Seamless cylindrical filter bag and manufacturing method thereof

A technology of filter bags and cylinders, which is applied in the field of seamless cylindrical filter bags and its manufacturing, to avoid damage, solve the problem of reducing the strength of filter materials, and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

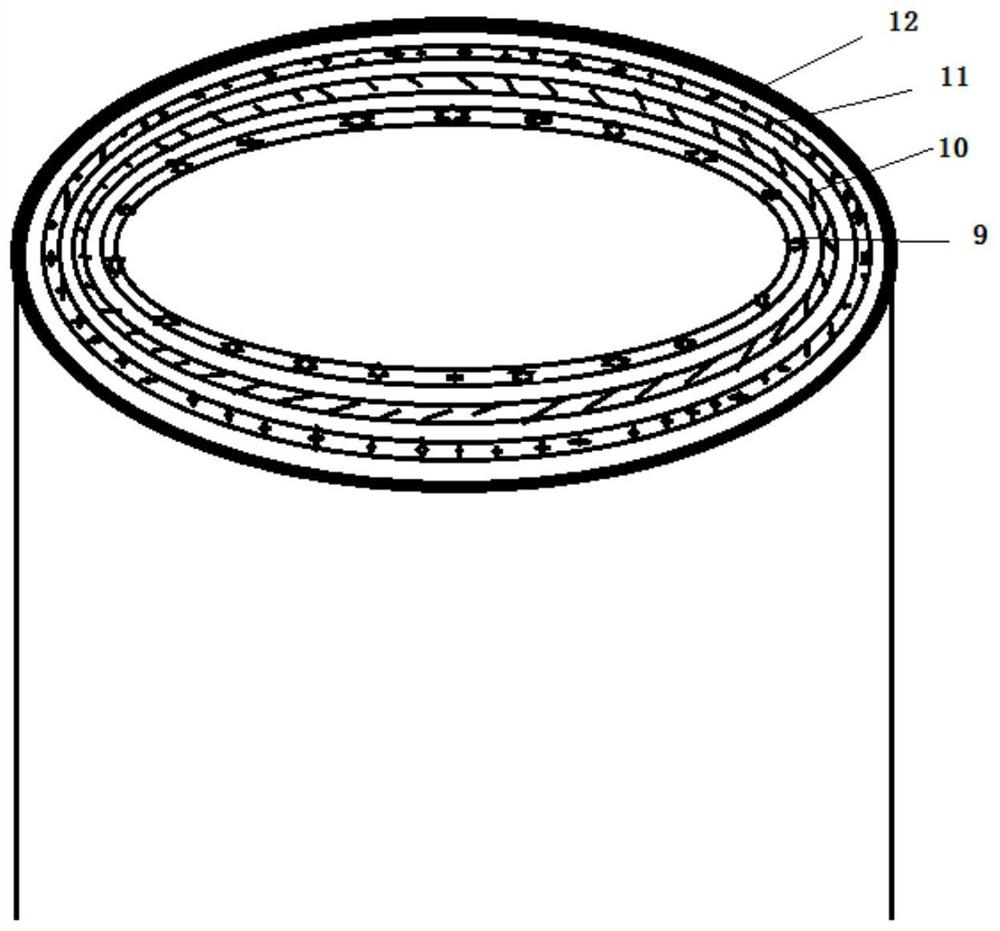

[0046] The cylindrical filter bag prepared in this example is suitable for use under the conditions of an instantaneous temperature of 300°C and a long-term filtration temperature of about 280°C.

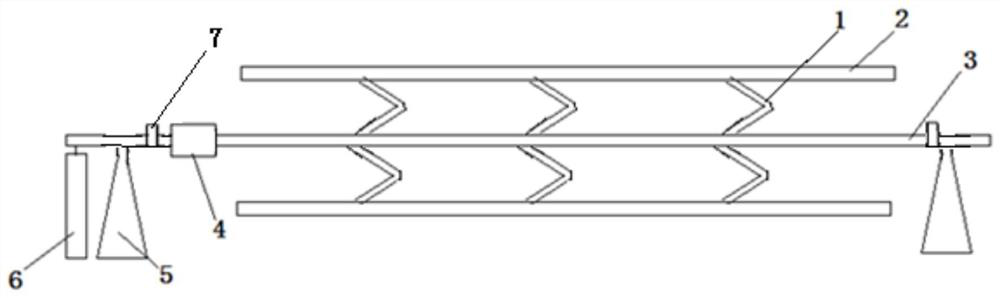

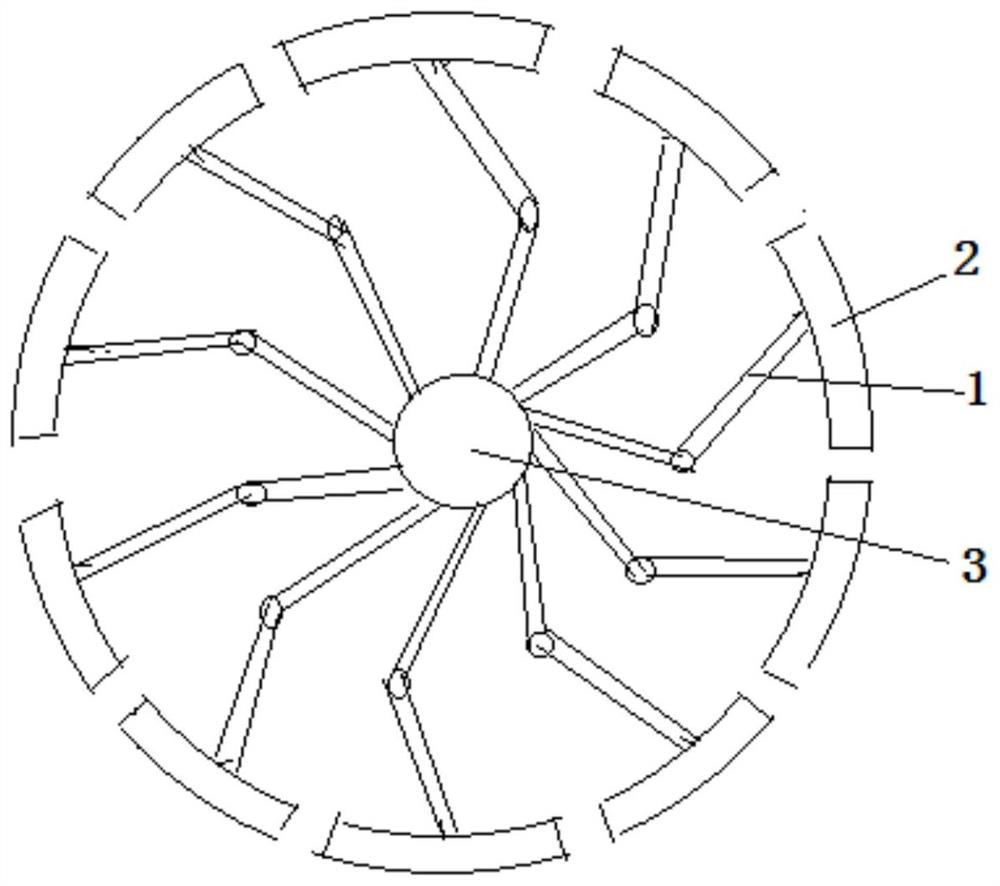

[0047] The 1350D basalt fiber bulked yarn produced by Zhejiang Shijin Basalt Fiber Co., Ltd. is used to weave cylindrical cloth on the CMS530HP35.2 flat knitting machine produced by STOLL, Germany, with a speed of 1.3m / min. This model is based on the CMS530HP35.1 computer On the basis of the flat knitting machine, the creel spacing of the creel is enlarged to 350mm to meet the needs of using large package yarn bobbins.

[0048] During weaving, in order to reduce the burrs of the yarn due to friction when the basalt yarn passes through the sinker and the tooth mouth piece, spray silicone oil on the yarn tube in advance, and seal it with a plastic bag for 4-5 hours, so that the silicone oil can penetrate into the surface of the inner fiber , Pre-waxing treatment is carried out on the ...

Embodiment 2

[0057] The cylindrical filter bag produced in this embodiment is suitable for use under the working conditions of a filtration temperature of 230°C.

[0058] Using 450D polytetrafluoroethylene filament produced by Shanghai Lingfulong New Material Technology Co., Ltd., weaving cylindrical cloth on WYZ-751×4 circular loom produced by Sail Machinery (Guangzhou) Co., Ltd. The model of this machine is Based on the WYZ-750×4 circular loom, the creel spindles have been expanded to 800 spindles, and the tube spacing has been increased to 450mm to meet the needs of large-capacity weaving with large packages. Before weaving, the filament tubes are stacked together, sprayed with 10% silicone oil emulsion, covered with plastic cloth, and treated for 5 hours, so that the silicone oil can penetrate into the surface of the inner fiber and prevent the filament from fluffing due to friction. The diameter of the cylindrical cloth is 300mm, and the weight is 170g / ㎡. During weaving, the channels...

Embodiment 3

[0069] The cylindrical filter bag produced in this embodiment is suitable for use under the working conditions of a filtration temperature of 230°C.

[0070] The polyimide filament 1500D produced by Shanghai Lingfulong New Material Technology Co., Ltd. is used to weave cylindrical cloth on the WYZ-751×4 circular loom produced by Sail Machinery (Guangzhou) Co., Ltd. The model of this machine is Based on the WYZ-750×4 circular loom, the creel spindles have been expanded to 800 spindles, and the tube spacing has been increased to 450mm to meet the needs of large-capacity weaving with large packages. Before weaving, the filament tubes are stacked together, sprayed with 10% silicone oil emulsion, covered with plastic cloth, and treated for 5 hours, so that the silicone oil can penetrate into the surface of the inner fiber and prevent the filament from fluffing due to friction. The diameter of the cylindrical cloth is 300mm, and the weight is 165g / ㎡. During weaving, the channels th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com