Staged packaging type potato combine harvester

A technology of combine harvester and grading device, applied in the direction of excavator harvester, harvester, excavator, etc., can solve the problems of low production efficiency, high labor intensity, large supporting power, etc., achieve reliable transportation, improve purity, The effect of reducing the digging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

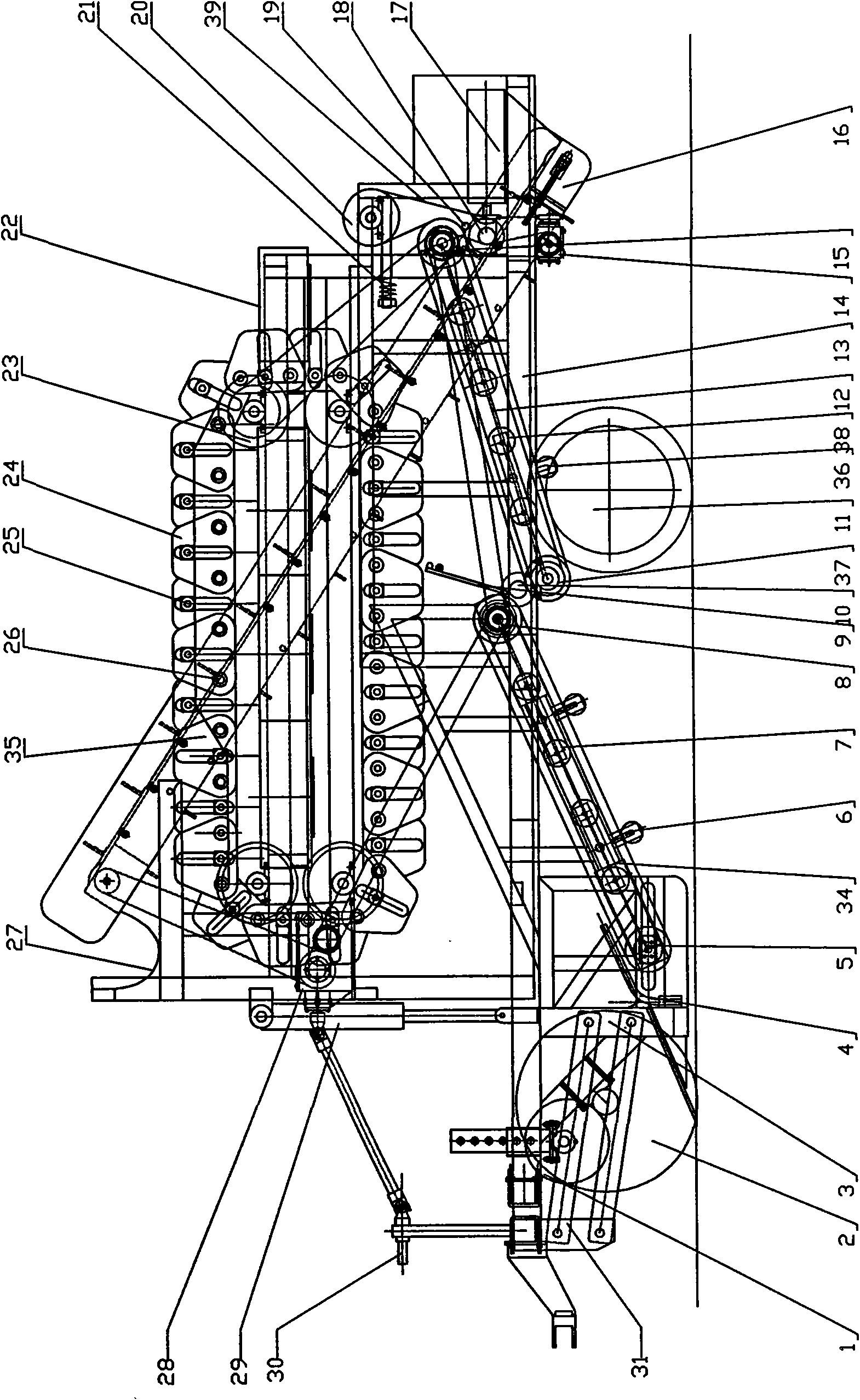

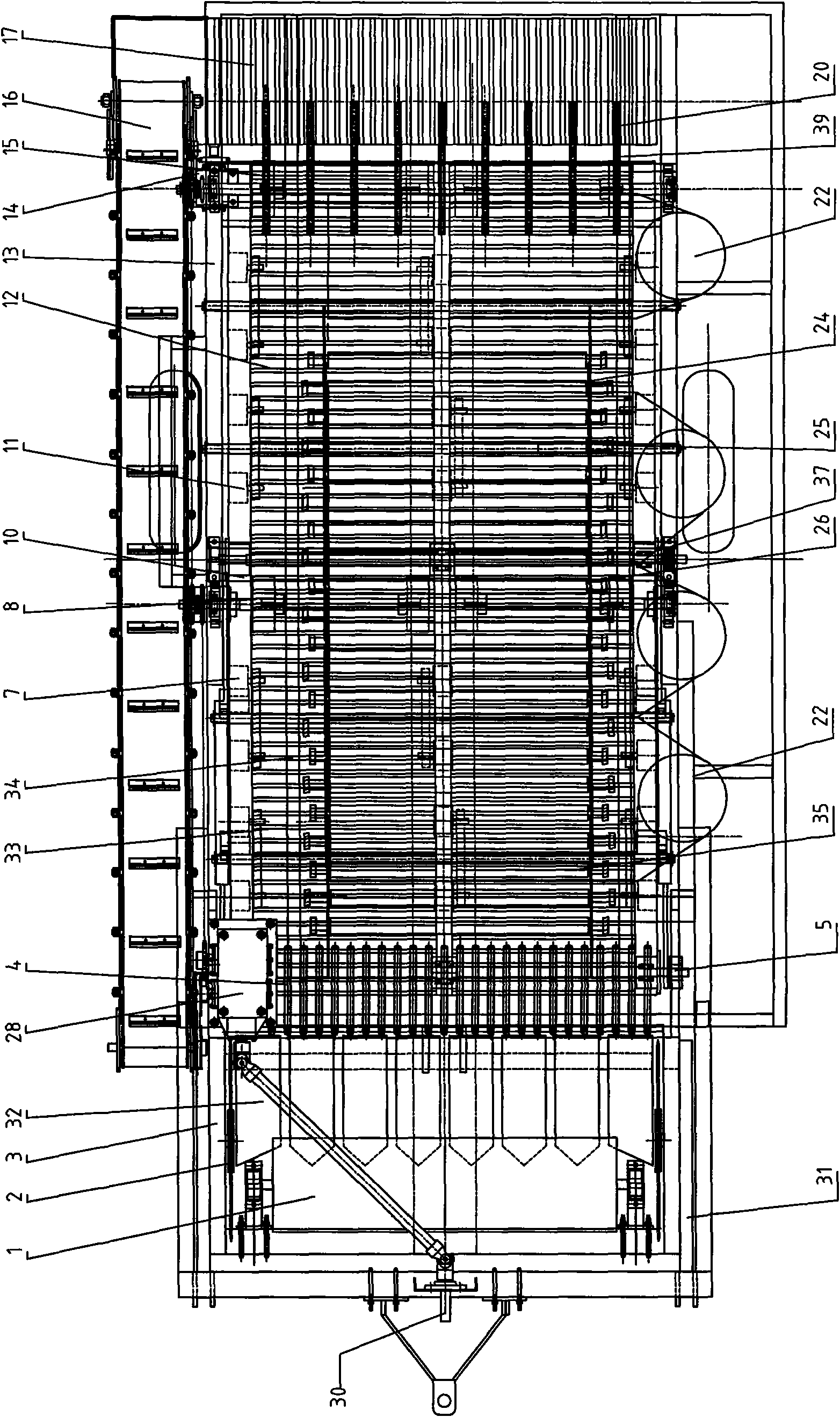

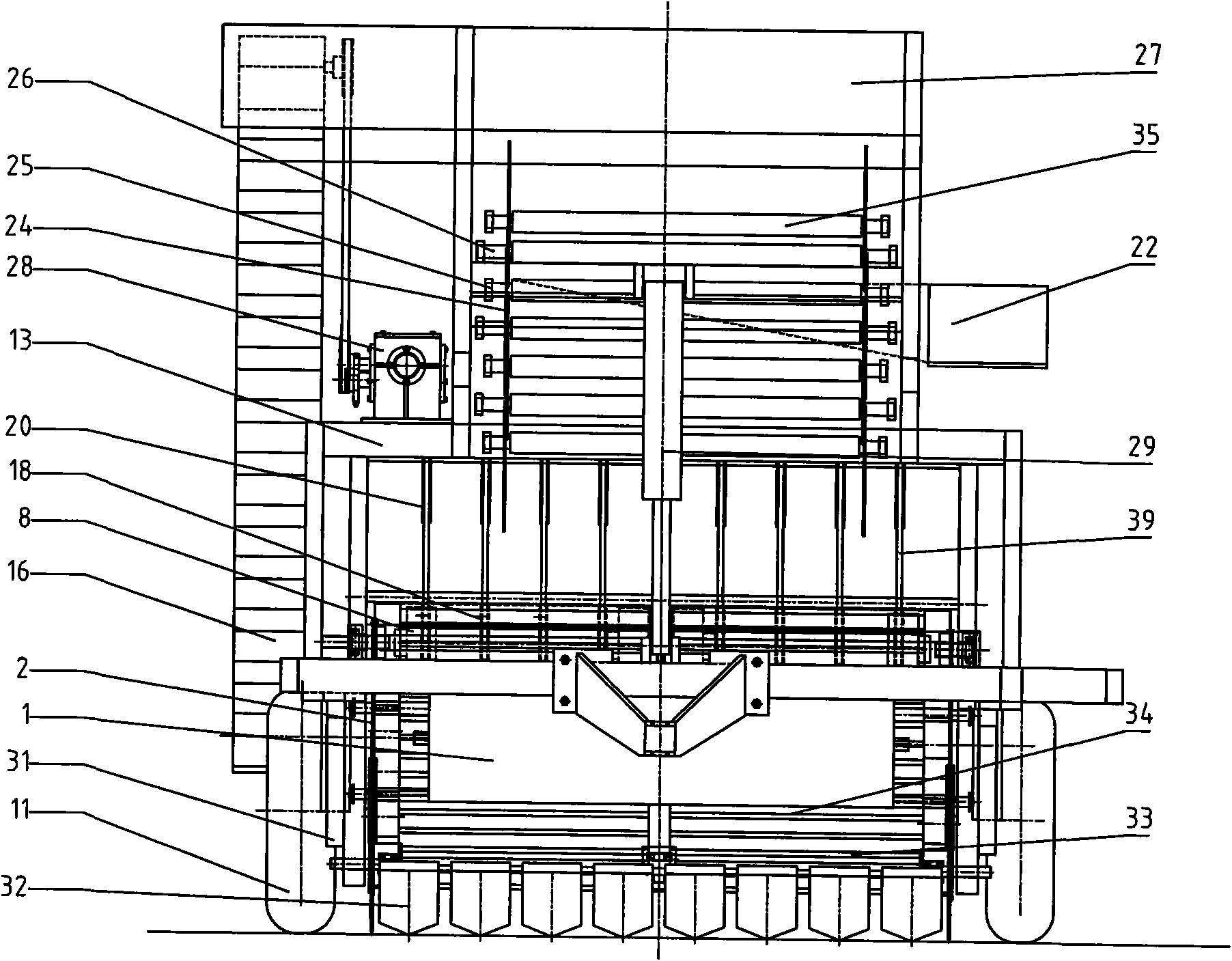

[0013] See figure 1 , 2 , 3, the described grading bagged potato combine harvester includes a frame 13, which is characterized in that the frame 13 is also provided with a roller chain grading device 35, a primary soil and potato separation Conveying device 34 and secondary soil and potato separation conveying device 12, the bottom of frame 13 is provided with ground wheel 11, the front end of frame 13 is provided with drawbar 31, and one side of frame 13 is provided with belt scraper type elevator 16 , the top of the roller shaft chain classifying device 35 is provided with a discharge chute 27 corresponding to the belt scraper type elevator 16, and the middle part of the roller shaft chain classifying device 35 is provided with a material receiving and bagging device 22, and the secondary soil and potato separation The rear end of conveying device 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com