Flexible electrode and preparation method thereof, as well as huge-energy flexible electric storage device with function of instant manufacturing for ready-to-use effect

A storage device, flexible conductive technology, applied in the direction of electrode manufacturing, active material electrodes, alkaline storage battery electrodes, etc., can solve the problems of waste, low energy density, increased production costs, etc., to reduce manufacturing costs, simplify the preparation process, and improve the shelf life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a preparation method of an electrode, comprising the following steps:

[0065] After mixing the first metal salt with redox ability and the solvent, the first mixture is obtained;

[0066] After mixing the second metal salt with redox ability and the solvent, a second mixture is obtained;

[0067] Immersing the positive electrode flexible conductive substrate in the first mixture obtained in the above steps, and drying to obtain the positive electrode;

[0068] Immersing the negative electrode flexible conductive substrate in the second mixture obtained in the above steps, and drying to obtain the negative electrode;

[0069] The electrodes include positive and / or negative electrodes.

[0070] In the present invention, the selection, combination and corresponding preferred range of the first metal salt with redox ability, the second metal salt with redox ability, and the positive / negative electrode flexible conductive substrate in t...

Embodiment 1

[0103] Step 1. Make a piece with a length of 4×4cm 2 The carbon cloth was soaked in concentrated nitric acid and ultrasonically treated for 15 minutes, then soaked in deionized water and ultrasonically treated for 15 minutes, and then dried naturally for use after taking it out;

[0104] Step 2, put the cleaned carbon cloth into an aqueous solution of nickel metal salt (1.0 mol per liter) for soaking, take it out after 30 minutes, absorb a layer of nickel metal salt on the surface of the carbon cloth, and dry it at 50°C to obtain Positive pole of power storage device;

[0105] Step 3: Put the cleaned 4×4cm 2 Put the carbon cloth into the metal salt solution (2.0 moles per liter) of the negative electrode iron for soaking, take it out after 30 minutes, absorb a layer of iron metal salt on the surface of the carbon cloth, and dry it at 50 ° C to obtain the negative electrode of the electric storage device;

[0106] Step 4, prepare aqueous alkali solution, control the concentra...

Embodiment 2

[0115] Step 1. Soak a carbon fiber with a length of 5 cm in concentrated nitric acid and apply ultrasonic treatment for 15 minutes, then soak in deionized water and apply ultrasonic treatment for 15 minutes, take it out and dry it naturally for use;

[0116] Step 2. Soak the cleaned carbon fiber in an aqueous solution of nickel metal salt (1.0 mol per liter), take it out after 30 minutes, absorb a layer of nickel metal salt on the surface of the carbon fiber, and dry it at 50°C to obtain a storage device piece positive;

[0117] Step 3, put the cleaned 5 cm long carbon fiber into the negative electrode iron metal salt solution (2.0 moles per liter) for soaking, take it out after 30 minutes, absorb a layer of iron metal salt on the surface of the carbon fiber, and dry it at 50°C to obtain Negative electrode of electric storage device;

[0118] Step 4, preparing alkali polyvinyl alcohol solid electrolyte, controlling the concentration of potassium hydroxide to 3 moles per liter...

PUM

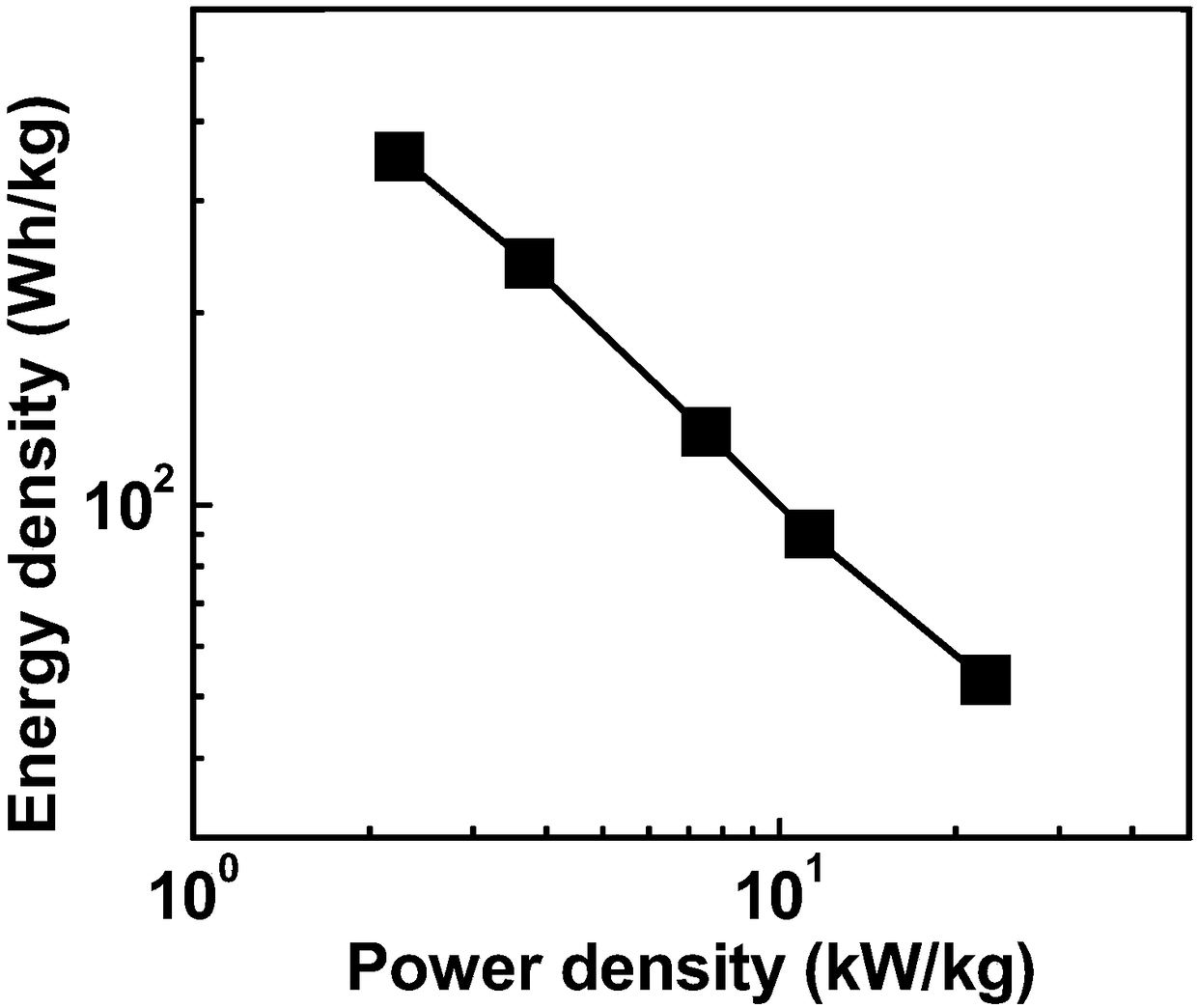

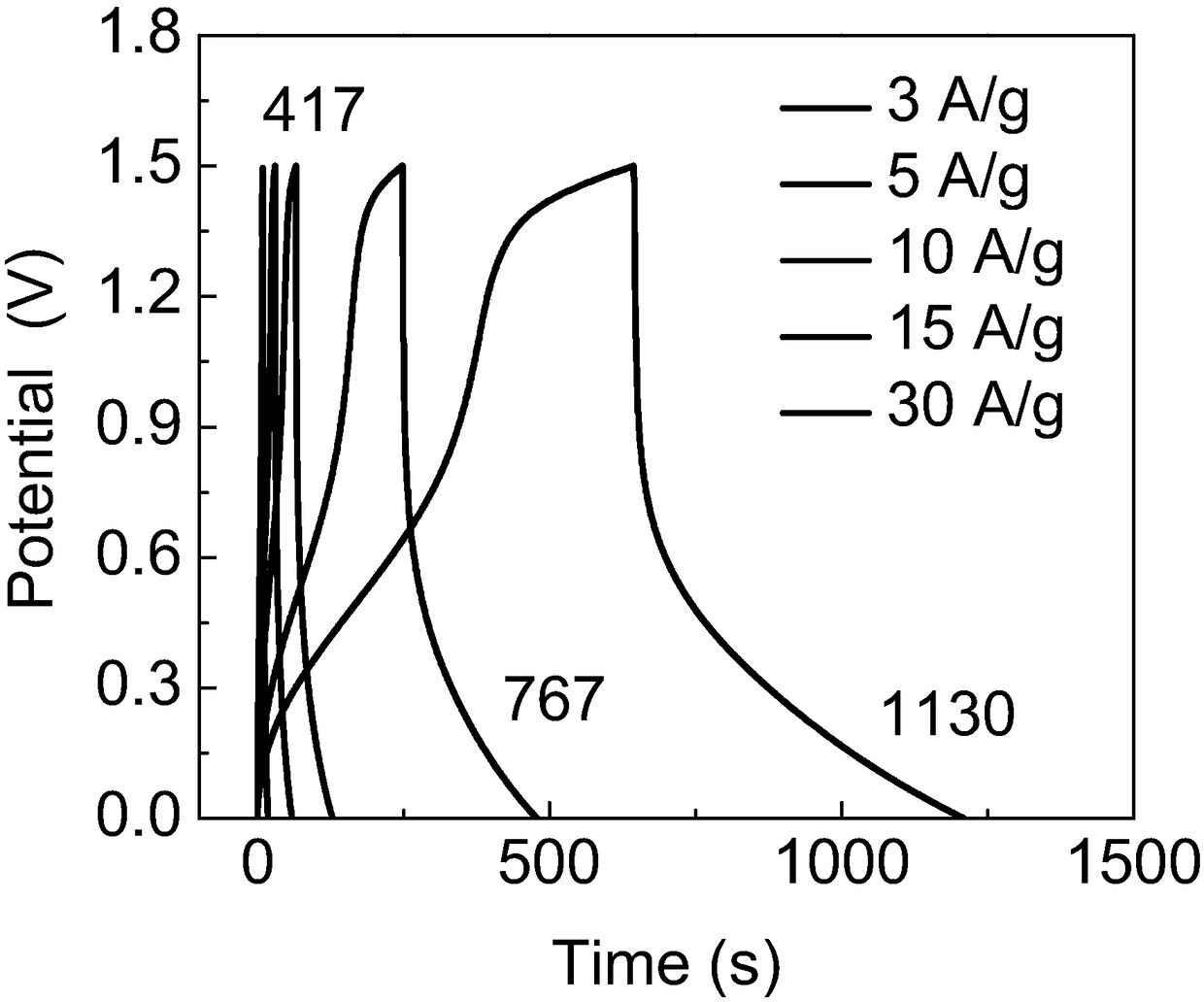

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com