Bucket and operation vehicle

A technology for working vehicles and buckets, which is applied to mechanically driven excavators/dredgers, etc., and can solve problems such as large digging resistance of buckets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0052]

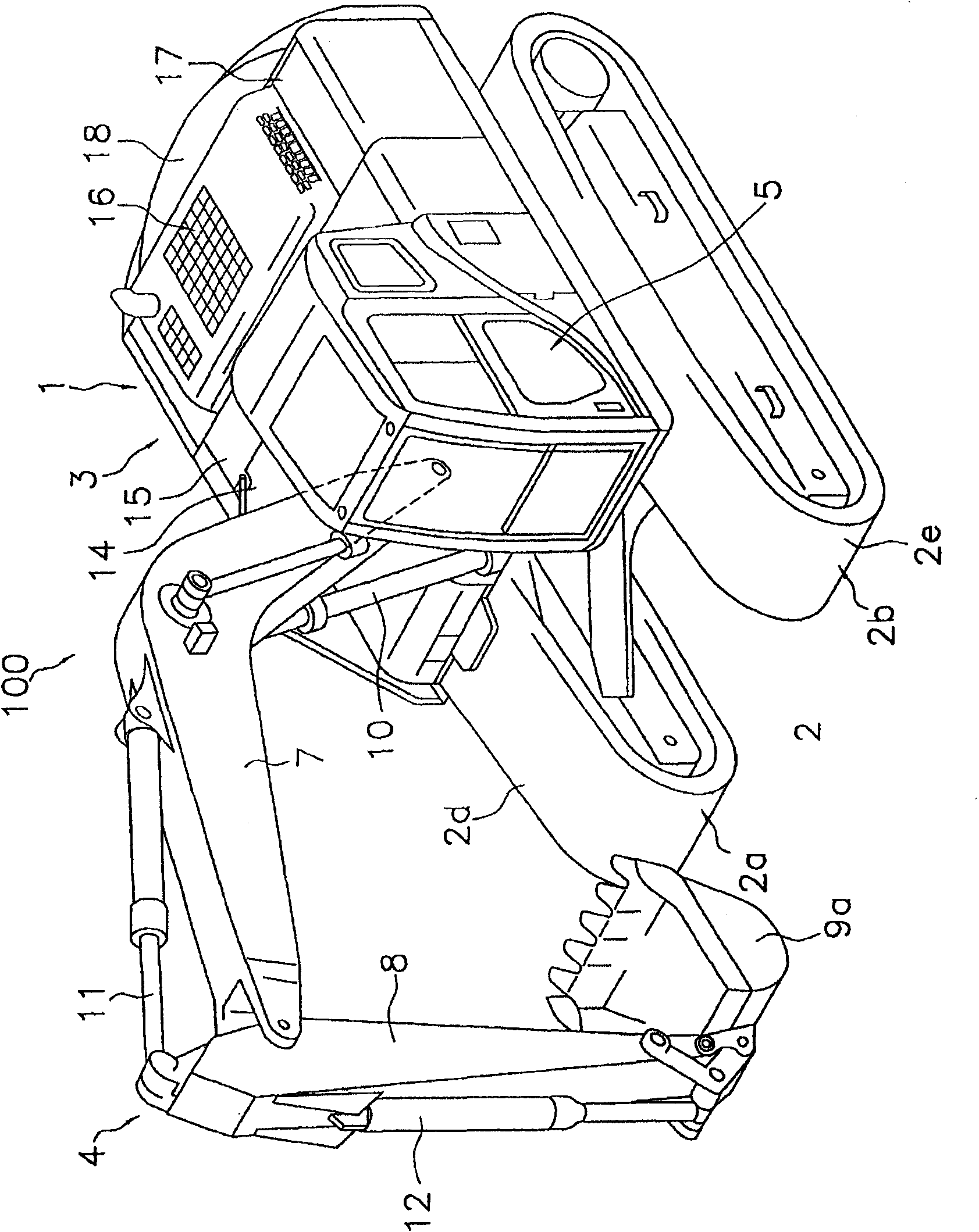

[0053] figure 1 A hydraulic excavator 100 according to a first embodiment of the present invention is shown. This hydraulic excavator 100 has a vehicle body 1 and a work machine 4 .

[0054] The vehicle body 1 has a traveling body 2 and a rotating body 3 . The running body 2 has a pair of running devices 2a, 2b. Each traveling device 2a, 2b has crawler belts 2d, 2e, and drives the hydraulic excavator 100 by driving the crawler belts 2d, 2e with the driving force from the engine. In the description of the overall structure, the front-rear direction refers to the front-rear direction of the vehicle body 1 . In addition, the left-right direction or the side surface refers to the vehicle width direction of the vehicle body 1 .

[0055] The rotating body 3 is mounted on the traveling body 2 . The rotating body 3 is arranged rotatably on the traveling body 2 . In addition, a cab 5 is provided at the front left side of the revolving body 3 . The rotating body 3 has...

no. 2 approach

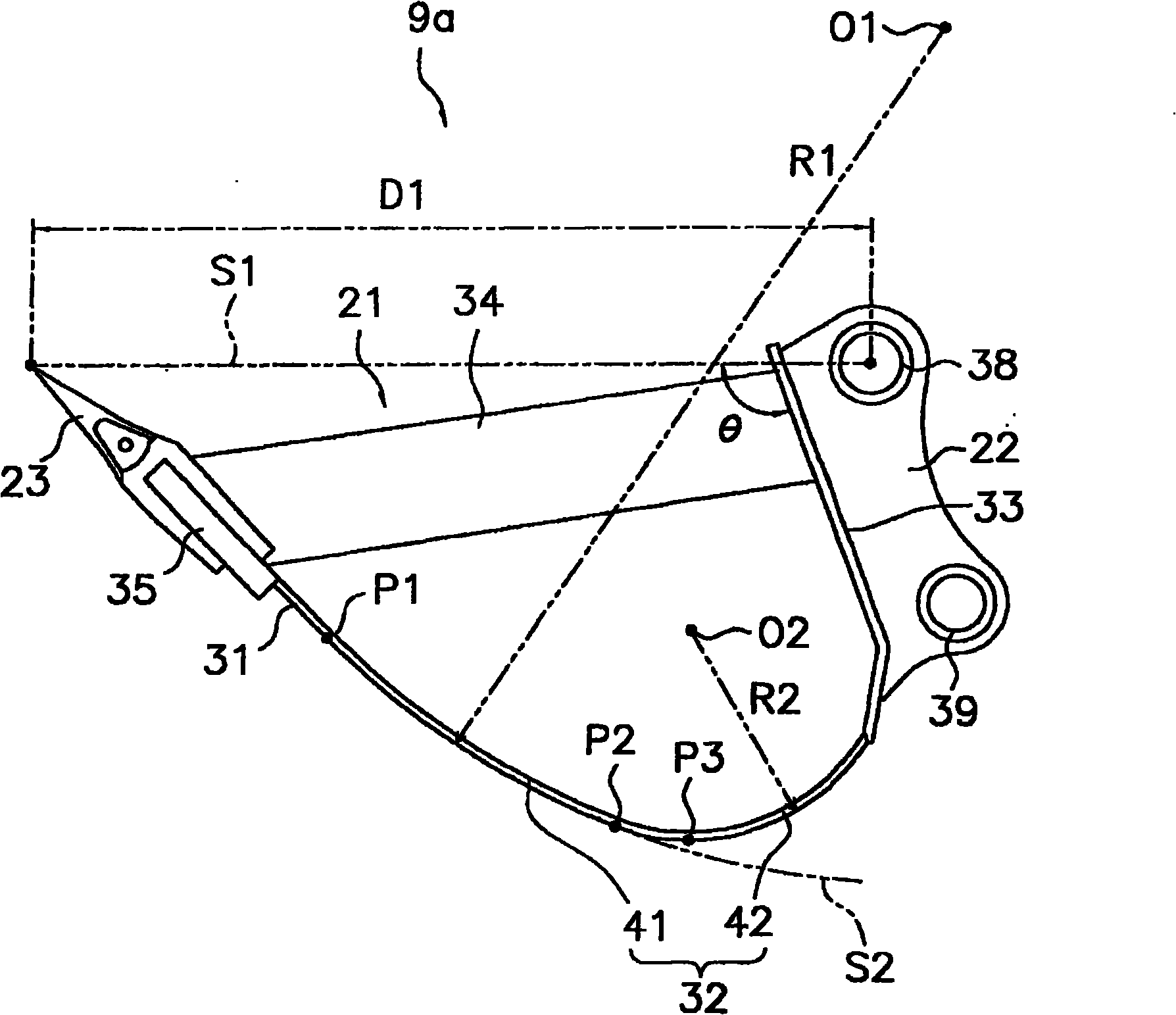

[0086] Figure 9 A bucket 9b according to the second embodiment of the present invention is shown. In this bucket 9b, the center O11 of the first curvature radius R11 of the first curved surface portion 41 is located outside the bucket 9b similarly to the first embodiment described above. In addition, the tooth tip radius ratio R11 / D11 satisfies the above-mentioned formula 1. However, the first curvature radius R11 is smaller than the tooth tip radius D11. For example, R11=1700mm, D11=2200mm, at this time, the tooth tip radius ratio R11 / D11=0.77. In addition, in a side view, the first curved surface portion 41 is arranged above the reference curved surface S2.

[0087] The other structures are the same as those of the bucket 9a in the above-mentioned first embodiment. The bucket 9b of this embodiment can also achieve the same effect as the bucket 9a of the first embodiment.

no. 3 approach

[0089] Figure 10 A bucket 9c according to a third embodiment of the present invention is shown. In this bucket 9c, the center O21 of the first curvature radius R21 of the first curved surface portion 41 is located outside the bucket 9c similarly to the first embodiment described above. In addition, the tooth tip radius ratio R21 / D21 satisfies the above-mentioned formula 1. However, the first curvature radius R21 is smaller than the tooth tip radius D21. For example, R21=1300mm, D21=2200mm, at this time, the tooth tip radius ratio R21 / D21=0.59. In addition, in a side view, the first curved surface portion 41 is arranged above the reference curved surface S2.

[0090] The other structures are the same as those of the bucket 9a in the above-mentioned first embodiment. The bucket 9c of this embodiment can also achieve the same effect as the bucket 9a of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com