Small-sized boxing type potato harvesting combined machine

A combined operation machine and potato technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and equipment, etc., can solve the problems of wide working width, difficulty in applying to small plots, and low entry efficiency, so as to reduce excavation resistance , Realize the effect of potato soil separation and potato soil separation thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

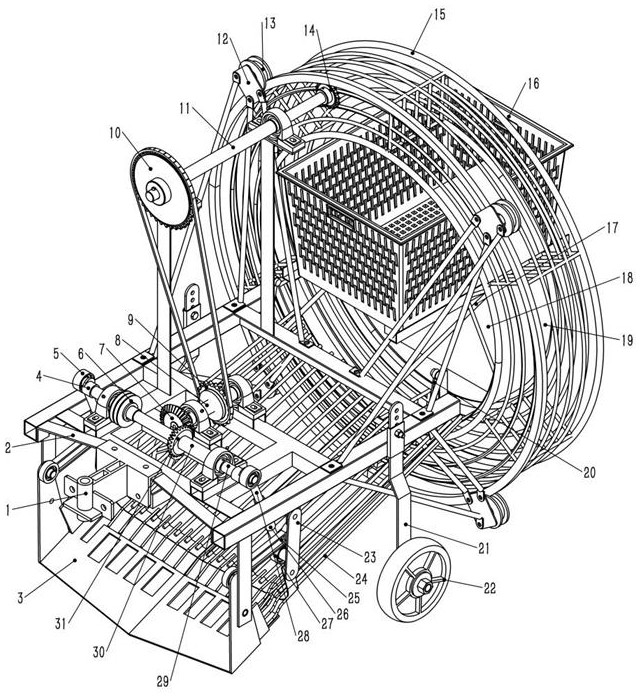

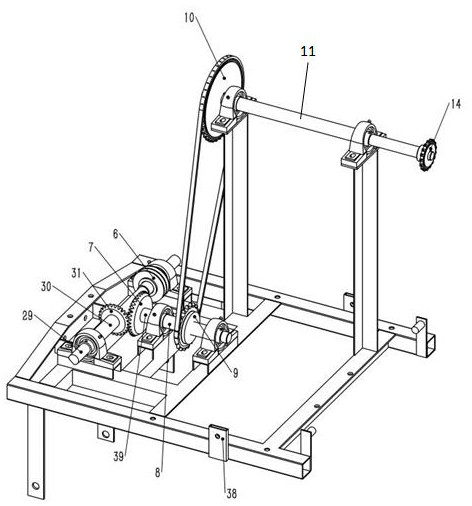

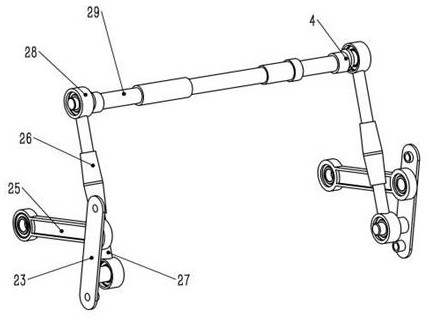

[0028]A small boxed potato harvesting combined operation machine, comprising a frame 2, a traction hanger 1, a compound digging shovel 3, a transmission device, a vibration separation device, an eccentric wheel mechanism, and a supporting wheel; the compound digging shovel, the supporting wheel and The vibrating screen is respectively connected to the lower end of the frame, and the eccentric wheel mechanism is installed on the upper end of the frame;

[0029] Described transmission device comprises the first drive shaft 29; The first drive shaft 29 is connected on the frame by the bearing seat, is provided with the drive pulley 6 on the first drive shaft 29, drives the pulley 6 on the first drive shaft 29 through the belt Drive connection with the tractor; the shaft end of the first drive shaft 29 is connected to the eccentric wheel mechanism;

[0030] The eccentric wheel mechanism and the vibratory separation device are connected into one, and the eccentric wheel mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com