Self-propulsion trailing suction hopper dredger

A trailing suction dredger, self-propelled technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. The location and dredging depth, affecting the production efficiency and construction progress of the self-propelled trailing suction dredger, can improve the digging capacity and increase the degree of loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

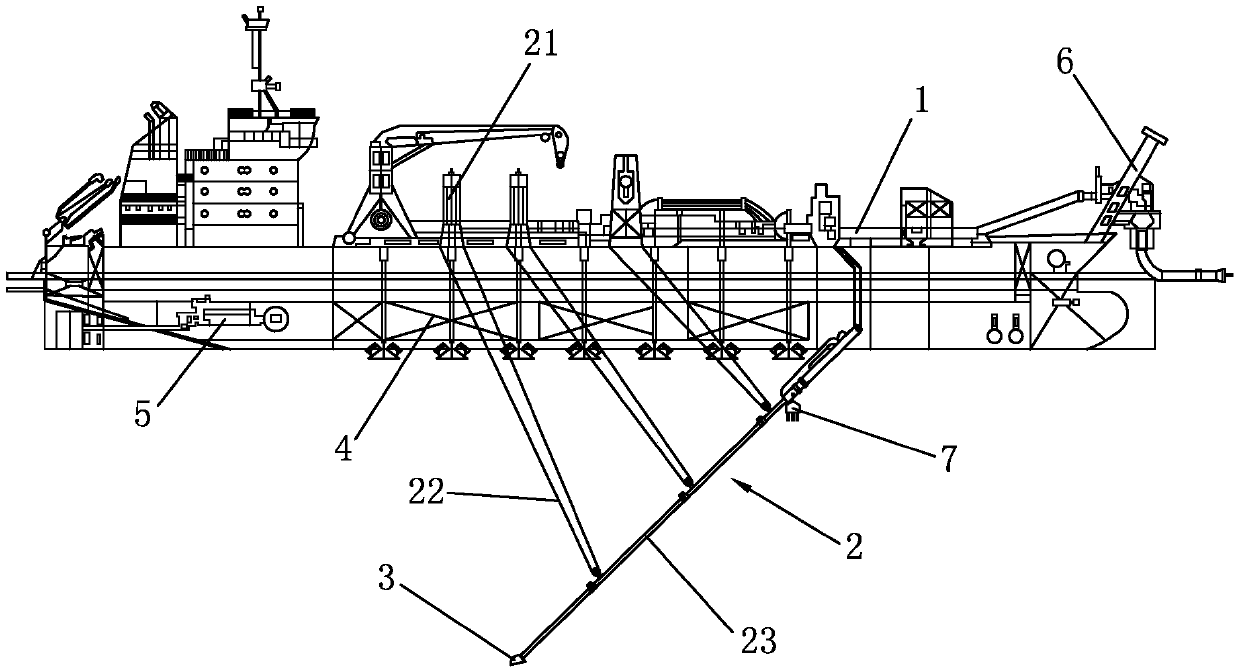

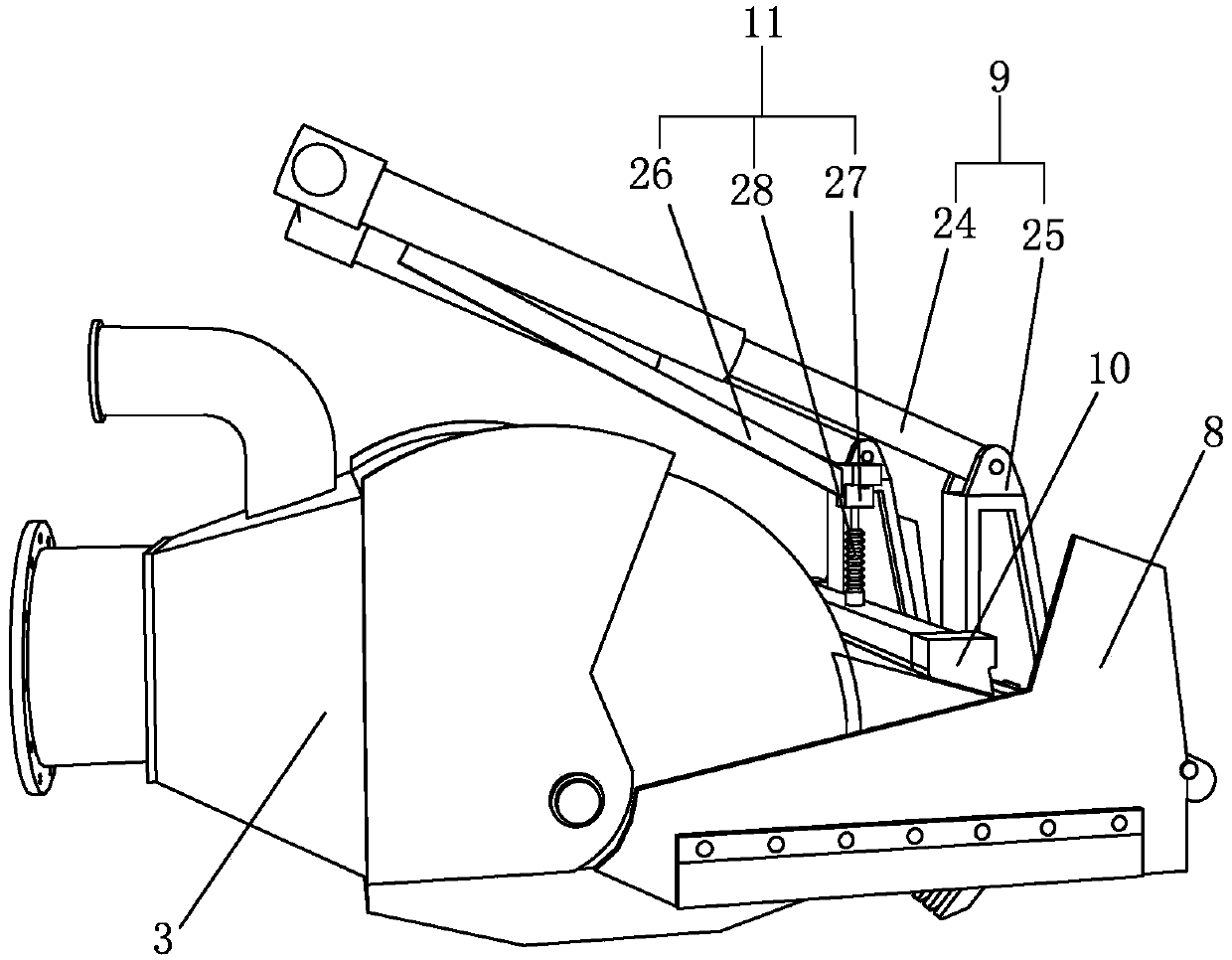

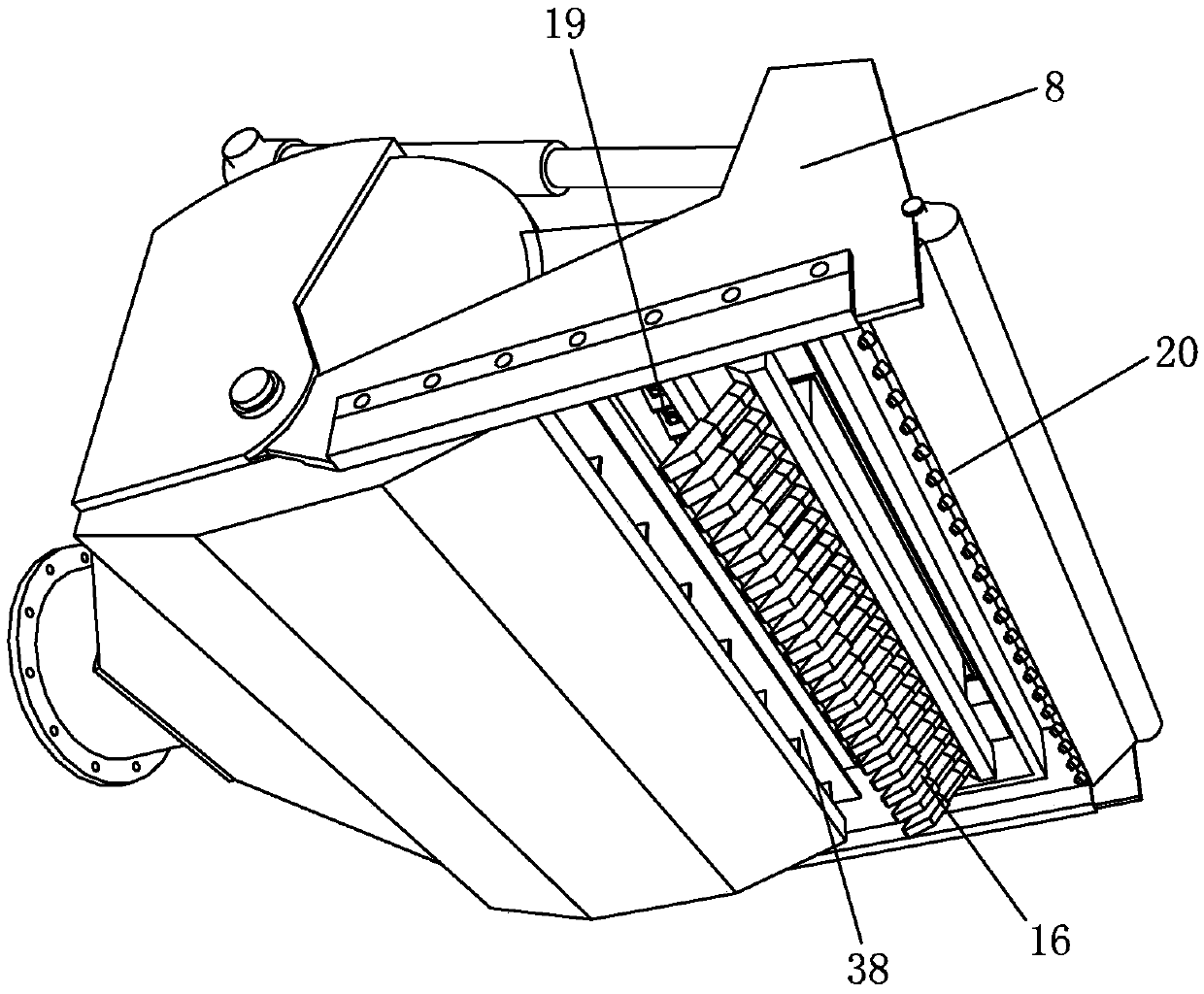

[0028] Such as Figure 1 to Figure 8 As shown, it is a self-propelled trailing suction dredger of the present invention, including a hull 1, a dredging mechanism 2 arranged on the hull 1, a drag head 3 arranged on the dredging mechanism 2, and a A mud bin 4, a propulsion mechanism 5 arranged on the hull 1 and a mud unloading mechanism 6 arranged on the hull 1. The propulsion mechanism 5 makes the hull 1 have good sailing performance, so that the hull 1 has self-propelled capability. Suction mechanism 2 comprises hanger 21, sliding device 22 and suction pipe 23, and hanger 21 is located on hull 1, and suction pipe 23 communicates with rake head 3, and hanger 21 hangs suction pipe 23 by sliding device 22. Put it on the bottom of the water, and the rake head 3 performs mud rake function. Using the vacuum effect of the mud pump, the rake head 3 and the suction pipe 23 absorb mud from the river bottom and enter the mud bin 4 in the hull 1, in a way of suction and sailing at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com