Numerical control shape-regulating jig frame

A tire frame and shape adjustment technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large adjustment distance of support rod height, large weight, small spacing between support rods, etc., and improve production quality. and production efficiency, reduce labor intensity, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

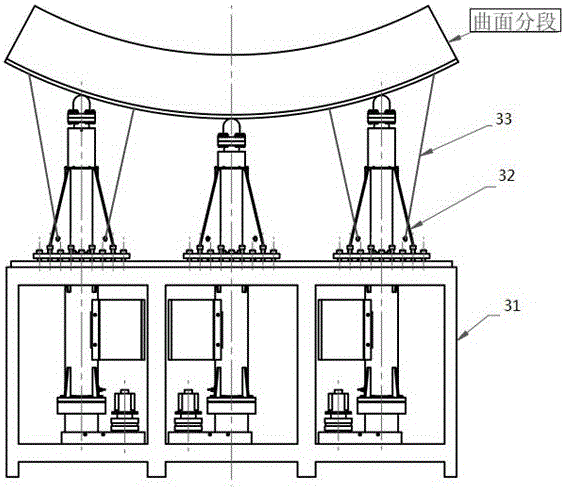

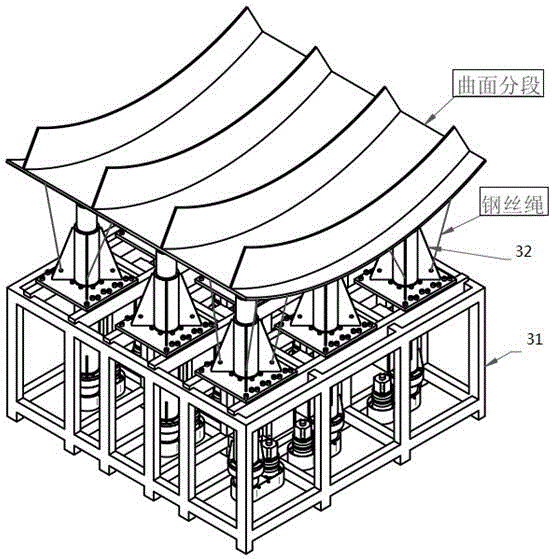

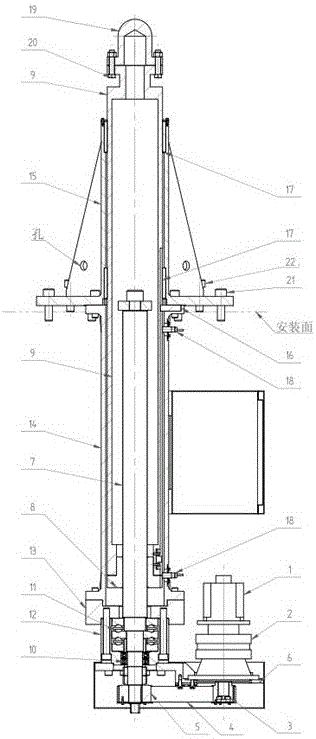

[0015] refer to figure 1 , The numerically controlled shape-adjusting tire frame of the present invention is composed of a tire frame seat, a numerically controlled shape-adjusting device, a control system and the like. The shape-adjusting tire frame includes a tire frame seat, and a numerically controlled shape-adjusting device and a fixing device are arranged on the tire frame seat; the described numerically controlled shape-adjusting device includes at least 3 numerically controlled lifting support rods, and the described numerically controlled lifting support rods include The reducer and the upper and lower sleeves are provided with lifting shafts inside the upper and lower sleeves, the reducer is connected with the lifting shaft through a transmission mechanism, and two travel switches are arranged on the outer wall of the lower sleeve. The tire frame seat is a steel structure welded by steel plates and section steel. It is used to install the numerical control shape adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com