Railway ballast cleaner

A ballast cleaning machine and railway technology, which is applied in the directions of roads, tracks, ballast layers, etc., can solve the problems such as the inability to guarantee the geometric size of the cross-section of the track bed, the inability to adjust the direction of the vertical rails, and the occupation time, etc., to achieve reliable performance and adaptability. Good performance and the effect of reducing digging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

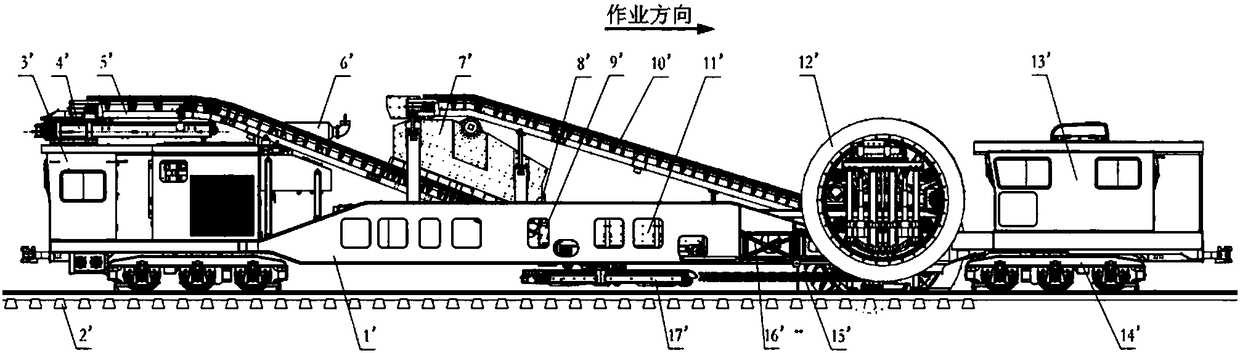

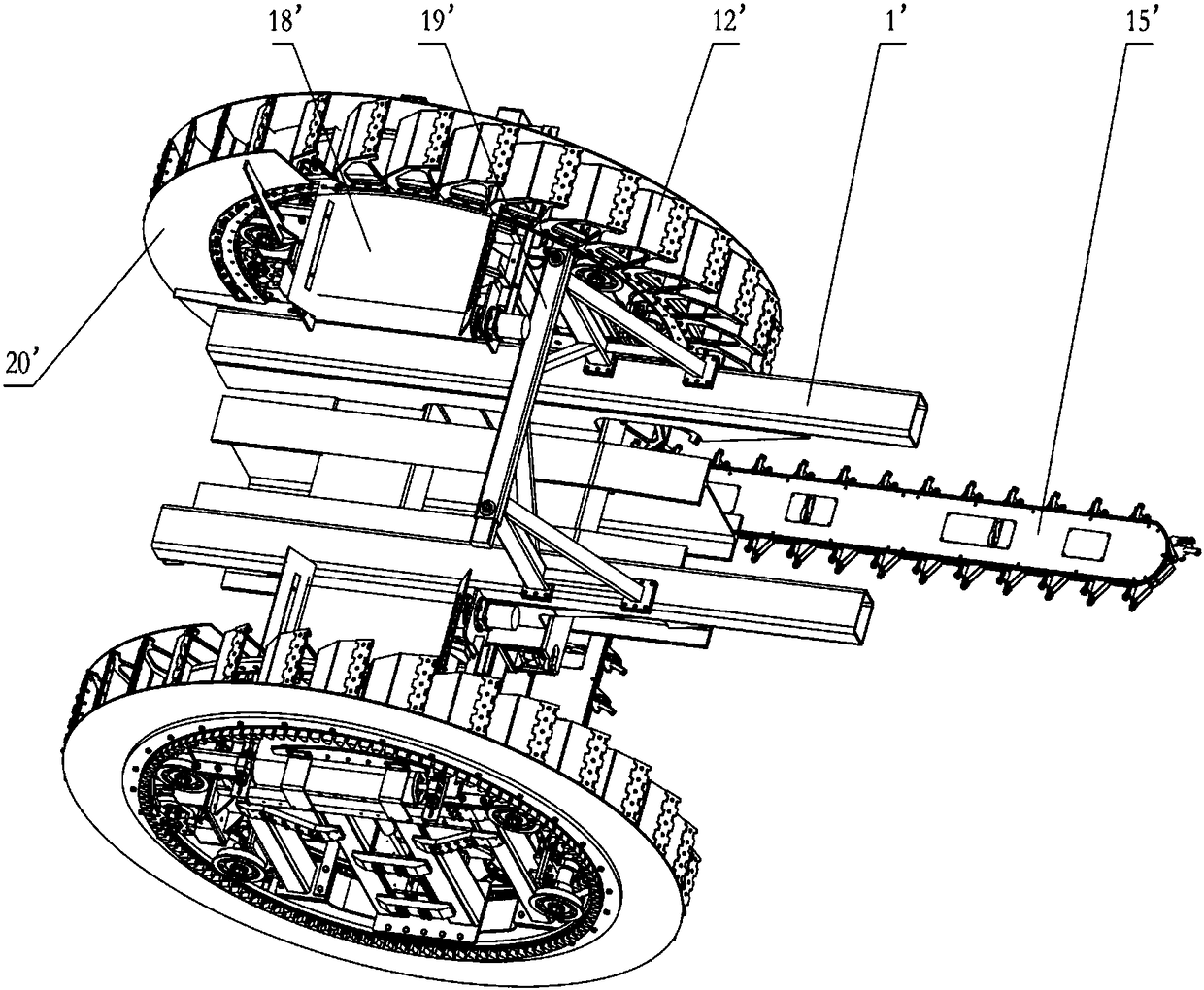

[0052] Embodiment 1.1: a kind of railway track ballast cleaning machine, it comprises vehicle frame 1 ', and this vehicle frame 1 ' is positioned at the front end of working direction and is provided with operator's cab 13 ', and the rear end of vehicle frame 1 ' is provided with running The driver's cab 3', on the frame 1' between the driver's cabs at both ends, there is an excavation bucket wheel 12' arranged from front to back according to the working direction. A screening device 7' is provided at the lower end of the conveyor belt 10', a ballasting device 8' and a main dirt conveyor belt 5' are provided below the screening device 7', a ballasting bucket 9' is provided below the ballasting device 8', The front of the ballasting bucket 9' is provided with a loading and unloading storage and transportation box 11', the lower part of the main dirt conveyor belt 5' is provided with a rotating dirt conveyor belt 4', and the bottom of the ballasting bucket 9' is provided with Ba...

Embodiment 12

[0056] Embodiment 1.2: A railway ballast cleaning machine is the same as Embodiment 1.1, except that the vertical sliding locking device realizes vertical sliding and locking through pneumatic means.

Embodiment 13

[0057] Embodiment 1.3: A railway ballast cleaning machine, the same as Embodiment 1.1, the difference is that the vertical sliding locking device realizes vertical sliding and locking by mechanical means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com