Liquorice harvesting machine

A harvester and licorice technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of low operating efficiency and high labor intensity of workers, and achieve the goals of improving efficiency, reducing labor input, and increasing excavation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

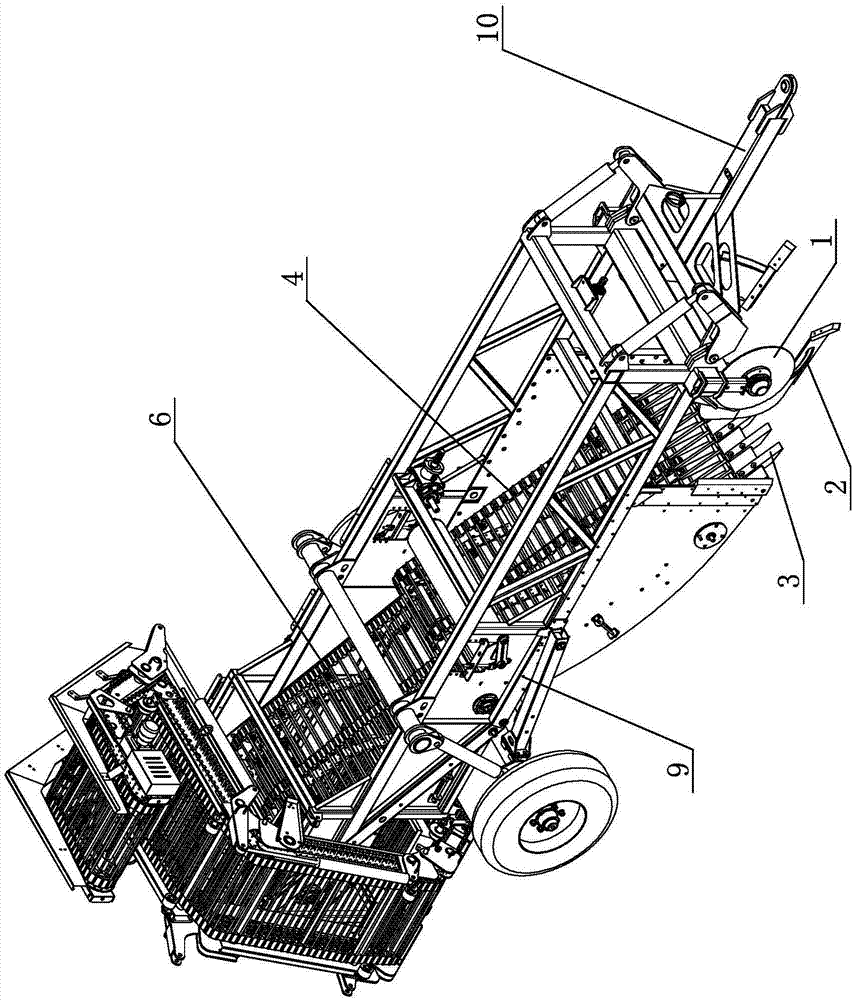

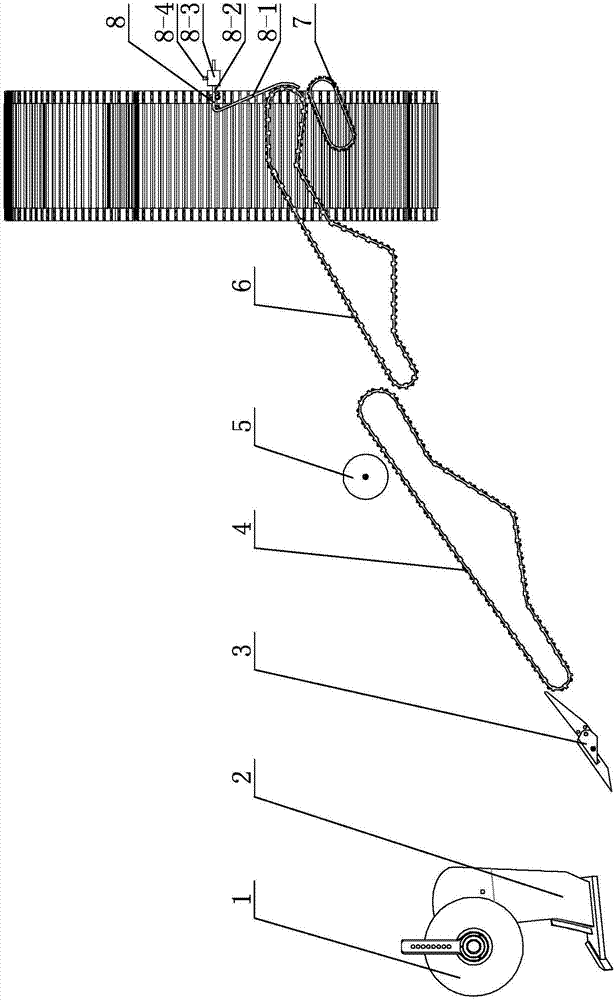

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a kind of licorice harvester described in this embodiment includes disc cutter 1, deep pine teeth 2, digging knife 3, first transmission chain 4, second transmission chain 6, third transmission chain 7, separation mechanism 8 and the vehicle frame 9, the subsoiling teeth 2, the digging knife 3, the first transmission chain 4, the second transmission chain 6, and the separation mechanism 8 are installed on the vehicle frame 9 in sequence from front to back, and the disc cutter 1 is installed on the subsoiling The upper end of the tooth 2, the third transmission chain 7 is installed on the rear end of the vehicle frame 9, and the third transmission chain 7 is located below the second transmission chain 6 rear end.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, a licorice harvester described in this embodiment is characterized in that: the separation mechanism 8 includes a separation plate 8-1, a connecting rod 8-2, a positioning sleeve 8-3 and a bolt 8-4, and the connecting rod 8 -2 is inserted in the positioning sleeve 8-3, the positioning sleeve 8-3 is installed on the vehicle frame 9, the bolt 8-4 for fixing the connecting rod 8-2 is inserted on the positioning sleeve 8-3, and the separation plate 8 The upper end of -1 is connected to the end of the connecting rod 8-2 towards the second transmission chain 6, and the separation plate 8-1 is attached to the second transmission chain 6. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the licorice harvester described in this embodiment is characterized in that: the licorice harvester also includes a crushed soil roll 5, which is installed on the vehicle frame 9, and the crushed soil roll 5 is located Above the first conveyor chain 4 rear ends, the distance between the wheel rim of the soil-crushing roller 5 and the first conveyor chain 4 surface is 3-5cm. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com