One-step molding vulcanization technology of hollow-core rubber product

A rubber product, a one-time technology, applied in household components, applications, household appliances, etc., can solve the problems of uneven thickness, large tolerances, damaged splices, etc., to eliminate the hidden danger of damage after inflation and avoid secondary damage , the effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The one-time molding vulcanization process of the hollow rubber product of the present embodiment comprises the following steps:

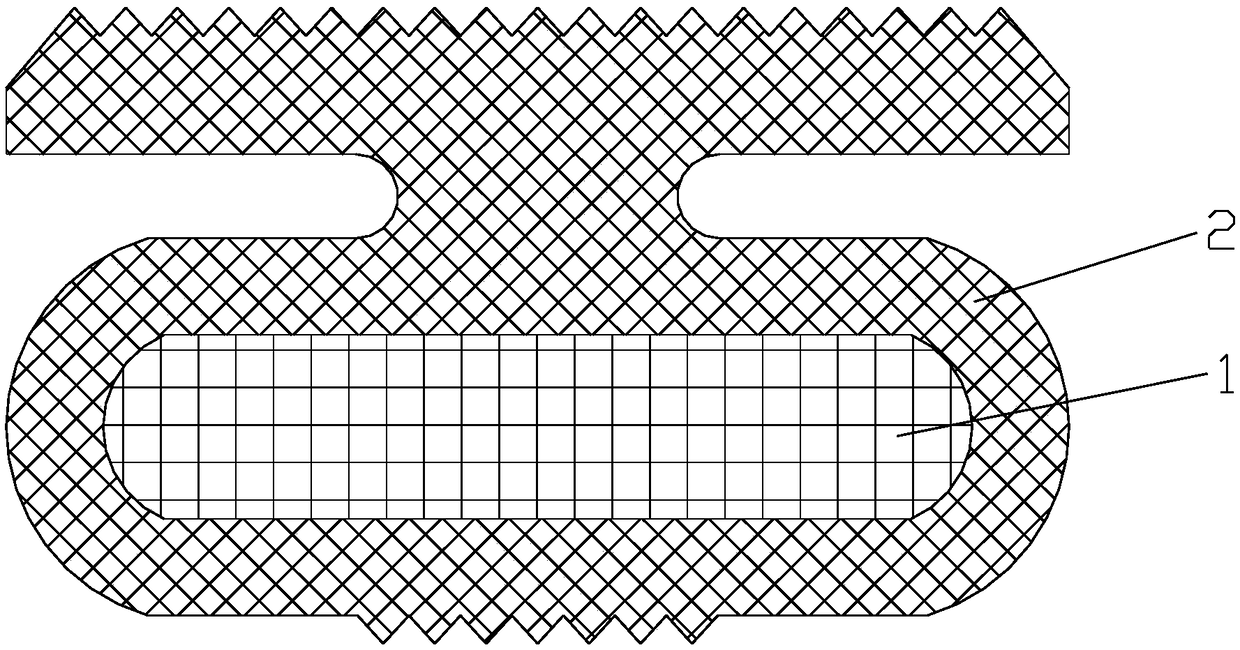

[0025] Step 1, using the coating extrusion process to prepare rubber-coated rods; as figure 1 As shown, the rubber-coated rod consists of a rod core 1 and a rubber coating layer 2 coated on the rod core 1. The material of the rod core 1 is a phase change material, which is mixed with the following raw materials in weight percentage Uniformly made: 7% boron trioxide, 20% aluminum hydroxide, 17% sodium nitrate, 30% paraffin wax, 3% silicon dioxide, 5% talc, 6% rosin, 4% liquid coumarone, hard 2% fatty acid, 6% calcium carbonate, the phase change material is solid at room temperature, and the phase change temperature is 120°C; the rubber is EPDM rubber;

[0026] Step 2. Remove part of both ends of the rod core 1 of the rubber-coated rod described in step 1 (the removal length is about 100mm-200mm), fill it with rubber compound, and embed the a...

Embodiment 2

[0031] The one-time molding vulcanization process of the hollow rubber product of the present embodiment comprises the following steps:

[0032] Step 1, using the coating extrusion process to prepare rubber-coated rods; as figure 1 As shown, the rubber-coated rod consists of a rod core 1 and a rubber coating layer 2 coated on the rod core 1. The material of the rod core 1 is a phase change material, which is mixed with the following raw materials in weight percentage Uniformly made: boron trioxide 5%, aluminum hydroxide 22%, sodium nitrate 15%, solid paraffin 35%, silicon dioxide 2%, talc 3%, rosin 5%, liquid coumarone 4%, hard 1% fatty acid, 8% calcium carbonate, the phase change material is solid at room temperature, and the phase change temperature is 150°C; the rubber is EPDM rubber;

[0033] Step 2. Remove part of both ends of the rod core 1 of the rubber-coated rod described in step 1 (the removal length is about 100mm-200mm), fill it with rubber compound, and embed the...

Embodiment 3

[0038] The one-time molding vulcanization process of the hollow rubber product of the present embodiment comprises the following steps:

[0039] Step 1, using the coating extrusion process to prepare rubber-coated rods; as figure 1 As shown, the rubber-coated rod consists of a rod core 1 and a rubber coating layer 2 coated on the rod core 1. The material of the rod core 1 is a phase change material, which is mixed with the following raw materials in weight percentage Uniformly made: boron trioxide 8%, aluminum hydroxide 18%, sodium nitrate 20%, solid paraffin 25%, silicon dioxide 4%, talc 7%, rosin 7%, liquid coumarone 3%, hard 3% fatty acid, 5% calcium carbonate, the phase change material is solid at room temperature, and the phase change temperature is 135°C; the rubber is EPDM rubber;

[0040] Step 2. Remove part of both ends of the rod core 1 of the rubber-coated rod described in step 1 (the removal length is about 100mm-200mm), fill it with rubber compound, and embed the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com