Cutter-suction device based on ultrasonic-assisted rock breaking, and rock breaking method

An auxiliary device and ultrasonic technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of high energy consumption, easy damage, insufficient rock breaking ability, etc., to optimize the cutter suction device, reduce the excavation The effect of resistance and reducing energy consumption of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

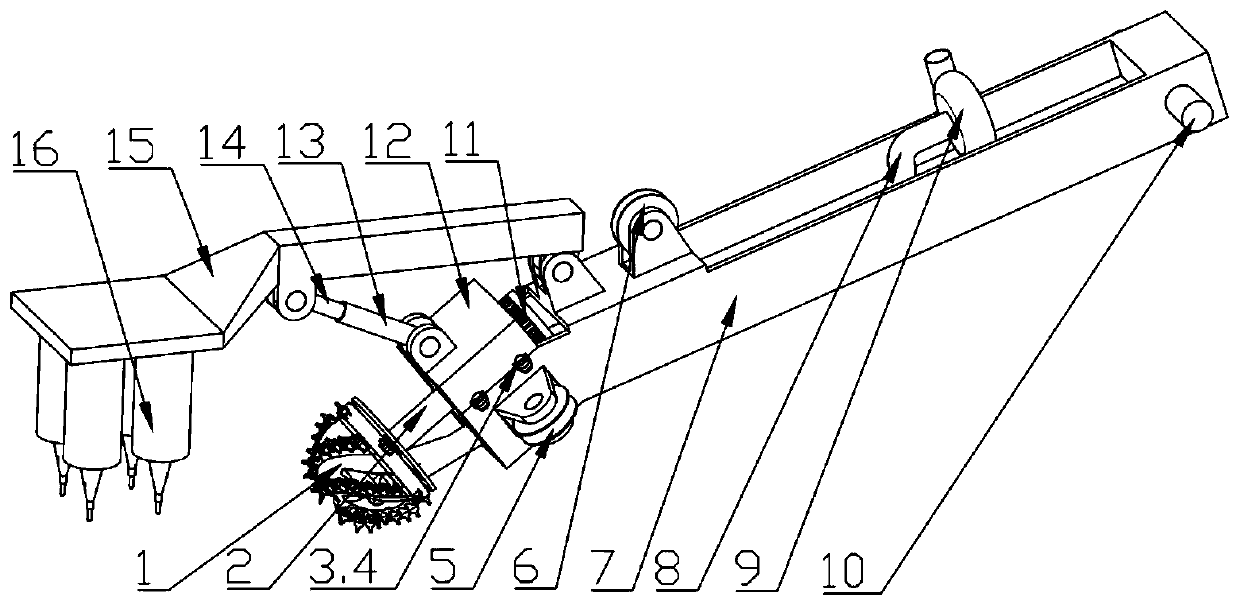

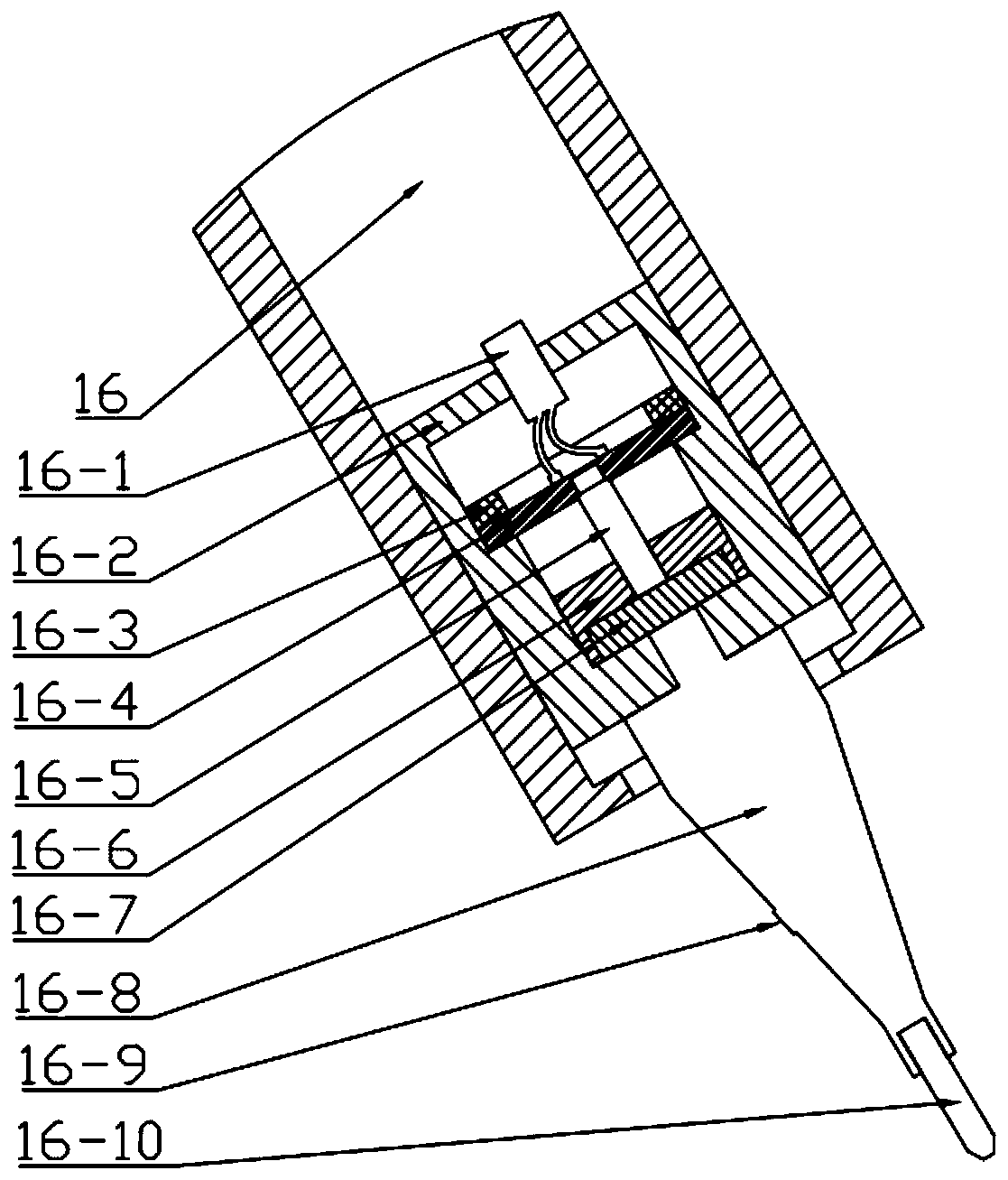

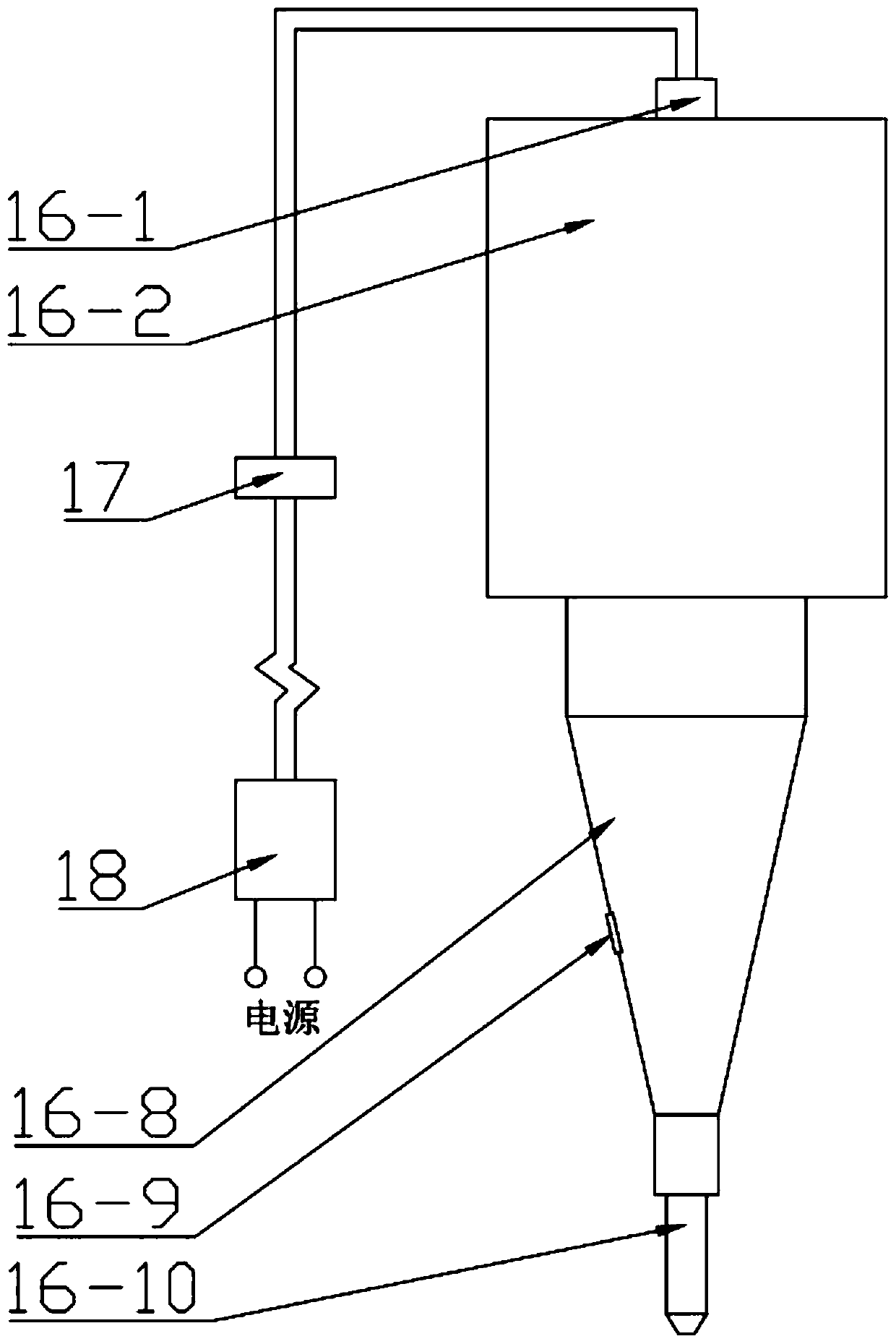

[0026] Such as figure 1 As shown, a cutter suction device based on ultrasonic assisted rock breaking includes a cutter suction dredger cutter suction device, a connecting device and an ultrasonic auxiliary device. Several ultrasonic devices 16 of the ultrasonic auxiliary device are welded on the bracket 15 of the connecting device.

[0027] Further, the cutter suction device of the cutter suction dredger includes a bridge frame 7, a tail shaft 10 fixed on the bridge frame 7, an underwater pump 9, a suction pipe 8, a bridge frame pulley 6, and a traverse pulley 5, which are fixed on the bridge frame 7 by bolts. Underwater motor 11, reamer 1 and reamer shaft 2. The cutter suction device is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com