Clay bucket for excavator

An excavator, clay technology, used in mechanically driven excavators/dredgers, anodizing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

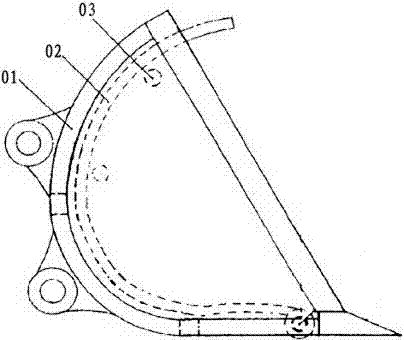

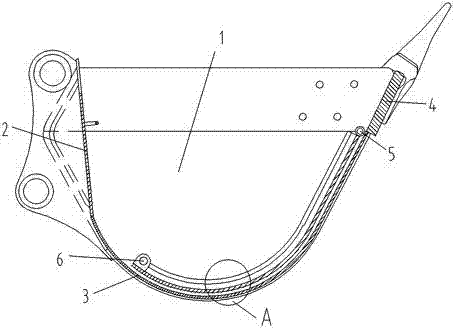

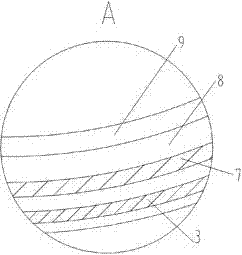

[0037] Such as Figure 2-Figure 7 As shown, a clay bucket of an excavator, the bucket body includes two parallel left side panels 1 and right side panels 10, the left side panels and the right side panels are connected by a transverse curved bottom panel 3 and a back panel 2 , the back plate is located behind the bottom plate, and the front edge of the bottom plate is provided with a main knife plate 4 . A scraper bucket and a wire rope 11 are arranged in the bucket body. The scraper includes an arc-shaped plate 7 that can be attached to the base plate and scrapers positioned at the left and right sides of the arc-shaped plate, and the scraper is vertically placed on the sides of the arc-shaped plate. The scraper includes a strip-shaped base plate 8 and a blade 9, and the blade of the scraper faces the mouth of the bucket and abuts against the side plate on the corresponding side, so as to cut off the clay on the side plate of the bucket body. Such as Figure 7 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com