Rake head dredging system, trailing suction hopper dredger and method for reducing digging resistance by rolling friction

A technology of trailing suction dredgers and rolling friction, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of insufficient power consumption of drag head resistance, and achieve improved excavation Efficiency, reduction of cutting resistance, and reduction of excavation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

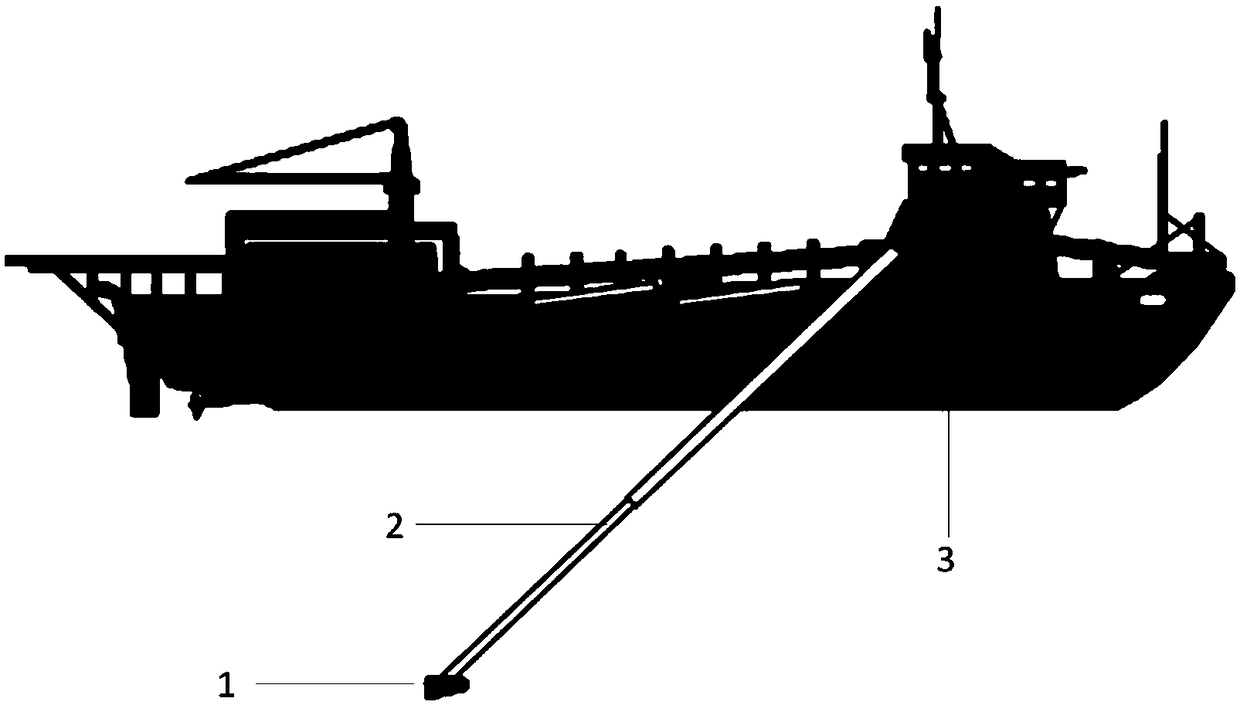

[0032] Such as figure 1 As shown, usually, when the hull 3 of the trailing suction dredger is excavating in the water area, the rake arm first needs to be lowered, and the rake arm includes the rake pipe 2 and the rake head 1 .

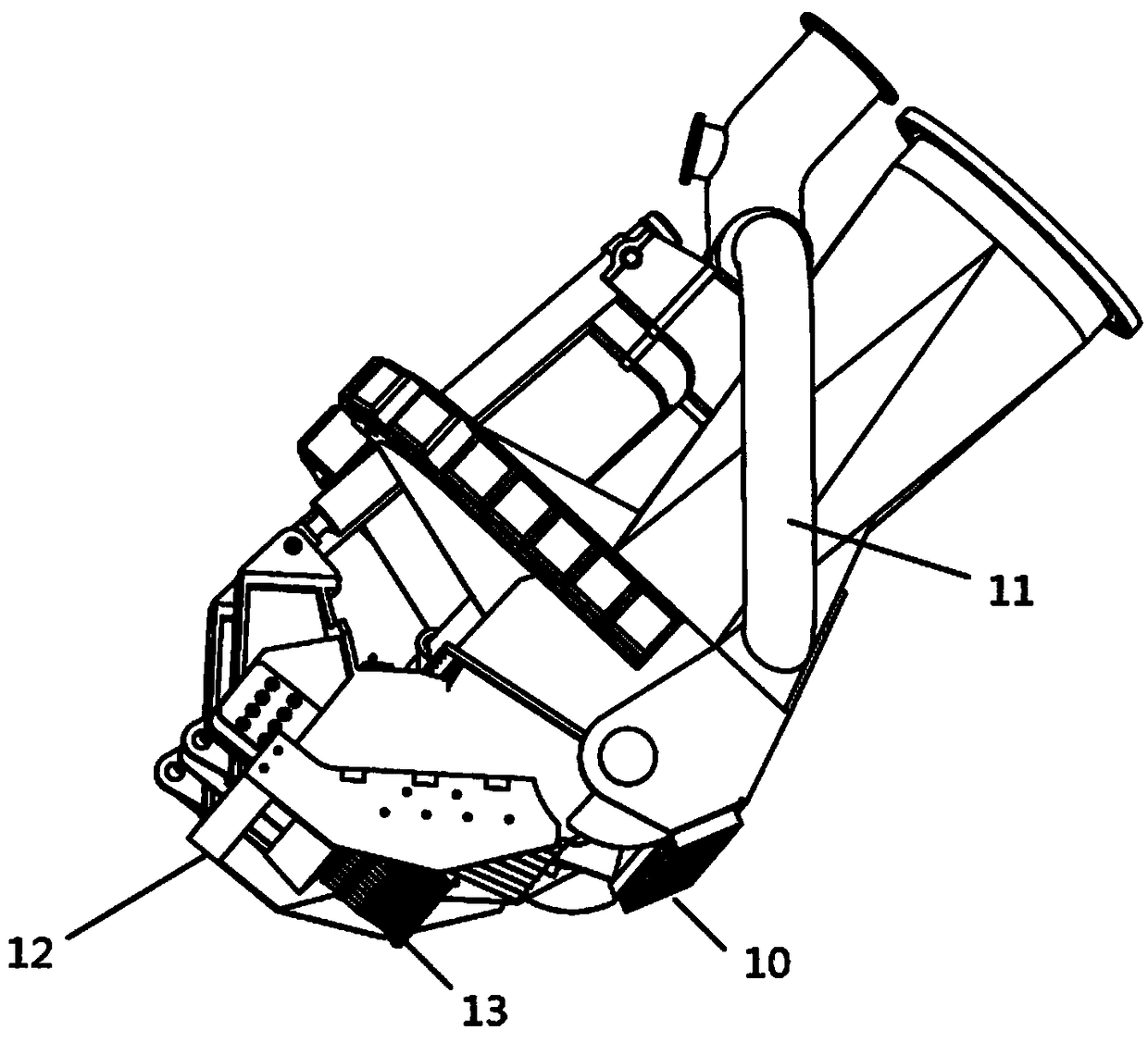

[0033] Such as figure 2 As shown, the existing rake head 1 usually includes a rake head fixed body 11 and a rake head movable cover 12 equipped with rake teeth 13, wherein the rake head fixed body 11 is connected to the end of the rake pipe 2, and the rake head fixed body 11 is movable with the rake head. The cover 12 is connected to form an excavation system for excavating the underwater soil. Further, the friction block 10 is installed under the rake head fixed body 11 to reduce the contact wear of the rake head fixed body 11 during the excavation operation, but at the same time it also increases the friction resistance of the rake head 1, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com