Traction type four-row beet harvester

A harvester and traction type technology, which is applied in the field of traction type four-row sugar beet harvester, can solve the problems of high harvesting cost, unclean soil shaking, doping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

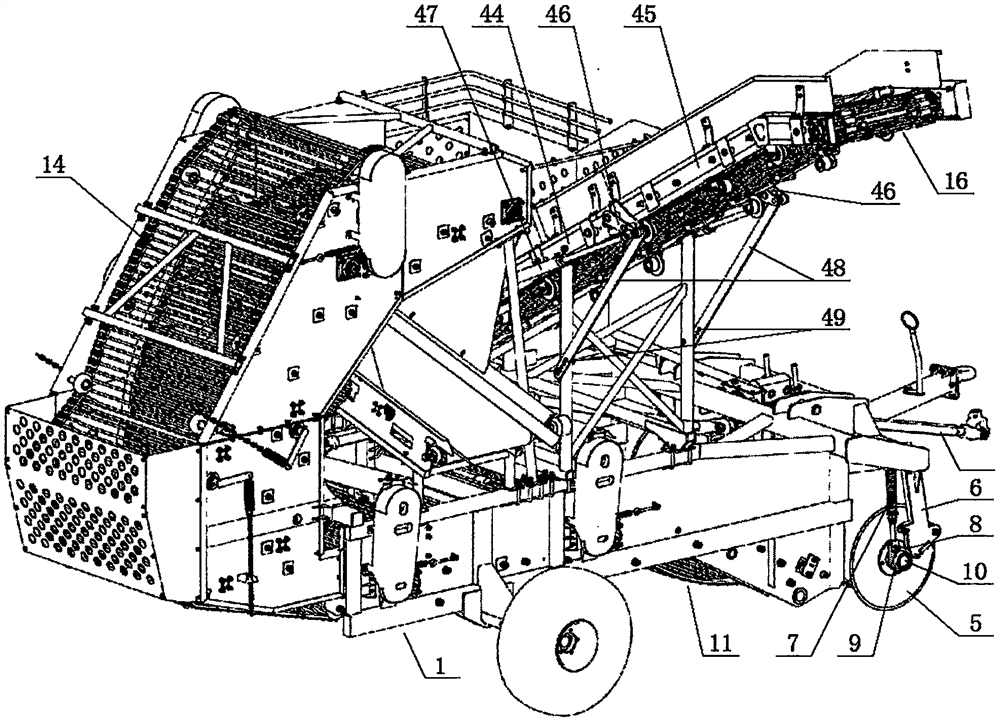

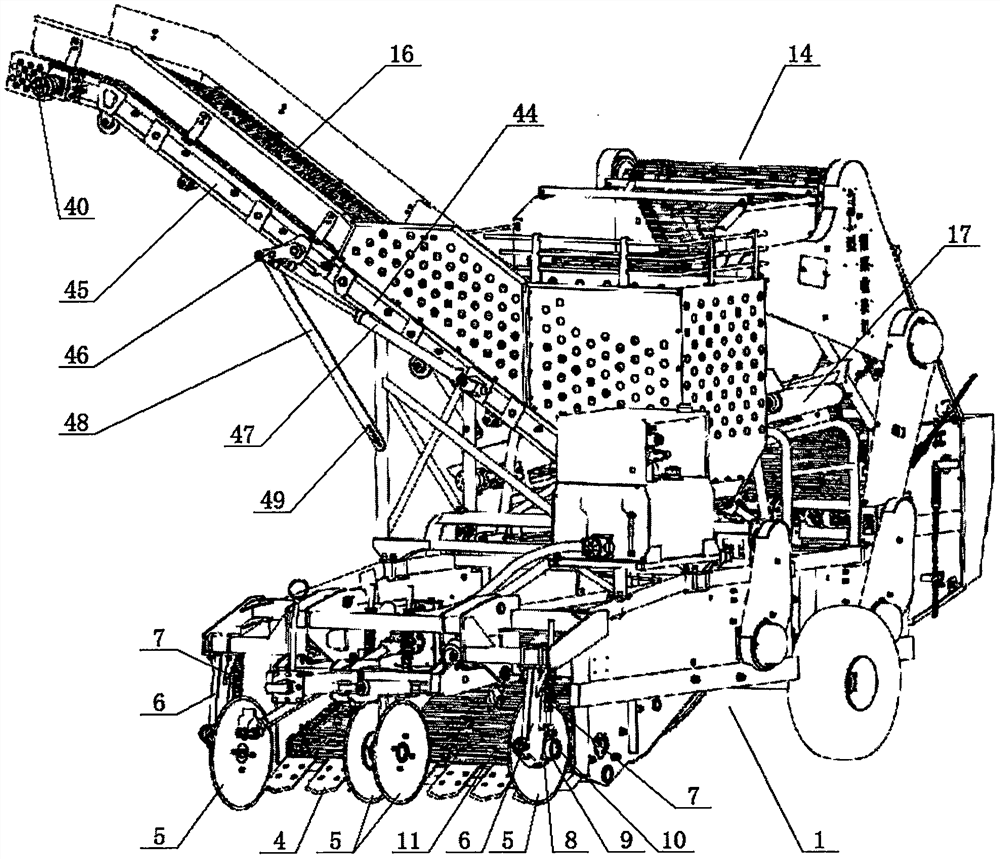

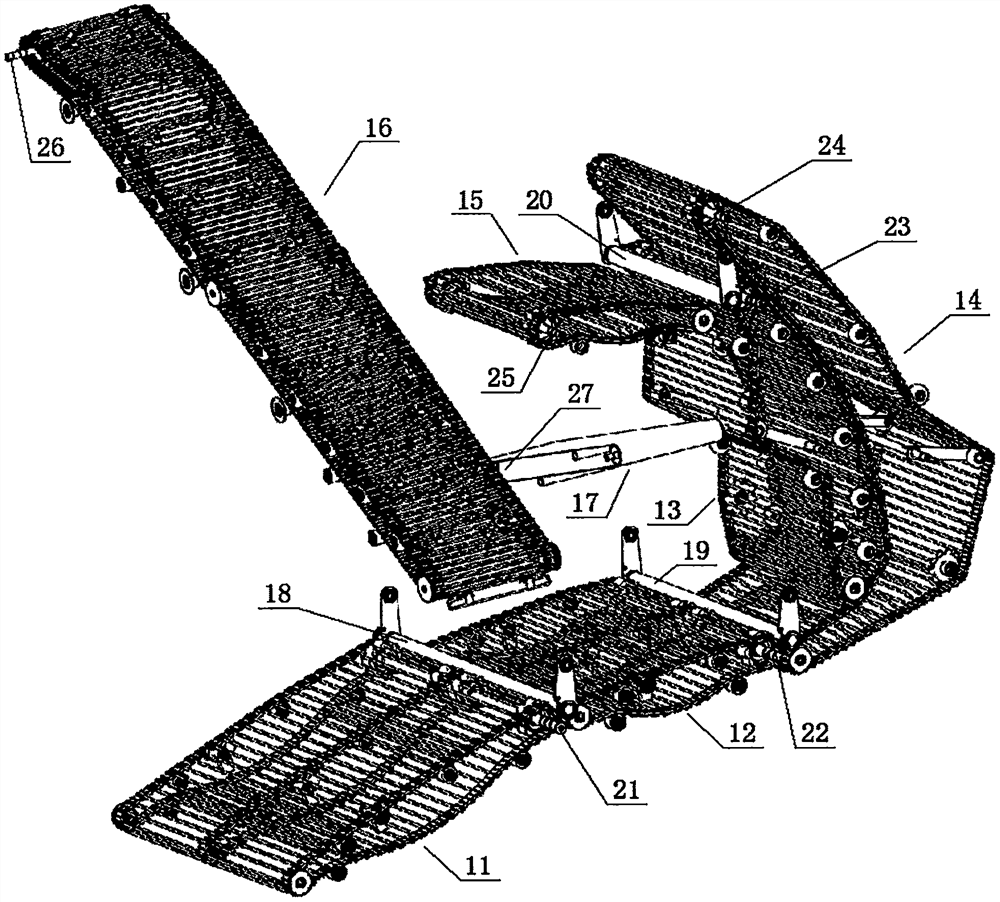

[0042] Such as Figure 1 to Figure 7 Shown, a kind of traction type four-row sugar beet harvester, it comprises frame 1, digging device, conveying system and transmission system, and conveying system comprises backward conveying device, hoisting device, loading conveying device; Described excavating device comprises The digging shovel that can excavate the width of two film-coated belts of four rows of sugar beet, each film-covered belt both sides are provided with cutting discs 5; said digging shovel includes a shovel beam 2 fixedly mounted on the front end of the frame 1 horizontally, The front lower side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com