Automatic detecting, stacking and storing integrated production line and method for machine tool discharging drill bits

An automatic detection and production line technology, applied in the direction of mechanical measuring devices, measuring devices, traveling mechanisms, etc., can solve the problems of inability to automate and waste manpower, and achieve the effects of saving costs, protecting the environment and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

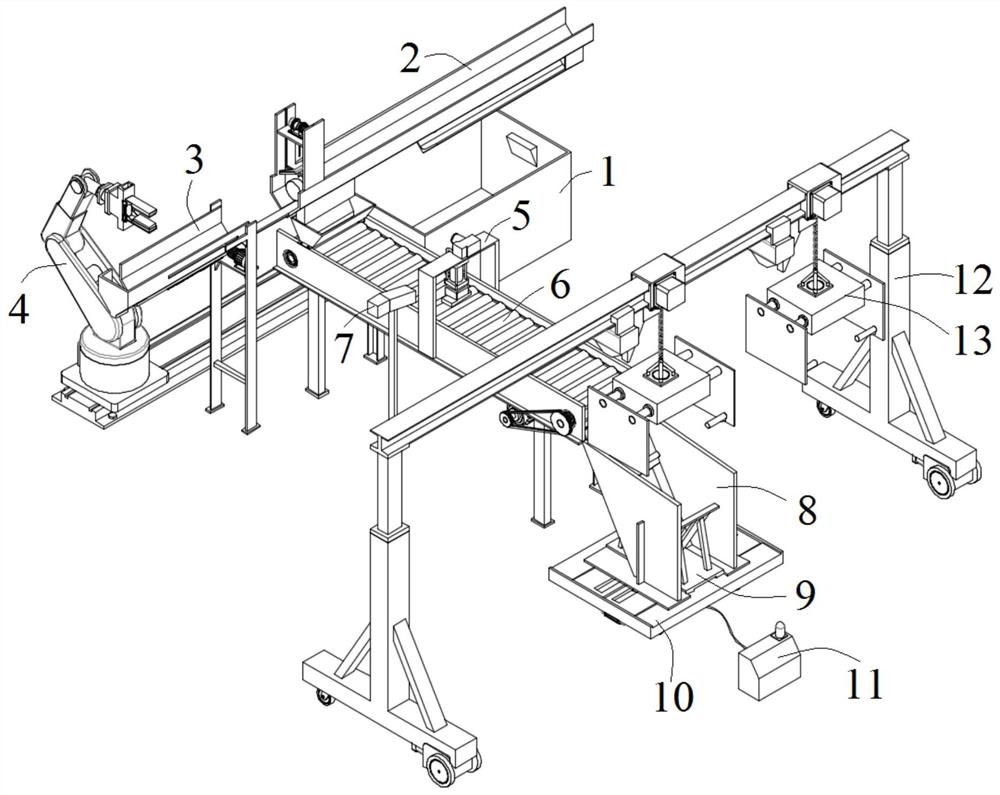

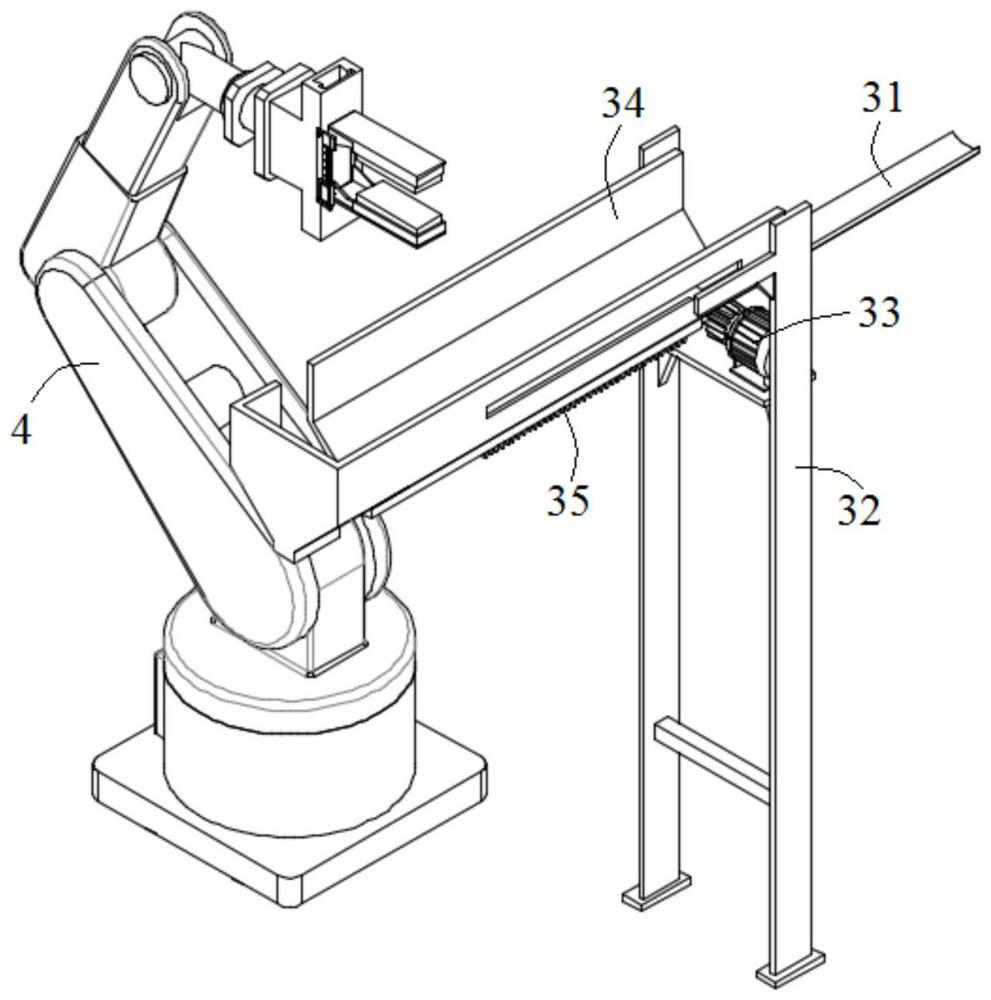

[0048] to combine figure 1 , a machine tool discharging drill bit automatic detection, stacking and stacking integrated production line of the present embodiment includes a discharge chute 2, a manipulator 4, an adjustment mechanism 5, a conveying mechanism 6, a monitoring mechanism 7 and a tripod 9; One end of the discharge chute 2 is connected to the outlet of the drill bit production machine, and the other end is provided with a manipulator 4 to carry out spot checks on the drill bits; the conveying mechanism 6 is connected to the outlet of the discharge chute 2, the monitoring mechanism 7 monitors the orientation of the drill bit head, and the adjustment mechanism 5 adjusts the head of the drill bit. The head is adjusted towards the wrong drill bit; the tripod 9 is arranged at the outlet of the conveying mechanism 6 for stacking the drill bits. The lower end of the outlet chute 2 is provided with an oil tank 1 .

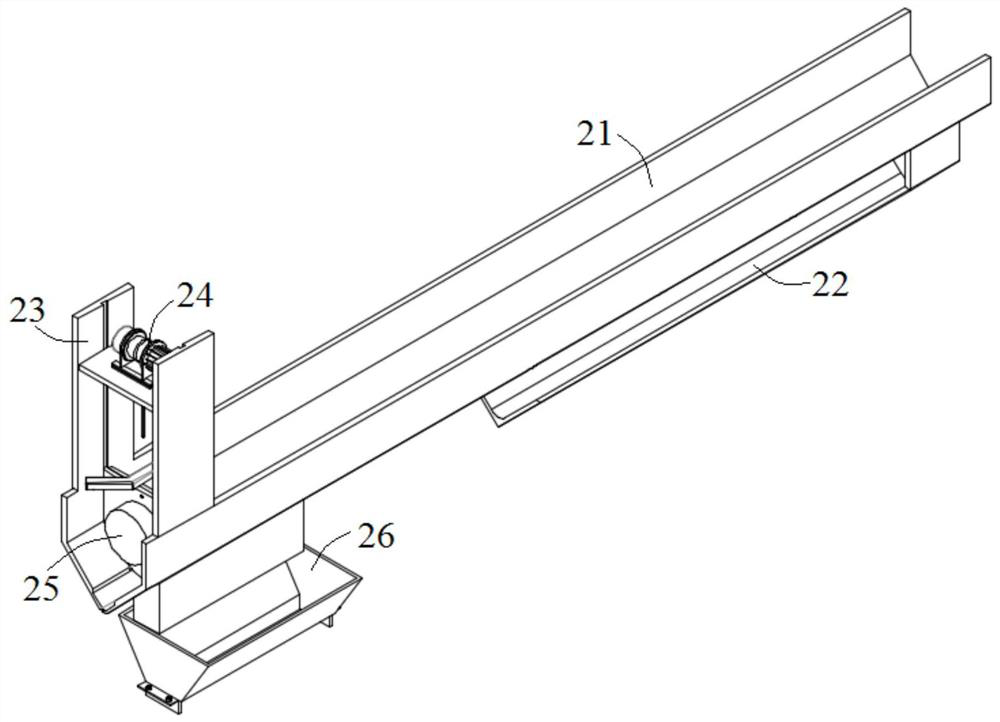

[0049] to combine figure 2 , the discharge chute 2 inclu...

Embodiment 2

[0057] The production line structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the bottom of the tripod 9 is provided with a base 10, and a side plate 8 is respectively arranged on both sides of the tripod 9, and the side plates 8 are movably mounted on On the base 10; the bottom of the base 10 is provided with a weighbridge, and is connected with the alarm 11 (see Figure 7 ), the present embodiment utilizes the weighbridge to detect the quality of the tripod 9, and when the quality reaches a certain level, the staff is notified by the alarm 11 to reduce manual labor. to combine Figure 8 , the base 10 includes a bottom plate 101, a bottom plate gear 102, and a bottom plate rack 103; the bottom plate gear 102 is installed on the bottom plate 101, and the two bottom plate racks 103 mesh with the bottom plate gear 102, and are fixedly connected with a side plate 8 respectively . The bottom plate gear 102 is driven by the motor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com