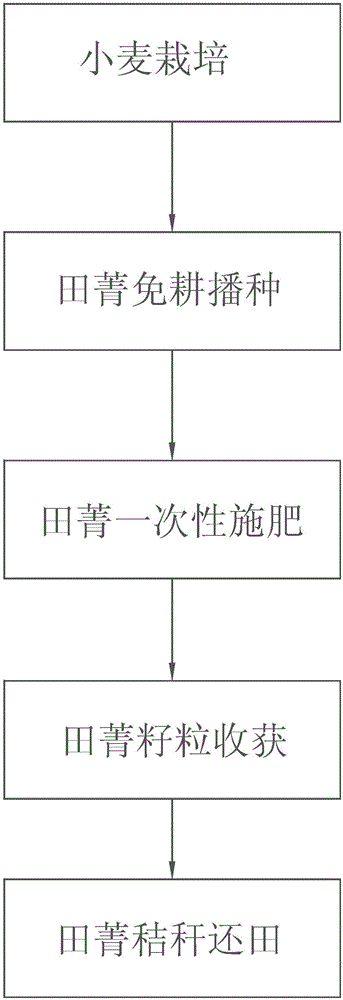

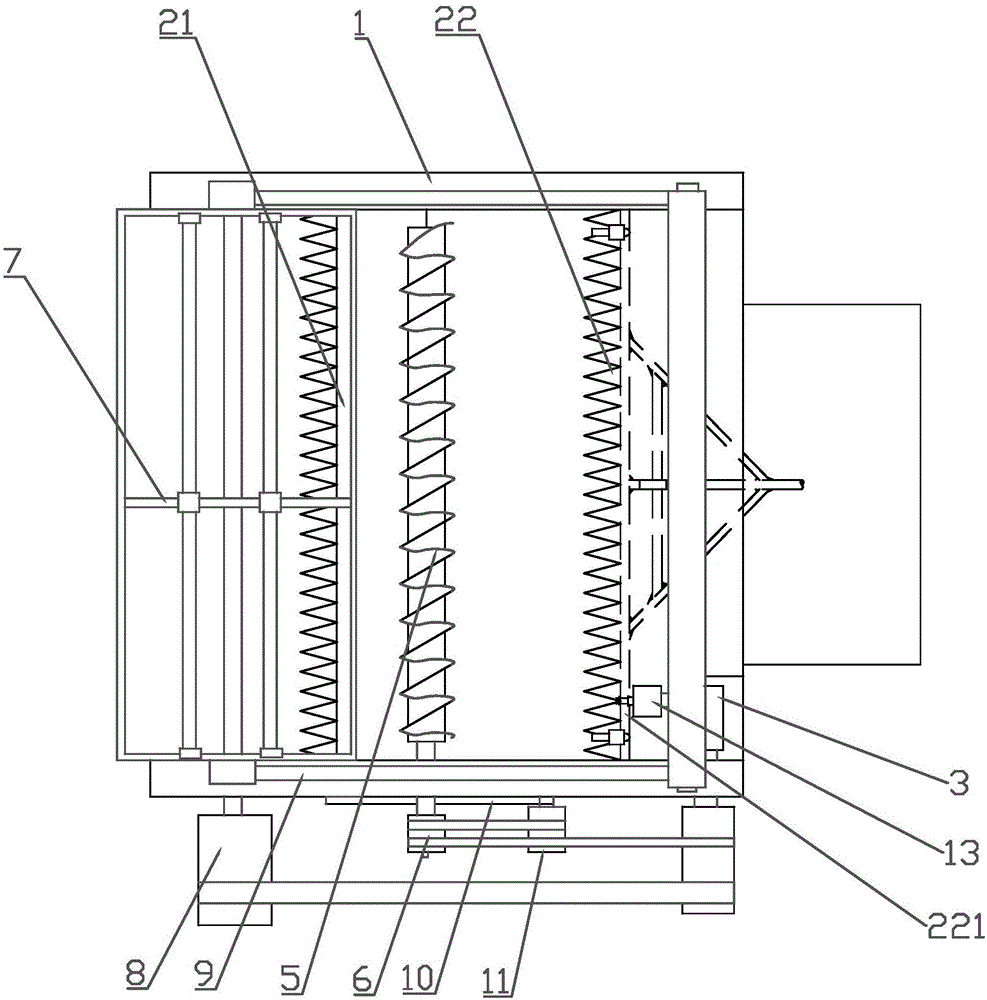

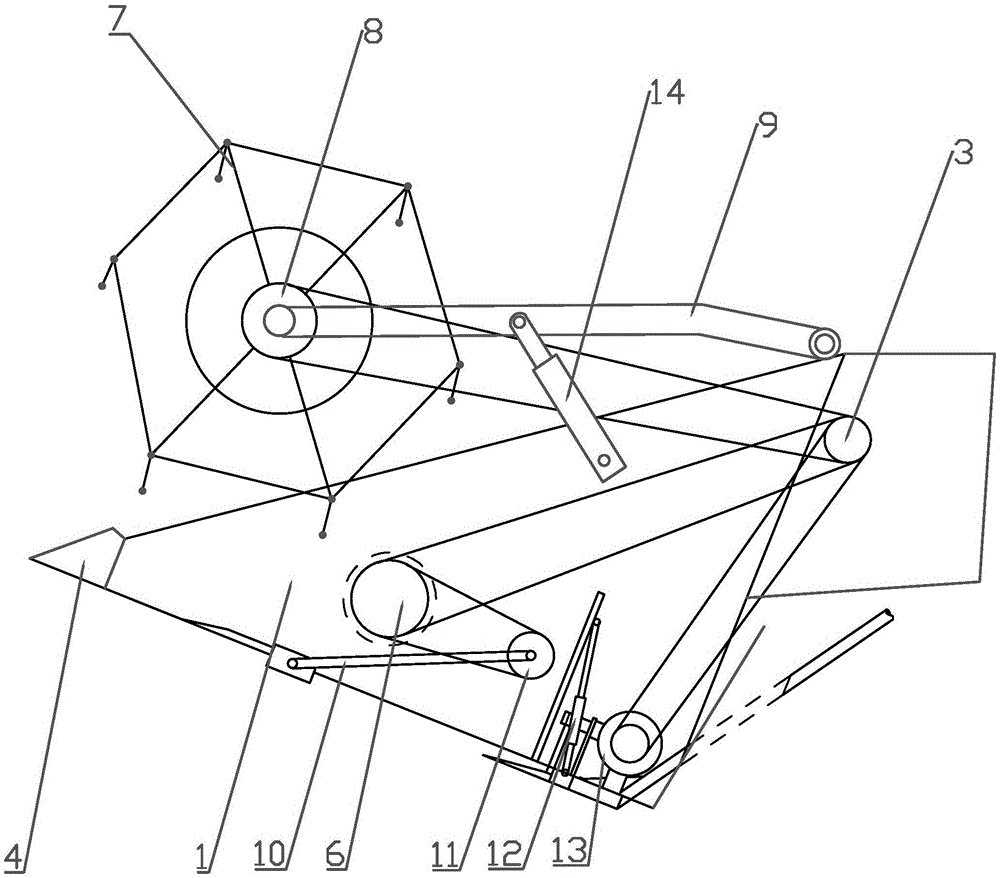

A high-efficiency cultivation method for double-cropping of wheat greens and matching harvesting platform for wheat greens

A cultivation method and high-efficiency technology, applied in the direction of headers, harvesters, botanical equipment and methods, etc., can solve the problems of waste of land resources and long production cycle, and achieve the goal of accelerating soil desalination, improving production efficiency and saving labor resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Experimental cultivation location 1 is Licheng District, Jinan City, Shandong Province, and the land type is non-saline-alkali high-yield field. The specific test process is as follows:

[0061] Wheat was sown and planted on October 12, 2011 and October 16, 2012, harvested using the header of the present invention on June 3, 2012 and June 8, 2013, leaving 5 cm of stubble, and covering the ground with wheat straw .

[0062] On June 4, 2012 and June 8, 2013, the 2BXF-16 disc precision seeder was used for sowing and fertilizing the field greens, the narrow row spacing was 45cm, the wide row spacing was 75cm, the sowing depth was 3cm, and the amount of seeds used was 4.5kg / hm2, basic application of diammonium phosphate 184kg / hm2, depth 8cm. On October 13, 2012 and October 12, 2013, the header of the present invention was used to harvest grain. The grains are dried in the sun until the moisture content reaches 12.5%, and stored in storage.

[0063] After harvesting, 5 c...

Embodiment 2

[0065] The experimental cultivation location 2 is Kenli County, Dongying City, Shandong Province. The land type is low-to-medium yield field (saline-alkali land). The specific experimental process is as follows:

[0066] On October 17, 2011 and October 19, 2012, wheat was sown and planted respectively. On June 8, 2012 and June 10, 2013, harvesting was carried out using the header of the present invention. The stubble was 4 cm, and the wheat straw covered the ground surface. .

[0067] On June 8, 2012 and June 10, 2013, the 2BXF-16 disc-type precision seeder was used for sowing and fertilizing of field greens. The narrow row spacing was 40cm, the wide row spacing was 80cm, the sowing depth was 2cm, and the amount of seeds used was 7.5kg. / hm 2 , based on diammonium phosphate 245kg / hm 2 , depth 8cm. On October 18, 2012 and October 18, 2013, the header of the present invention was used to harvest grain. The grains are air-dried until the moisture content reaches 12.9%, and st...

Embodiment 1

[0076] Embodiment 1 high-yield field

[0077]

[0078] Note: Net income = crop output × unit price - field expenses (seeds, pesticides, fertilizers, machinery and other miscellaneous expenses)

[0079] It can be seen from Table 1 that the net income of Example 1 and Example 2 is higher than that of the comparative example under the same soil fertility conditions, and the net income of Example 1 has increased by 62.77 yuan / hm compared with Comparative Example 1 2, an increase of 4.49%, and the net income of Example 2 increased by 126.58 yuan / hm compared with Comparative Examples 2, 3, and 4 2 , 509.92 yuan / hm 2 and 299.76 yuan / hm 2 , an increase of 13.18%, 88.32% and 38.06%. It can be seen that under the same soil fertility conditions, the economic benefits of wheat-seed green planting methods are higher than other common planting methods, and the economic benefits of low- and medium-yielding fields are more obvious.

[0080] Table 2. Embodiment and comparative example s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com