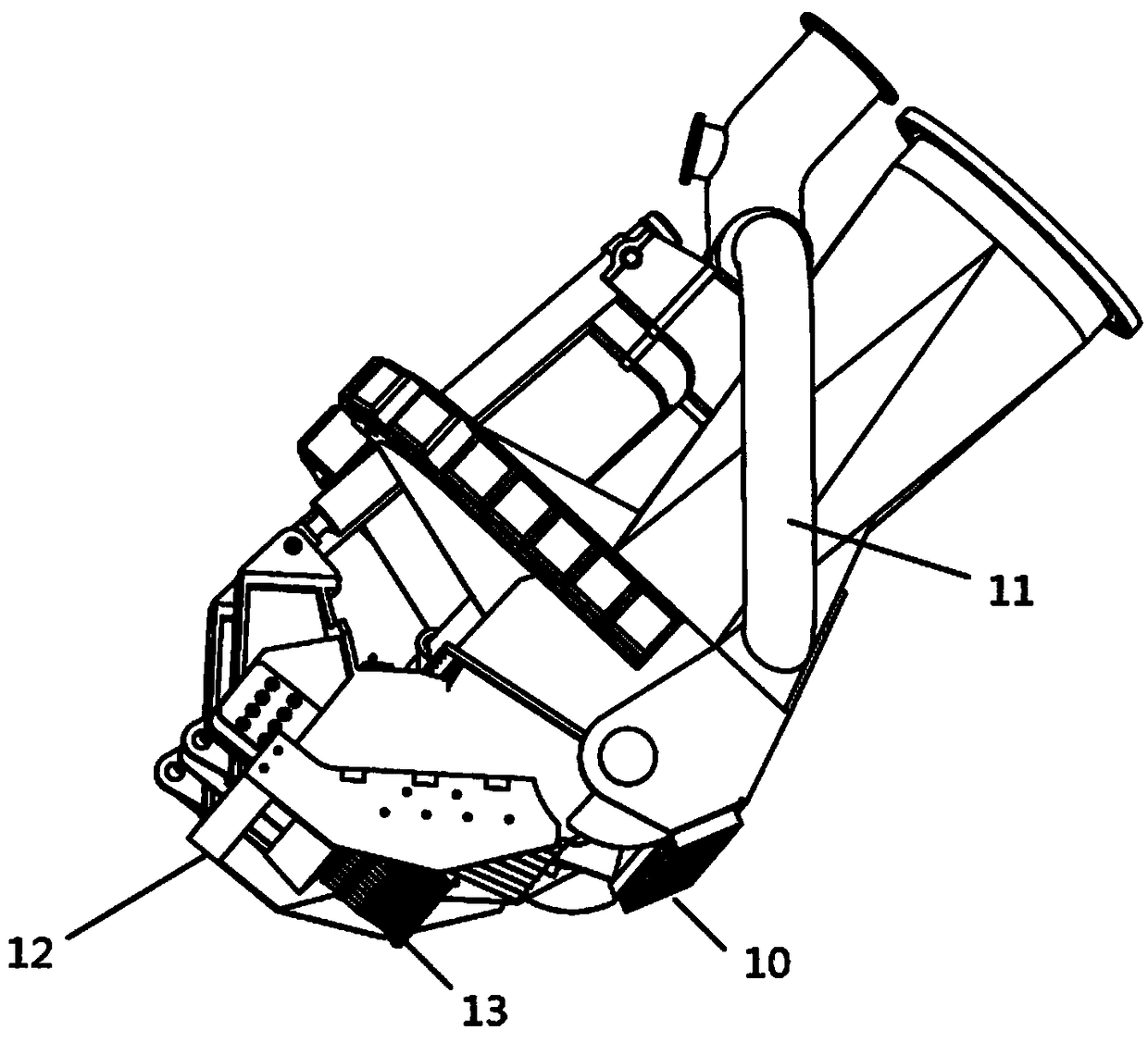

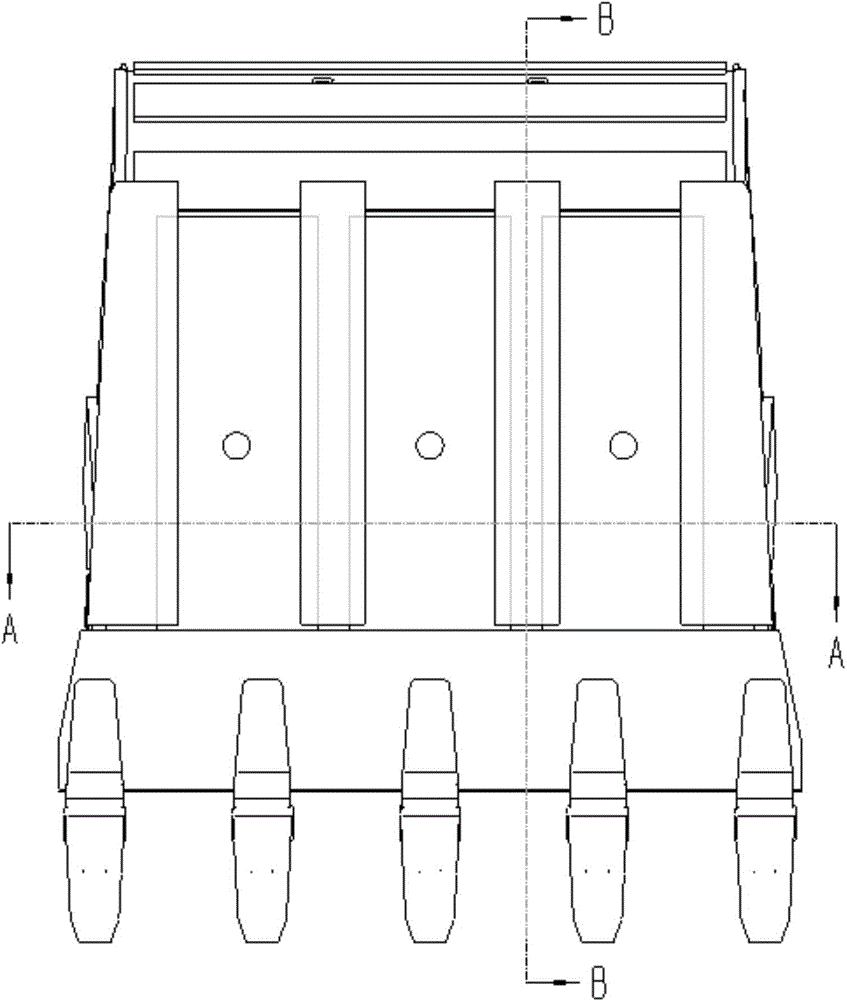

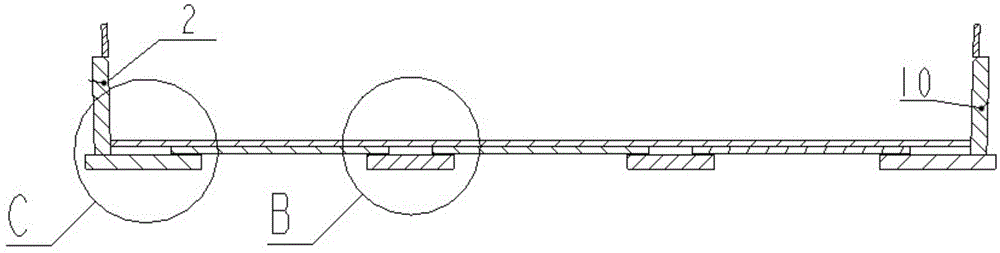

Clay bucket for excavator

ActiveCN103088856AExtrusion process is simpleEasy to cutAnodisationMechanical machines/dredgersBlade plateFront edge

The invention provides a clay bucket for an excavator. The clay bucket for the excavator can achieve forcible soil discharge. A bucket body comprises a left side plate and a right side plate which are parallel. A transverse arc-shaped base plate and a back plate are connected between the left side plate and the right side plate. A main blade plate is arranged at the front edge of the base plate. A scraping bucket and a steel wire are arranged in the bucket body. The scraping bucket comprises an arc-shaped plate capable of being attached to the base plate and scrapers located at the left side and the right side of the arc-shaped plate. Each scraper comprises a strip-shaped substrate and a blade. The blade of each scraper faces a bucket opening and is attached to the side plate at the corresponding side. A whole cross section of the scraping bucket is in a in the shape of a left square bracket. An included angle portion of each scraper and the arc-shaped plate is in arc transition. The front edge of the arc-shaped plate is hinged with the front edge of the base plate. Two ends of the steel wire are respectively fixed on the rear edge of the arc-shaped plate and a lower surface of a bucket rod near the rear portion of a front hinged point of the bucket rod. When the arc-shaped plate is attached to the base plate tightly, the steel wire is in a tightened state. The left side plate and the right side plate are respectively provided with a limit block used for stopping further motion of the scraping bucket when the bucket reaches a maximal discharge angle.

Owner:山东鲁班机械科技有限公司

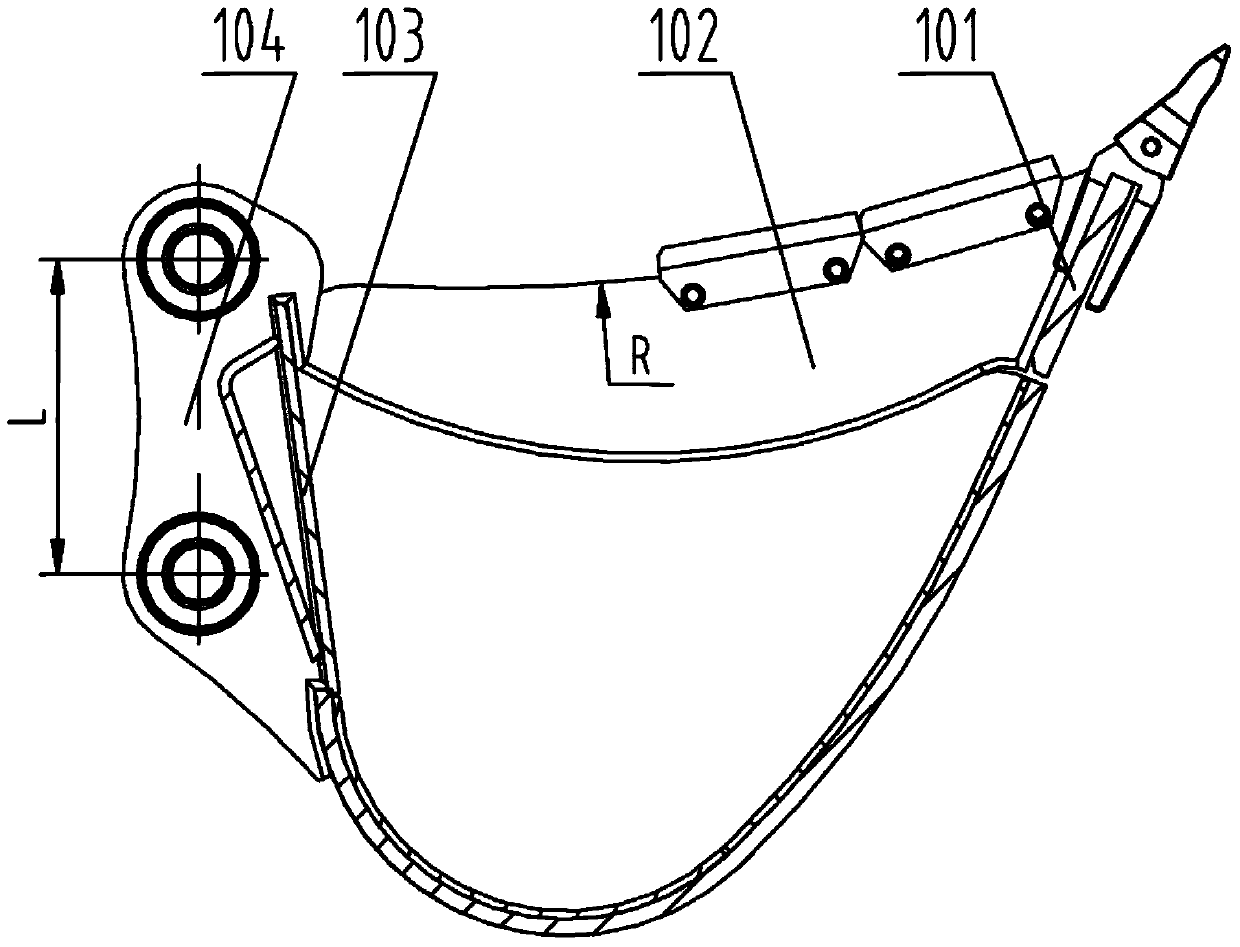

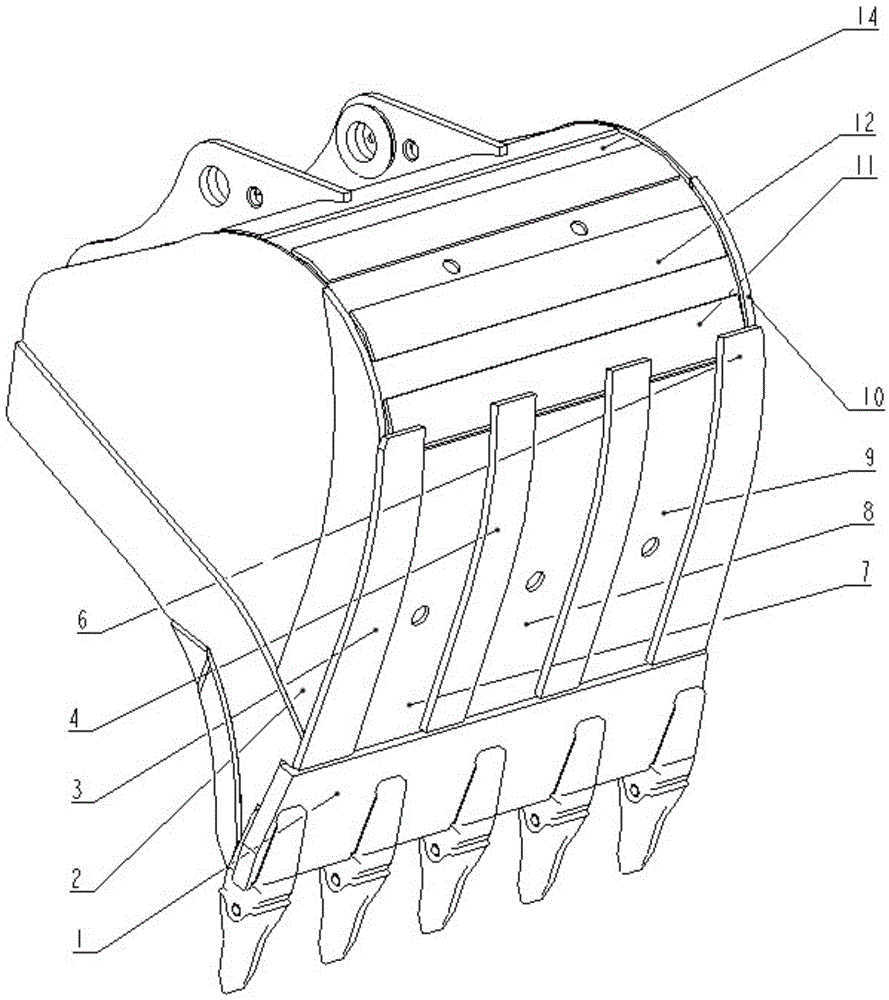

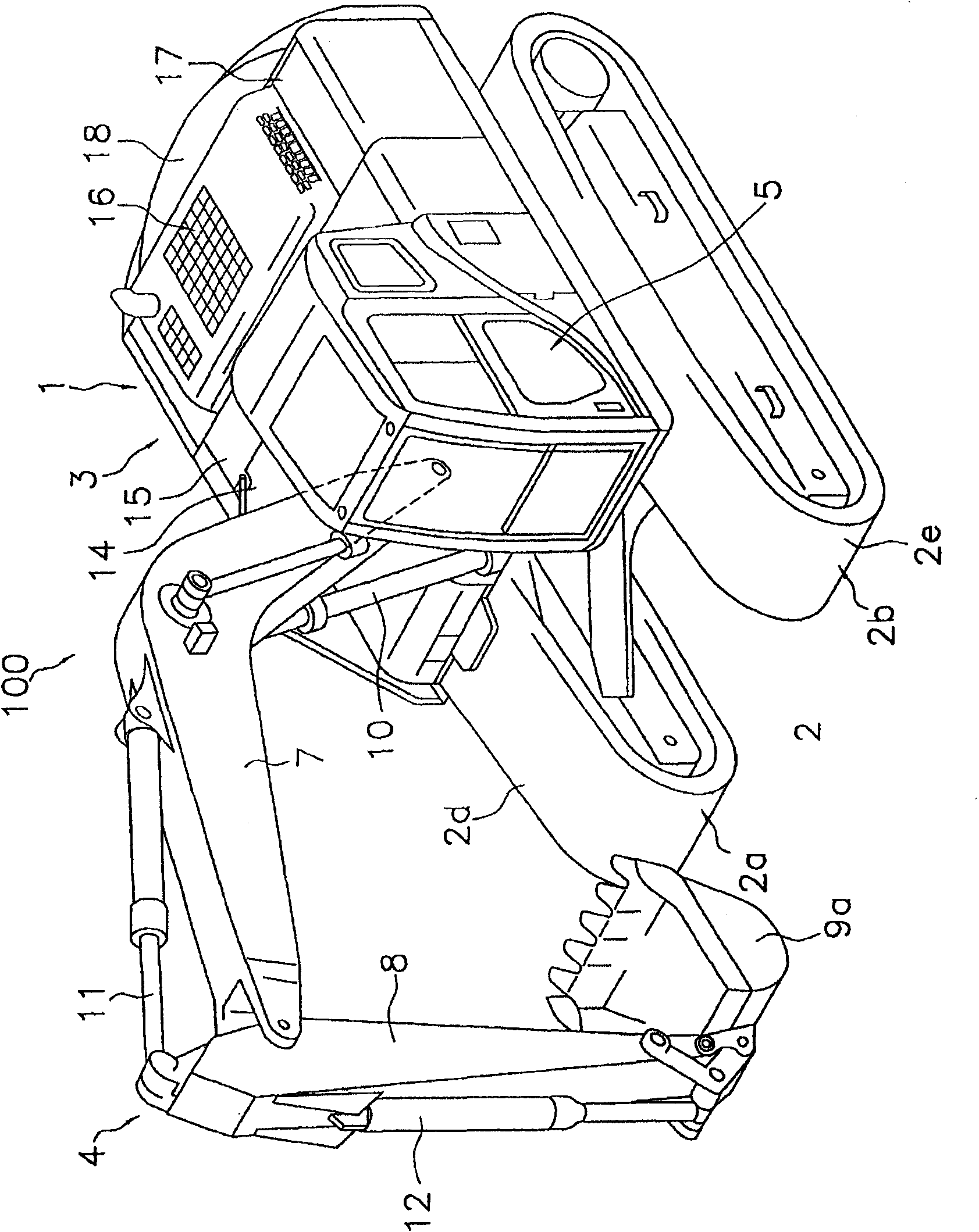

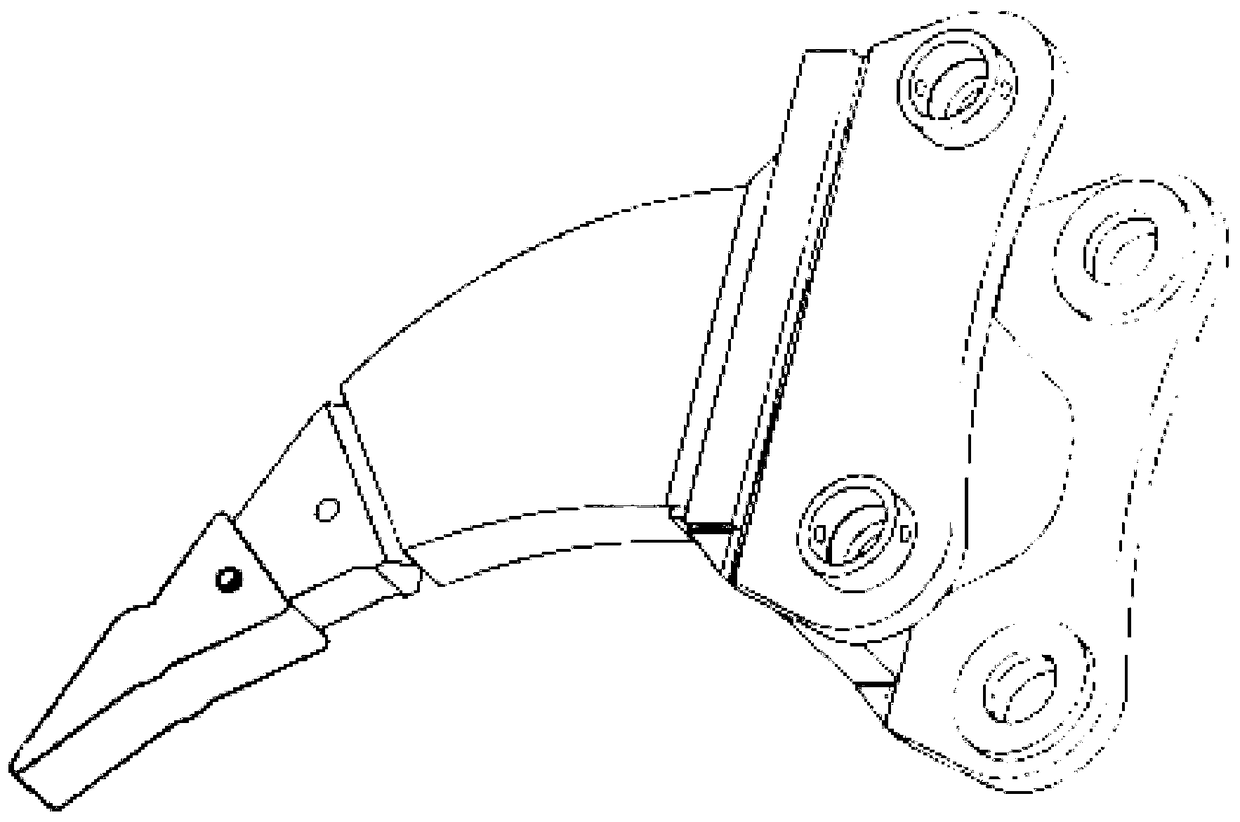

Digging bucket and bucket teeth thereof

InactiveCN102733446AEasy to uninstallExtended service lifeMechanical machines/dredgersVertical planeEngineering

The invention provides a digging bucket and bucket teeth of the digging bucket. Each of the bucket teeth comprises a wedge-shaped bucket tooth body, an upper thick tooth surface and an upper thin tooth surface, wherein the upper thick tooth surface is positioned at the upper surface of the wedge-shaped bucket tooth body; and the upper thin tooth surface is of a curved surface formed by downward depressing the upper surface of the wedge-shaped bucket tooth body, and is positioned at two sides of the upper thick tooth surface, and the projection of the curved surface, in the vertical plane, is of the projection region of a surrounding area. The strength and wear resistance of the bucket teeth can be improved, and the service lives of the bucket teeth can be prolonged.

Owner:DOOSAN INFRACORE CHINA

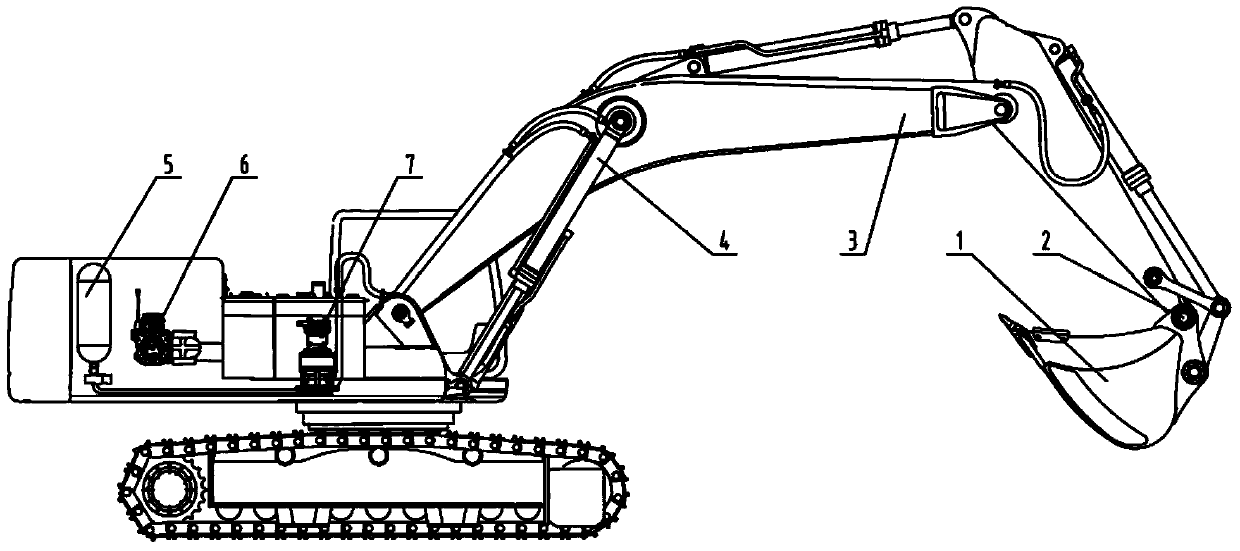

Efficient energy-saving environment-friendly oil-hydraulic hybrid powder excavator

The invention discloses an efficient energy-saving environment-friendly oil-hydraulic hybrid powder excavator. The efficient energy-saving environment-friendly oil-hydraulic hybrid powder excavator comprises an upper frame, a swivel plate, a scraper bucket, a scraper bucket pin shaft connecting mechanism, a boom, a boom working device, an energy accumulator energy-charging device, an oil supply device and a rotating power assembly; the upper frame is mounted on the swivel plate which is connected to the rotating power assembly; the scraper bucket is assembled on a bucket rod by virtue of the scraper bucket pin shaft connecting mechanism; the boom is hinged to the bucket rod by virtue of the scraper bucket pin shaft connecting mechanism on one hand, and other the other hand, the boom is connected with the upper frame by virtue of an upper frame pin shaft; the boom working device is a three-cylinder boom working device; the oil supply device is a three-pump oil supply device; the three-cylinder boom working device is hinged between the boom and the upper frame; the energy accumulator energy-charging device, the three-pump oil supply device and the rotating power assembly are mounted on the upper frame, respectively, wherein the energy accumulator energy-charging device and the three-pump oil supply device both are connected with the three-cylinder boom working device. The efficient energy-saving environment-friendly oil-hydraulic hybrid powder excavator is very obvious in energy saving effect and also greatly improved in working efficiency.

Owner:SHANDONG CCHC HYDRAULICS

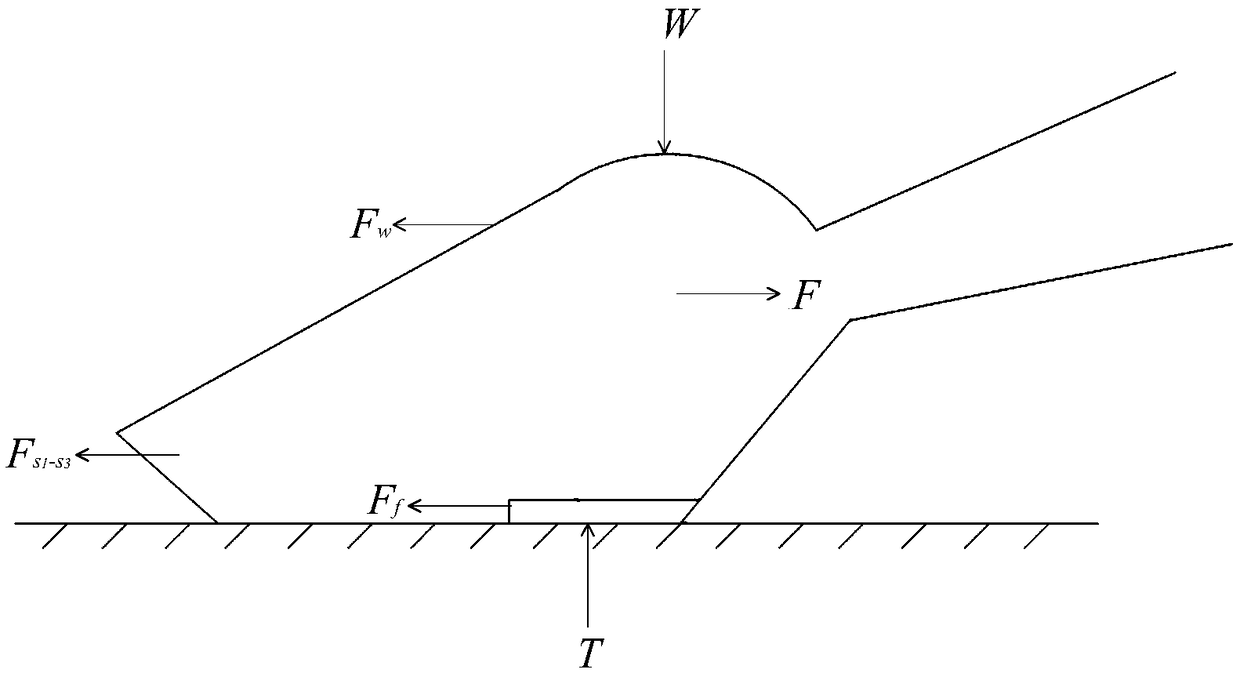

Rake head dredging system, trailing suction hopper dredger and method for reducing digging resistance by rolling friction

PendingCN108708414AReduce frictional resistanceReduce digging resistanceMechanical machines/dredgersRolling resistanceWater flow

The invention provides a rake head dredging system, trailing suction hopper dredger and method for reducing digging resistance by rolling friction and belongs to the technical field of dredging engineering. The rake head dredging system comprises a rake head fixed body, a rake head movable cover with rake teeth, a drag reduction rolling body and a high-pressure cleaning system. The rake head movable cover is assembled with the rake head fixed body, and the drag reduction rolling body is installed at the bottom of the rake head fixed body. The high-pressure cleaning system comprises multiple grooves formed in the surface of a wear reduction roller in the direction of a connecting shaft, multiple high-pressure nozzles arranged in each groove and a pressure pipeline connected with the high-pressure nozzles. The rake head dredging system has the beneficial effects that the drag reduction rolling body is provided in the rake head structure, the digging resistance is reduced, and the diggingefficiency is improved under the installed power of an existing drag suction dredger; and meanwhile, the high-pressure cleaning system is used to wash and loosen a soil layer by high-pressure water flow before the rake teeth cut the soil layer to reduce the cutting resistance and wash the soil attached to the wear reduction roller.

Owner:NAT ENG RES CENT OF DREDGING TECH & EQUIP

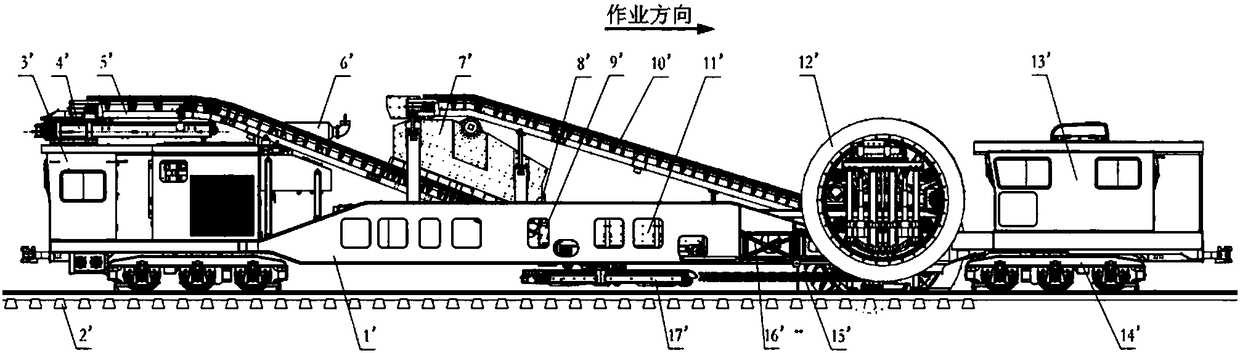

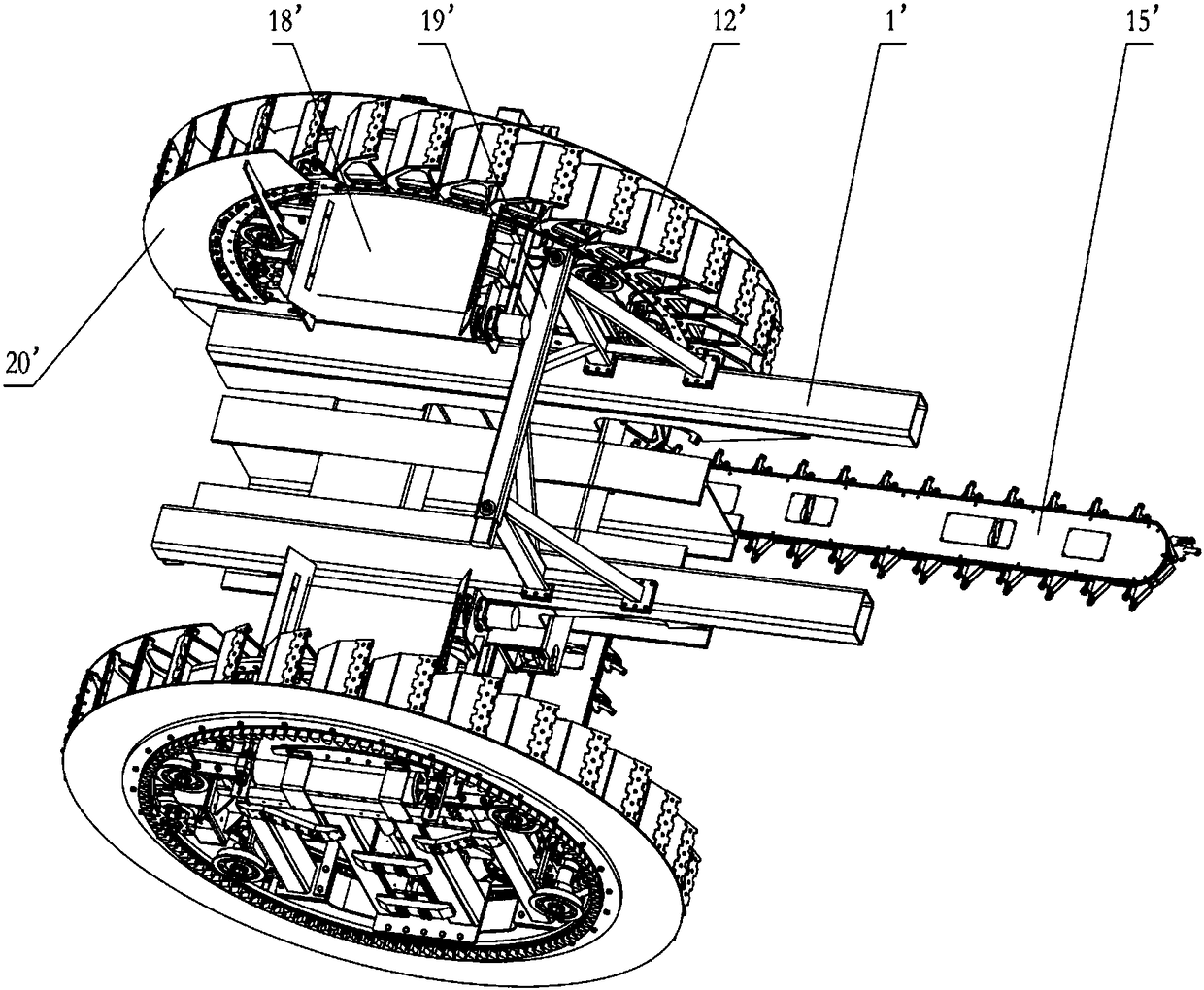

Railway ballast cleaner

InactiveCN108930204AGuaranteed geometryImprove adaptabilityBallastwaySoil-shifting machines/dredgersVehicle frameElectrical control

A railway ballast cleaner comprises a vehicle frame. Cabs are arranged at the two ends on the vehicle frame. An excavation bucket wheel 12' is further arranged in the position, between the cabs at thetwo ends, of the vehicle frame 1' from front to back in the operation direction. The position behind the excavation bucket wheel 12' is connected with a mixed ballast conveyor belt 10'. A screening device 7' is arranged on the lower portion at the tail end of the mixed ballast conveyor belt 10'. A ballast separation device 8' and a main dirty soil conveyor belt 5' are arranged below the screeningdevice 7'. A ballast falling hopper 9' is arranged below the ballast separation device 8'. A loading and unloading storage and transportation box 11' is arranged in front of the ballast falling hopper 9'. A rotary dirty soil conveyor belt 4' is arranged on the lower portion behind the main dirty soil conveyor belt 5'. A backfill conveyor belt 17' is arranged below the ballast falling hopper 9'. Arail lifting device 16' is arranged in the position, behind the excavation bucket wheel 12', of the vehicle frame. The vehicle frame 1' is further provided with a power transmission system 6', an electrical control system, a hydraulic control system, a brake system, a pneumatic system and a walking system. The excavation bucket wheel 12' comprises a multi-degree-of-freedom lateral cutting type knife board 15'. The multi-degree-of-freedom lateral cutting type knife board can be adjusted at multiple degrees of freedom in the X direction, the Y direction and the Z direction in the use process according to the construction requirements, and the geometric dimension of a ballast bed section can be guaranteed.

Owner:CRCC HIGH TECH EQUIP CORP LTD

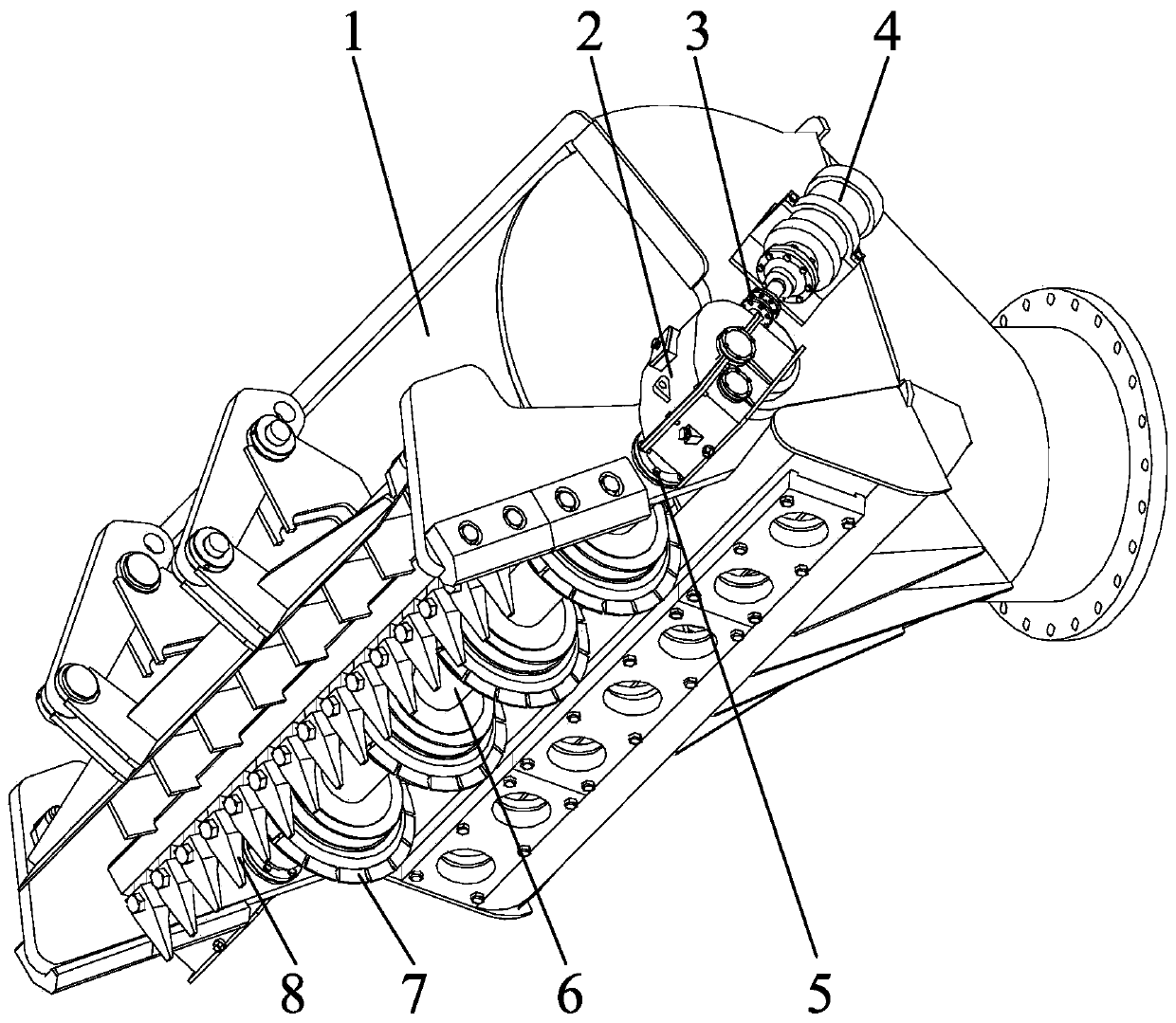

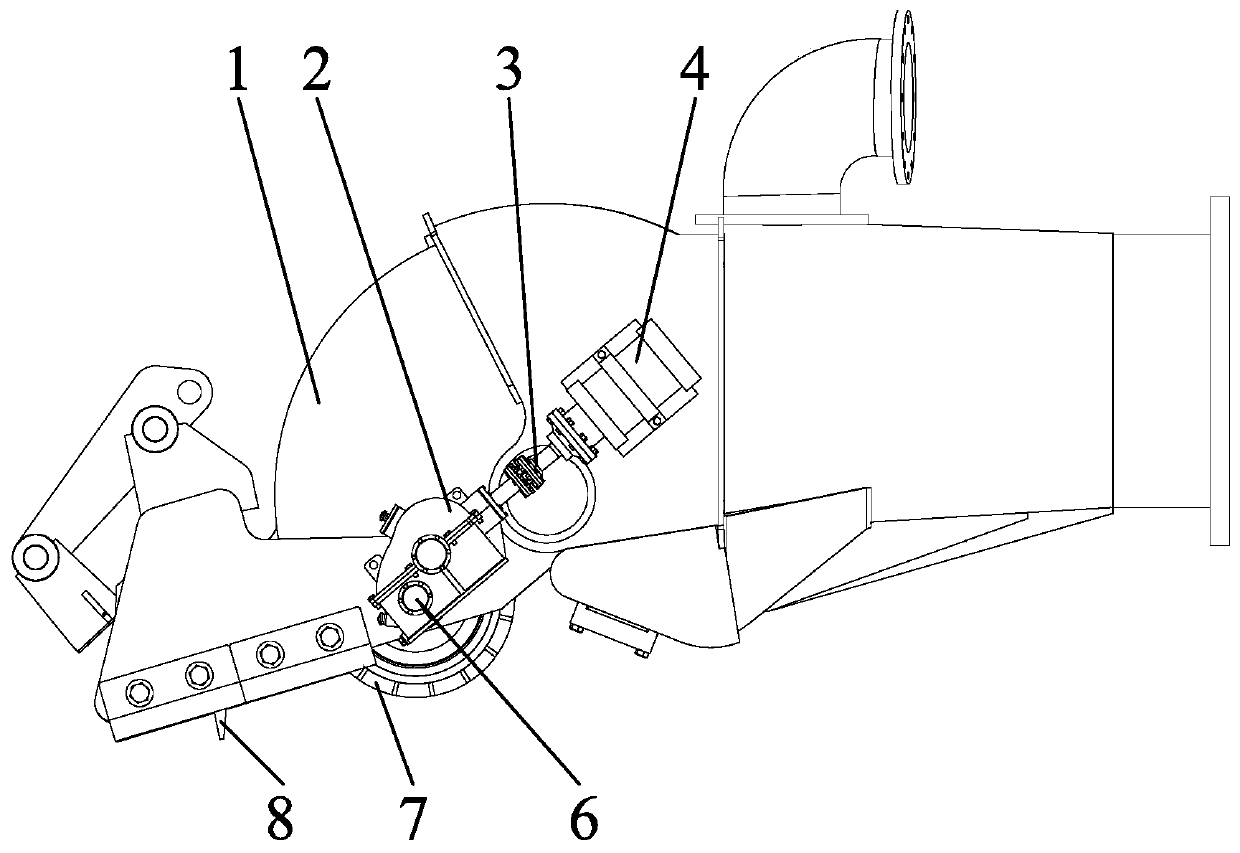

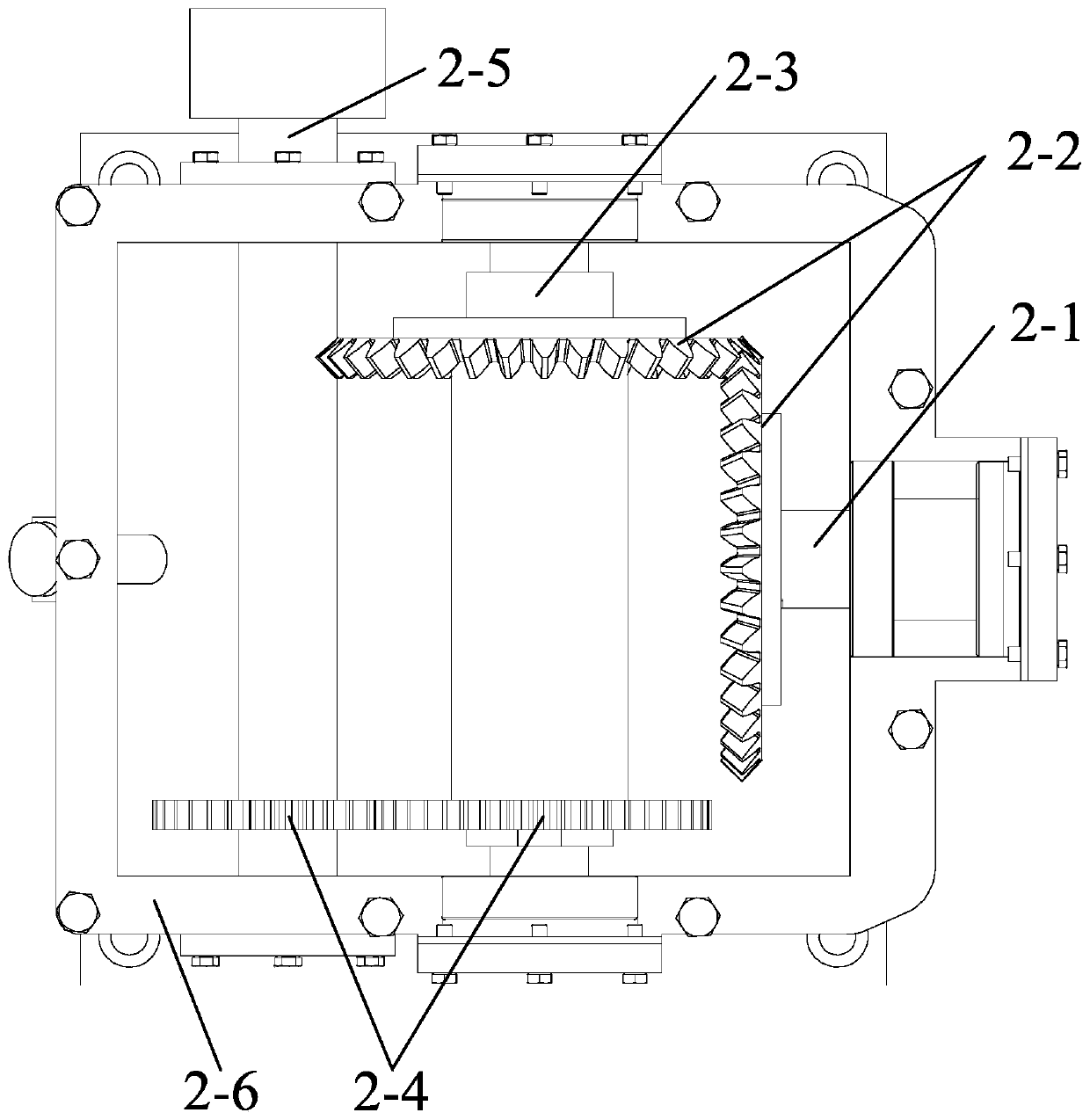

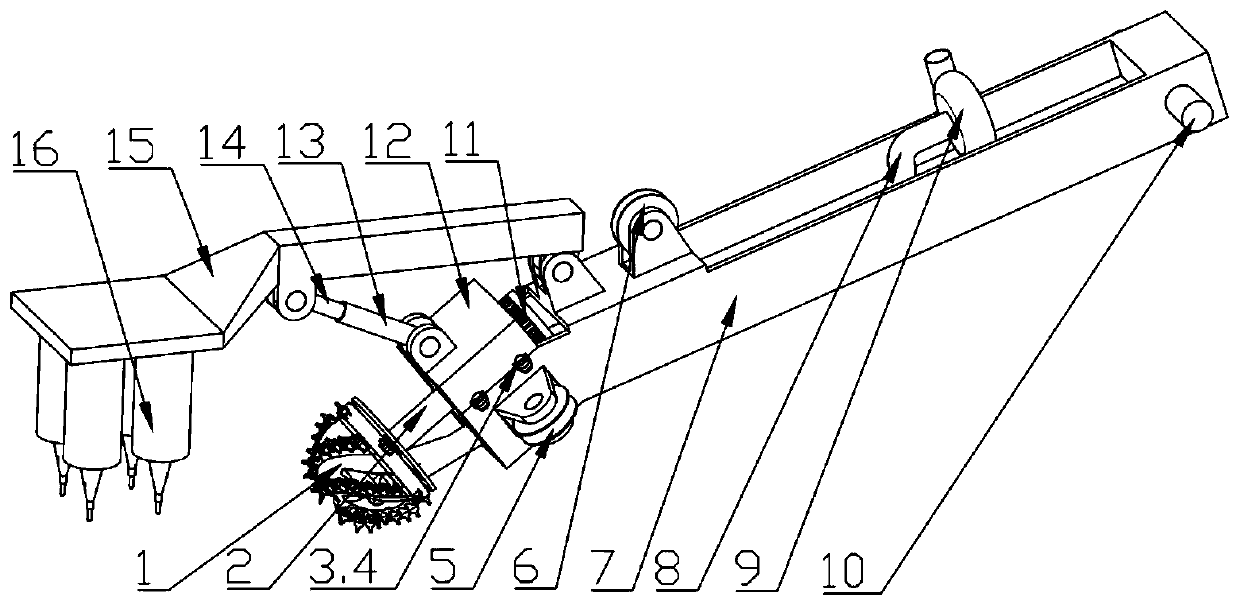

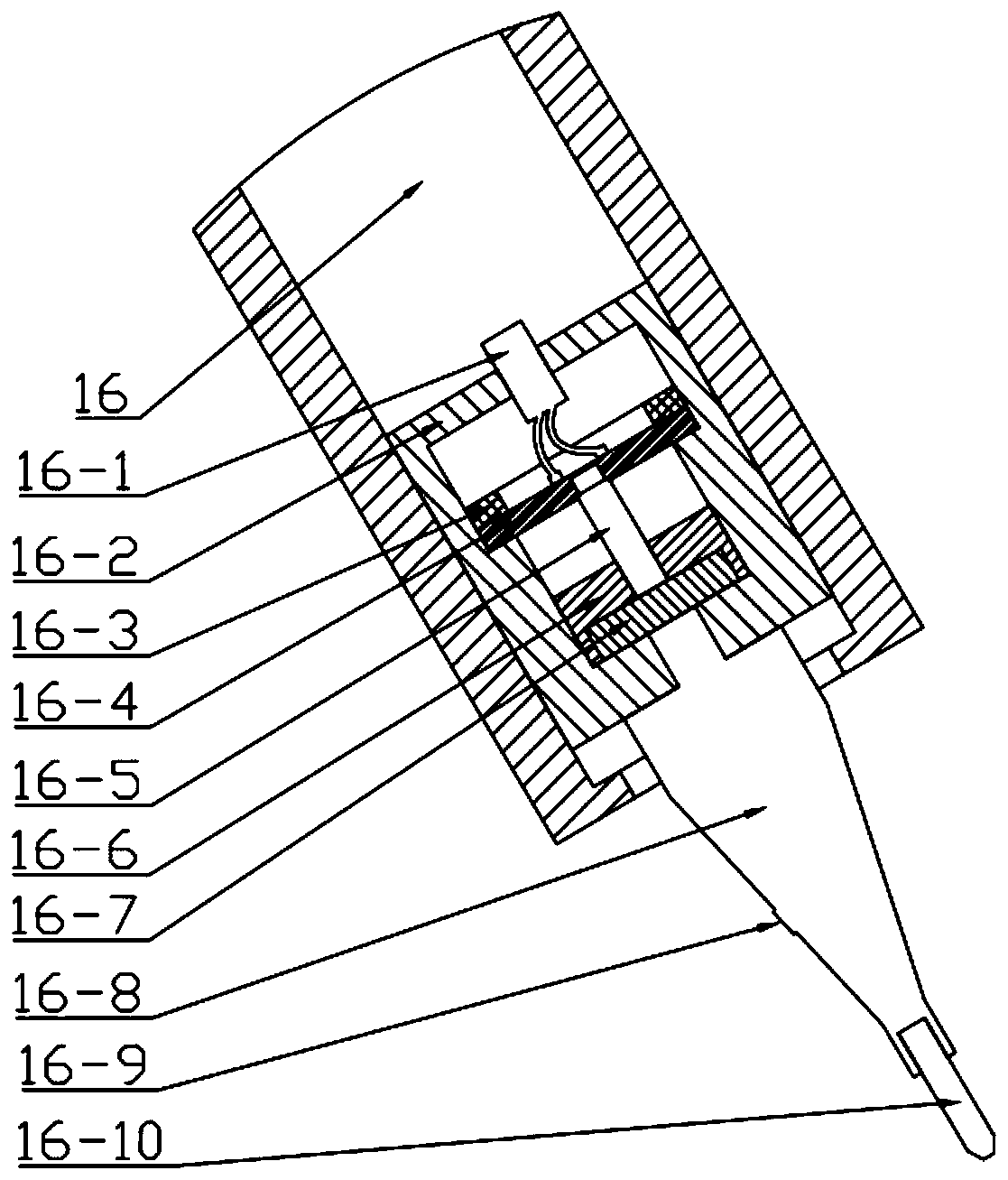

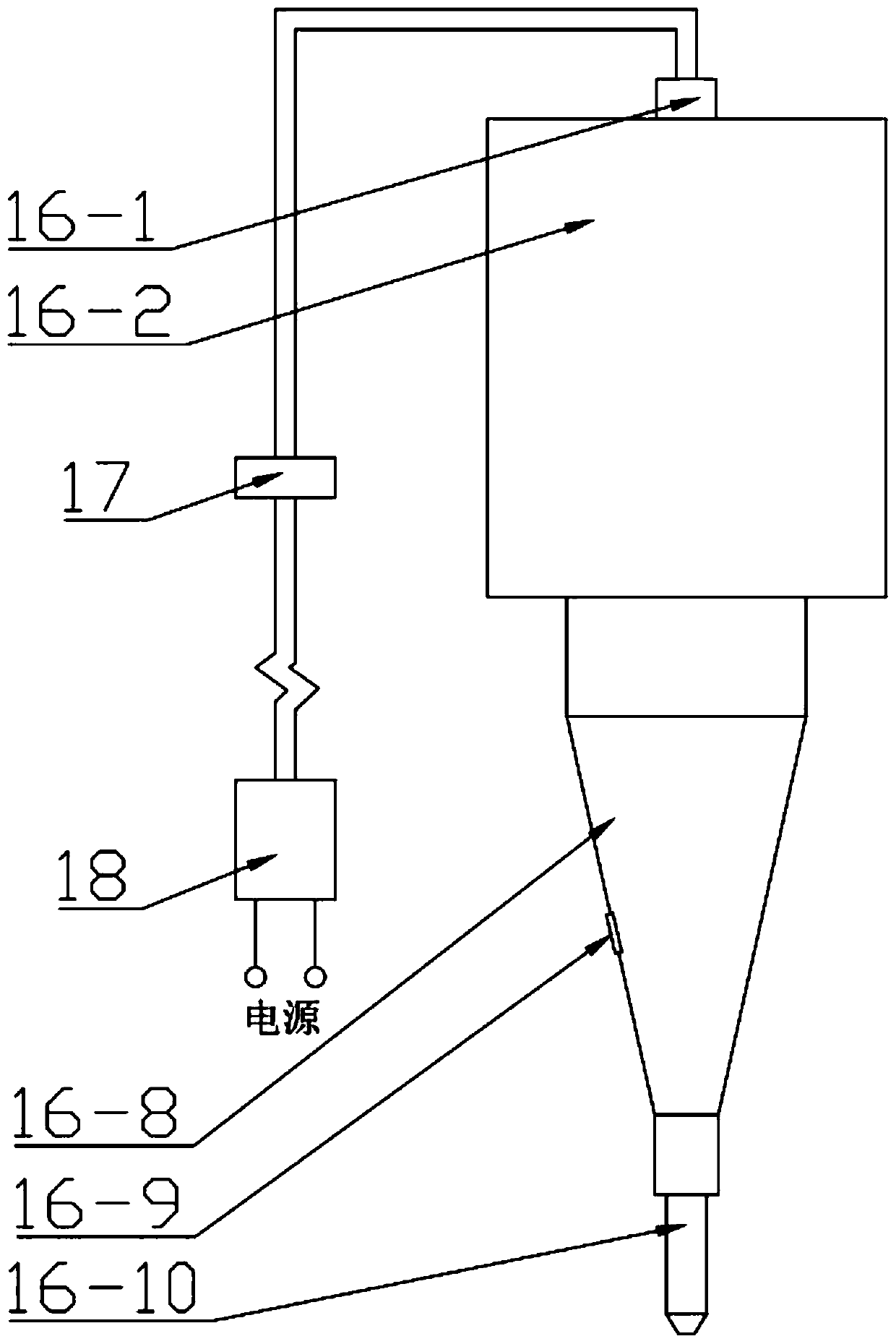

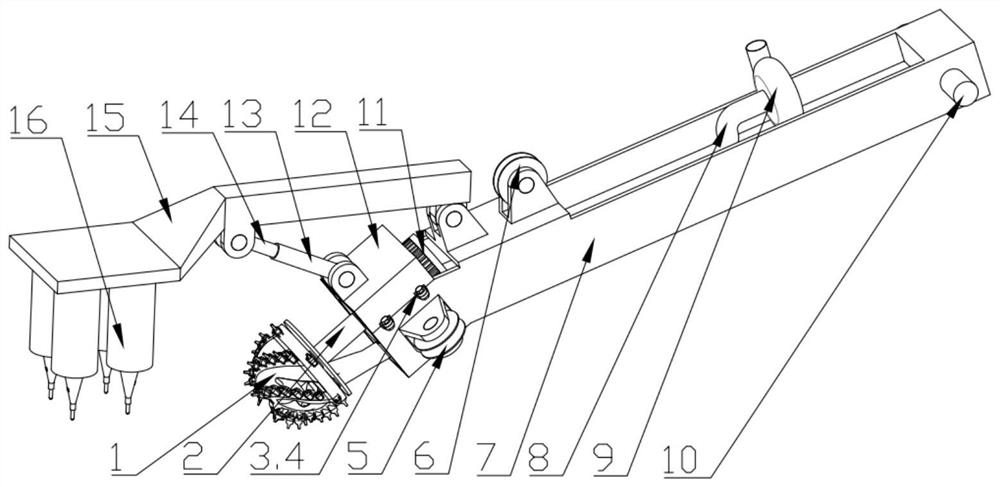

Novel hob auxiliary type drag suction dredger drag head

ActiveCN110318437AImprove digging efficiencyDestroy integrityMechanical machines/dredgersCouplingEngineering

the invention discloses a novel hob auxiliary type drag suction dredger drag head. The drag head comprises a drag head cover, a reduction gearbox, a coupler I, a coupler II, an underwater motor, a rotating shaft, a hob and a drag tooth, wherein the reduction gearbox, a coupler I, a coupler II and the underwater motor are located on the side of the drag head cover, the rotating shaft, the hob andthe drag tooth are located in the drag head cover, an output shaft of the underwater motor is connected with an input shaft of the reduction gearbox through the coupler I, an output shaft of the reduction gearbox is connected with the rotating shaft through the coupler II, the rotating shaft drives the hob to rotate for cutting, the drag tooth is located at the front end of the drag head, and thehob is located at the rear end of the drag tooth. According to the novel hob auxiliary type drag suction dredger drag head, the novel hob is adopted to assist the drag head to break rocks, so that theproblem of insufficient rock breaking capability of a traditional drag head is overcome, the efficiency of cutting the rocks by the drag suction dredger is improved, and the application range of thedrag suction dredger is enlarged.

Owner:HOHAI UNIV CHANGZHOU

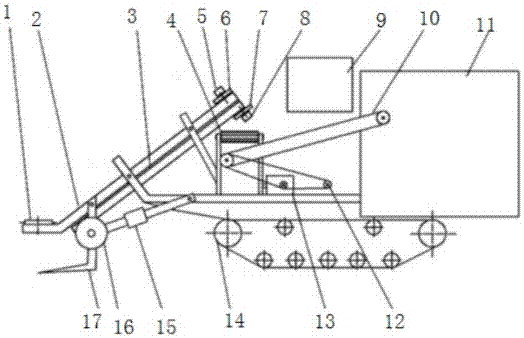

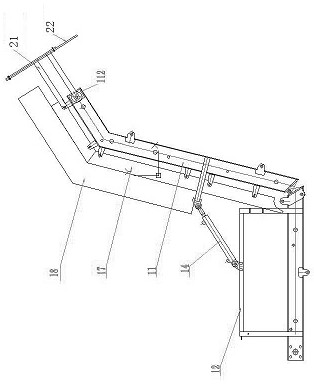

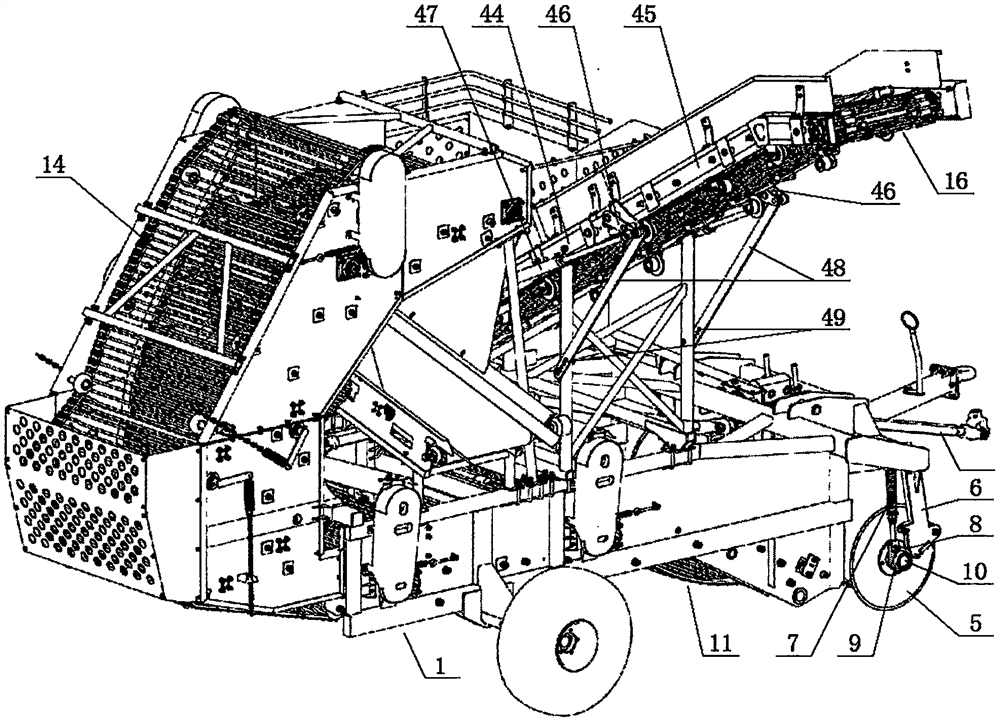

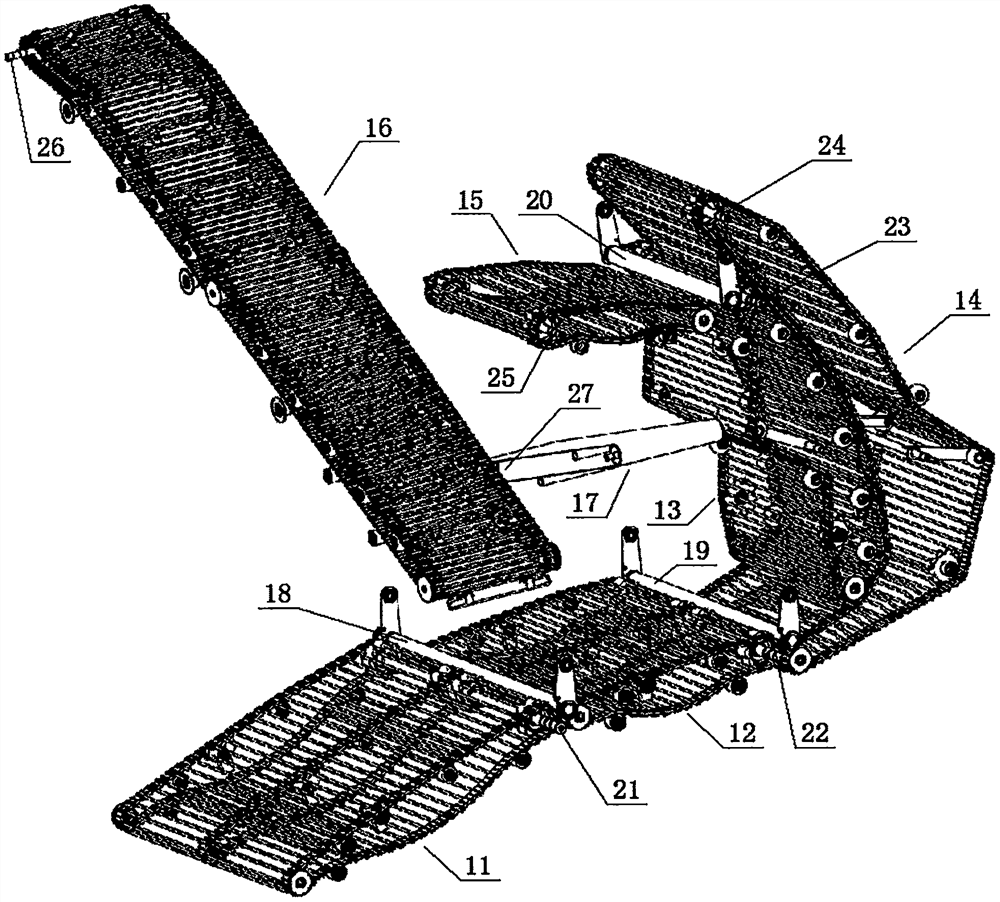

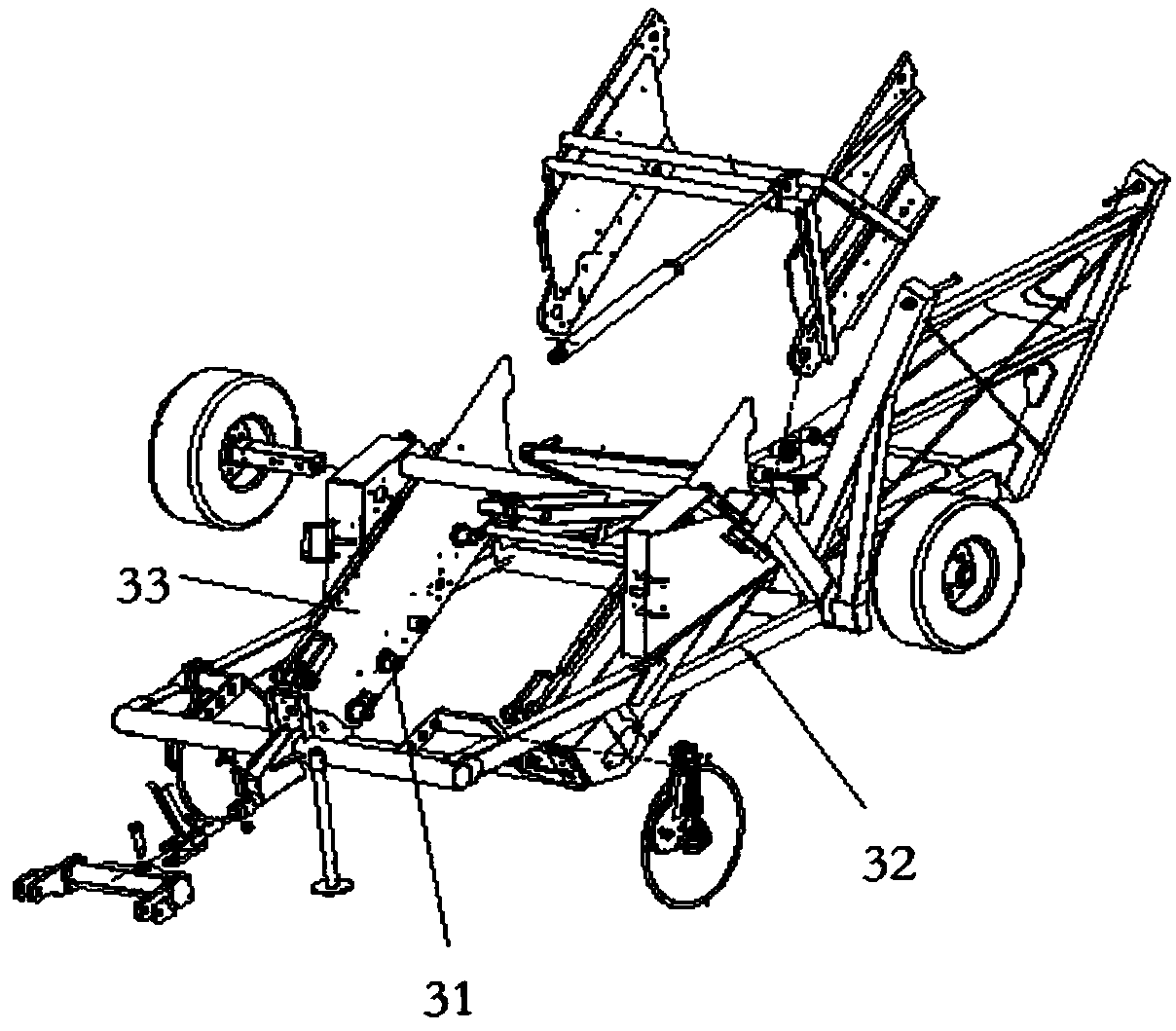

Vibratory digging harvester for winter potato

The invention relates to a vibratory digging harvester for winter potato, comprising a frame, a gearbox, a vibratory digging device, a two-stage conveyer and a separation mechanism, with the gearbox,the vibratory digging device, the two-stage conveyer and the separation mechanism mounted on the frame. The gearbox powers the vibratory digging device, the two-stage conveyer and the separation mechanism. The vibratory digging device comprises a vibratory digging blade to dig crops. The two-stage conveyer comprises a conveying chain screen to convey and primarily screen silt. The separation mechanism comprises a vibratory flow-combing slide mesh to screen silt, the front end of the conveying chain screen is positioned at the rear of the digging blade, and the rear end of the conveying chain screen is positioned above the front end of the vibratory flow-combing slide mesh. The vibratory digging harvester for winter potato is simple in structure and convenient to operate, has adjustable positions and adjustable vibrational amplitude, digging depth and penetrating angle, may arrive at optimal digging as practice requires so as to achieve reduced digging drag, increased potato exposure rate and reduced damage rate, has a promising market in the harvest of potato and other tubers, and is a harvesting machine for potato and other tuberous crops.

Owner:SOUTH CHINA AGRI UNIV

Cassava harvester

InactiveCN107484485AReduce digging resistanceReduced Power RequirementsTopping machinesDiggersHydraulic motorHydraulic cylinder

The invention discloses a cassava harvester. There is a forced conveying wheel at the front end of the front longitudinal beam. The forced conveying wheel is connected to the motor through the clamping belt and the pulley. The motor is connected to the hydraulic motor through the hydraulic pump. There is also a potato cutter at the end of the clamping belt. A digging shovel is provided, and the digging shovel is connected to the hydraulic cylinder through the depth-limiting wheel, and the hydraulic cylinder is fixed to the machine body. A soil and potato separation device is installed under the potato cutter, and the soil and potato separation device is connected to the potato block transport device through the main drive shaft and the transmission. The potato piece transport device is connected with the potato piece box, the front side of the potato piece box is provided with a driver's cab, and the bottom of the frame is provided with a crawler chassis. The invention can complete cassava excavation, clamping transportation, potato stem separation and soil removal and collection at one time; the clamping and conveying mechanism can effectively reduce the excavation resistance and reduce the power requirement of the machine; the harvesting process consumes less labor and significantly improves production. efficiency.

Owner:谷家淑

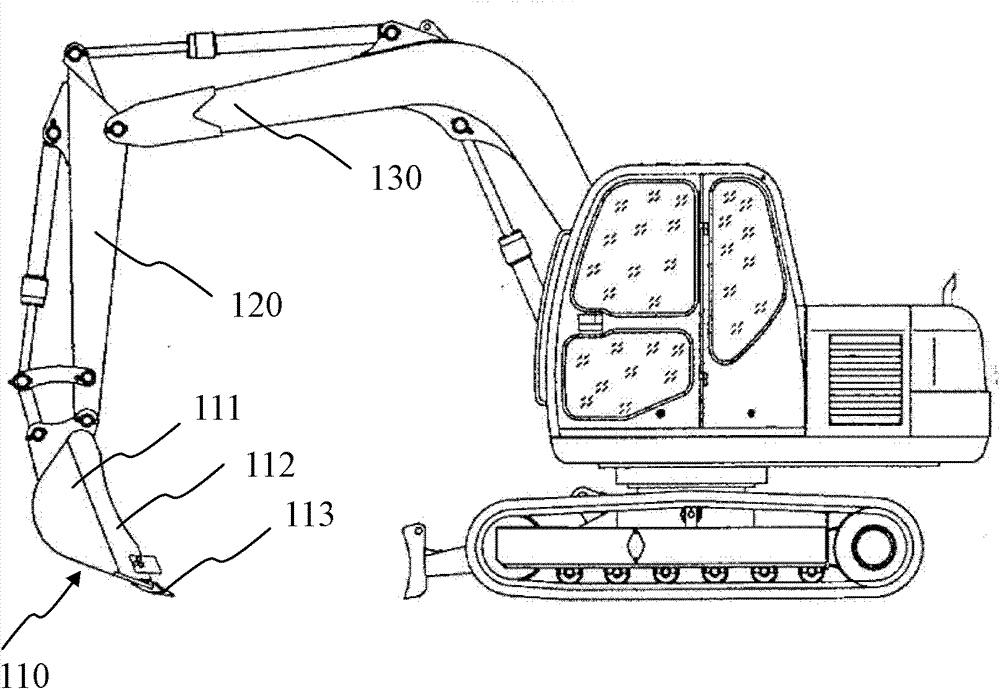

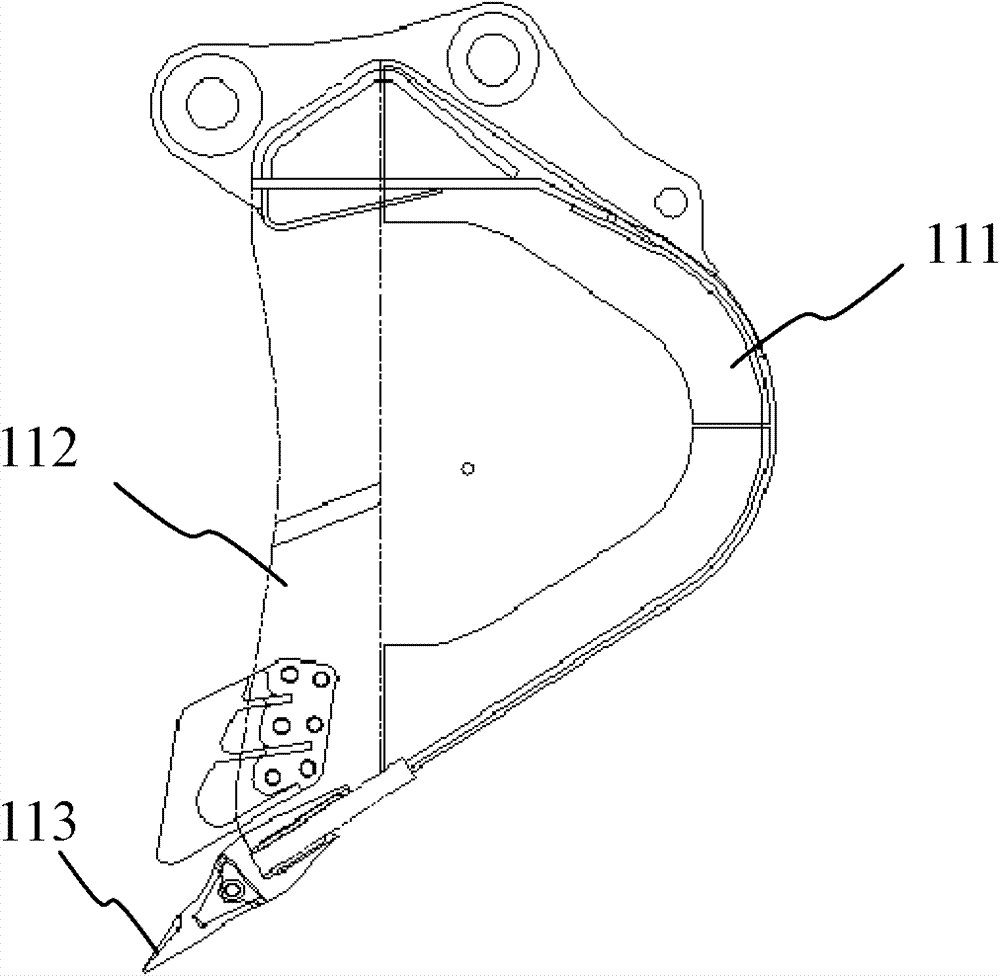

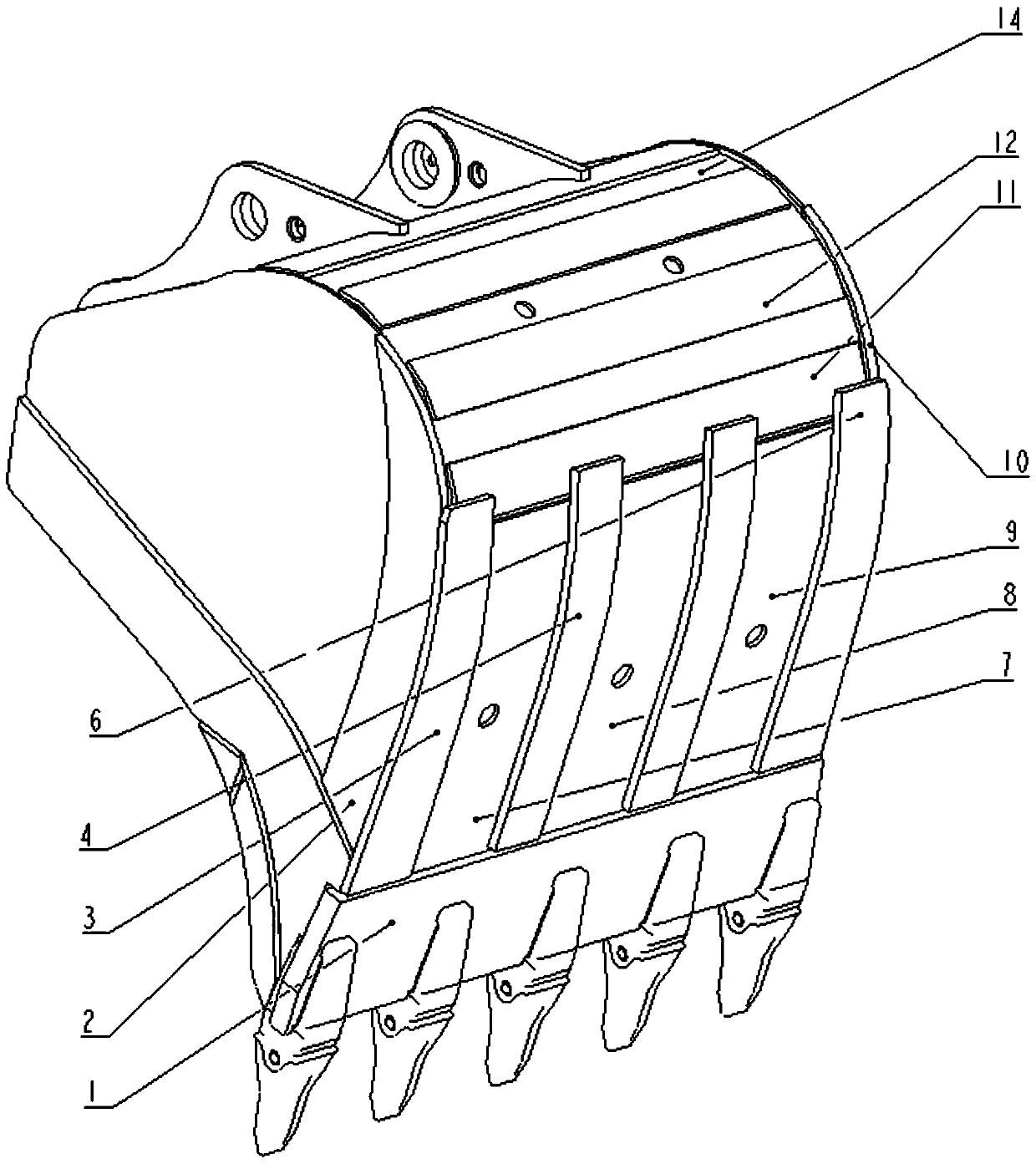

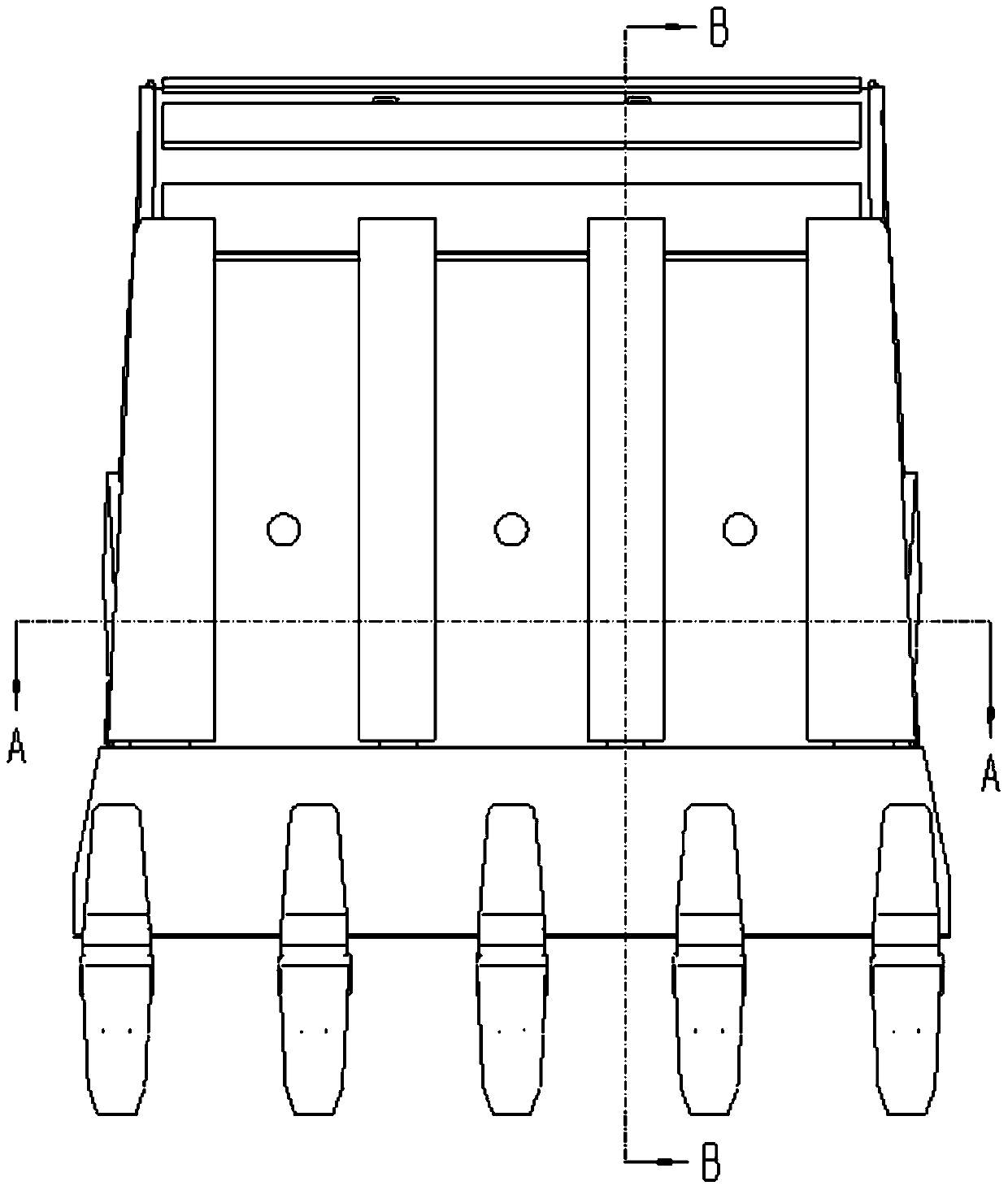

Excavator bucket

ActiveCN104631528AReduce dosageImprove structural rigidityMechanical machines/dredgersLeading edgeEngineering

The invention relates to an excavator bucket which aims to overcome the defect that an existing bucket is heavy and large in digging resistance. A main cutter board is arranged on the edge of an inner layer plate. A left side plate and a right side plate are provided with a left protection plate and a right protection plate respectively, and the left protection plate and the right protection plate extend from the front ends of the respective bottoms to the left end and the right end of an arc connection portion at the bottom of the bucket respectively. Horizontal reinforcing slats are welded to the outer portion of the arc connection portion at intervals. Longitudinal reinforcing plates are welded to the outer side of the front portion of the bottom of the bucket at intervals. The rear ends of the reinforcing plates are welded to the reinforcing slats. The front ends of the reinforcing plates are welded to the main cutter board. Longitudinal wear-resisting plates are arranged between the adjacent reinforcing plates and between the reinforcing plates and the left protection plate and the right protection plate. Compared with the prior art, the excavator bucket has the advantages that the structure rigidity is high, the structure design is more reasonable, the digging resistance is reduced, more materials are saved, and cost is saved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

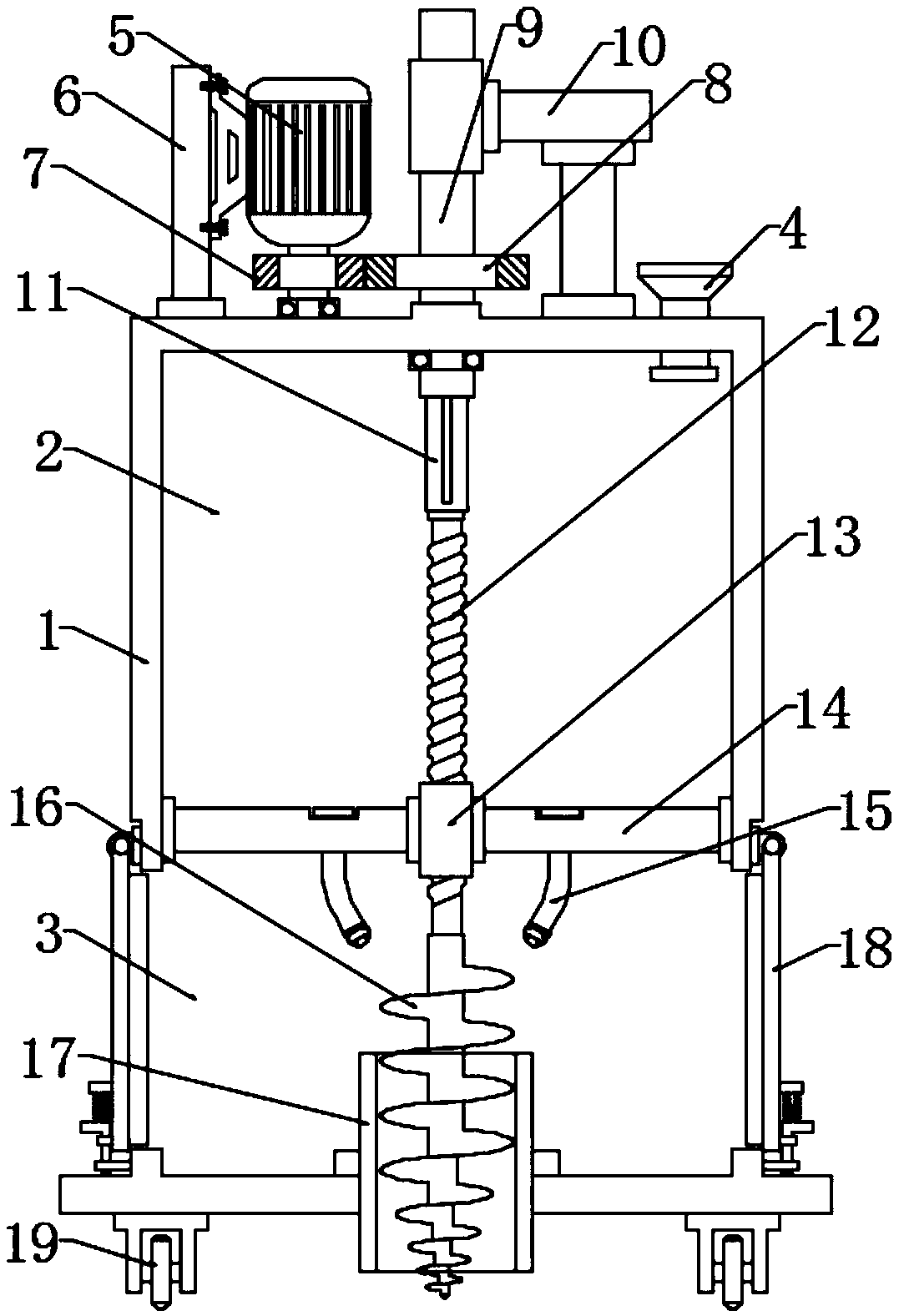

Automatic pit digging device for planting of garden seedlings

InactiveCN108834490AAvoid scatterSolve the problem of manual excavation and low efficiencyPlantingFurrow making/coveringEngineeringPinion

The invention discloses an automatic pit digging device for planting of garden seedlings. A water tank is arranged above the inside of a device body, a partition board is arranged at the bottom of thewater tank, the periphery of the partition board is fixedly connected with the inner walls of the device body, the side edge of the upper end of the device body is communicated with a water inlet hopper, and a soil storage chamber is formed in the lower part of the water tank; a motor is arranged at the upper part of the device body, the lower part of the motor is connected with a rotating shaft,the lower end of the rotating shaft is rotationally connected with the outer wall of the device body, a pinion is fixedly connected to the middle of the rotating shaft, and a guide wire of the motoris connected with a power supply and a switch. According to the device, a conical screw roller is driven to rotate and downwards probe through rotation of a screw rod, progressive digging is realized,water is injected into a barrel through electromagnetic valves and liquid guide pipes, soil is wetted, the digging resistance is reduced, the problem that soil is scattered all around during diggingof pit foundations is effectively solved by means of the closed soil storage chamber, and the problem of low efficiency due to manual digging of existing garden pit foundations is solved.

Owner:六安市武福地生态农业开发有限公司

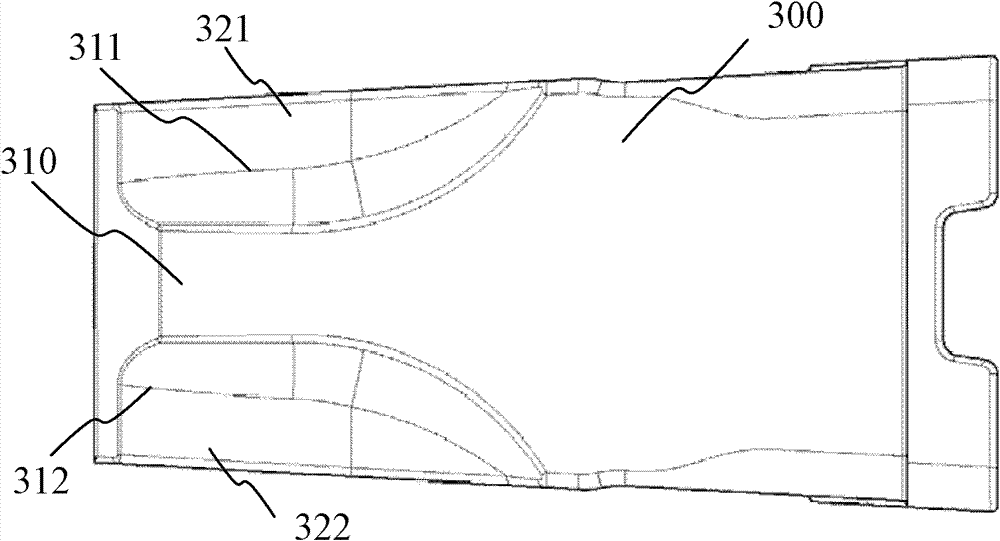

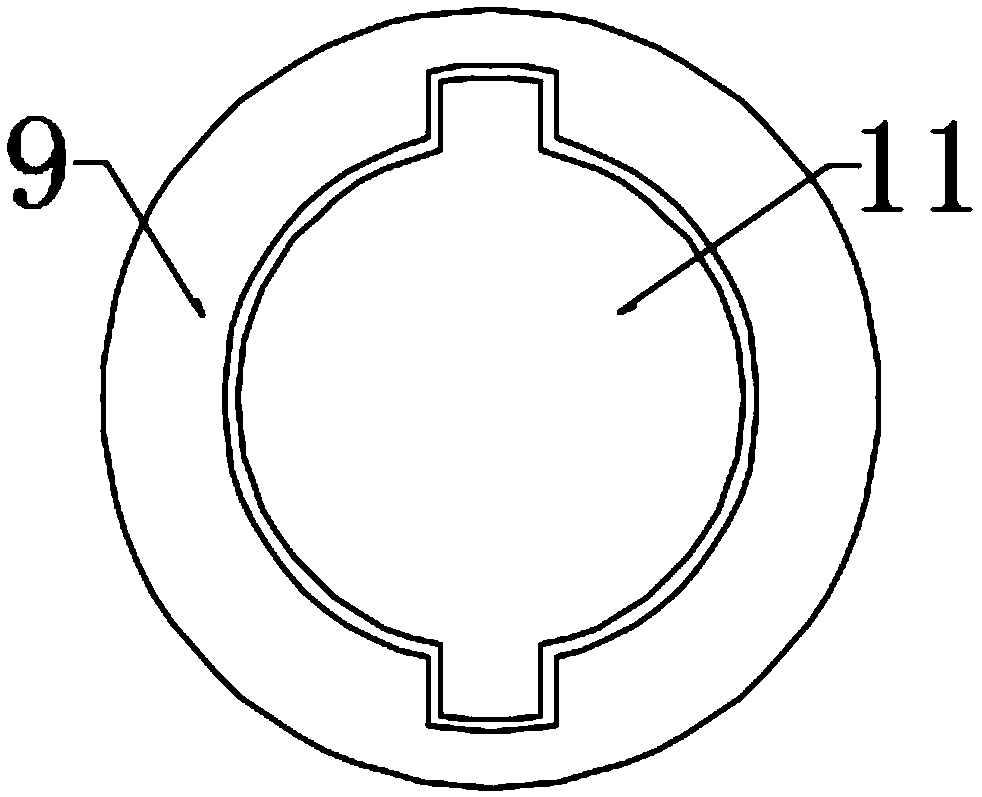

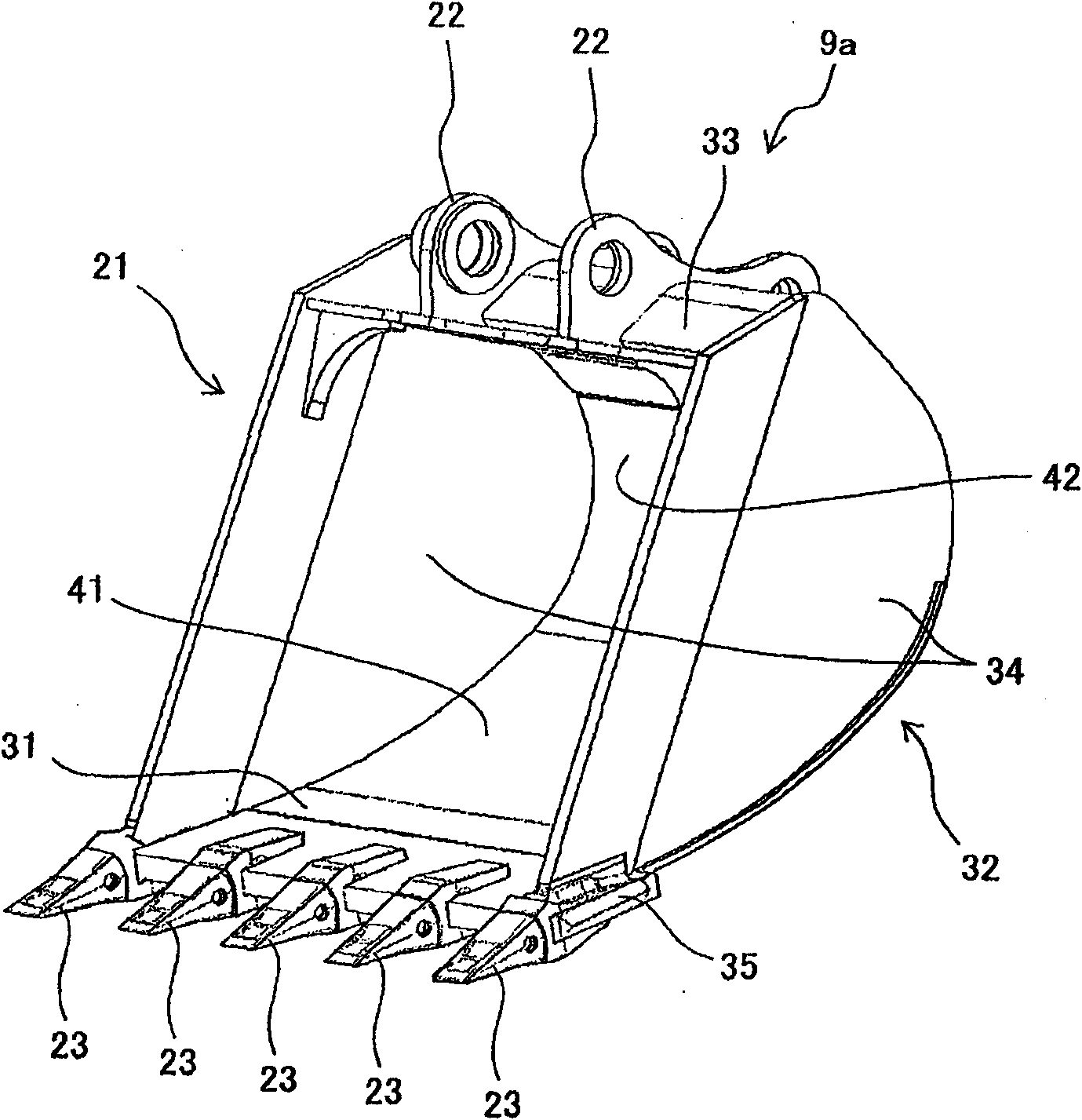

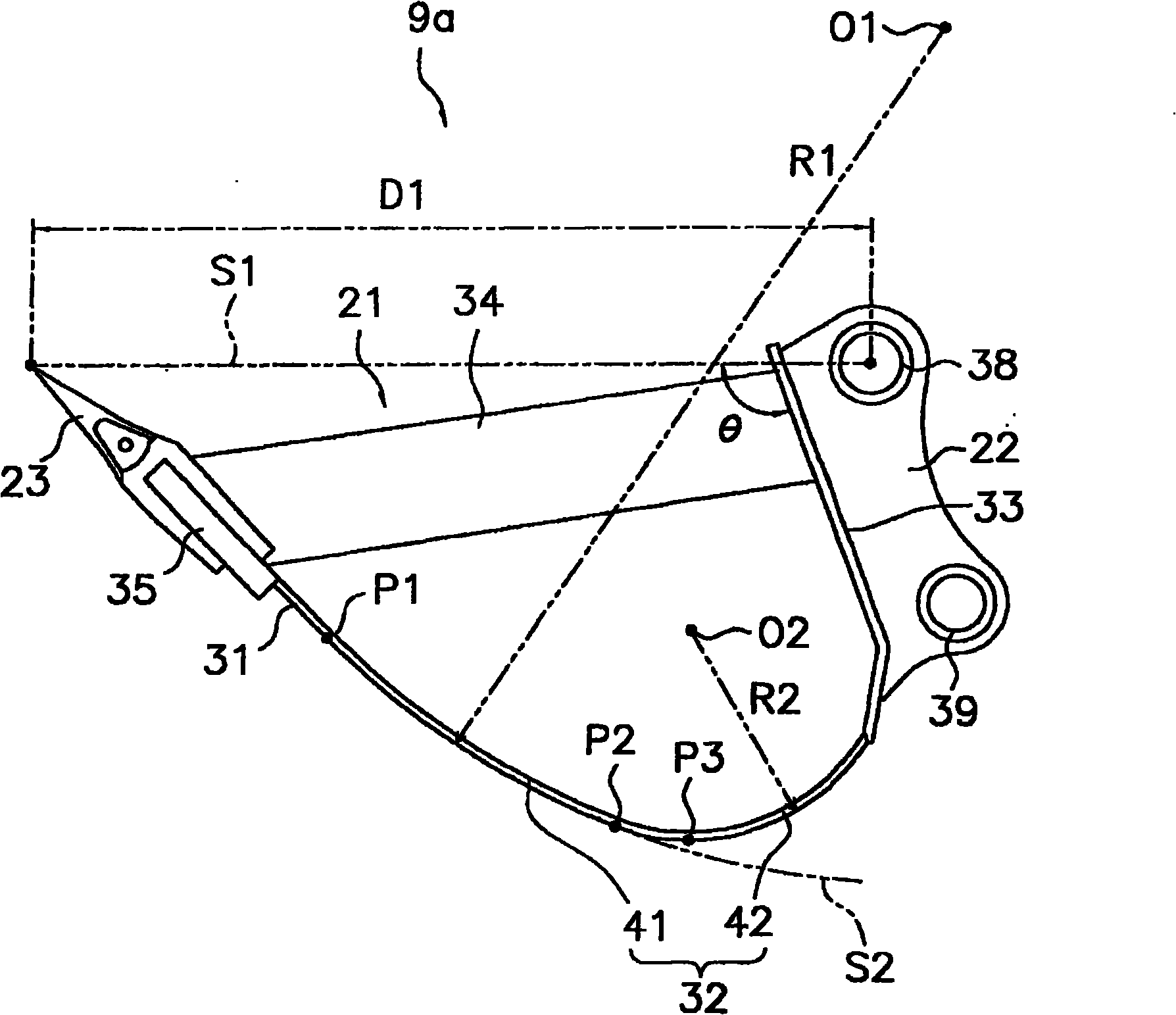

Bucket and operation vehicle

ActiveCN102041821AReduce digging resistanceMechanical machines/dredgersEngineeringElectrical and Electronics engineering

The present invention provides a bucket and an operation vehicle. A bottom surface section (32) of the bucket (9) has a first curved surface section (41) and a second curved surface section (42). The second curved surface section (42) is located nearer the back side than is the first curved surface section (41), and is connected to the first curved surface section (41). A second radius of curvature (R2) of the second curved surface section (42) is smaller than a first radius of curvature (R1) of the first curved surface section (41). From a side view, the center of radius of curvature (O1) ofthe first curved surface section (41) is located outside a bucket body (21). Furthermore, from the side view, the first curved surface section (41) is disposed along a reference curved surface (S2) or above the reference curved surface (S2) in a horizontal state where a phantom line (S1) is disposed horizontally and where the bottom surface section (32) is positioned below the phantom line (S1). Moreover, from the side view, a connection section (P2) between the first curved surface section (41) and the second curved surface section (42) is located, in a horizontal state, nearer a lip section(35) than is that portion (P3) of the bottom surface section (32) which is located at the lowest position.

Owner:KOMATSU LTD

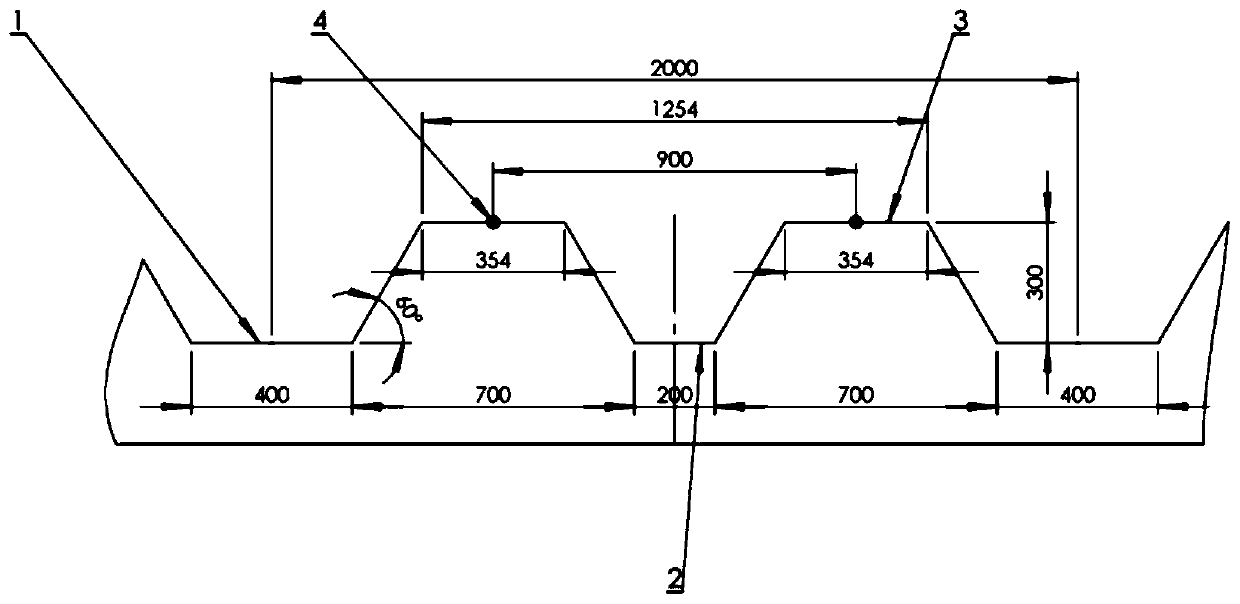

Cassava cultivation method applicable to whole-process mechanical operation

PendingCN110604022ARealize the whole process of mechanizationImprove the level of mechanized operationsCrop conditionersMowersDiseaseAgricultural engineering

The invention relates to a cassava cultivation method applicable to whole-process mechanical operation. The method includes: rotary tillage and ridging, to be specific, mechanically scarifying a landparcel, smashing soil, smoothening the land surface, and adopting a two-ridge or four-ridge ridger for rotary tillage and ridging to make required ridges, wherein the ridges are in shapes of isoscelestrapezoid, and line spacing between every two adjacent ridges is in a manner of alternate narrow line spacing and wide line spacing; cassava selection; cassava seed stem planting; field management, to be specific, manually completing operation of filling gaps with seedlings and thinning; mechanical completion of intertillage, weeding, fertilization and top dressing; disease and pest prevention and control; harvesting, to be specific, before harvesting, adopting a tractor for traction of a cassava straw smashing and returning machine to realize cassava straw smashing and returning; adopting the tractor for traction of a two-row four-shovel vibratory cassava digger for digging and harvesting. By adoption of the cassava cultivation method, whole-process mechanical operation of the cassava planting industry can be realized beneficially, planting cost is reduced, and the profit rate of the cassava planting industry is increased.

Owner:CHINA AGRI UNIV

Potato combine harvester

PendingCN114521383AEasy to separateReduce digging resistanceSaving energy measuresDiggersAgricultural engineeringTraction frame

The invention discloses a potato combine harvester which comprises a digging and conveying device, disc type straw cutting mechanisms are arranged at the front end and the rear end of the digging and conveying device respectively, and a digging shovel is arranged at the bottom of the front end of the digging and conveying device; the traction frame is arranged at the front end of the excavation conveying device and used for being connected with traction equipment; the elevation-angle-adjustable lifting device is arranged at the rear end of the excavating and conveying device and is used for conveying the potatoes to accompanying transporting equipment; and the power transmission device is connected with the power output end of the traction equipment and then transmits power to the excavation conveying device and the lifting device with the adjustable elevation angle in sequence. The problems that in existing potato harvesting equipment, small and medium-sized equipment often needs to be manually picked up after potatoes are dug out, time and labor are wasted, and large equipment is large in size, complex in structure and limited in use can be solved.

Owner:DINGXI SANNIU AGRI MACHINERY MFG

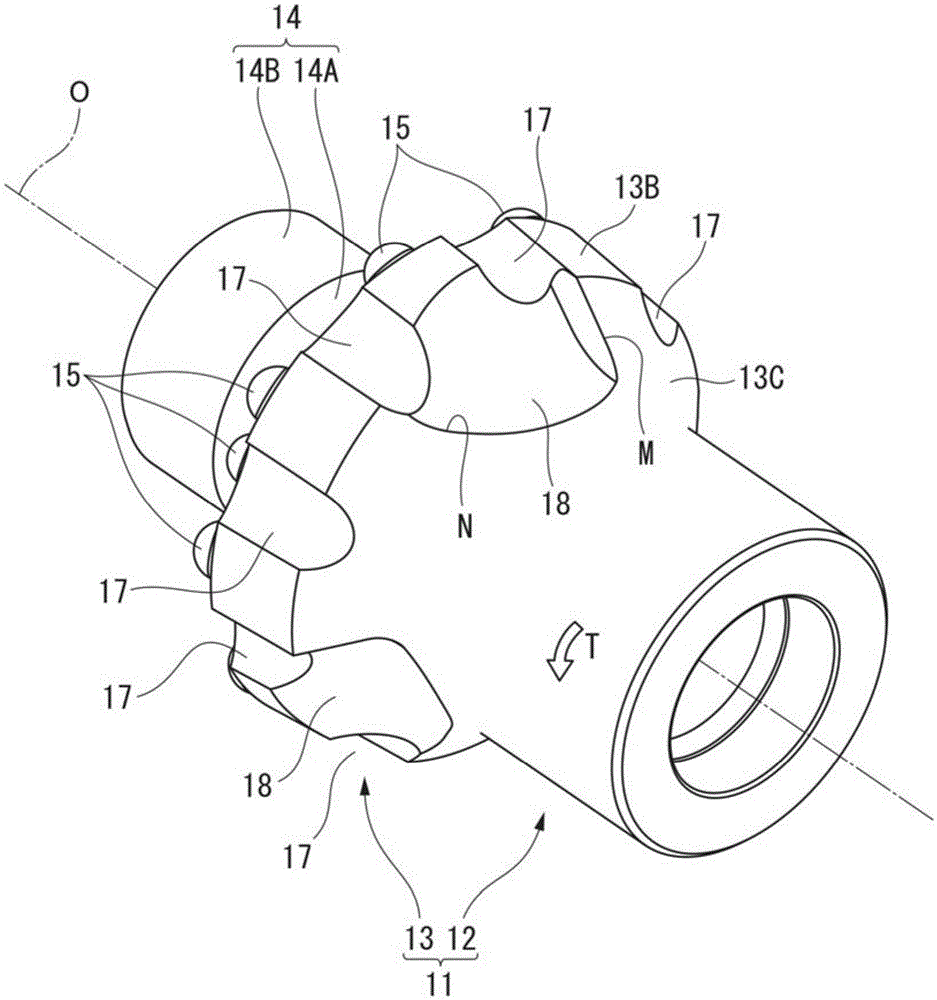

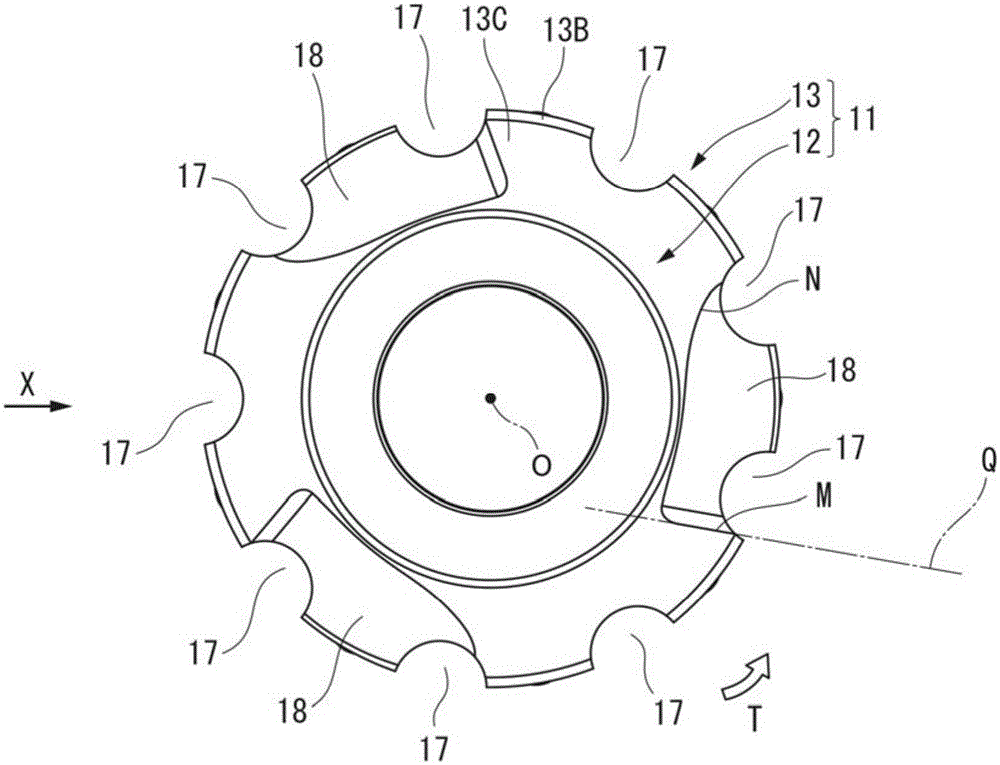

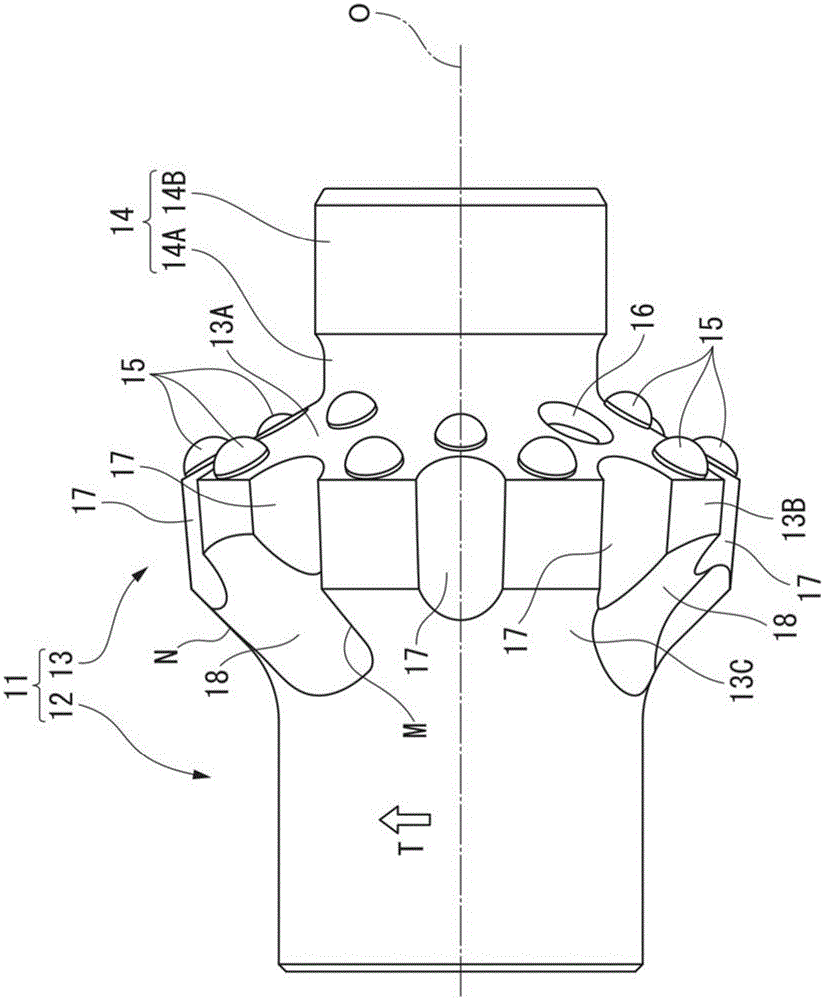

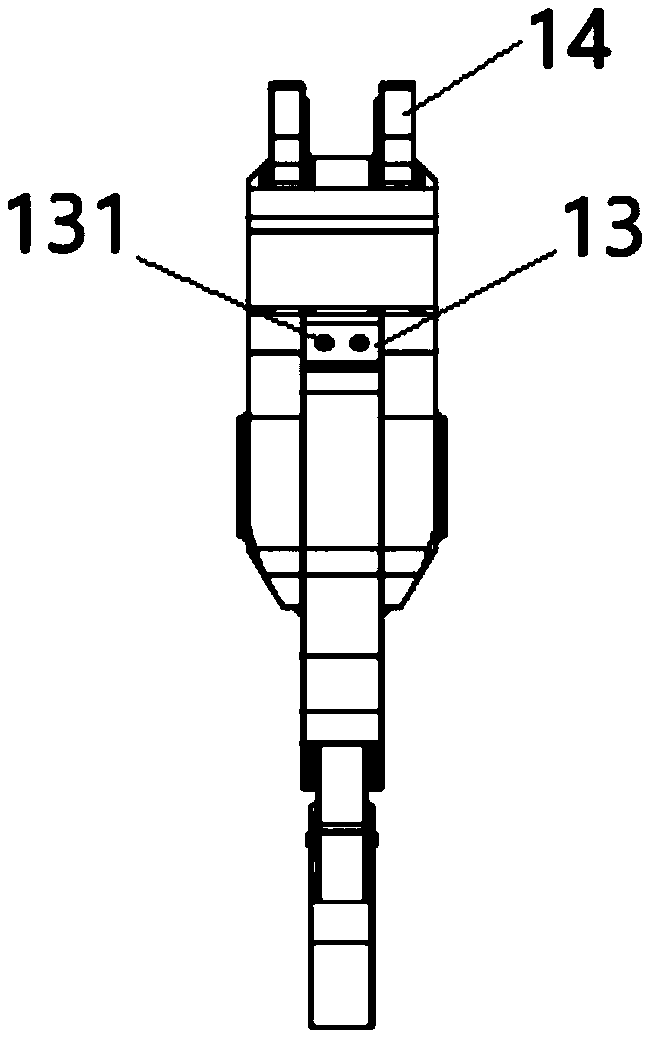

Digging bit

A reaming section (13) is provided at the front end of a bit body (11) which is rotated about an axis (O), and the reaming section (13) has a greater diameter than the rear end of the bit body (11). Digging tips (15) are arranged at the front end of the reaming section (13). Earth discharge grooves (17) extending in the direction of the axis (O) are formed in the outer periphery of the reaming section (13). Connection grooves (18) connecting to the earth discharge grooves (17) are formed so as to extend from the outer periphery of the reaming section (13) to the rear end.

Owner:RYUKI PRECISION TOOLS CO LTD

excavator bucket

ActiveCN104631528BReduce dosageImprove structural rigidityMechanical machines/dredgersLeading edgeExcavator

Owner:LIUZHOU LIUGONG EXCAVATORS +2

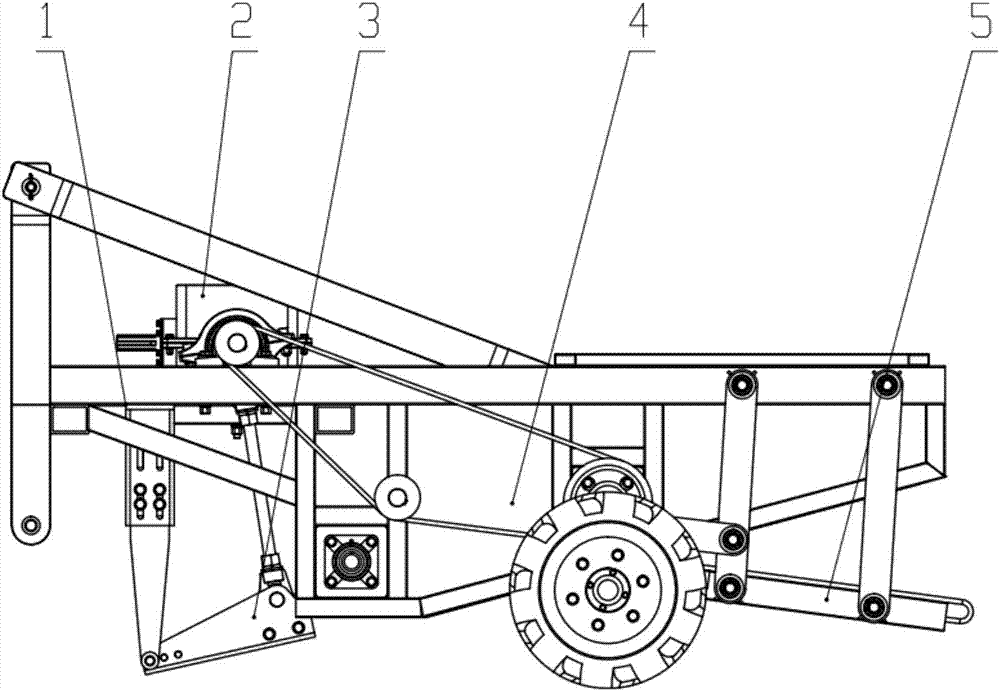

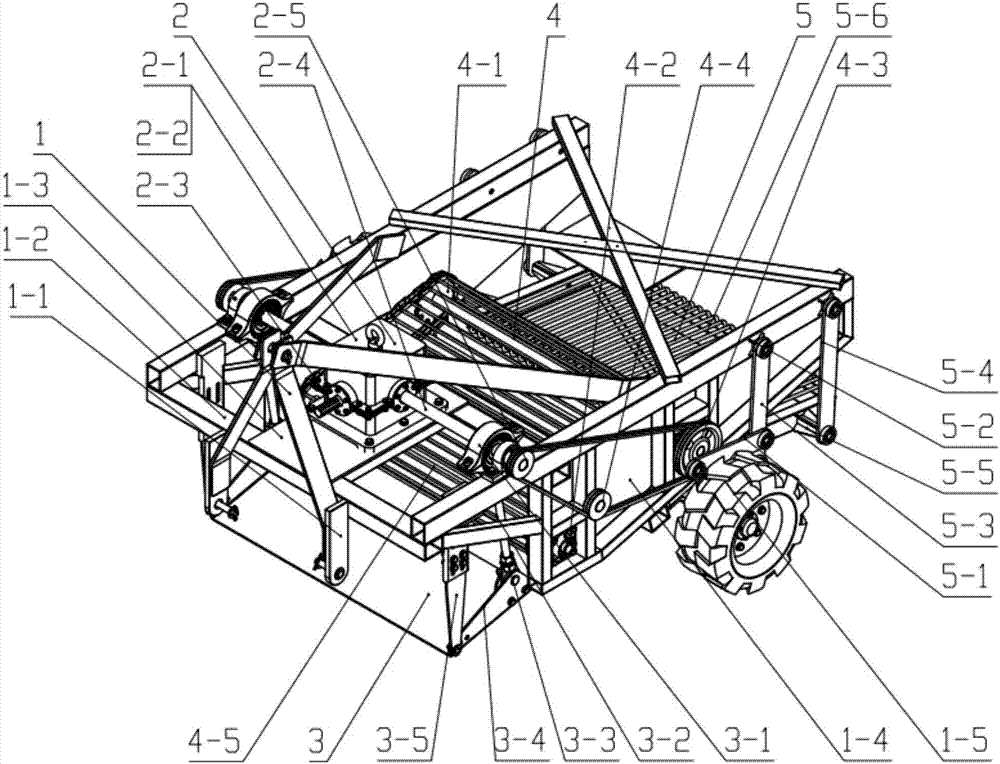

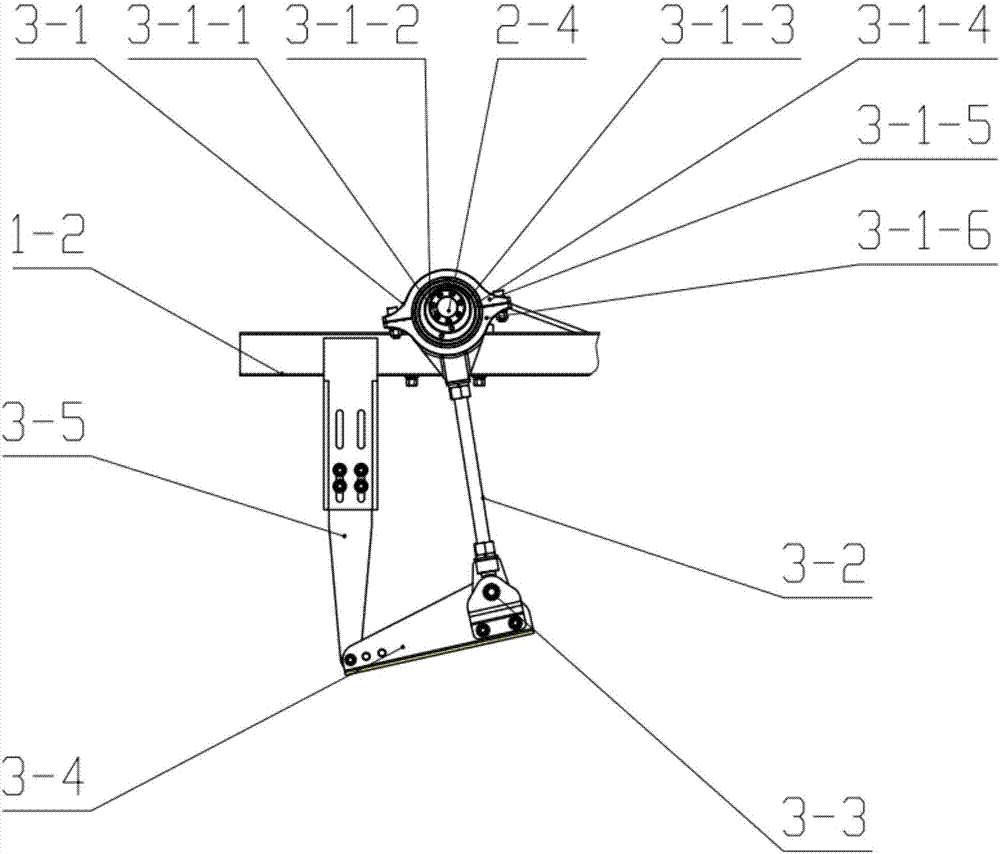

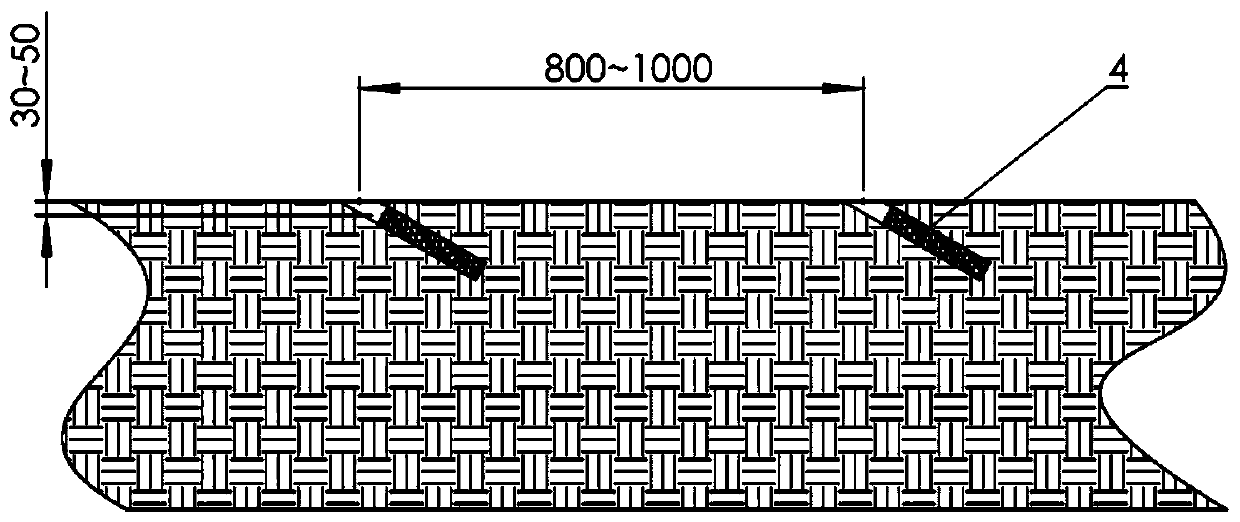

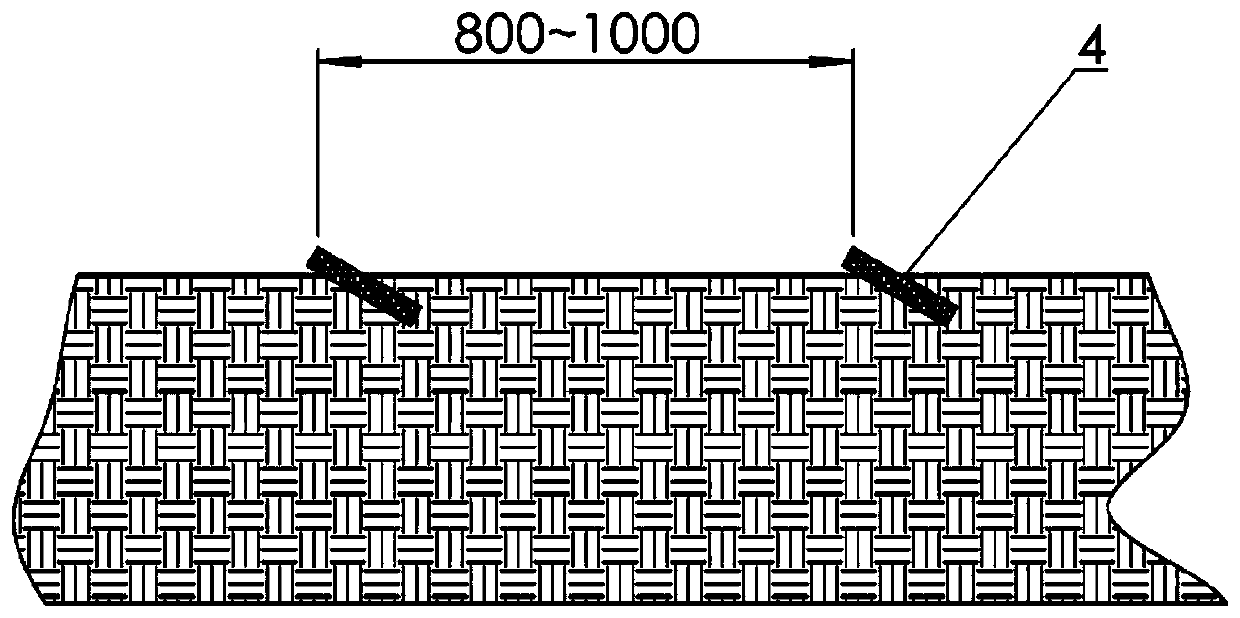

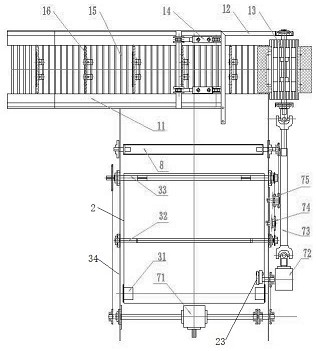

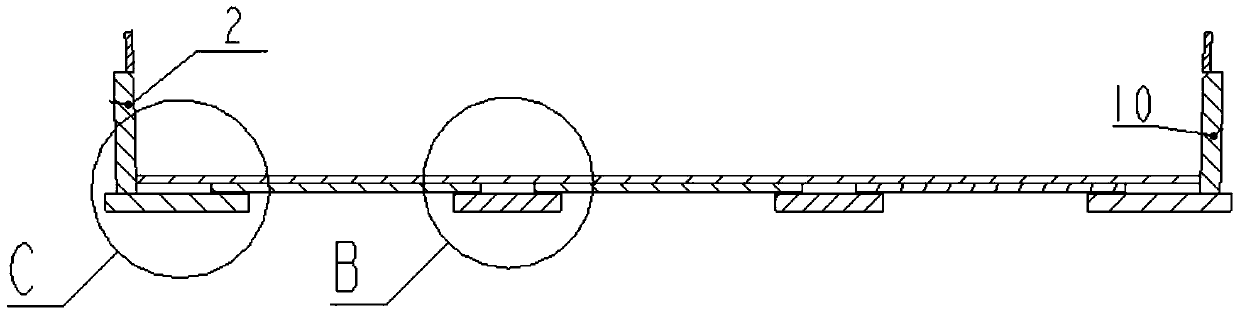

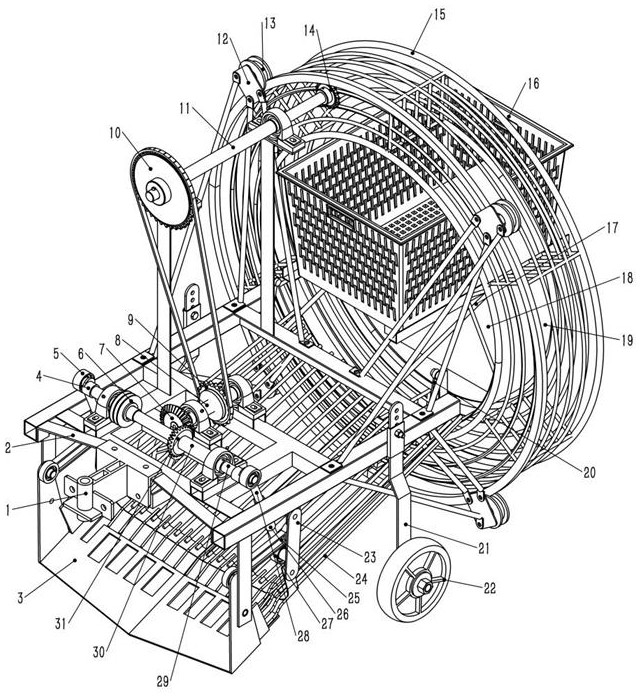

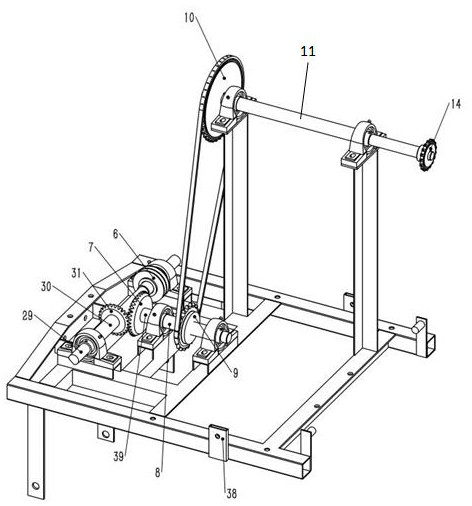

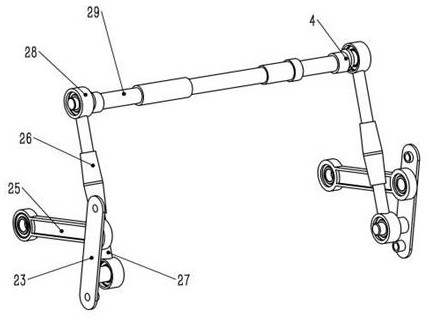

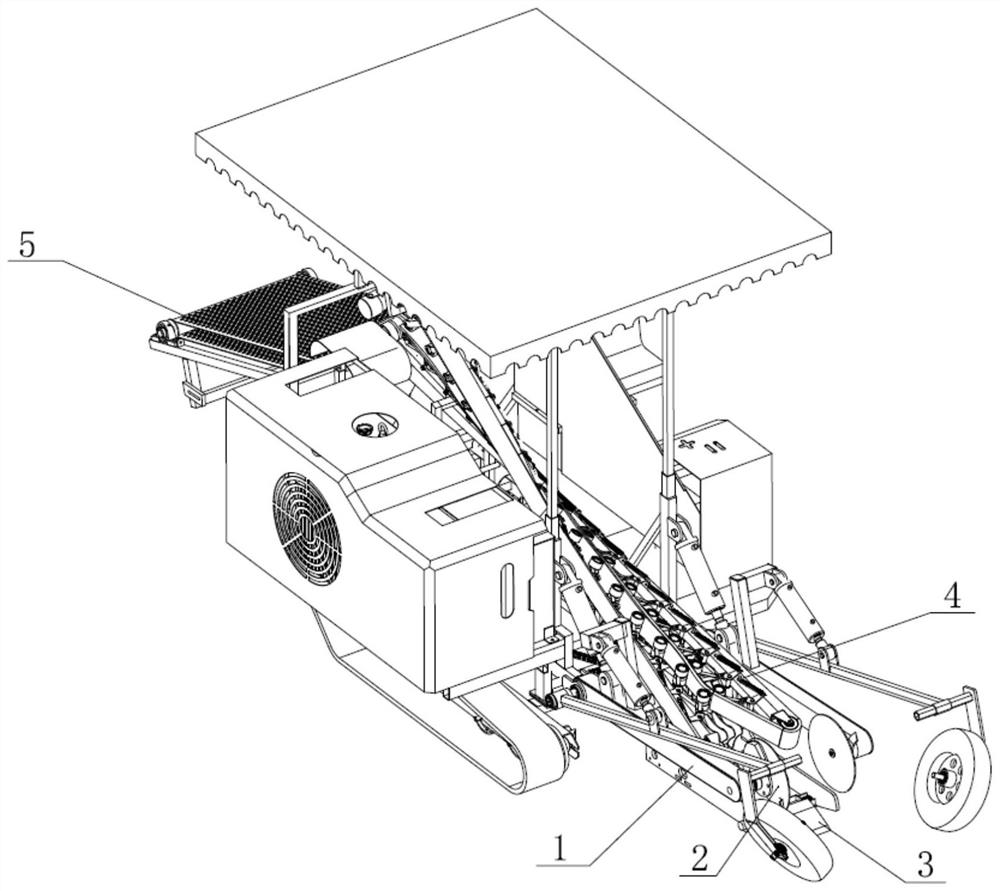

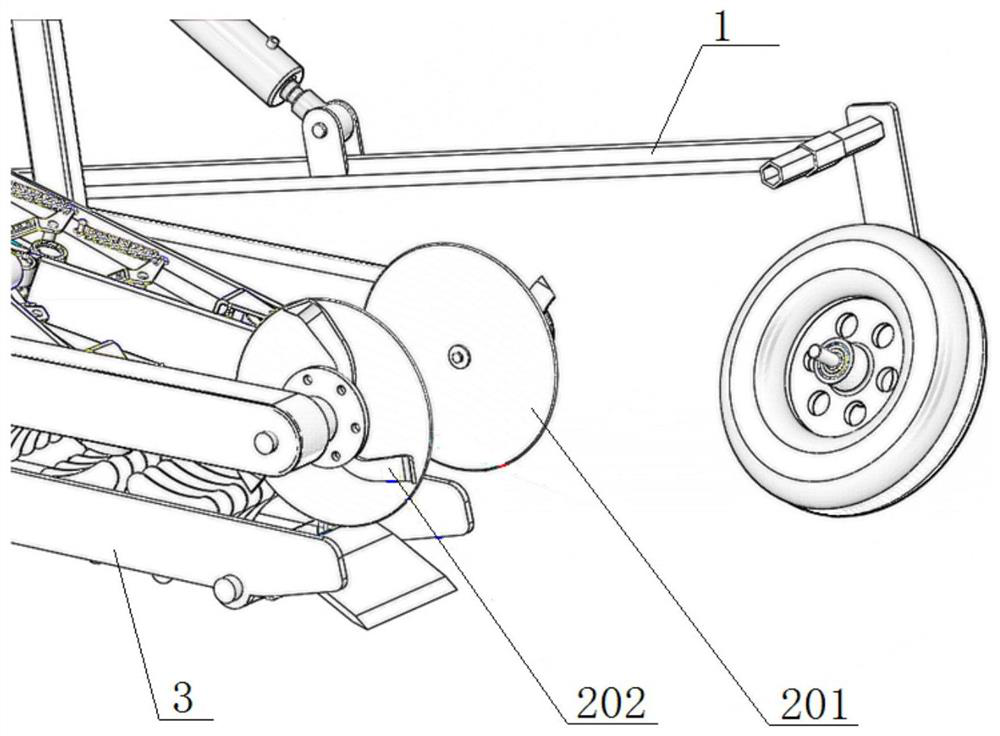

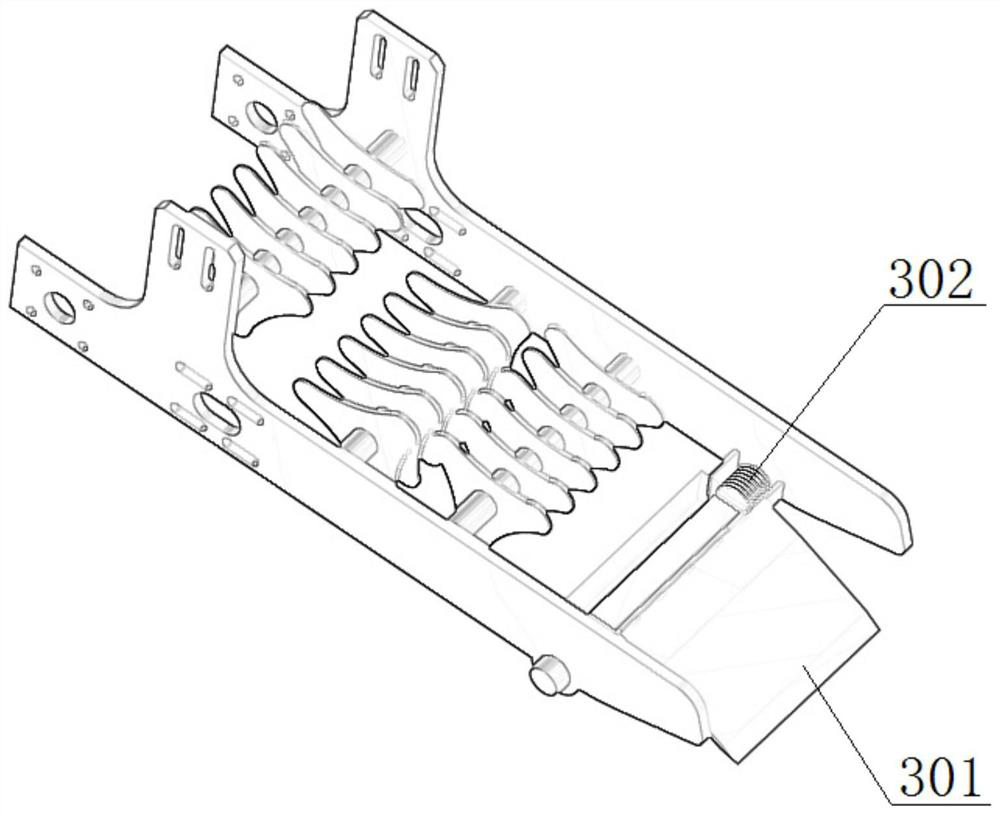

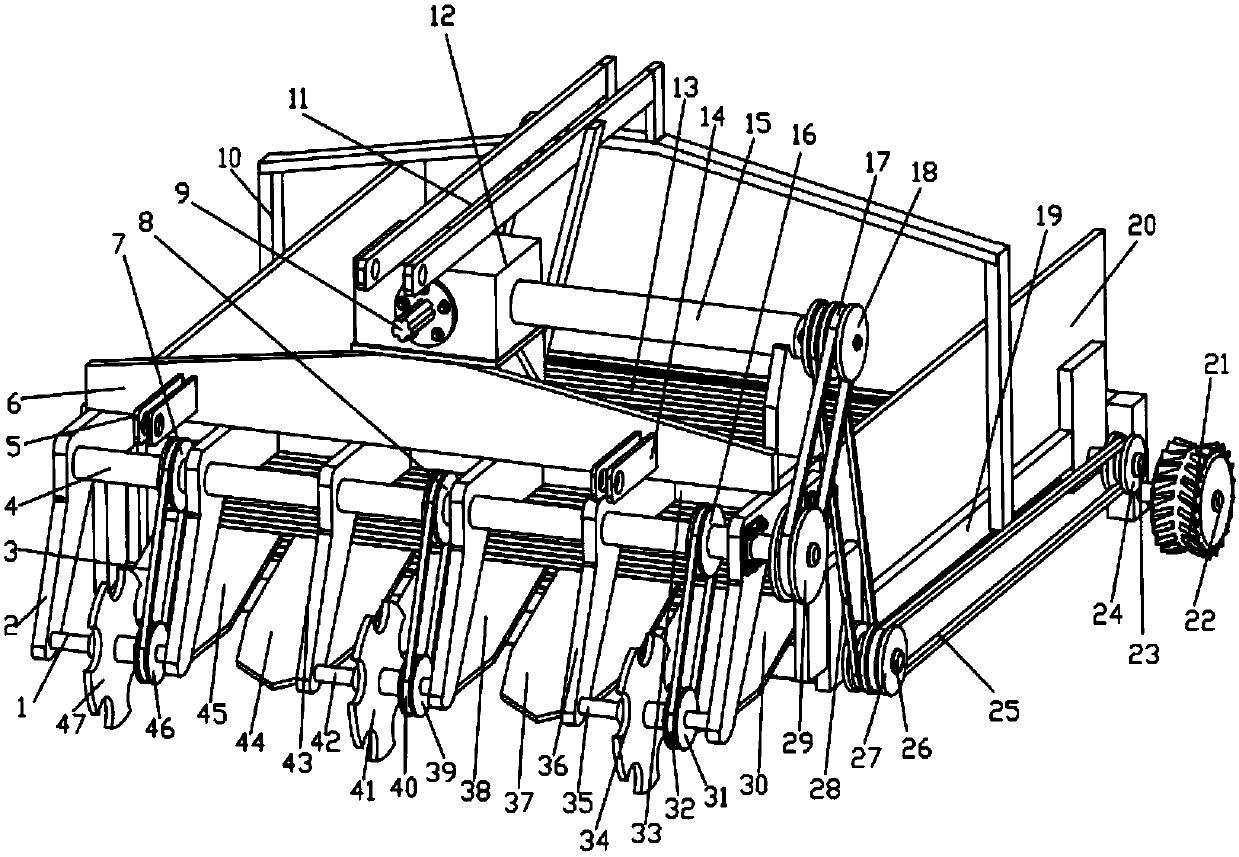

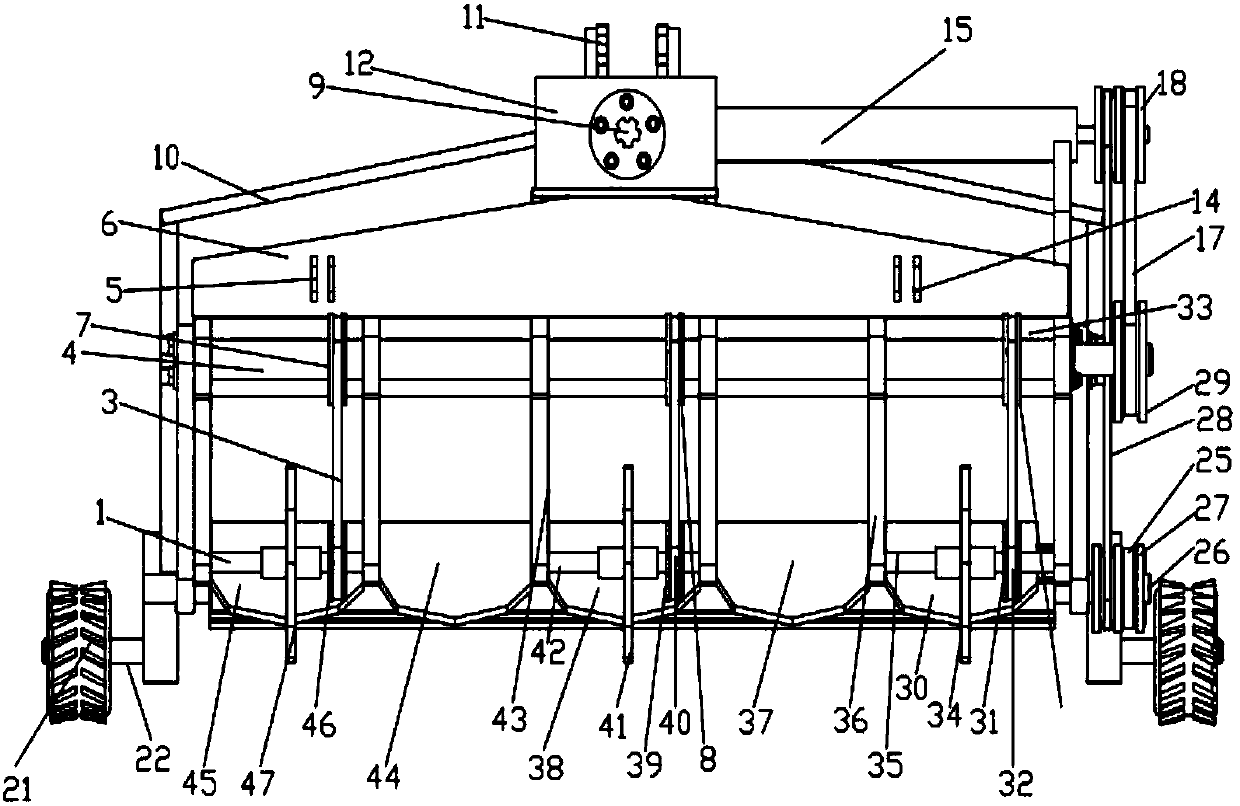

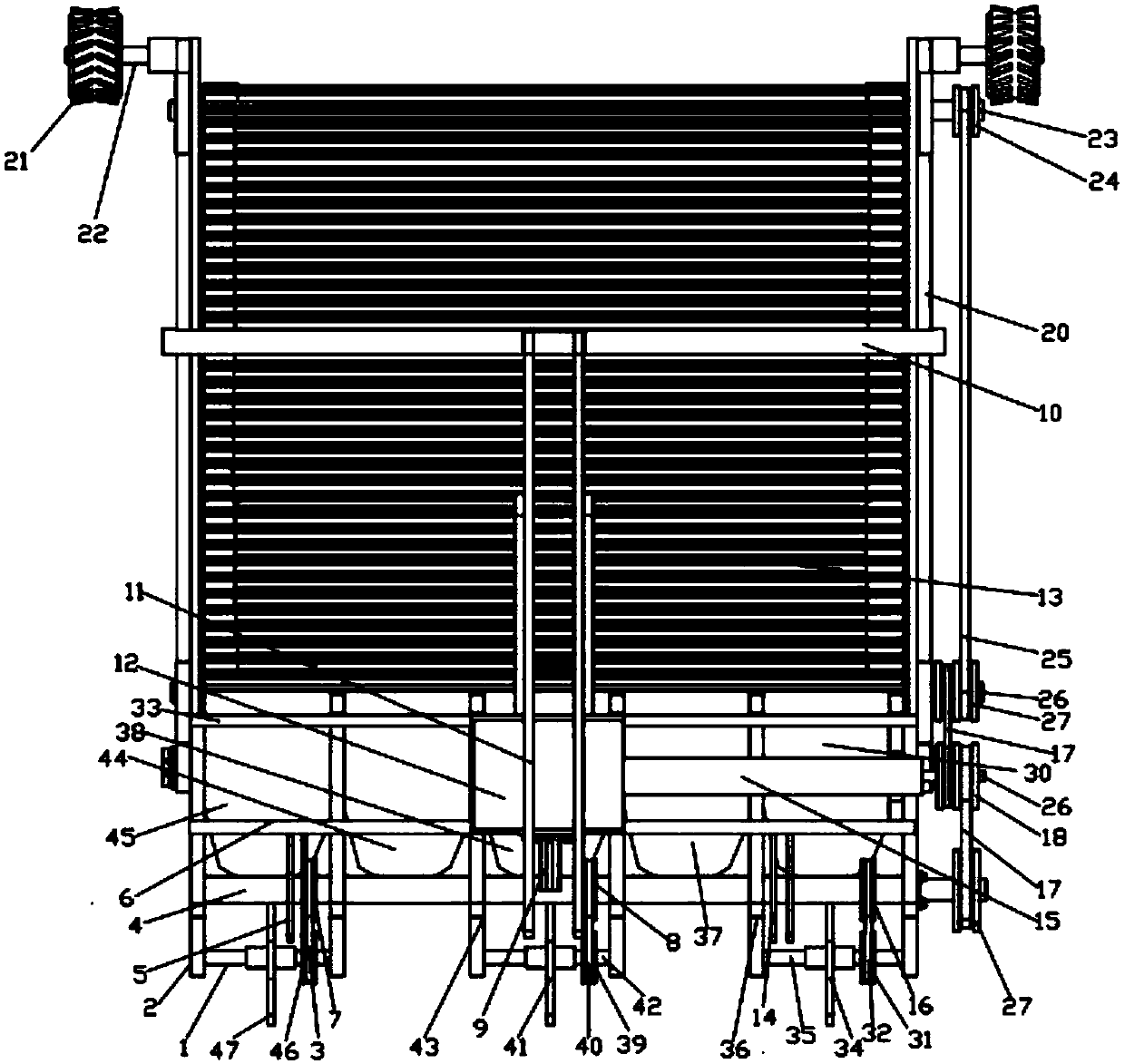

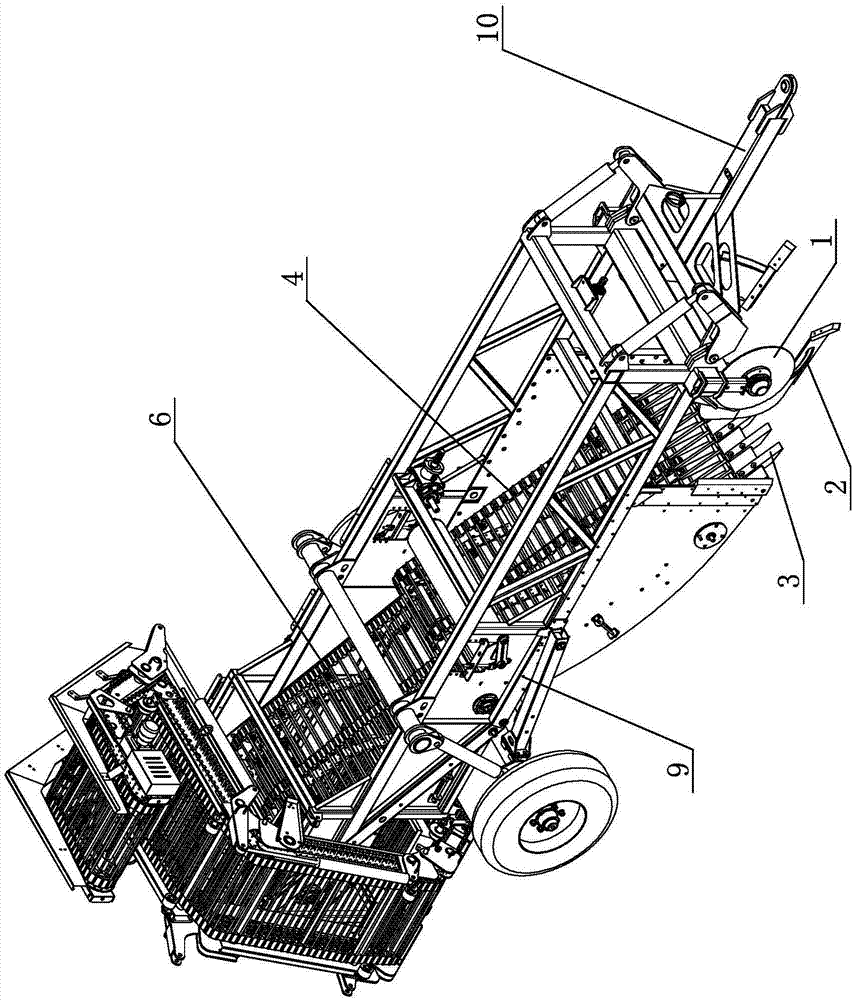

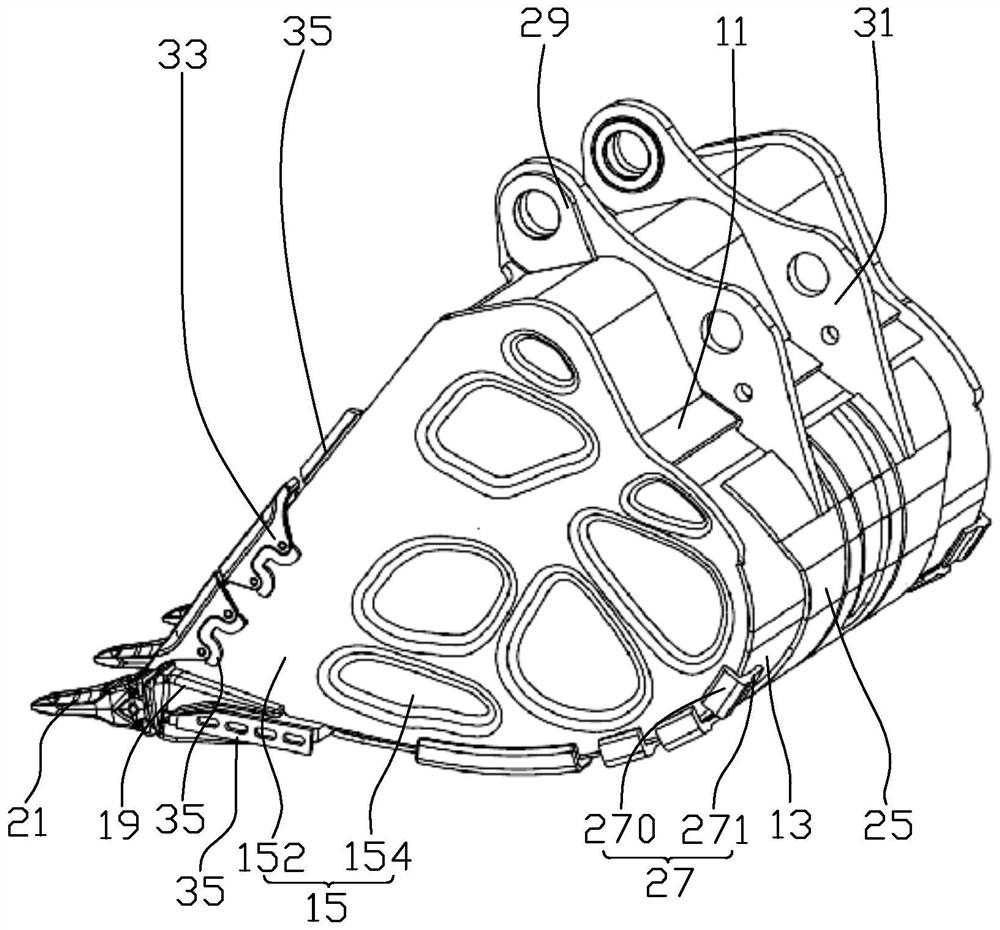

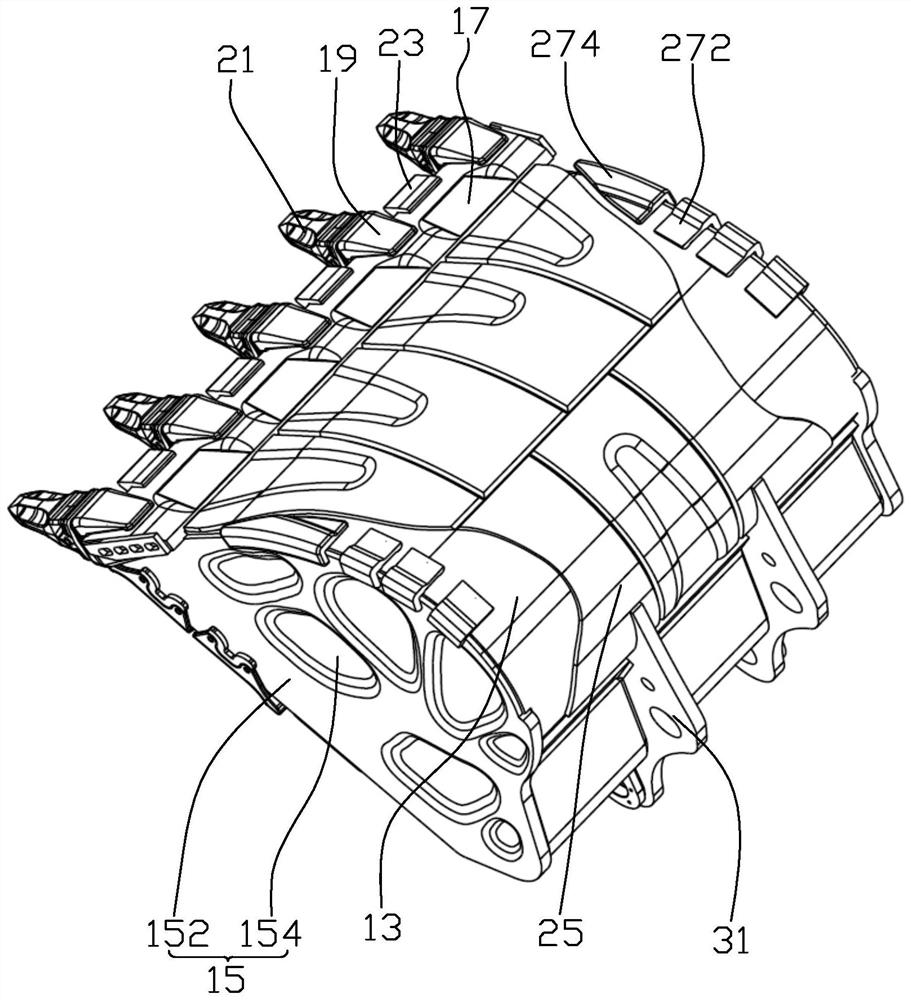

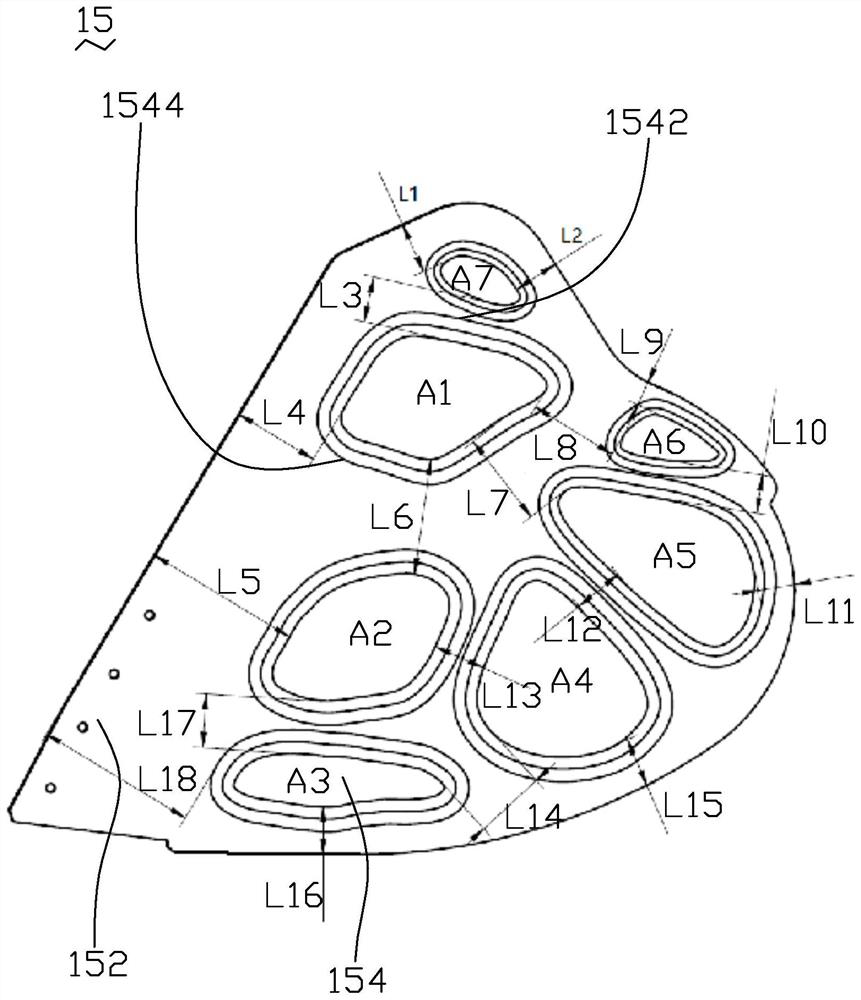

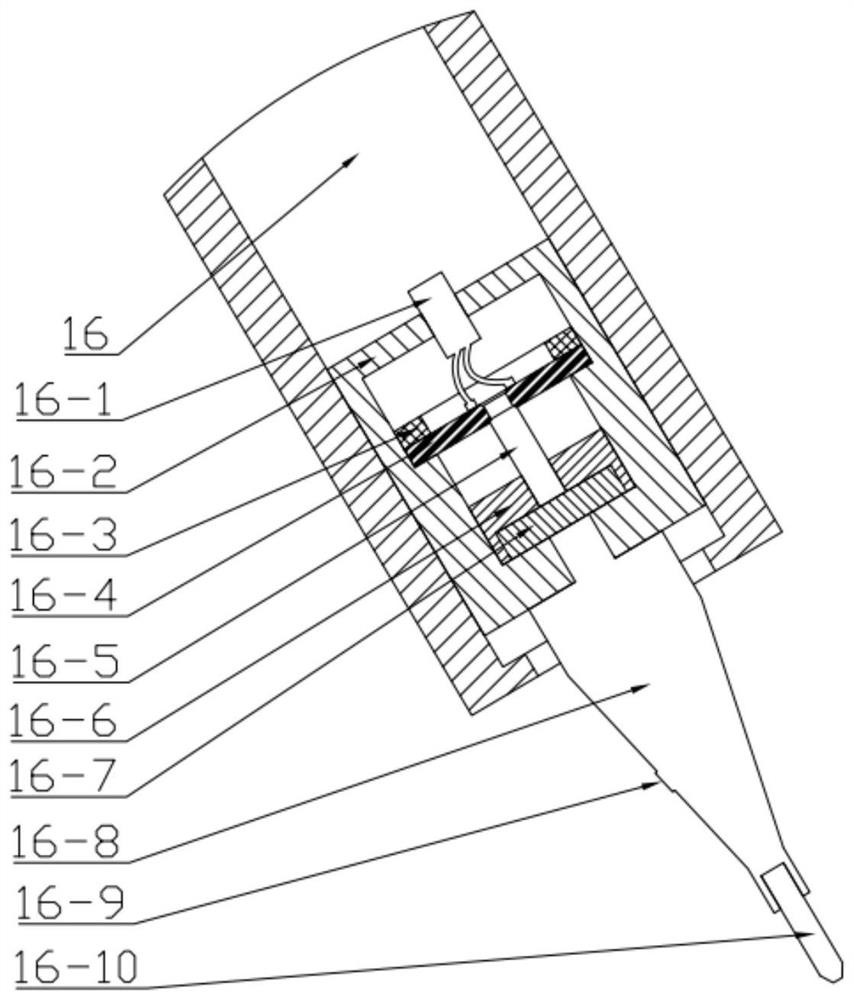

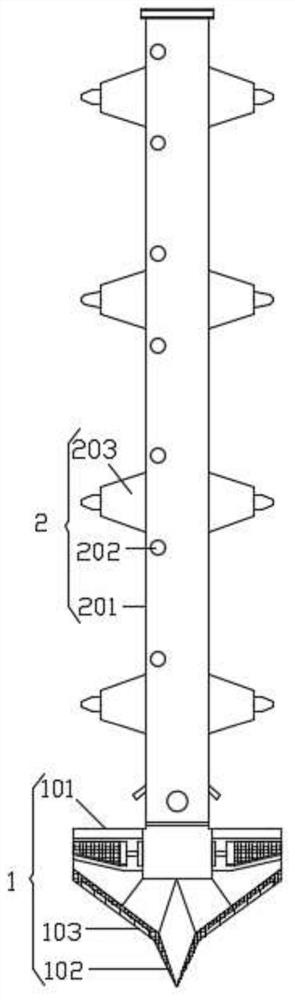

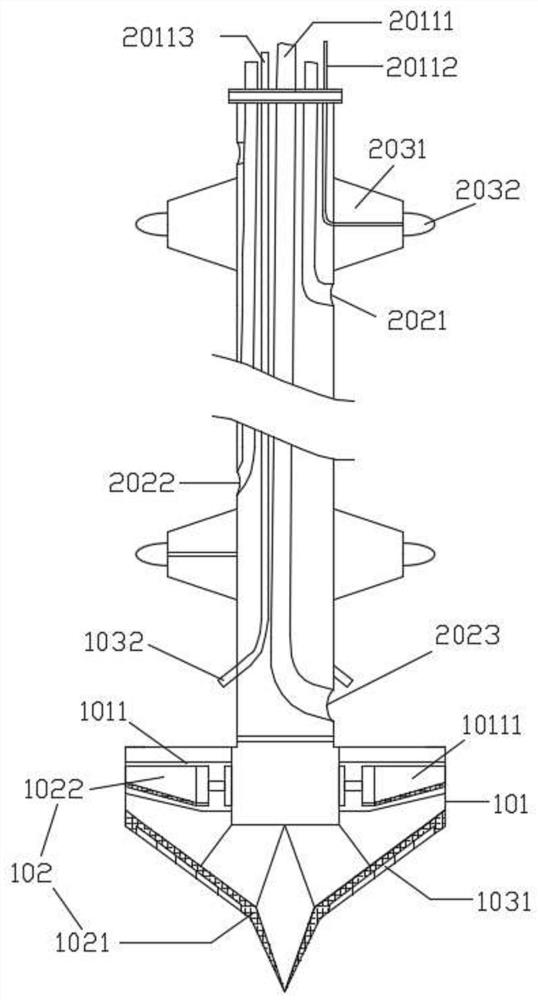

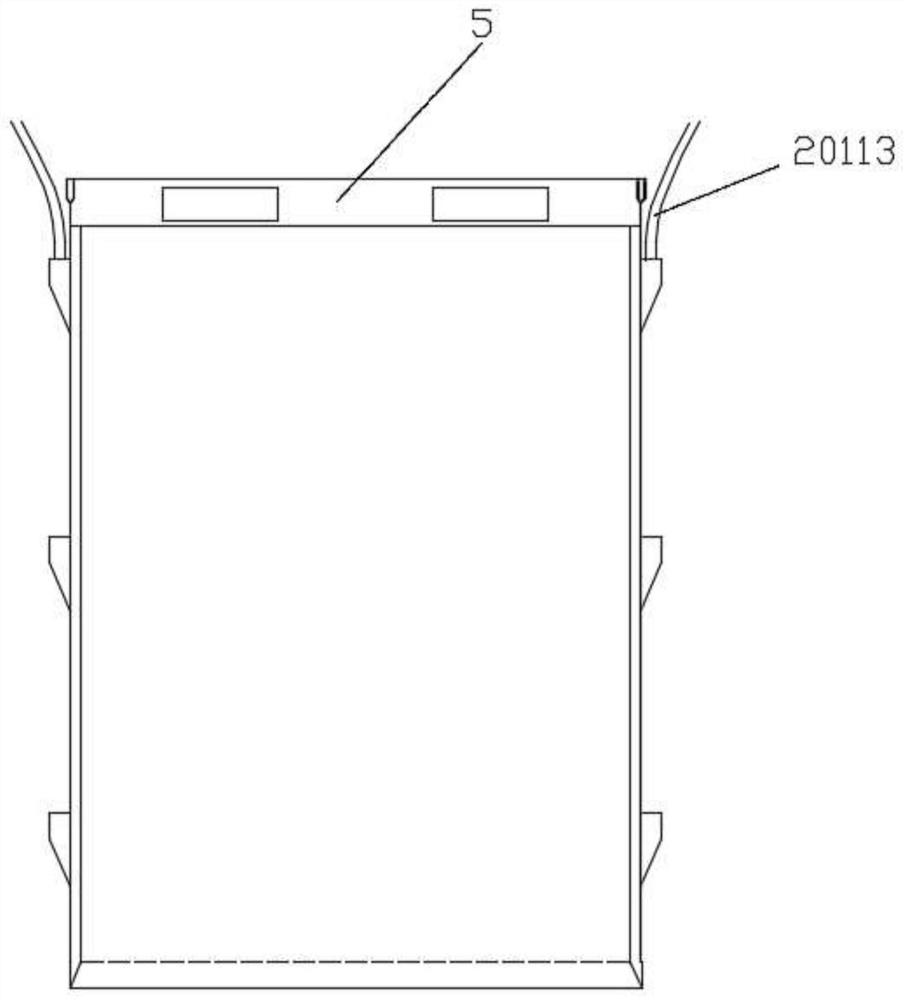

Small-sized boxing type potato harvesting combined machine

ActiveCN113519252AClosely connectedReduce digging resistanceSaving energy measuresDiggersAgricultural engineeringAgricultural science

The invention relates to the technical field of agricultural machinery, in particular to a small boxing type potato harvesting combined machine. The small boxing type potato harvesting combined machine comprises a rack, a traction hanging frame, a composite digging shovel, a transmission device, a vibration separation device, an eccentric wheel mechanism and a supporting wheel, wherein the composite digging shovel, the supporting wheel and the vibrating screen are connected to the lower end of the rack correspondingly, and the eccentric wheel mechanism is installed at the upper end of the rack. The eccentric wheel mechanism is used for simultaneously driving the digging shovel and the vibrating screen, so that the digging shovel and the vibrating screen simultaneously reciprocate in the horizontal direction, and the design concept of coaxial transmission but different amplitudes is adopted, so that the horizontal amplitude of the vibrating screen is increased while the digging resistance is reduced as far as possible, potatoes and soil are separated more thoroughly in addition, a rotary barrel frame collecting device is designed, and the integrated operation process of digging, soil screening and boxing is achieved, and another function is to further realize potato-soil separation, so that the collected potatoes are cleaner, meanwhile, vibration optimization is conducted on the digging shovel, the resistance of the machine is reduced, and meanwhile the digging shovel and the vibrating screen are connected more compactly.

Owner:GANSU AGRI UNIV

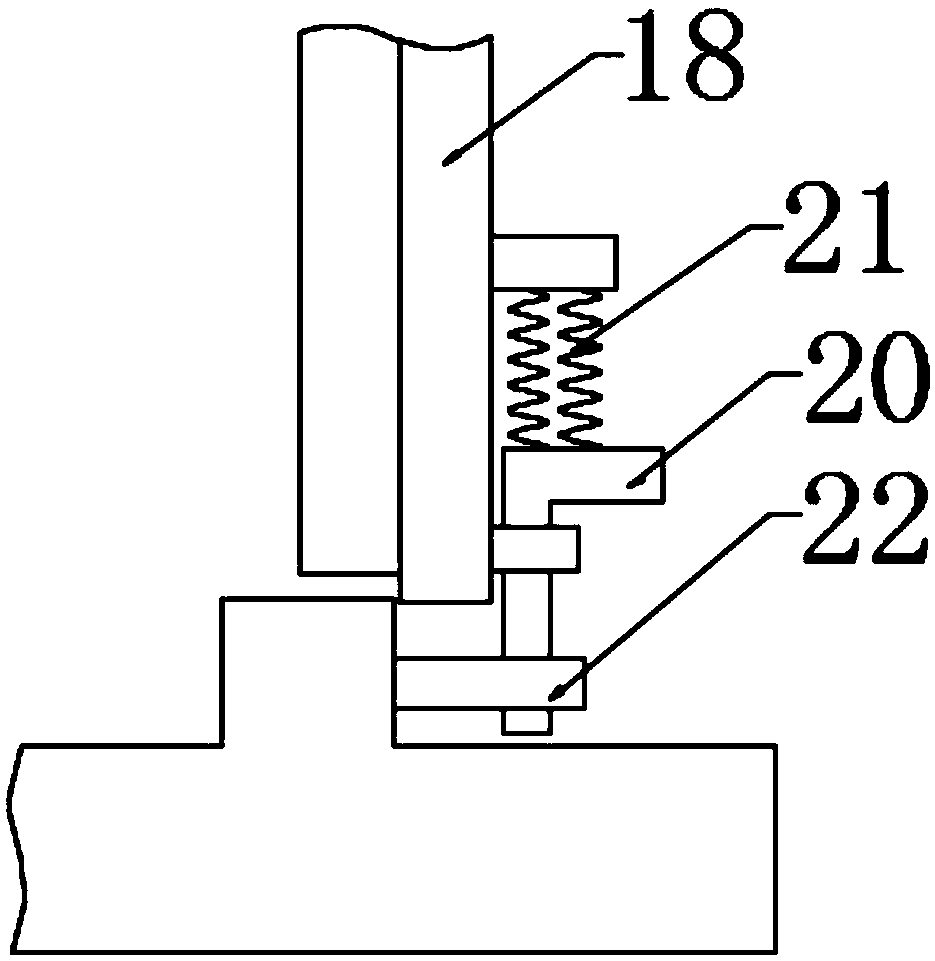

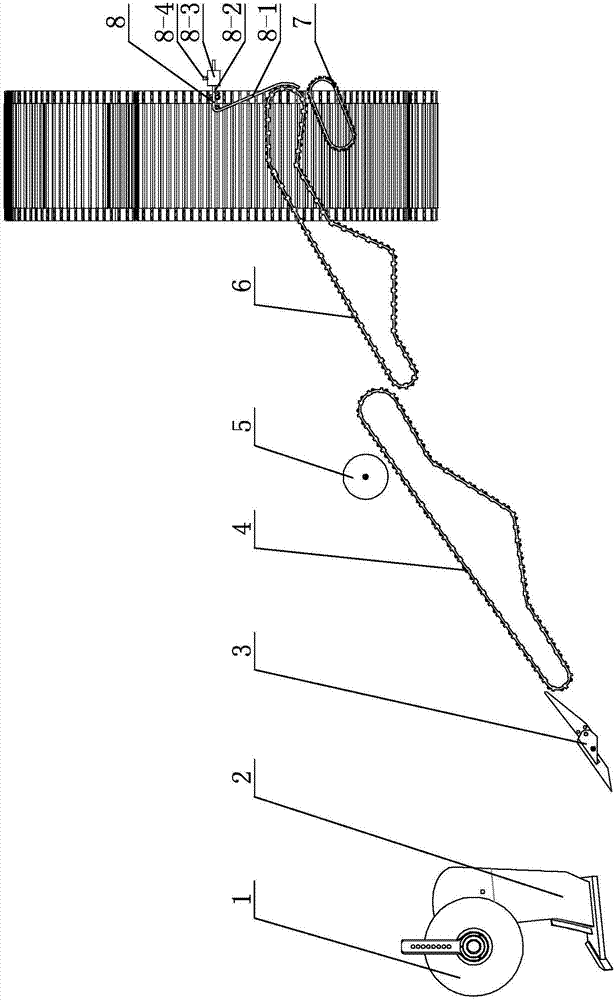

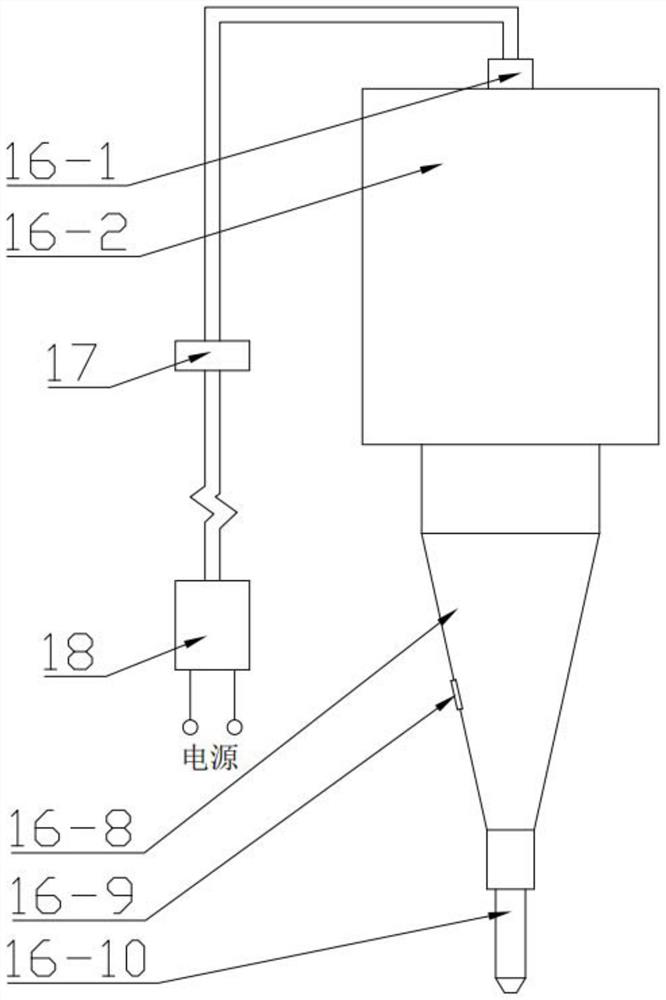

Self-propelled green Chinese onion combine harvester

InactiveCN112753350ASolve congestionReduce digging resistanceLiftersDiggersAgricultural scienceAgricultural engineering

The invention relates to agricultural machinery, in particular to a self-propelled green Chinese onion combine harvester. The self-propelled green Chinese onion combine harvester comprises a rack, a soil separating mechanism, a vibration excavating mechanism, a forming torsion mechanism and a quantitative laying mechanism, wherein the soil separating mechanism, the vibration excavating mechanism, the forming torsion mechanism and the quantitative laying mechanism are sequentially arranged on the rack from front to back; the vibration excavating mechanism is located below the soil separating mechanism; the digging mechanism comprises a digging shovel, a spring I, a permanent magnet, a coil and a sliding shaft; the rear end of the digging shovel is fixedly connected with the permanent magnet; the front end of the digging shovel faces the soil separating mechanism; the sliding shaft is sleeved with the spring I, the permanent magnet and the coil; the permanent magnet is located between the spring I and the coil; the two ends of the permanent magnet are fixedly connected with the spring I and the coil respectively; and the two ends of the sliding shaft are fixedly connected with the rack 1. The resistance in the green Chinese onion digging process is reduced, green Chinese onions are conveniently collected, and automatic harvesting of the green Chinese onions is achieved.

Owner:QINGDAO AGRI UNIV

Traction type four-row beet harvester

PendingCN111837579AShort tripImprove work efficiencyLiftersDiggersSugar beetAgricultural engineering

The invention discloses a traction type four-row beet harvester. The traction type four-row beet harvester comprises a rack, an excavating device, a conveying system and a transmission system, whereinthe conveying system comprises a backward conveying device, a lifting device and a loading conveying device; the excavating device comprises an excavating shovel capable of excavating the width of four rows of beets of two film laminating belts, and cutting discs are arranged on the two sides of each film laminating belt; the backward conveying device comprises a first backward conveying chain and a second backward conveying chain; the lifting device comprises a front side upward lifting chain and a rear side upward lifting chain; the loading conveying device comprises a forward conveying chain and a loading conveying chain; a soil guide conveying belt is arranged at the lower part of the forward conveying chain; a first film stripping roller is arranged at the joint of the first backwardconveying chain and the second backward conveying chain; a second film stripping roller is arranged at the joint of the second backward conveying chain and the rear side upward lifting chain; and a third film stripping roller is arranged at the joint of the front side upward lifting chain and the forward conveying chain. The beet harvester is reasonable in structure, low in failure rate, relatively high in beet harvesting efficiency, good in soil shaking and film removing effect and good in beet harvesting quality.

Owner:CHIFENG XINDA MACHINERY MFG

Split crusher and breaking device thereof

The invention discloses a split crusher and a breaking device thereof. The crusher comprises clamping plates, a positioning part and a crushing head, wherein the two clamping plates are arranged oppositely for clamping and fixing the positioning part; the crushing head comprises a crushing part, a middle part and a fixing part; the fixing part is contacted with the positioning part; the space formed by the positioning part and the clamping plates in a surrounding mode is used for accommodating and fixing the fixing part; and the fixing part and the clamping plates are detachably connected through fixing pieces. The crusher is split and is formed by three parts of the clamping plates, the positioning part and the crushing head; the crushing head is a vulnerable component which directly contacts an excavation surface; the clamping plates and the positioning part are arranged for clamping the crushing head and surrounding and fixing the crushing head through the corresponding space, the crushing head can be replaced or maintained quickly in a condition of ensuring the overall working strength to be unchanged, different types of crushing heads can be replaced conveniently, and the adaptability is improved; and thus, the material cost and the time cost are saved, the labor intensity of manual replacement is reduced, and the efficiency is improved.

Owner:刘裕志

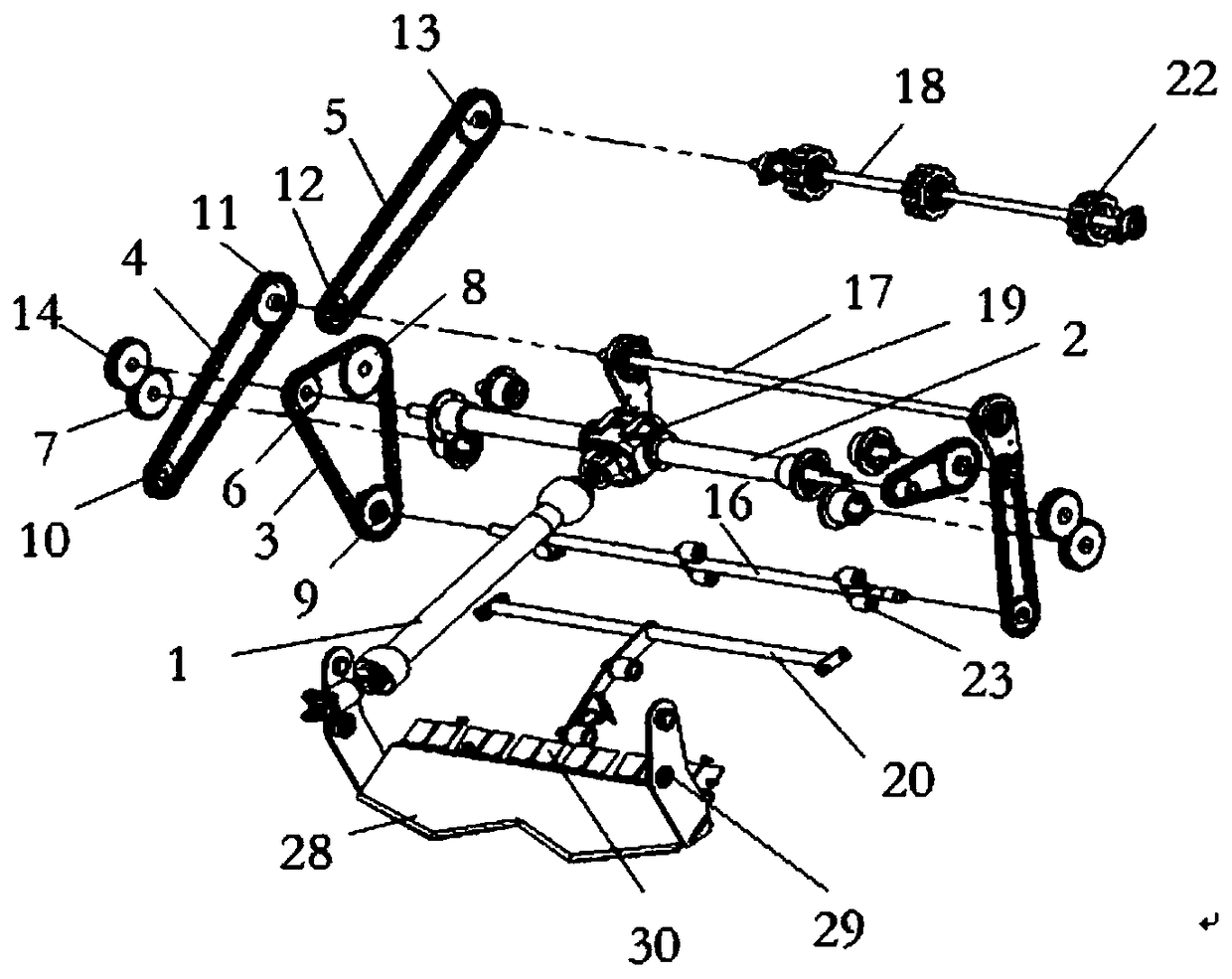

Soil-cutting excavation-type potato harvesting machine

The invention discloses a soil-cutting excavation-type potato harvesting machine. The soil-cutting excavation-type potato harvesting machine includes a cutting device, an excavation device, a conveying device, a walking device, a three-point hanging device, a transmission device and a rack. The cutting device is composed of a first cutter shaft, a first cutter rest, a third soil cutting circular disc and the like. The excavation device is composed of a first excavation shovel, a second excavation shovel, a third excavation shovel, a fourth excavation shovel and a fifth excavation shovel; the conveying device is composed of a conveying chain and baffle plates. The walking device is composed of wheels and wheel shafts. The three-point hanging device is composed of an upper suspension, a first lower suspension, a second lower suspension and a rear support frame. The power transmission device is composed of a decelerator, a first belt, a first cutter shaft drive belt wheel, a second belt wheel, a fourth belt and the like. All soil cutting circular discs are mounted on the forefront of the whole machine, all the excavation shovels are mounted behind the soil cutting circular discs, during operation, the soil cutting circular discs enter and cut soil, and then the excavation shovels conduct secondary excavation on the cut soil. By adopting the soil-cutting excavation-type potato harvesting machine, the problems are solved that by adopting a single excavation shovel, excavation operation resistance is large and the excavation effect is poor; therefore, soil breaking and harvestingoperation can be better conducted.

Owner:徐曼 +1

Liquorice harvesting machine

The invention relates to a harvesting machine, in particular to a liquorice harvesting machine. In order to solve the problems that during the existing liquorice harvesting operation, semi-manual operation is mainly adopted, the labor intensity of workers is high and the operation efficiency is low, the liquorice harvesting machine comprises a cutting disc, a deep scarification tooth, digging knives, first conveying chains, second conveying chains, third conveying chains, a separating mechanism and a vehicle rack, wherein the deep scarification tooth, the digging knives, the first conveying chains, the second conveying chains and the separating mechanism are sequentially installed on the vehicle rack from front to back, the cutting disc is installed at the upper end of the deep scarification tooth, and the third conveying chains are installed at the rear end of the vehicle rack and located below the rear end of the second conveying chains. The invention belongs to the technical field of agricultural machines.

Owner:HEILONGJIANG BEIDAHUANG ZHONGRONG AGRI MASCH CO LTD

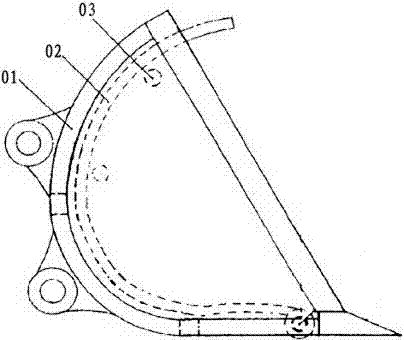

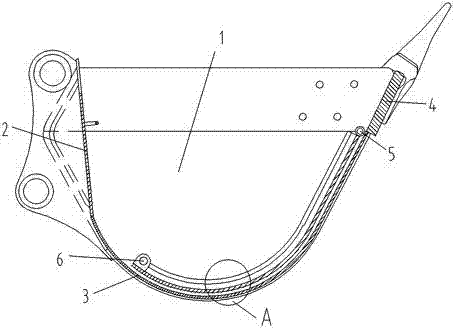

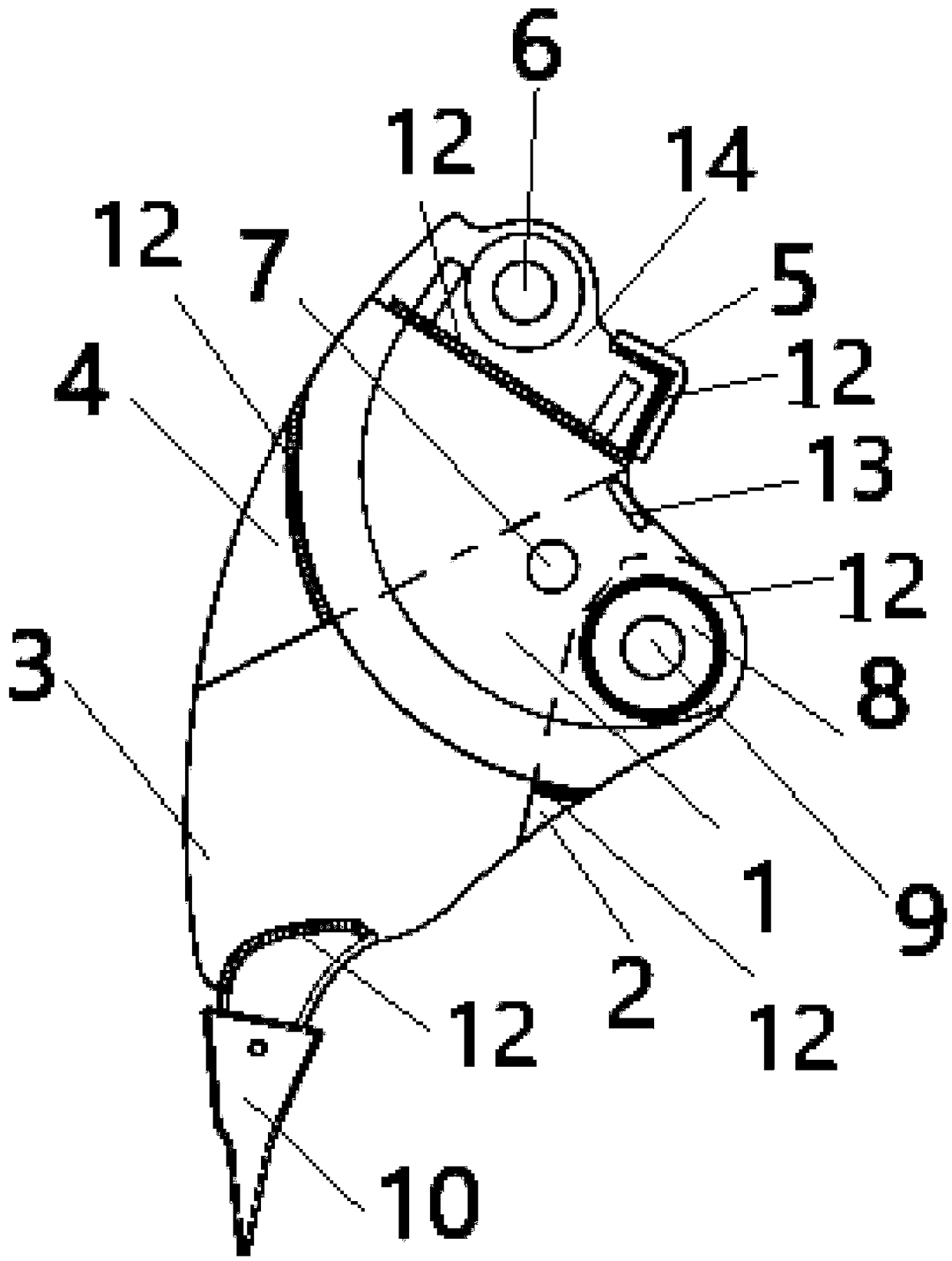

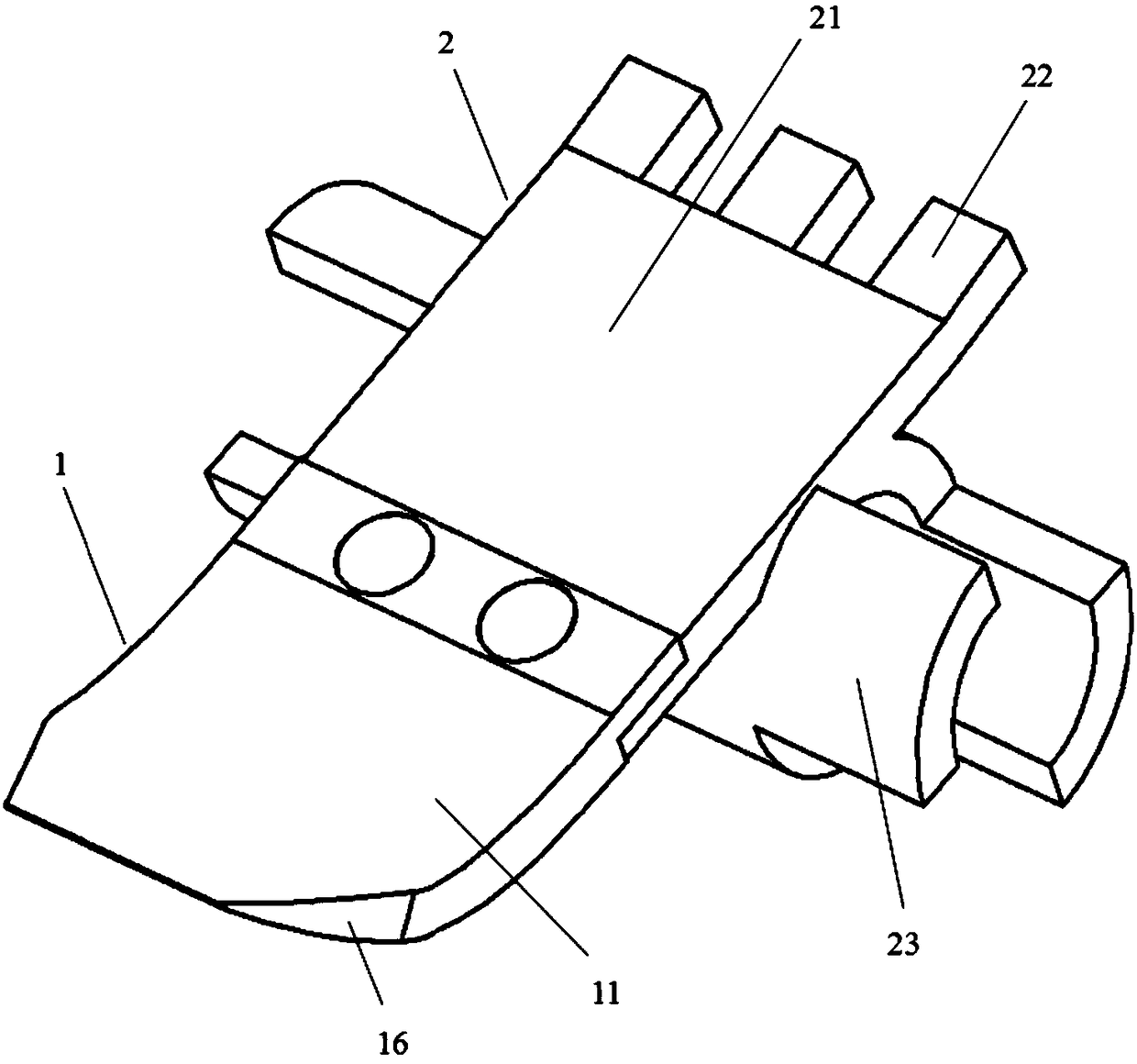

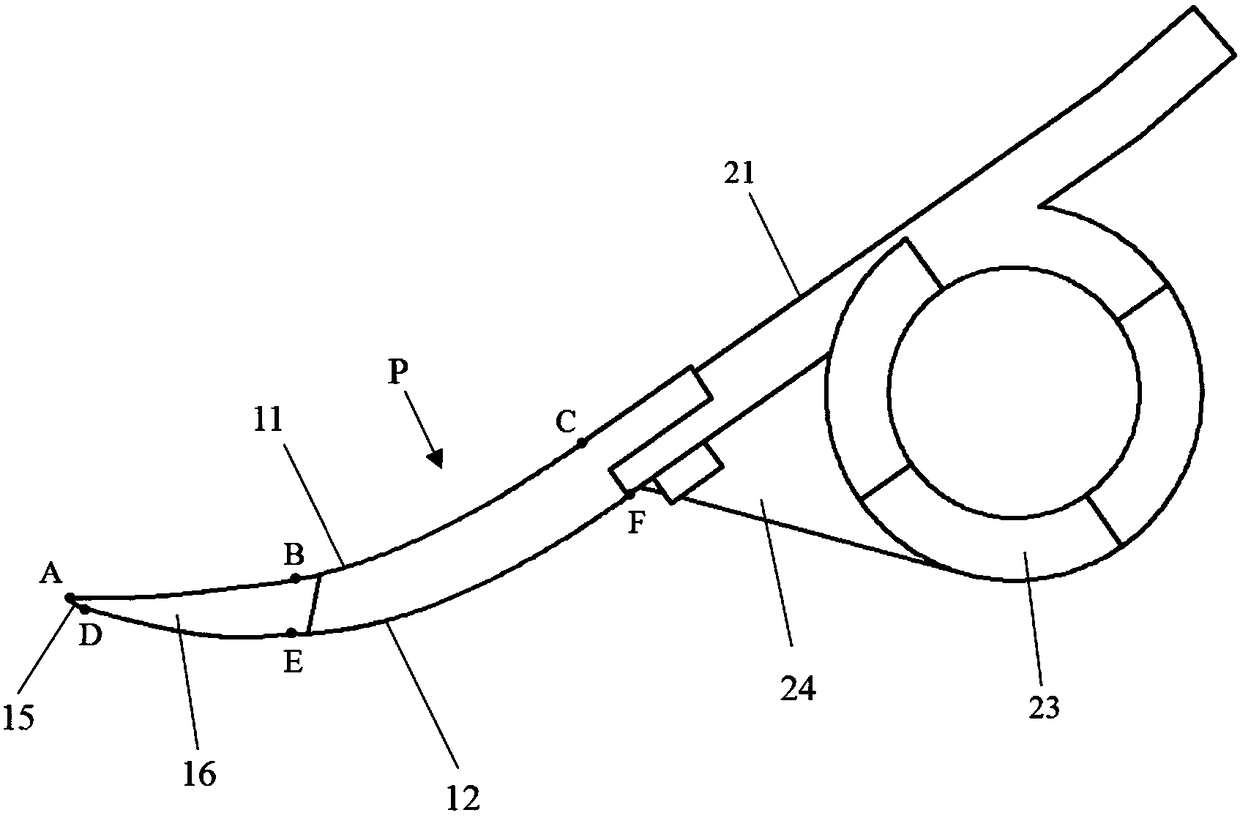

Bionic digging shovel blade for potatoes

ActiveCN108243701AReduce digging resistanceCutting effect is obviousGeometric CADDiggersAgricultural engineeringShovel

The invention discloses a bionic digging shovel blade for potatoes. The bionic digging shovel blade comprises a shovel handle, the front end of the shovel handle is provided with a shovel tip, and theshovel tip comprises an upper shovel face and a lower shovel face; the upper shovel face comprises a curved segment AB and a curved segment BC which imitate the outer contour of a first toe of a front paw of a mole; the lower shovel face includes a curved segment DE and a curved segment EF which imitate the inner contour of the first toe of the front paw of the mole; the front end of the shovel tip is provided with a combined wedge-shaped cutting edge. According to the bionic digging shovel blade for the potatoes, the upper and lower shovel faces adopt bionic designs of the outer and inner contours of the first toe of the front paw of the mole respectively, dug-out soil is bent and crushed in a lifting process of the shovel faces, the effect of digging the crushed soil is achieved, and the digging resistance of a digging shovel is reduced. The combined wedge-shaped shovel tip has an obvious cutting effect on the soil, and not only is good resistance reduction performance achieved butalso a certain soil crushing effect is achieved. The bionic digging shovel blade for the potatoes is convenient to disassemble and easy to maintain.

Owner:XIHUA UNIV

Bucket and excavator

ActiveCN114108724ASimple structureIncreased load carrying areaMechanical machines/dredgersBlade plateThin slab

The bucket comprises a top plate, a bottom plate and two side plates, one end of the bottom plate is connected to one end of the top plate, the bottom plate is bent to enable the bucket to form a bucket shape, a certain distance is formed between the ends, away from each other, of the top plate and the bottom plate, so that an opening of the bucket is formed, and the two side plates are fixedly connected to the two sides of the bottom plate respectively. The two side plates are further fixedly connected to the two sides of the top plate respectively, the side plates comprise side blade plates and side thin plates, the thickness of the side blade plates is larger than that of the side thin plates, the side blade plates extend to the ends, adjacent to the bottom plate, of the side plates from the ends, adjacent to the opening of the bucket, of the side plates, and the side thin plates are distributed on the side plates at intervals. According to the bucket and the excavator, the side blade plates extend to all the areas of the whole side plates, the structures of the side blade plates are optimized, the load transfer area of the side blade plates is increased, the excavating load path is optimized, excavating resistance and loads are reduced, excavating force and excavating efficiency are improved, meanwhile, a light-weight structure is formed, and energy and oil are saved.

Owner:ZOOMLION HEAVY IND CO LTD

Cutter-suction device based on ultrasonic-assisted rock breaking, and rock breaking method

ActiveCN110778271ABreach of integrityReduce intensityDisloding machinesVibration drillingTool bitUltrasonic assisted

The invention discloses a cutter-suction device based on ultrasonic-assisted rock breaking, and a rock breaking method. The device comprises a cutter-suction dredger cutter-suction device, a connecting device and an ultrasonic-assisted device. The cutter-suction dredger cutter-suction device comprises a bridge frame, a tail shaft, an underwater pump, a suction pipe, a bridge frame pulley, a transverse movement pulley, an underwater motor, a reamer and a reamer shaft. The connecting device comprises an upper cover, a plunger cylinder and a support. The ultrasonic-assisted device comprises an ultrasonic generator, an ultrasonic switch and an ultrasonic device. According to the cutter-suction device based on ultrasonic-assisted rock breaking, and the rock breaking method provided by the invention, through the ultrasonic-assisted device, an ultrasonic cutter bit and a rock achieve resonance, so that the rock forms cracks and fissures, the completeness of the rock is broken, the strength ofthe rock is reduced, and the digging resistance of the reamer is correspondingly reduced; and in addition, from officinal cutting on, the reamer and the ultrasonic device start to work at the same time, so that the excavation ability and the efficiency are improved, the dredging energy consumption is reduced, and the aim on optimizing the cutter-suction dredger cutter-suction device and an application method thereof is finally achieved.

Owner:HOHAI UNIV CHANGZHOU

A winch suction device and rock breaking method based on ultrasonic assisted rock breaking

ActiveCN110778271BBreach of integrityReduce intensityDisloding machinesVibration drillingTool bitReamer

The invention discloses a cutter-suction device and a rock-breaking method based on ultrasonic-assisted rock breaking. The device comprises a cutter-suction dredger cutter-suction device, a connecting device and an ultrasonic auxiliary device. The cutter suction device of a cutter suction dredger includes a bridge frame, a tail shaft, an underwater pump, a suction pipe, a bridge frame pulley, a traverse pulley, an underwater motor, a reamer and a reamer shaft. The connecting device includes the upper cover, the plunger cylinder and the bracket. The ultrasonic auxiliary device includes an ultrasonic generator, an ultrasonic switch and an ultrasonic device. The present invention uses an ultrasonic auxiliary device to resonate the ultrasonic cutter head with the rock, allowing the rock to form gaps and cracks, destroying the integrity of the rock, reducing the strength of the rock, and correspondingly reducing the excavation resistance of the reamer. The knife and the ultrasonic device start to work simultaneously, which improves the excavation capacity and efficiency, reduces dredging energy consumption, and finally achieves the purpose of optimizing the cutter suction dredging reamer suction device and its use method.

Owner:HOHAI UNIV CHANGZHOU

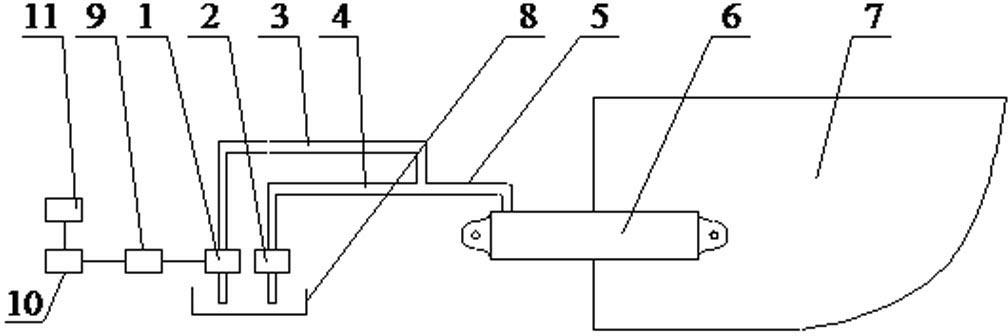

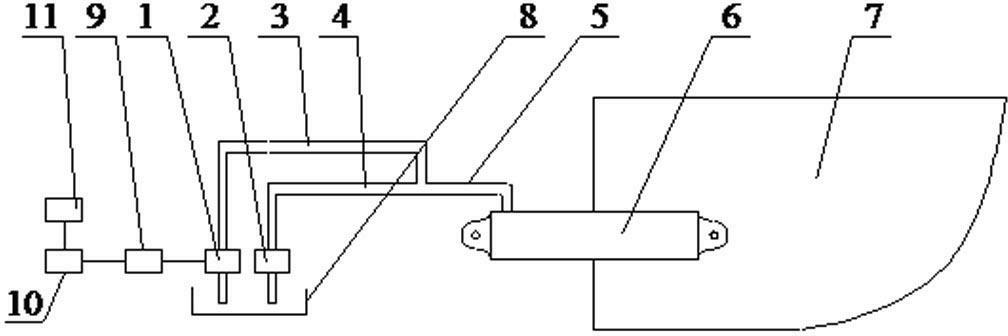

Vibration advancing and loading operation control system for loader

InactiveCN102312463AReduce digging resistanceAchieve vibrationSoil-shifting machines/dredgersContactorProgrammable logic controller

The invention discloses a vibration advancing and loading operation control system for a loader. The system comprises a steady-state hydraulic oil pump, a steady-state oil passage and a hydraulic cylinder, wherein the steady-state hydraulic oil pump is connected with the steady-state oil passage; the system is also provided with a pulsation hydraulic oil pump, a vibrating oil passage, a master oil passage, an instruction input device, a programmable logic controller (PLC) and a contactor, wherein the pulsation hydraulic oil pump is connected with the vibrating oil passage; the vibrating oil passage and the steady-state oil passage are connected in parallel and then connected with the master oil passage; the master oil passage is connected with the hydraulic cylinder; the pulsation hydraulic oil pump and the steady-state hydraulic oil pump are respectively connected with a hydraulic oil tank; and the instruction input device, the PLC and the contactor are sequentially connected with the pulsation hydraulic oil pump. The system can fully exert the rated advancing force of the loader and save energy.

Owner:昆山航天智能技术有限公司

A multifunctional drilling rig suitable for silt formation and its construction method

ActiveCN111119727BImprove protection strengthPlay the role of reinforcementEarth drilling toolsDrill bitsWell drillingWater jet cutter

Owner:江苏省地质矿产局第三地质大队

Transmission mechanism of cassava harvester

PendingCN109429669AImprove work efficiencyRun smoothlyDiggersSaving energy measuresSprocketEngineering

The invention discloses a transmission mechanism of a cassava harvester. The transmission mechanism comprises a transmission universal joint, a universal joint transmission shaft, a first transmissionchain, a second transmission chain, a third transmission chain and transmission chain wheels. The transmission chain wheels are correspondingly mounted with the various transmission chains, the firsttransmission chain wheel and a ninth transmission gear are mounted at two ends of the universal joint transmission shaft, a second transmission gear is mounted on a rotary shaft, the third transmission chain wheel is mounted on a shaft of a framework, the fourth transmission chain wheel and the fifth transmission chain wheel are mounted at two ends of a primary conveying vibrating shaft, the sixth transmission chain wheel and the seventh transmission chain wheel are mounted on a secondary conveying rotary shaft, and the eighth transmission chain wheel is mounted at two ends of a tertiary conveying rotary shaft. The transmission mechanism has the advantages that the integral transmission mechanism can be driven by a single power source to be operated and can stably and uniformly run, effects of driving digging shovels to carry out vibration type digging and driving conveying sieves to carry out vibration material conveying can be realized by the transmission mechanism, energy consumption can be reduced to a great extent, the work efficiency can be improved, and the like.

Owner:QINGDAO HONGZHU AGRI MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com