Soil-cutting excavation-type potato harvesting machine

A harvester and potato technology, applied in the direction of excavator harvester, excavator, harvester, etc., can solve the problems of deformation of excavation shovel, large excavation resistance, lower excavation efficiency, etc., and achieve low supporting power demand, reduce excavation resistance, The effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

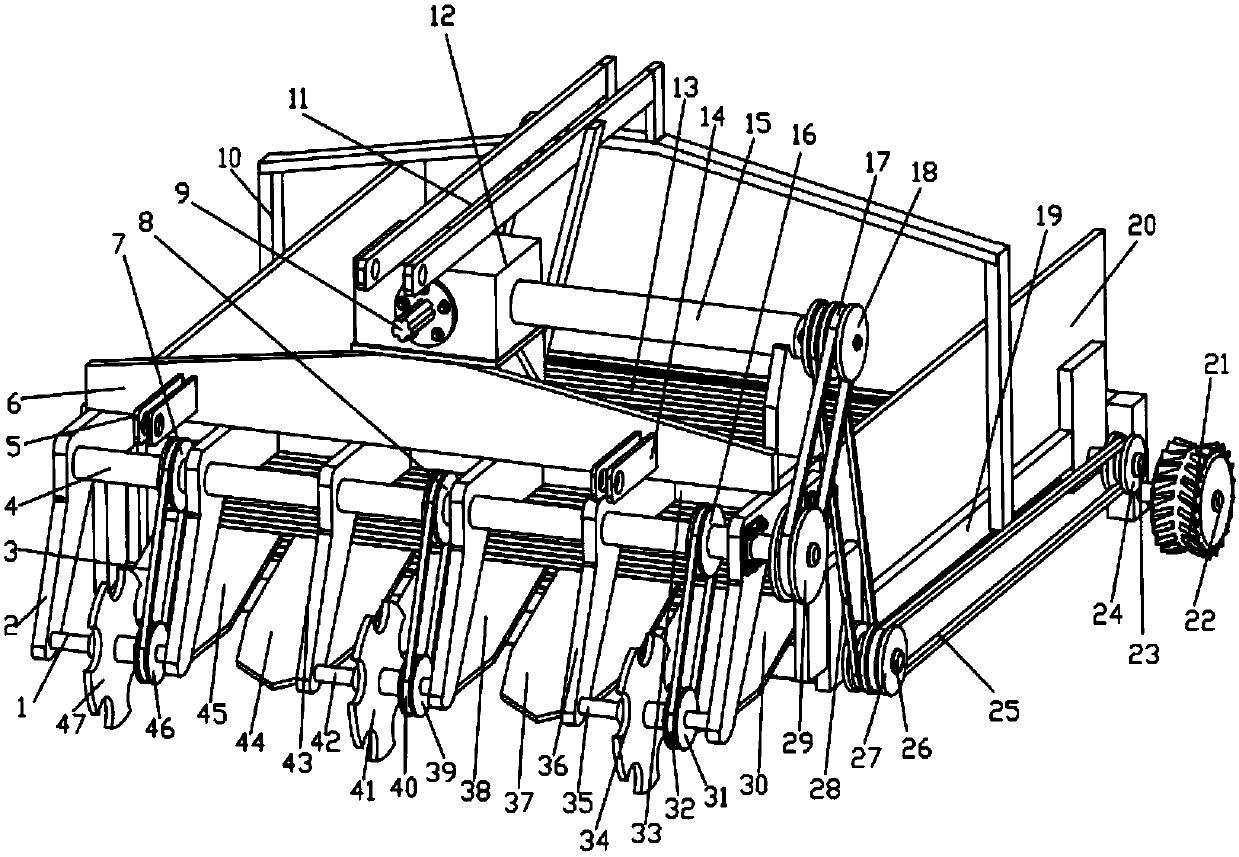

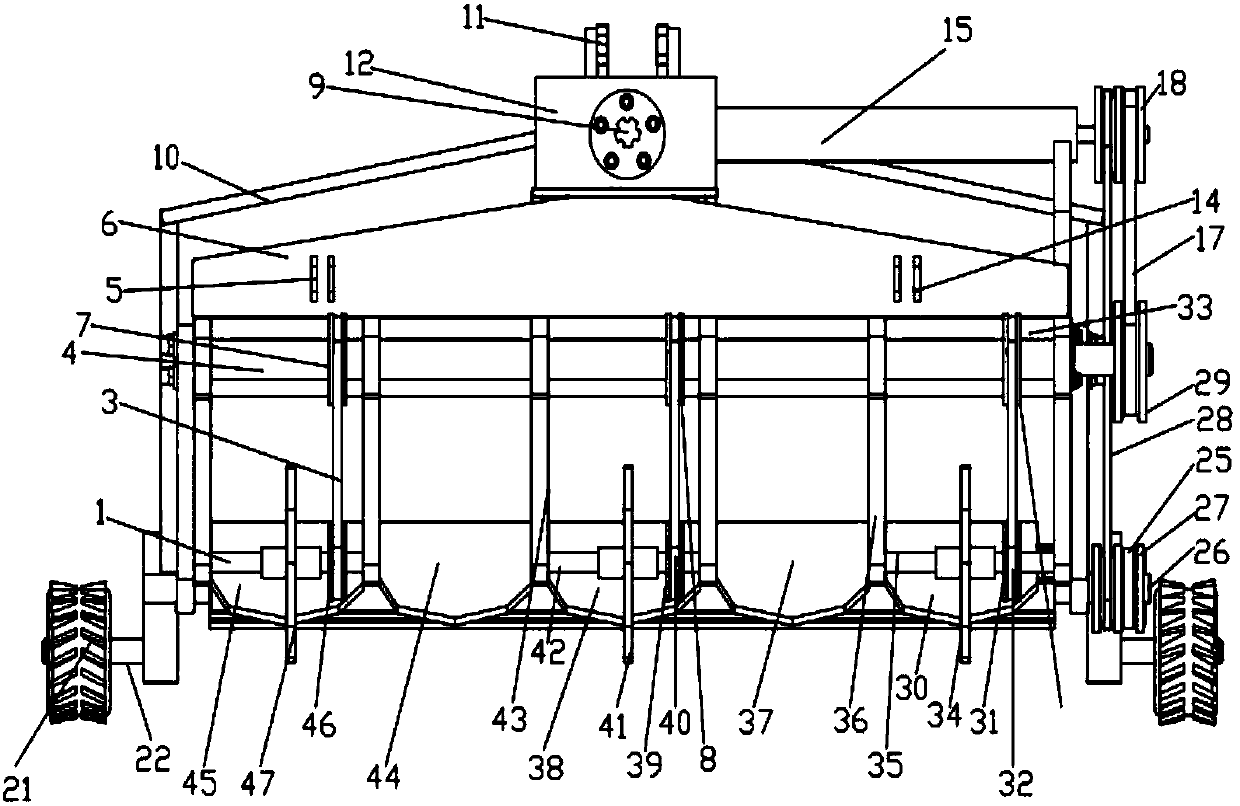

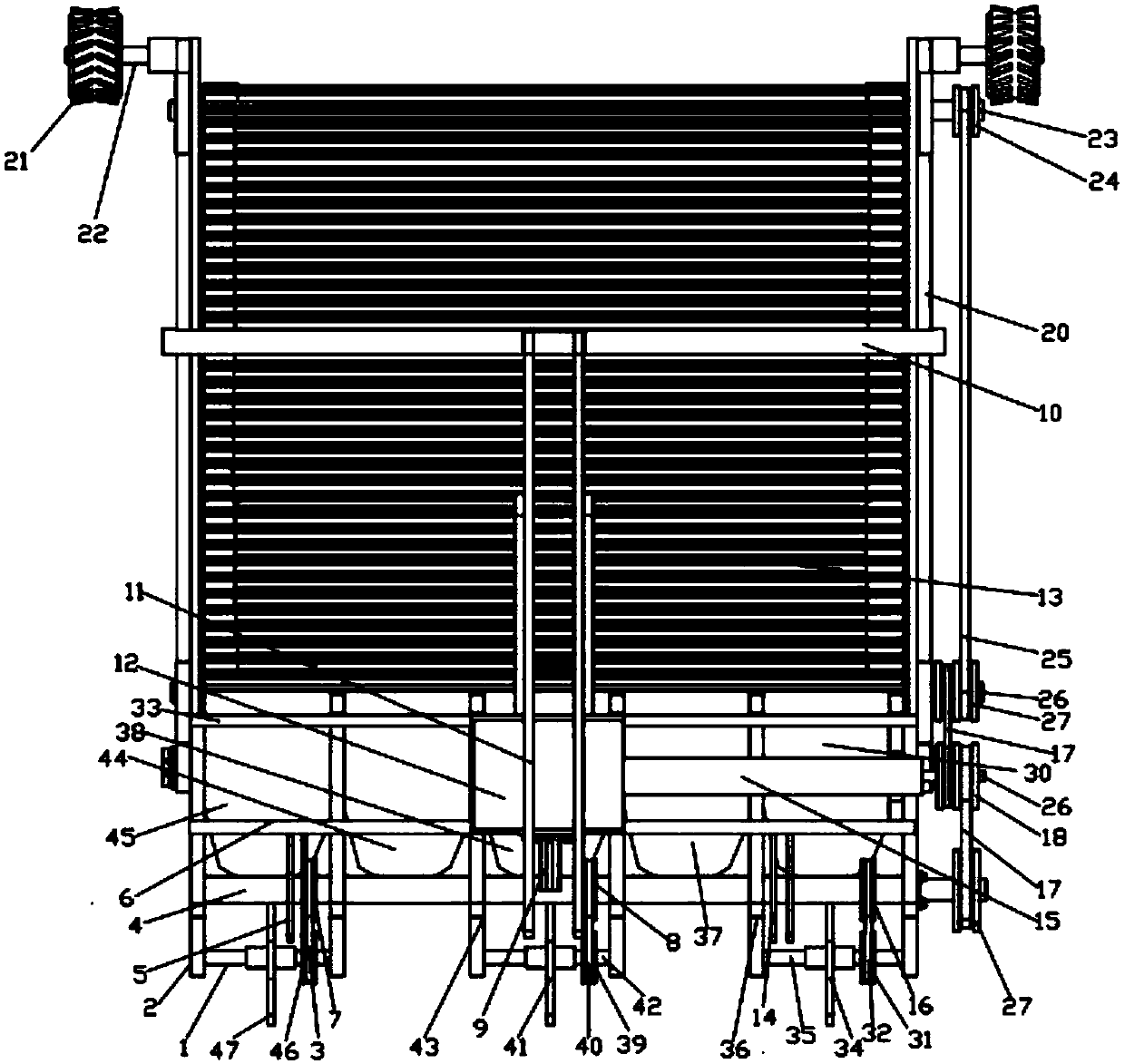

Embodiment 1

[0024] Embodiment 1: as Figure 1-4 As shown, a soil-cutting excavation type potato harvester is characterized in that: it includes a cutter shaft I1, a knife rest I2, a belt I3, a main shaft I4, a lower suspension I5, a large support plate 6, a cutter shaft driving pulley I7, a cutter shaft Driving pulley II8, input shaft 9, rear support frame 10, upper suspension 11, reducer 12, conveyor chain 13, lower suspension II14, lateral transmission device 15, knife shaft driving pulley III16, belt IV17, pulley I18, Frame 19, baffle plate 20, wheel 21, wheel shaft 22, secondary round roller shaft 23, pulley II24, belt VI25, primary round roller shaft 26, pulley III27, belt V28, pulley IV29, excavating shovel V30 , Knife shaft driven pulley III31, belt III32, knife holder mounting plate 33, soil cutting disc III34, knife shaft III35, knife holder III36, digging shovel IV37, digging shovel III38, cutter shaft driven pulley II39, belt II40 , cutting soil disc II41, cutter shaft II42, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com