Cassava cultivation method applicable to whole-process mechanical operation

A whole-process mechanization and cultivation method technology, applied in the field of cassava cultivation, can solve problems such as reducing farmers' enthusiasm for cassava planting, reducing the profit margin of the cassava planting industry, and difficulty in improving the level of mechanization, so as to achieve full-process mechanization, improve the level of mechanized operations, The effect of increasing profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] like Figure 1-4 Shown, the cassava cultivation method applicable to the whole mechanized operation of the present invention comprises the steps:

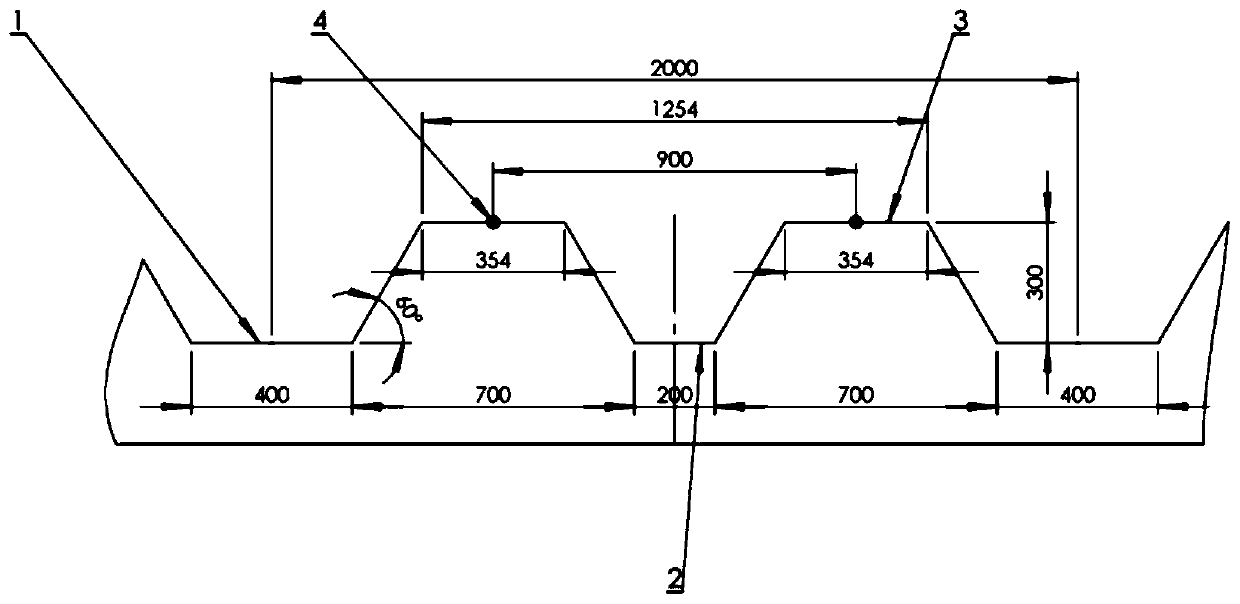

[0038] (1) Rotary tillage and ridging: After using a plow or subsoiler to plow the land (the plowing depth should be about 350mm, which is convenient for the later operation of the rotary tiller and ridging machine), use the rotary tiller to break the soil, Level the surface (the depth of rotary tillage should be about 300mm), and then use a double-ridge or four-ridge ridger to raise the required ridge shape. When ridging, it is best to adopt a north-south direction for the ridge shape, which is conducive to lighting during the cassava growth period and increasing cassava production.

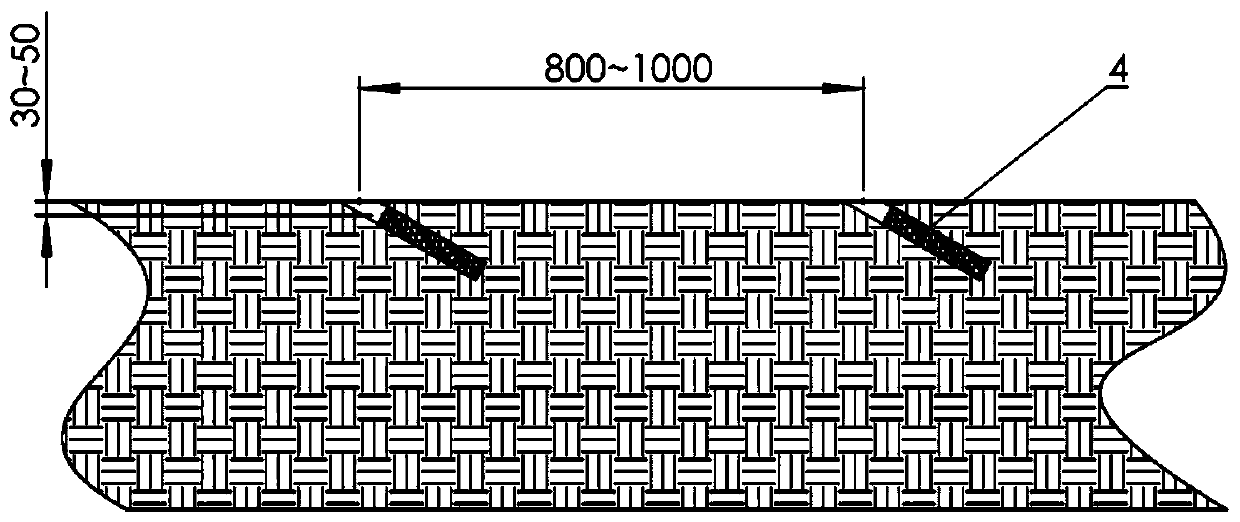

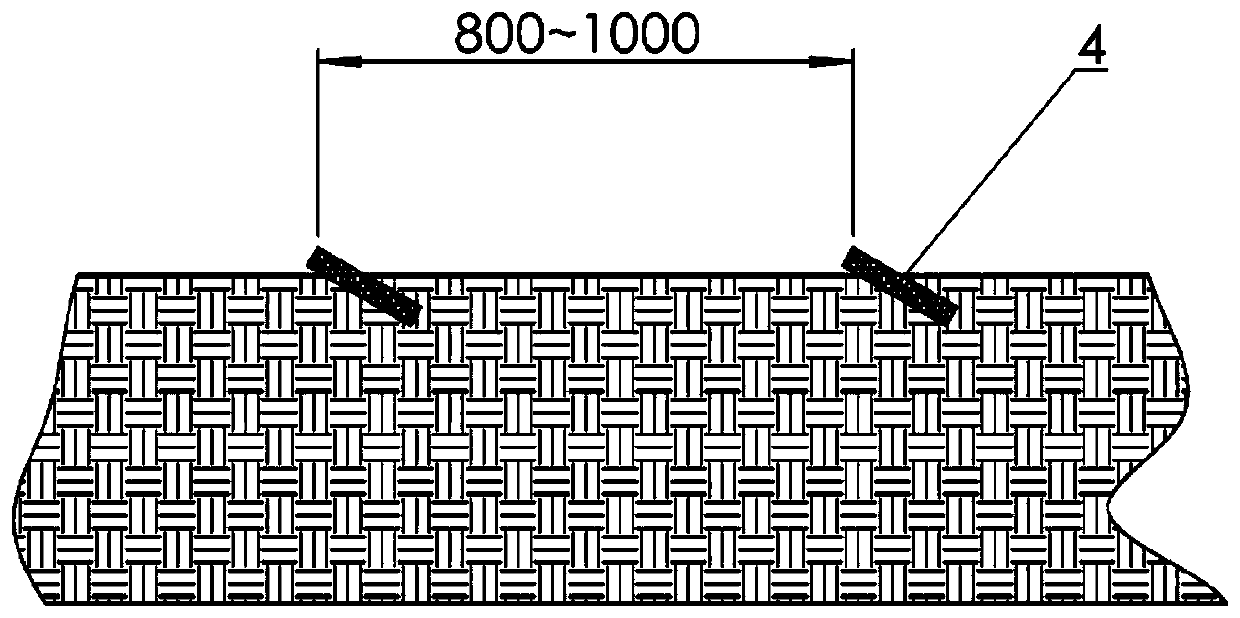

[0039] Rotary tillage and ridge cultivation is specifically a single ridge wide and narrow row ridge planting mode. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com