Folding apparatus for safety air sac for main drive

An airbag, main driving technology, applied in the direction of pedestrian/occupant safety arrangement, vehicle safety arrangement, transportation and packaging, etc., can solve the problems of poor product consistency, high randomness, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

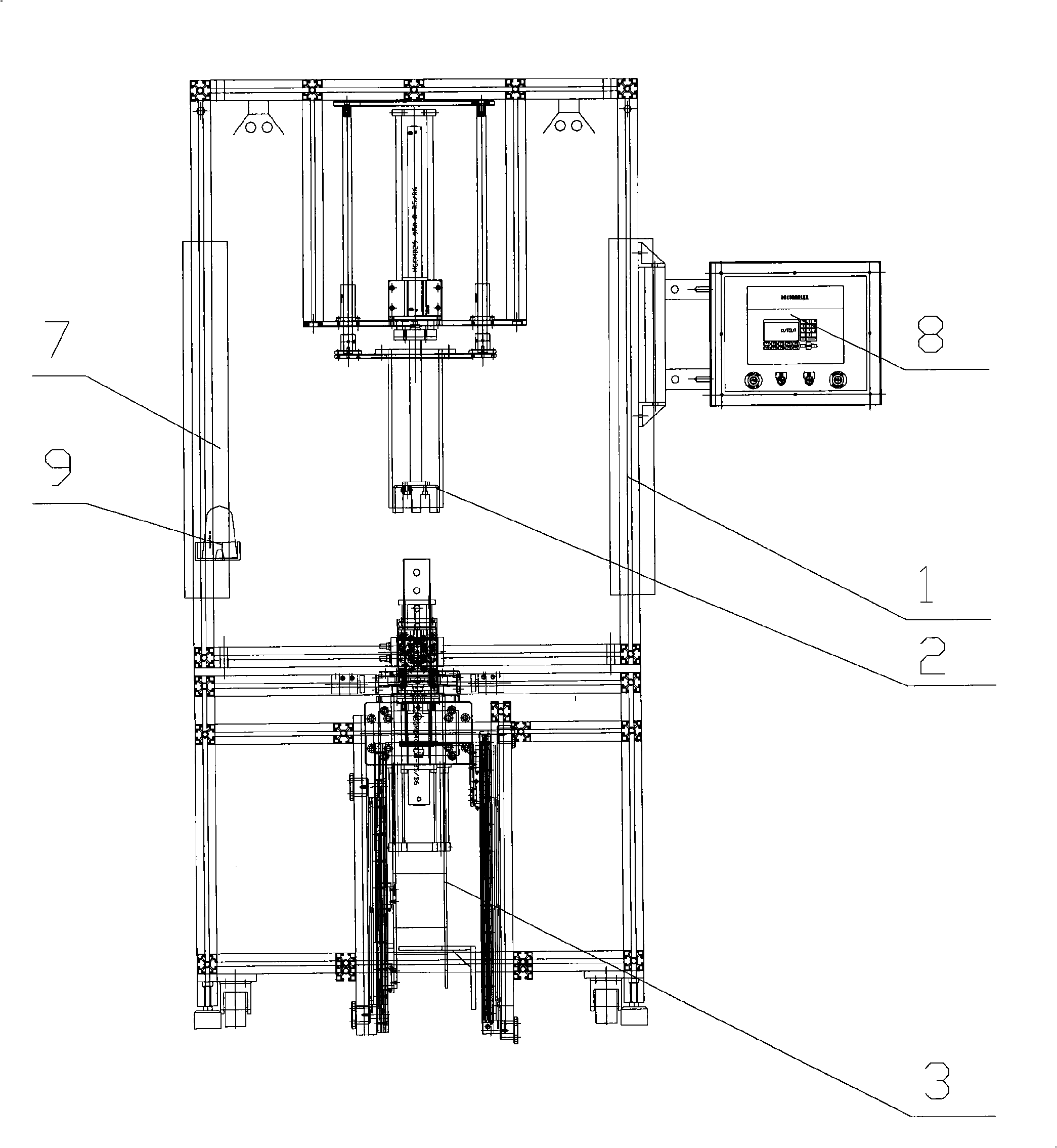

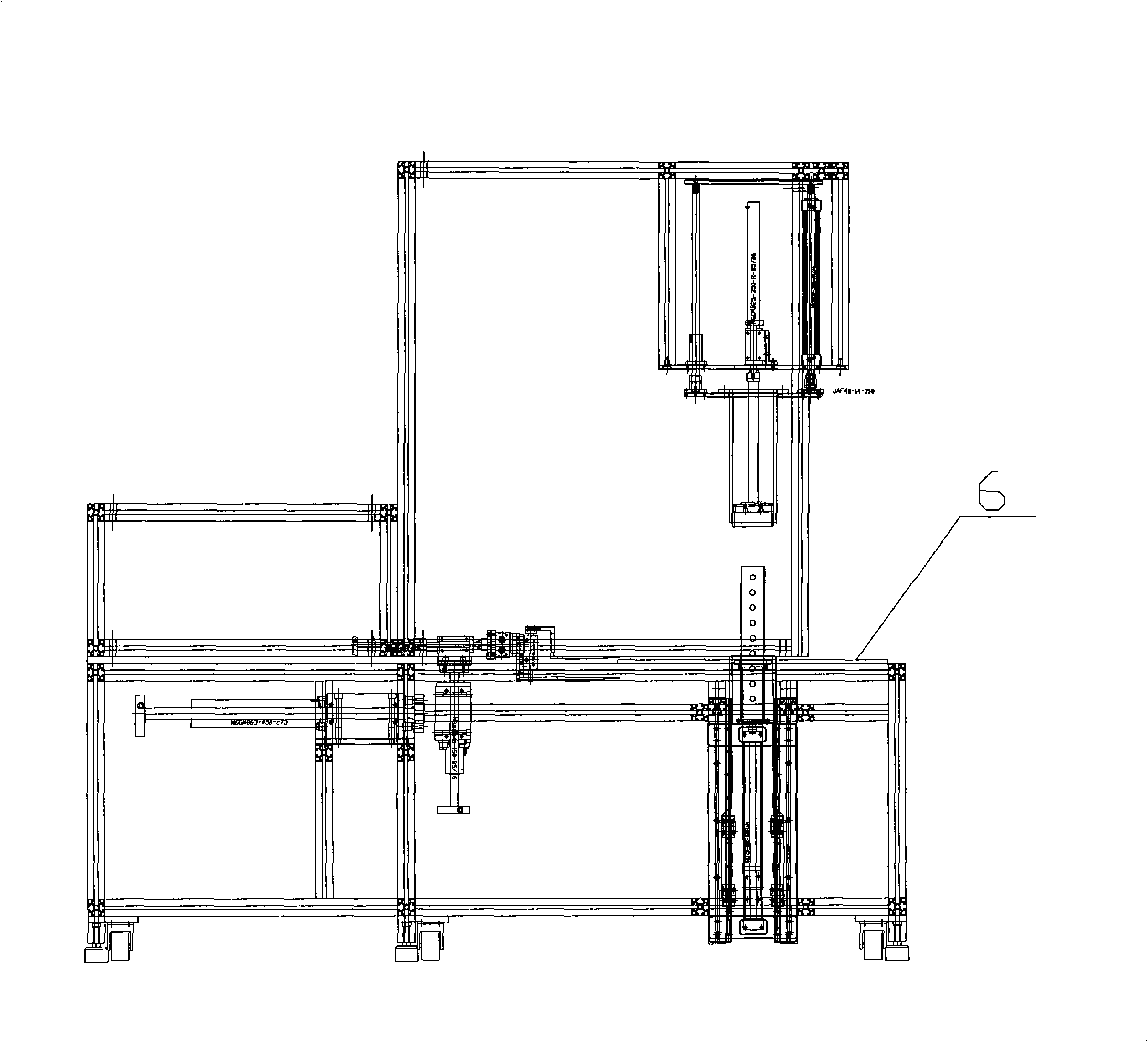

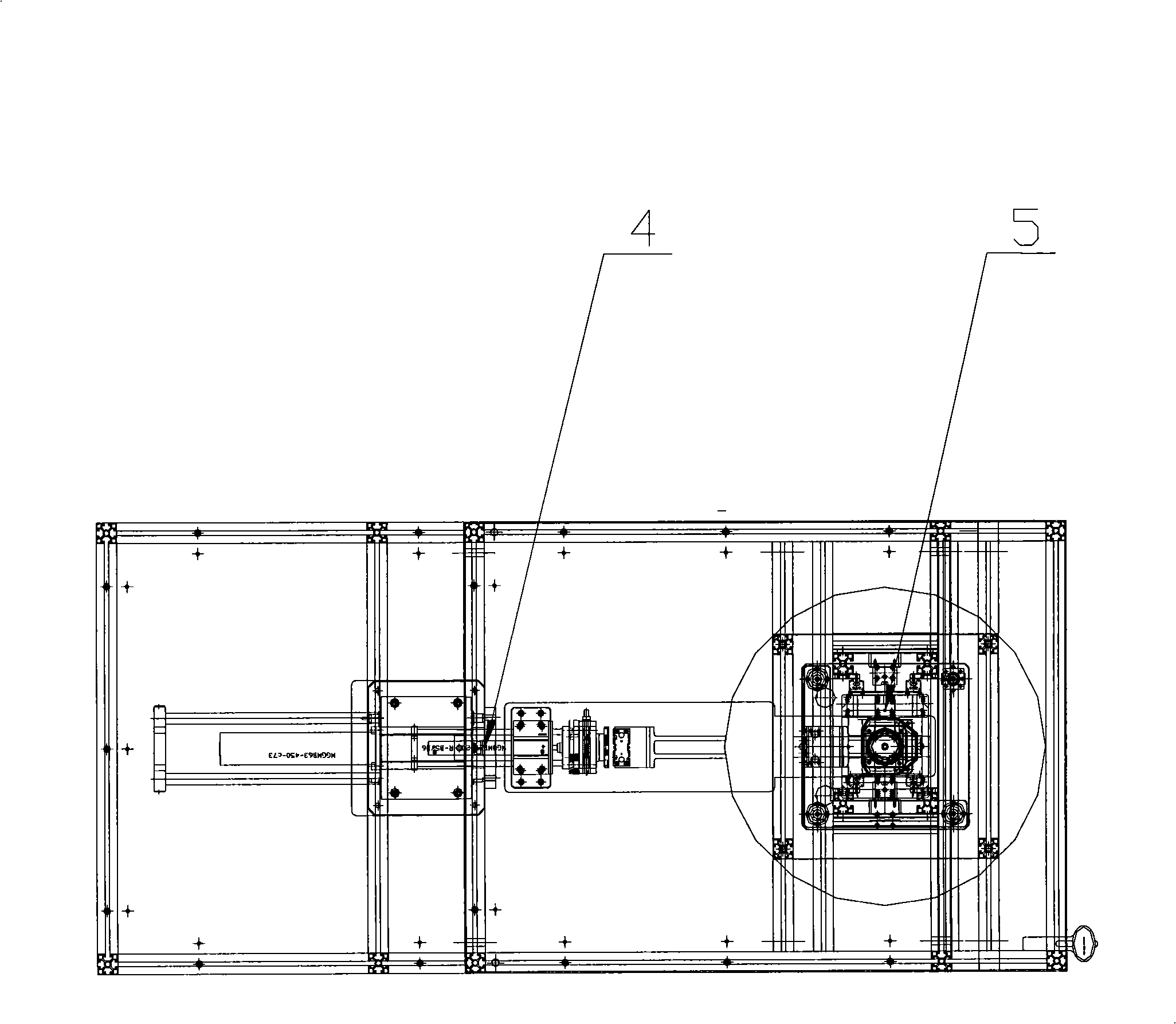

[0014] see figure 1 , figure 2 , image 3 , the base frame adopts an aluminum profile frame 1 structure, a plate 6 is provided in the middle of the base frame, the pressing part 2 is installed on the upper part of the platen 6, the upper pressing part 3 is installed on the lower part of the platen 6, and the pick-up part 4 is installed on the At the rear of the platen 6, the clamping part 5 is installed in the middle of the platen 6, below the pressing part 2 and above the pressing part 3. The pressing part 2 consists of the lower pressing cylinder 2-1, the lower pressing cylinder cylinder 2-3, down-pressing profiling head cylinder 2-6, down-pressing profiling head connecting rod 2-8, down-pressing profiling head 2-9, down-pressing cylinder cylinder magnetic switch 2-2, 2-4 1. The magnetic switch 2-5 and 2-7 of the pressure profiling head cylinder are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com