Full-dry nonmetal optical cable

A non-metallic, all-dry technology, applied in the direction of light guides, optics, optical components, etc., can solve environmental pollution and other problems, and achieve the effect of ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

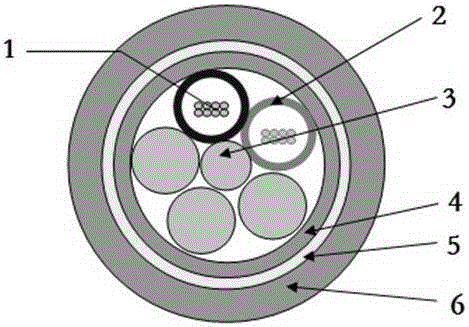

[0014] Such as figure 1 As shown, the fully dry non-metallic optical cable of the present invention includes a waterproof optical fiber 1 , a loose tube 2 , an FRP central strength member 3 , an inner sheath 4 , an aramid yarn 5 and an outer sheath 6 . Waterproof optical fiber 1 uses a coloring machine to coat a layer of liquid nylon on the outside of the existing 230μm optical fiber. The liquid nylon is made of modified PA11 produced by Polymei Plastic Technology Co., Ltd. The pressure of the coloring machine for the waterproof layer material is 0.4bar~1.0bar. Production The speed is 500-800m / min, and finally infrared heat curing (using the heat generated by the UV lamp to cure the waterproof material). The inner sheath 4 is provided with an FRP central reinforcement 3 and a plurality of loose tubes 2 . Each loose tube 2 is provided with a plurality of waterproof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com