Flexible forming method of secondary forming square tube

A flexible molding and secondary molding technology, applied in the field of flexible molding of secondary molding square and rectangular tubes, can solve the problems of difficult to guarantee production, short mold deformation interval, low product output and product qualification rate, etc., to meet production needs, improve Physical properties, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

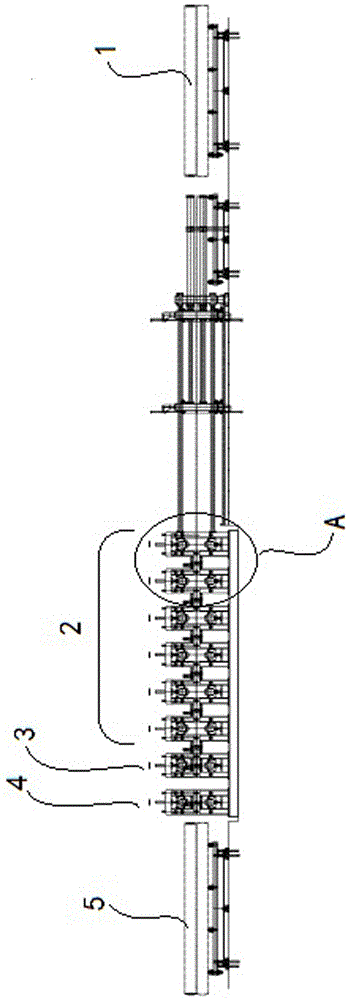

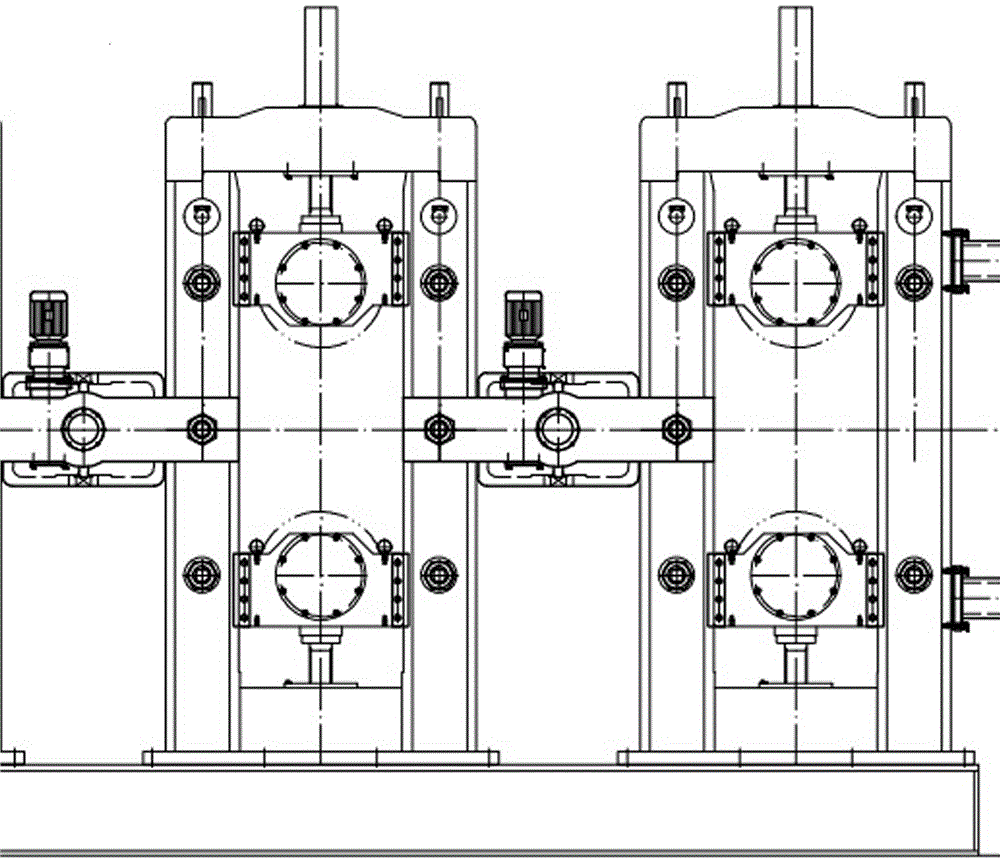

[0031] See Figure 1-Figure 3 .

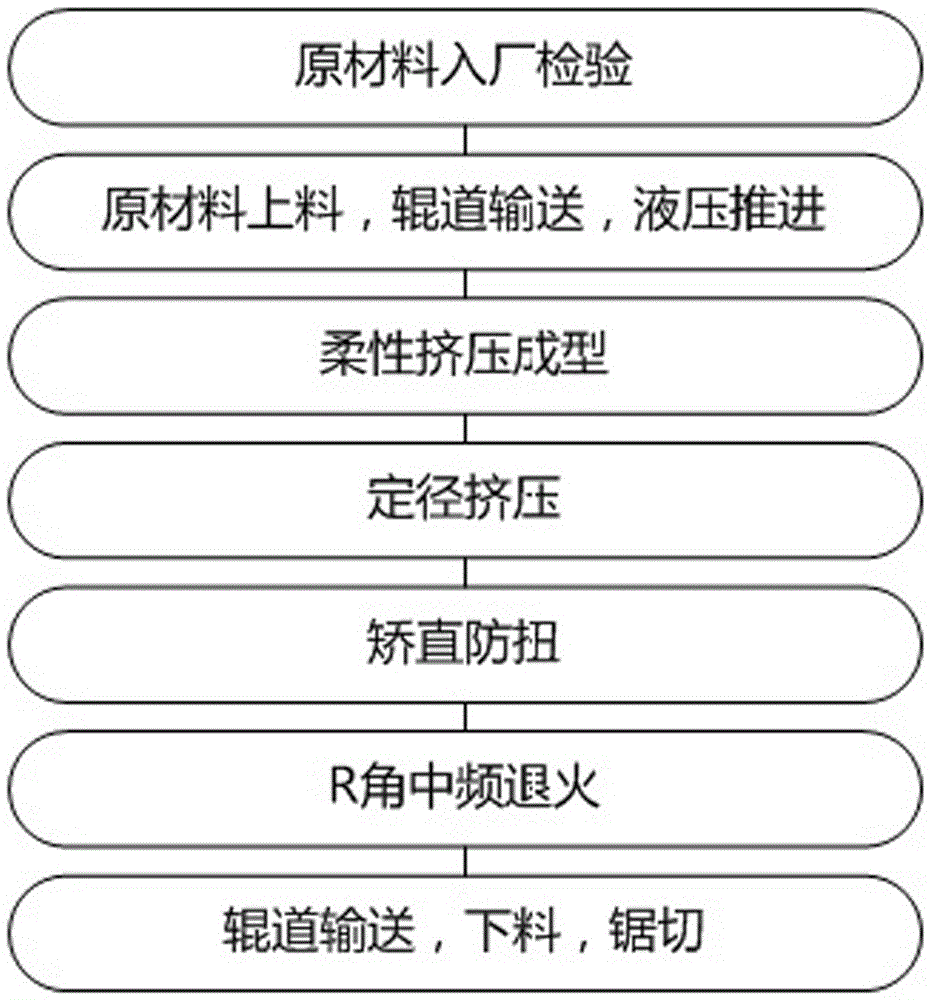

[0032] A flexible forming method for secondary forming square rectangular tubes, comprising the following steps:

[0033] S1 raw material 1 incoming inspection, including appearance inspection, geometric dimension inspection, chemical composition inspection and mechanical performance inspection;

[0034] S2 raw material feeding, roller conveying, hydraulic propulsion;

[0035] S3 flexible extrusion molding: select two opposite faces to extrude, and the other two faces to release the forming stress; after the extrusion is completed, the raw material is rotated to extrude the other two opposite faces, and the remaining two faces are used to release the forming pressure; Repeat the steps above to extrude; (see figure 2 Medium flexible extrusion pass 2)

[0036] S4 sizing: Determine the size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com