Vibration advancing and loading operation control system for loader

A control system and loader technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of high energy consumption, the loader cannot fully exert the rated breakout force, etc., and achieve the effect of reducing the excavation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

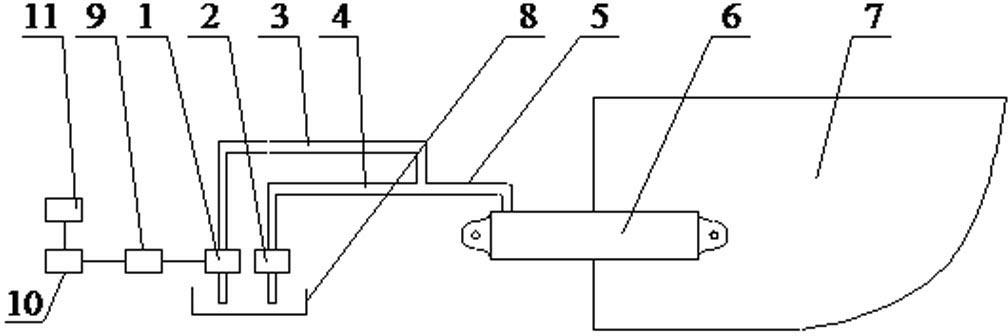

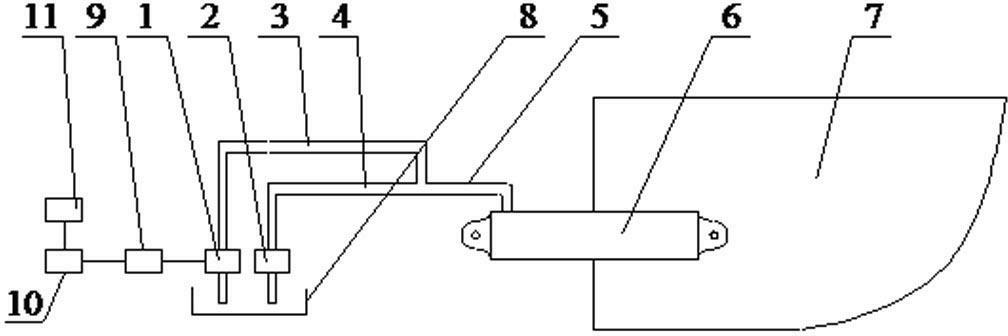

[0012] The following is attached figure 1 And embodiment further illustrate the present invention.

[0013] refer to figure 1 , this embodiment includes a steady-state hydraulic oil pump 2, a steady-state oil circuit 4, and a hydraulic cylinder 6. The steady-state hydraulic oil pump 2 is connected to the steady-state oil circuit 4, and a pulsating hydraulic oil pump 1, a vibration oil circuit 3, and a total oil circuit are also provided. 5. Command input device 11, PLC programmable controller 10, contactor 9, the pulsating hydraulic oil pump 1 is connected to the vibration oil circuit 3, and the vibration oil circuit 3 and the steady-state oil circuit 4 are connected in parallel to the total oil circuit 5, The total oil circuit 5 is connected to the hydraulic oil cylinder 6, the pulsating hydraulic oil pump 1 and the steady-state hydraulic oil pump 2 are respectively connected to the hydraulic oil tank 8, the command input device 11, the PLC programmable controller 10, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com