Efficient energy-saving environment-friendly oil-hydraulic hybrid powder excavator

An oil-liquid mixing, high-efficiency and energy-saving technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of hydraulic oil temperature rise, back pressure energy consumption, and large negative effects, etc. problem, to achieve the effect of increasing the transmission ratio, reducing the wear of the pin shaft, and increasing the power output torque value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

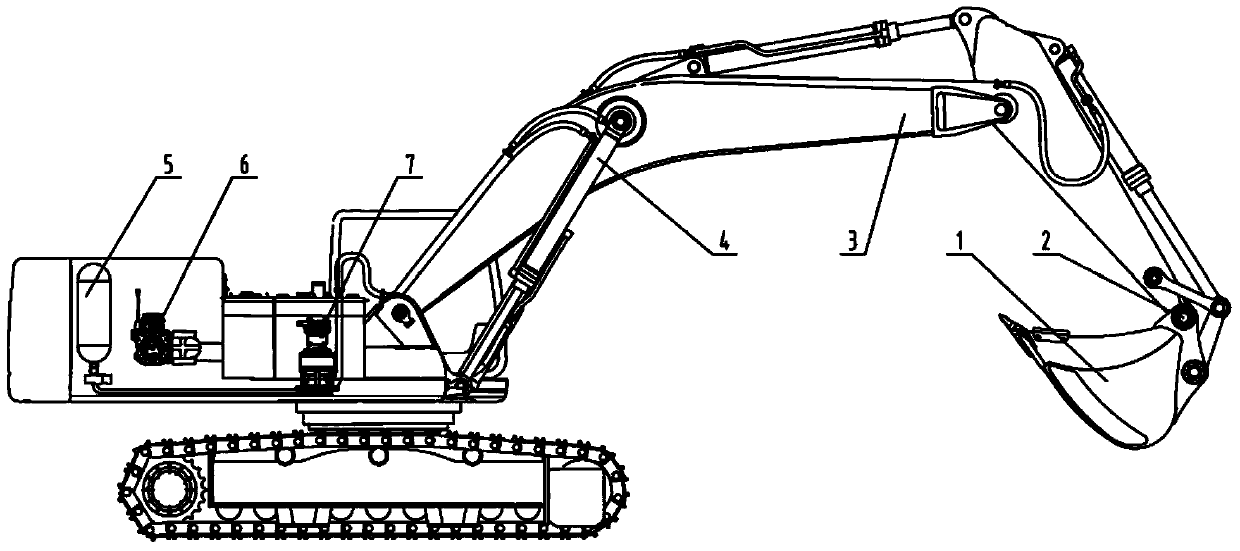

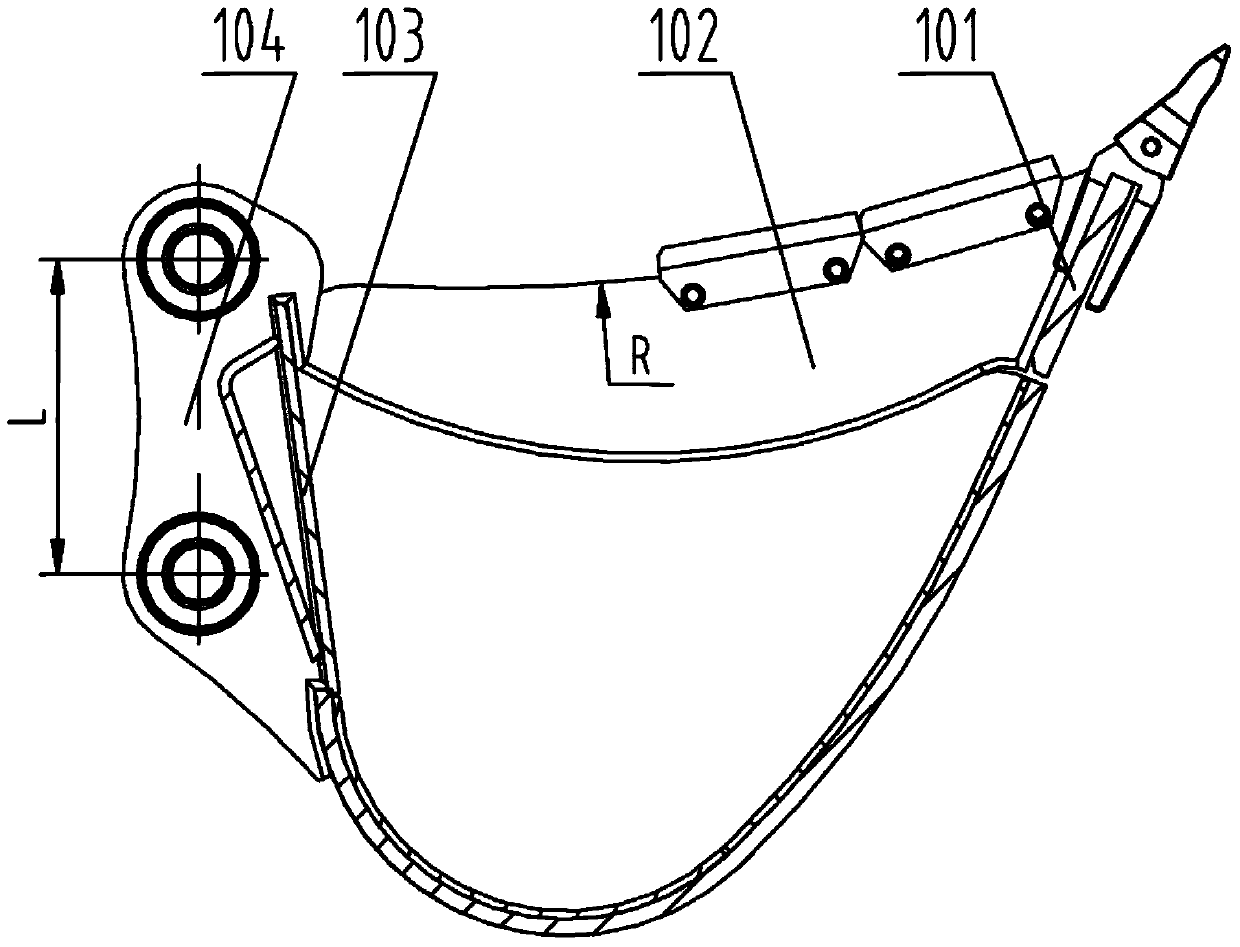

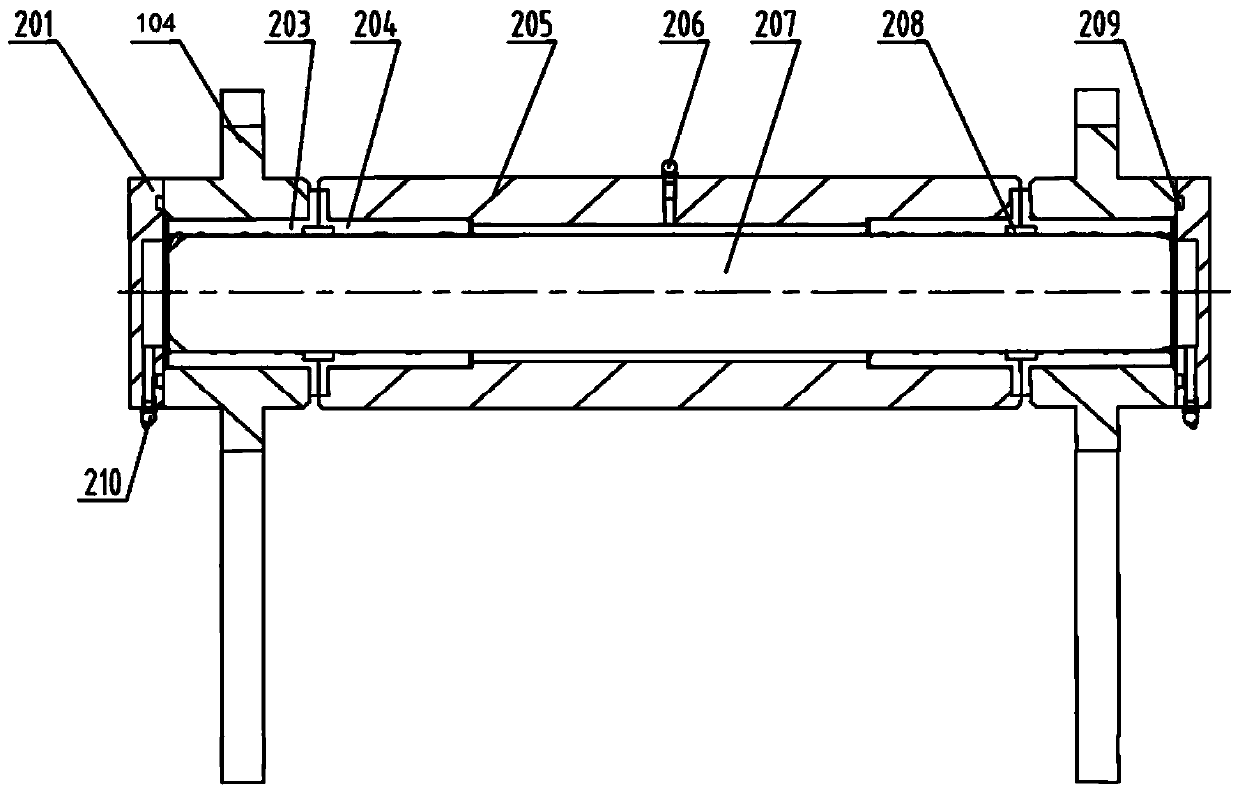

[0039] Refer to attached Figure 1-8 , a high-efficiency, energy-saving and environmentally friendly oil-liquid hybrid excavator, including an upper frame, a turntable, a bucket 1, a bucket pin connection mechanism 2, a boom 3, a boom working device, an accumulator charging device 5, a power supply Oil device, rotary power assembly 7, the upper frame is installed on the turntable, the turntable is connected to the rotary power assembly, the bucket is assembled on the arm through the bucket pin connection mechanism, and the boom passes through the bucket on the one hand The pin connection mechanism is hinged with the arm, and on the other hand is connected to the upper frame through the pin shaft of the upper frame. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com