Patents

Literature

81results about How to "Fast placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

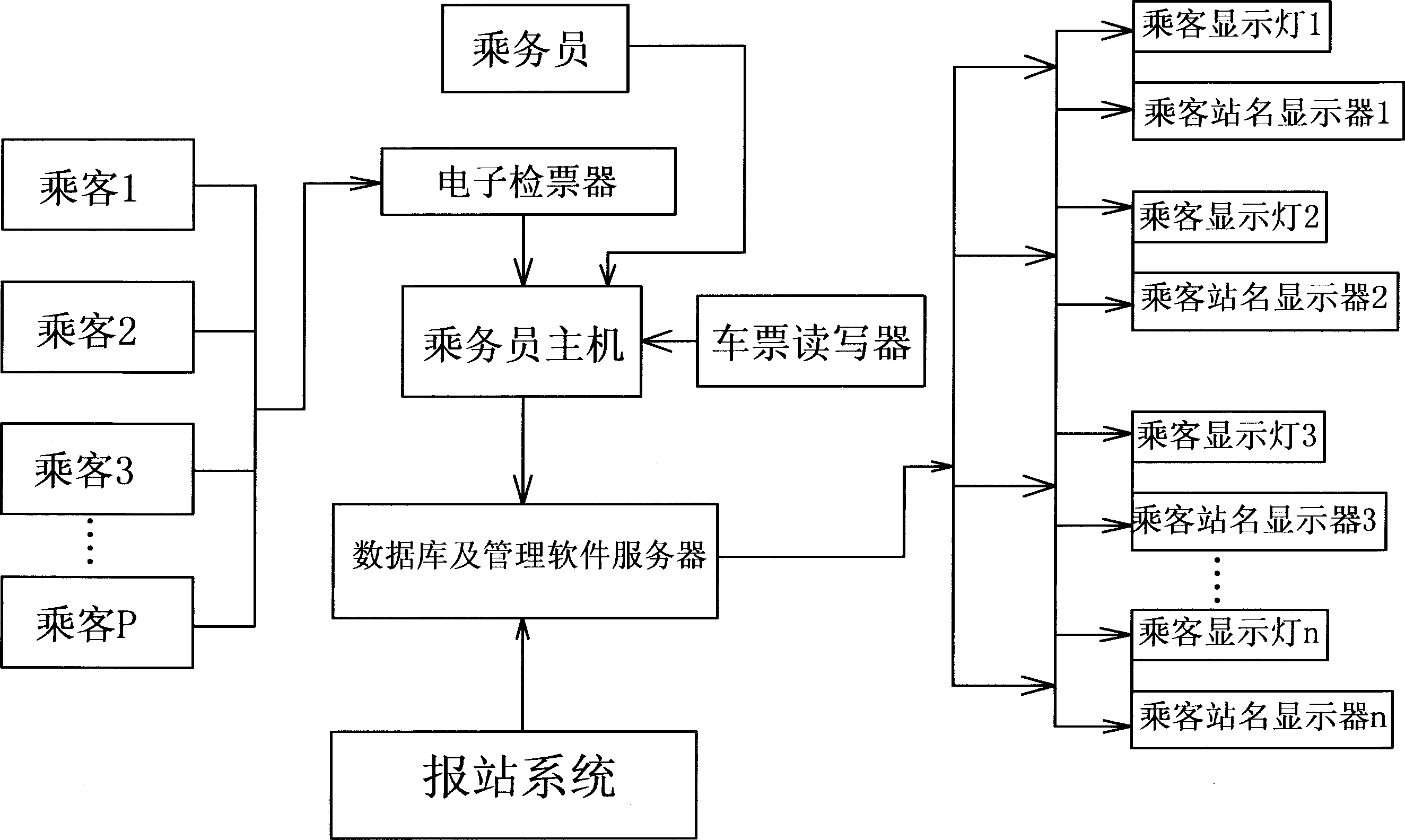

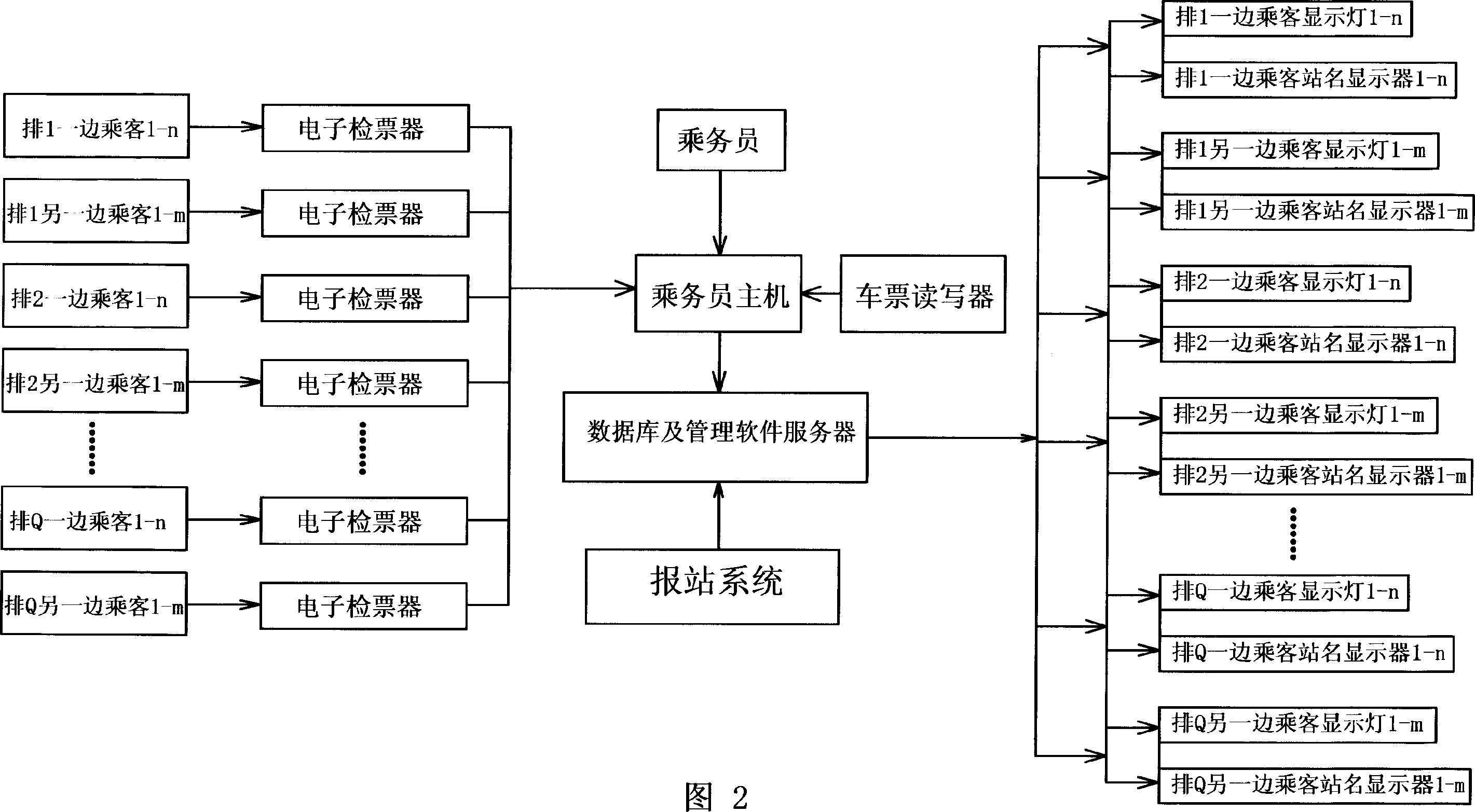

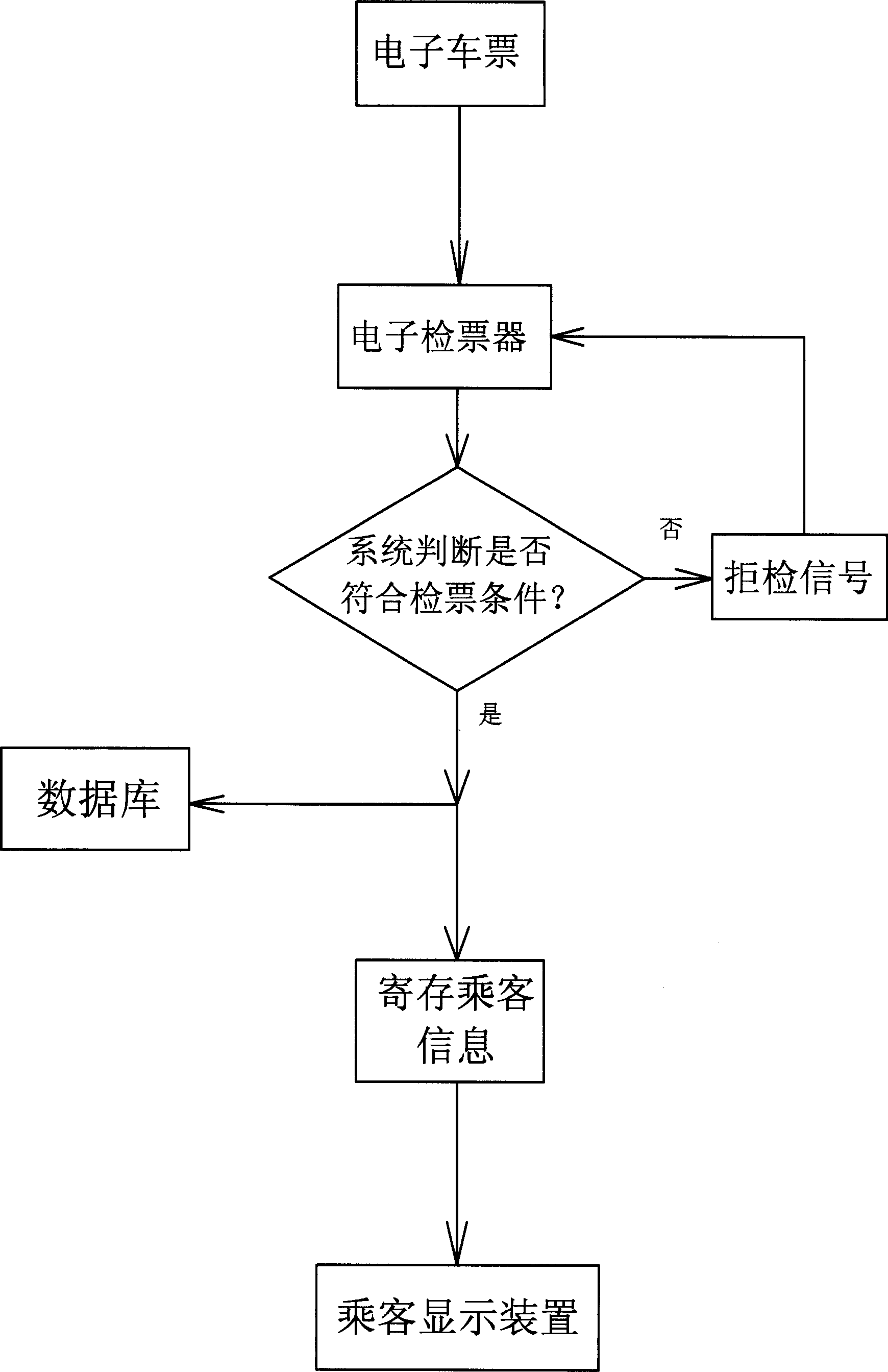

Electronic management system and method used in train and coach bus

InactiveCN1877642APrevent noEasy to manageTaximetersSpecial data processing applicationsDisplay deviceComputer science

The related passenger E-management system for train or coach comprises: an electronic ticket checker, a passenger display device, a server, a steward host, and a ticket read-write device. Wherein, with database and management software, using computer network to connect former checker, display device and host to form a system. This invention overcomes the asymmetry between current advanced tool and backward management mode, and improves opposite management and service level further.

Owner:XINKANG COMP TECH SUZHOU

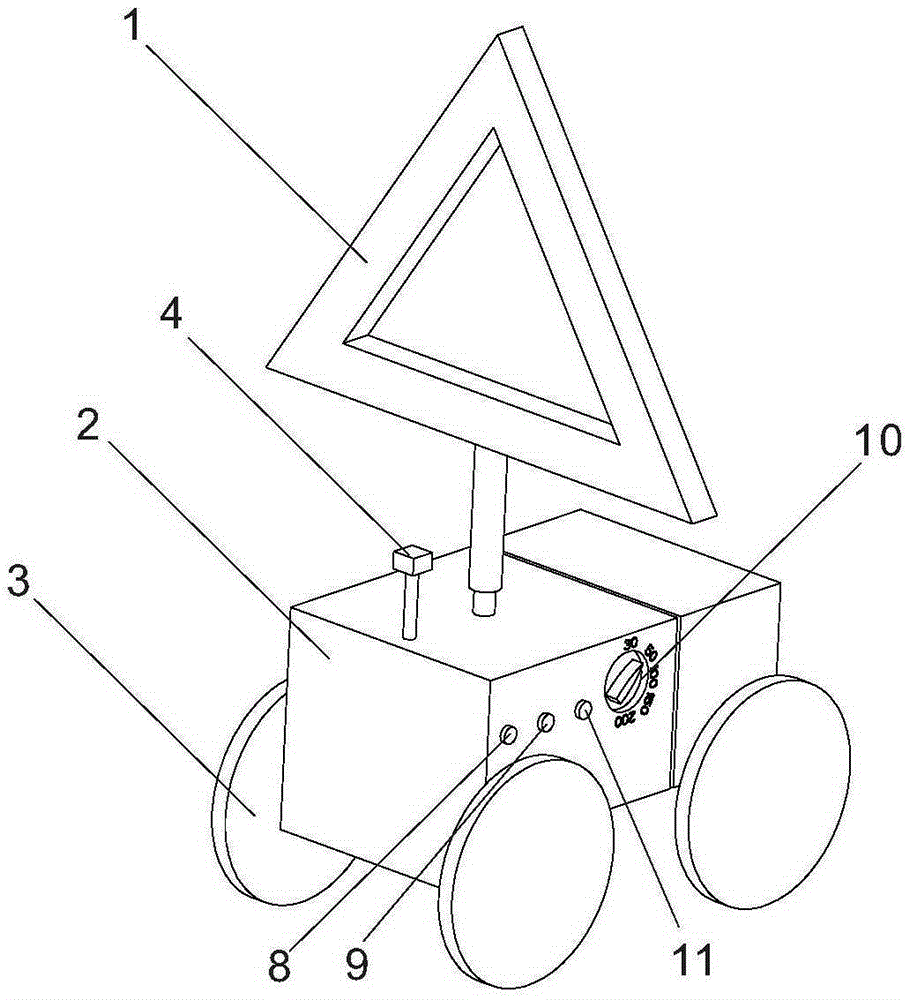

Vehicle warning device capable of automatically detecting highway guardrail position

InactiveCN105200931AAvoid influenceHigh degree of intelligenceTraffic signalsRoad signsElectricityComputer module

The invention discloses a vehicle warning device capable of automatically detecting a highway guardrail position. The vehicle warning device comprises a warning board and a warning board installation base, wherein the warning board installation base is provided with a power supply module, and the vehicle warning device also comprises a distance measurement module capable of measuring a distance from the warning board installation base to the highway guardrail position, and the distance measurement module is electrically connected with the power supply module. The warning board is high in arrangement speed, the intelligence degree is high, the manual intervention is reduced, the moving route is precise, the vehicle warning device can be well adaptive to the unfavorable weather condition and curve road conditions, the windproof performance is good, the warning board is flexible and diversified in transport way and is adaptive to different road conditions and weather situations, the warning board can be rapidly moved to a designated place, the warning board can be automatically restored after rolling over, and the cost is low.

Owner:孙立峰

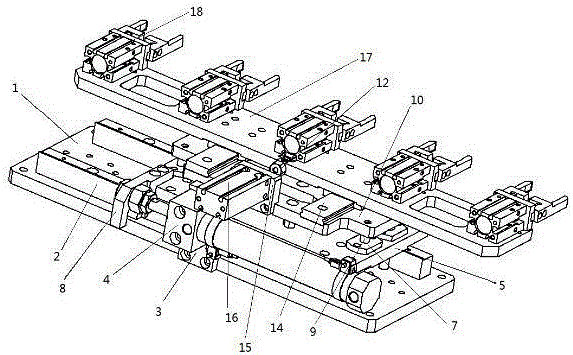

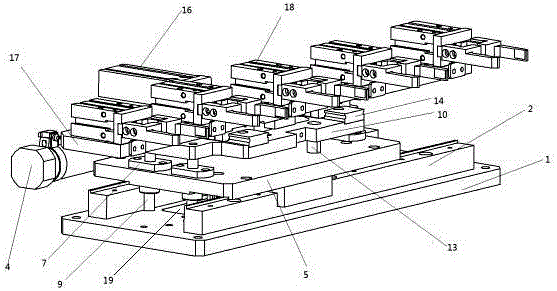

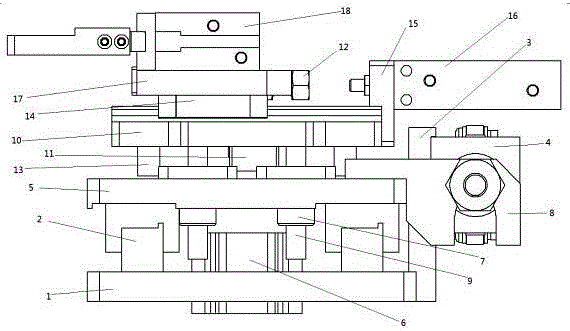

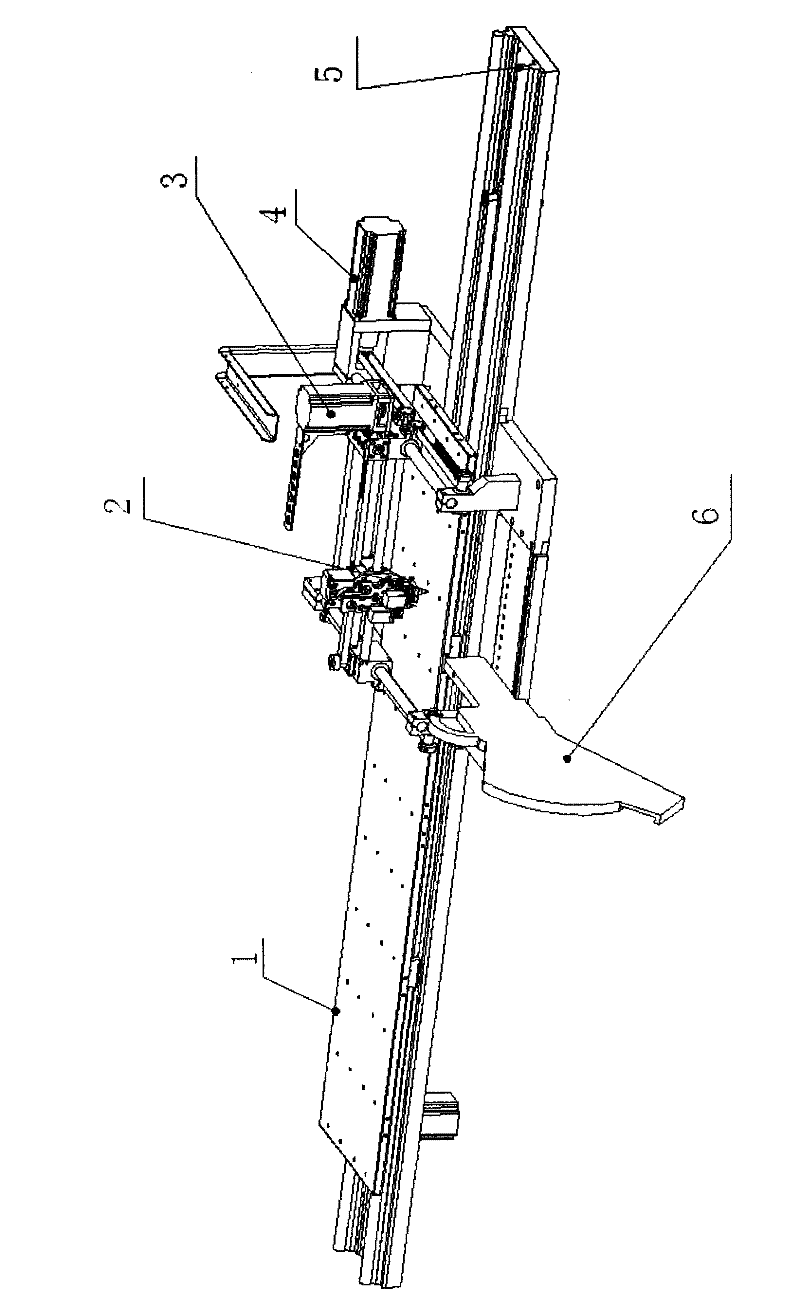

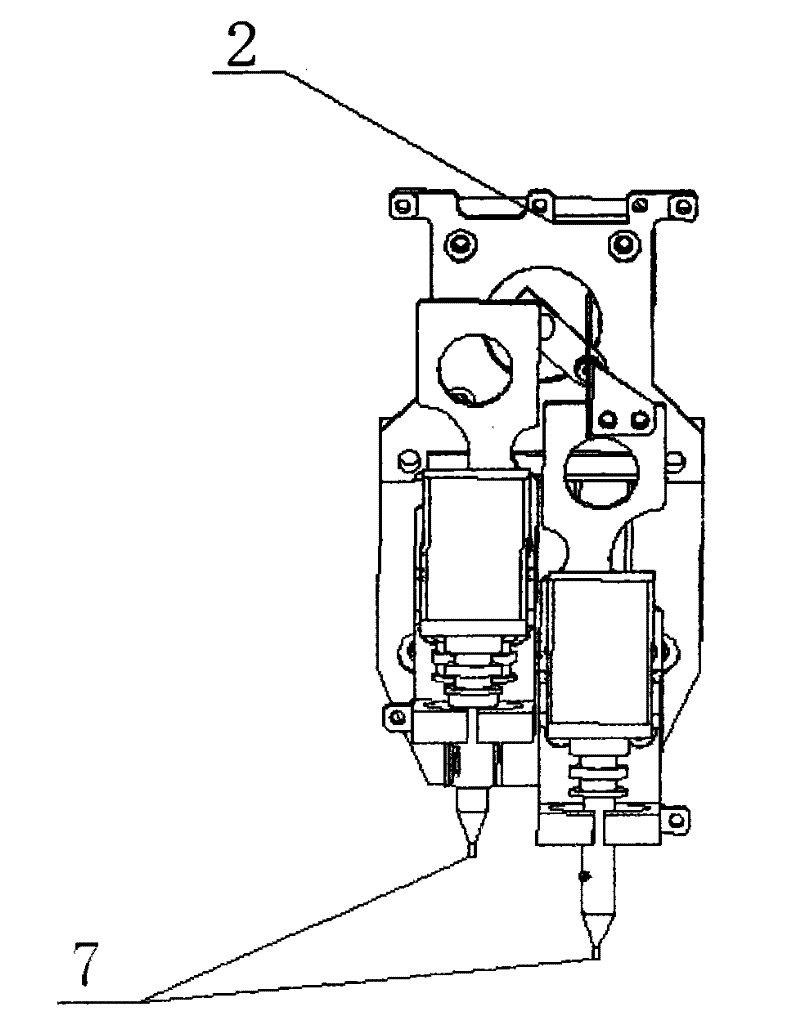

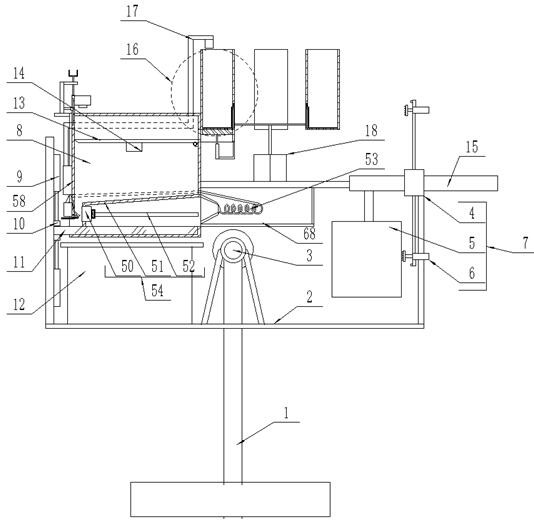

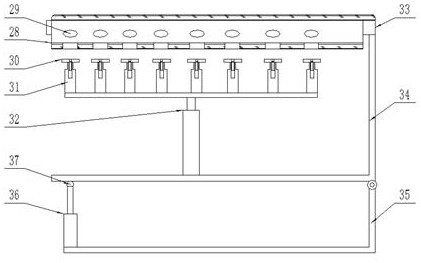

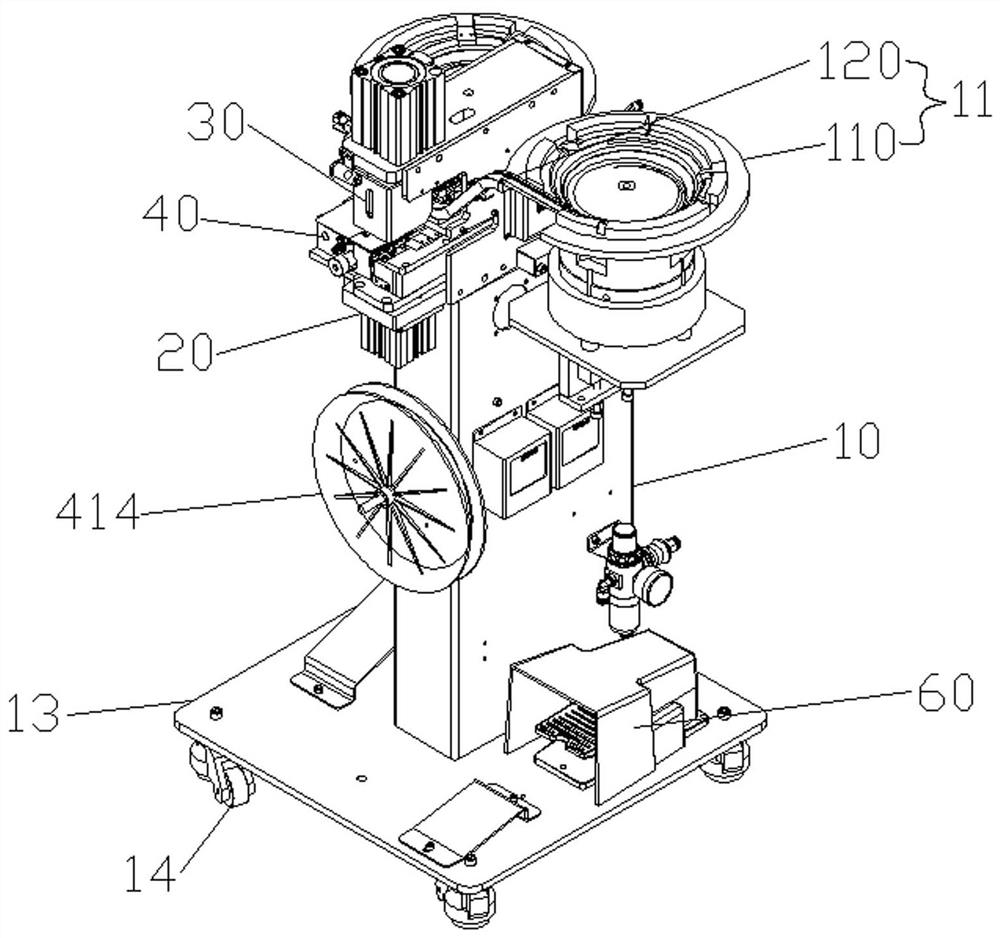

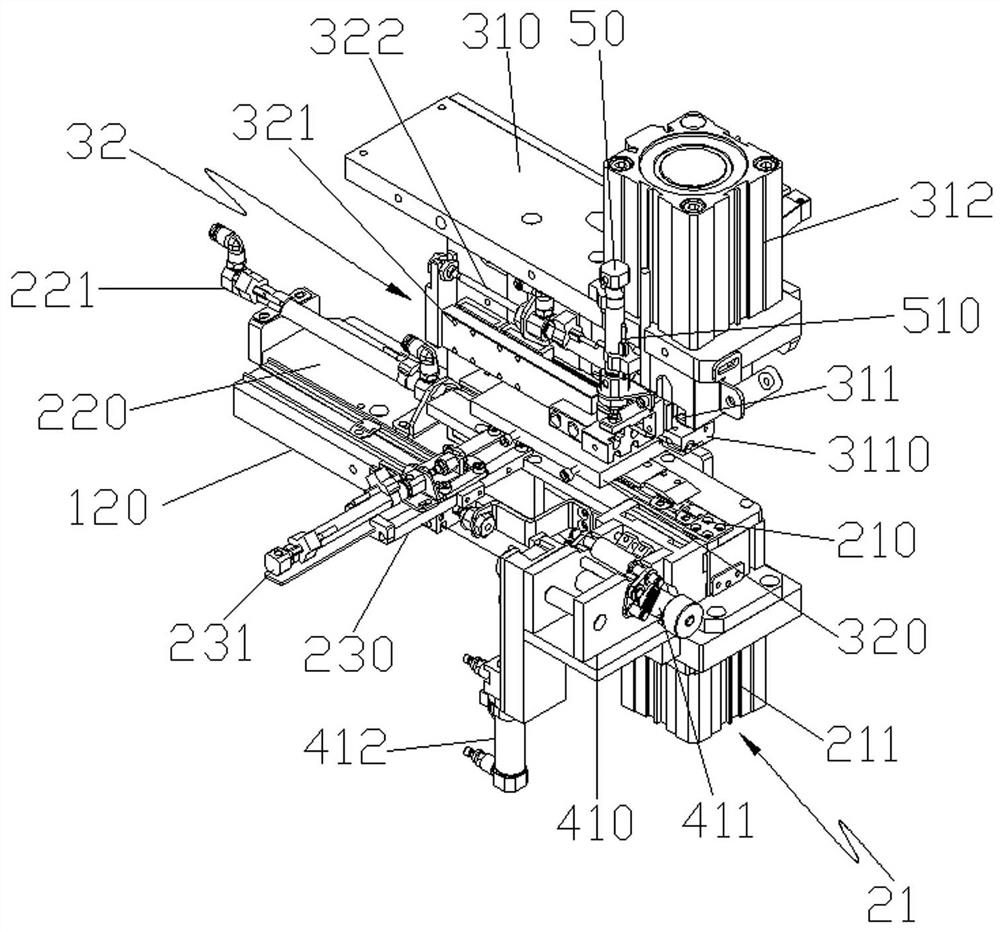

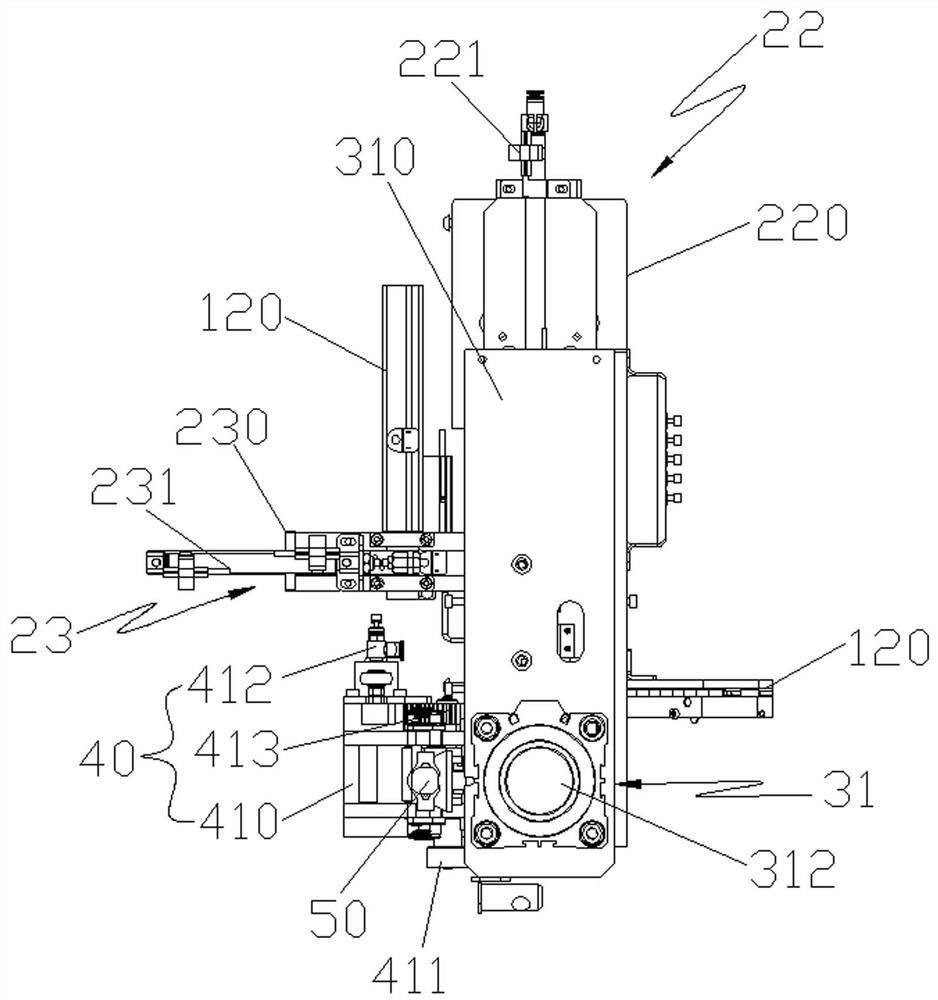

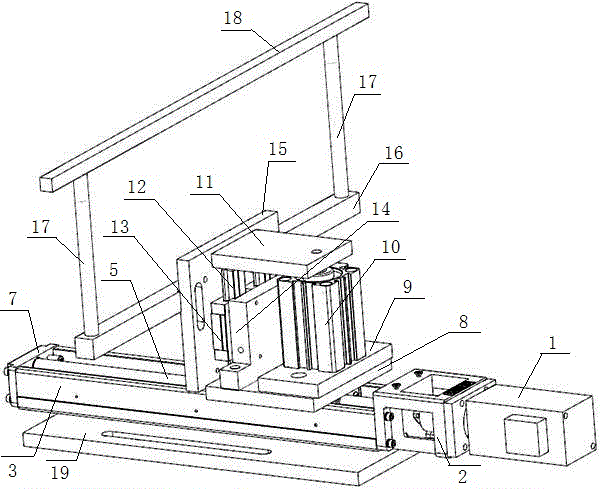

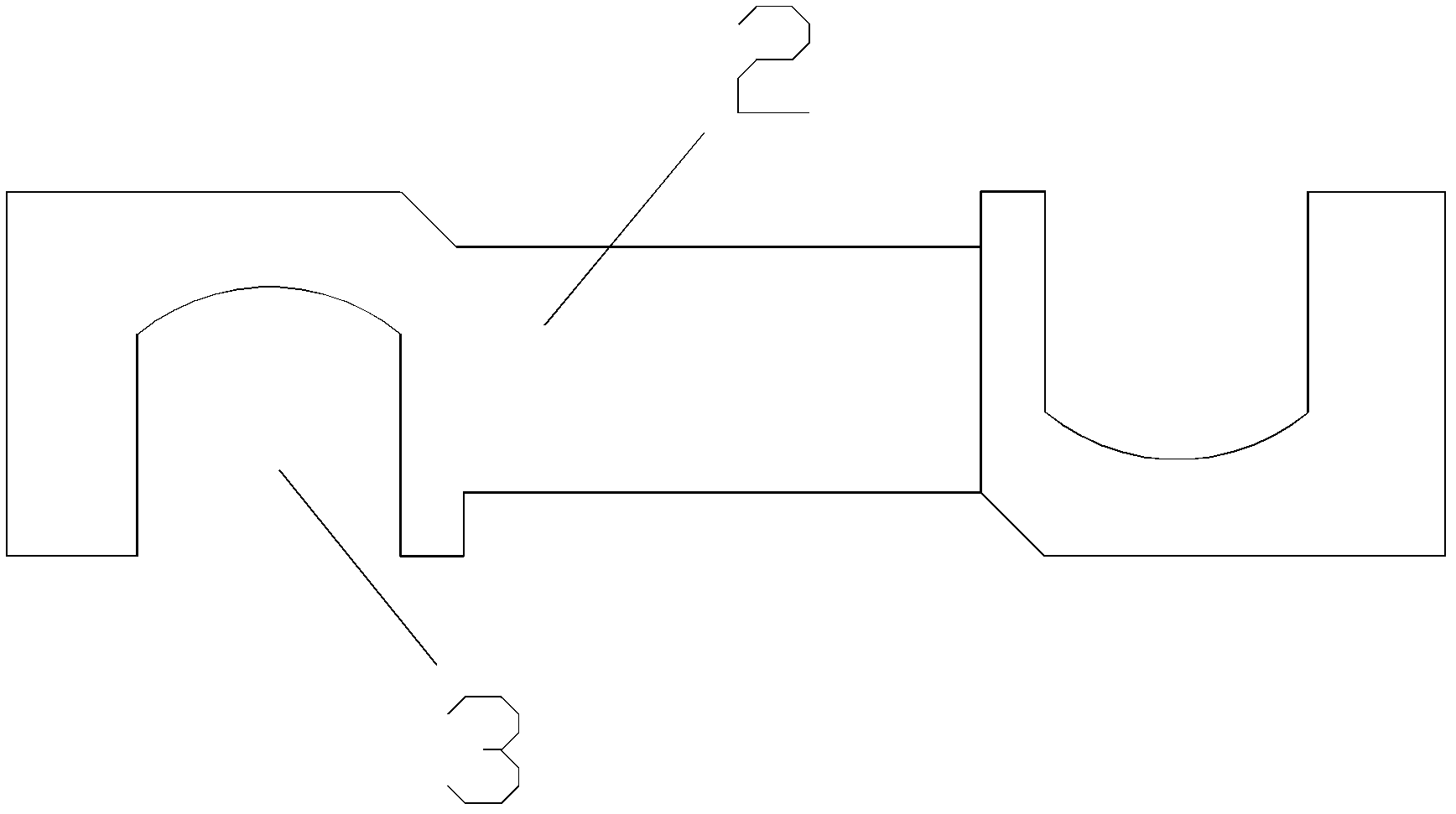

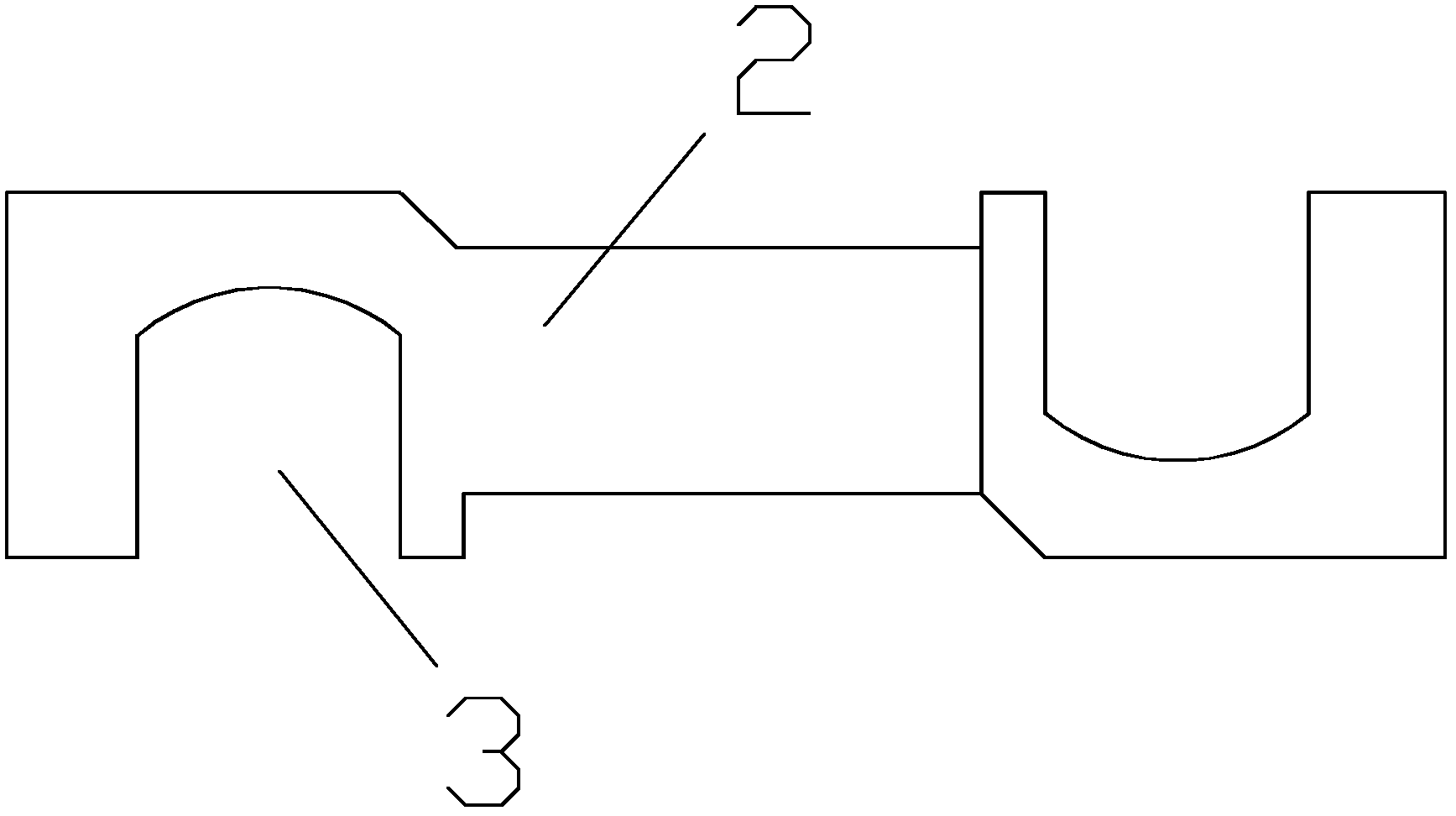

Multi-station clamping feed mechanism

InactiveCN105881520ASave electricityFast placementProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

The invention discloses a multi-station clamping feed mechanism. The multi-station clamping feed mechanism comprises a mechanism fixation plate, wherein X-direction guide rails are arranged at the upper end of the mechanism fixation plate, an X-direction cylinder fixation plate is arranged on one side of the X-direction guide rails and provided with an X-direction push cylinder, and an X-direction movable supporting plate is arranged on the X-direction guide rails in a sliding mode. The X-direction movable supporting plate is connected with a cylinder rod of the X-direction push cylinder. A plurality of linear bearings are arranged on the X-direction movable supporting plate. A Z-direction movable supporting plate is connected with the upper ends of guide shafts arranged inside the linear bearings. A Z-direction push cylinder is arranged above or below the Z-direction movable supporting plate. A cylinder rod of the Z-direction push cylinder is connected with the Z-direction movable supporting plate. Y-direction guide rails are arranged at the upper end of the Z-direction movable supporting plate. One lateral end of the Z-direction movable supporting plate is fixedly connected with a Y-direction push cylinder. A Y-direction movable supporting plate is arranged on the Y-direction guide rails. A plurality of clamping cylinders are fixedly connected with the upper end of the Y-direction movable supporting plate. According to the multi-station clamping feed mechanism, a plurality of products can be simultaneously clamped to be conveyed and installed. The structure is simple, cost is low, use is simple and convenient, and production efficiency is effectively improved.

Owner:SUZHOU INST OF TRADE & COMMERCE

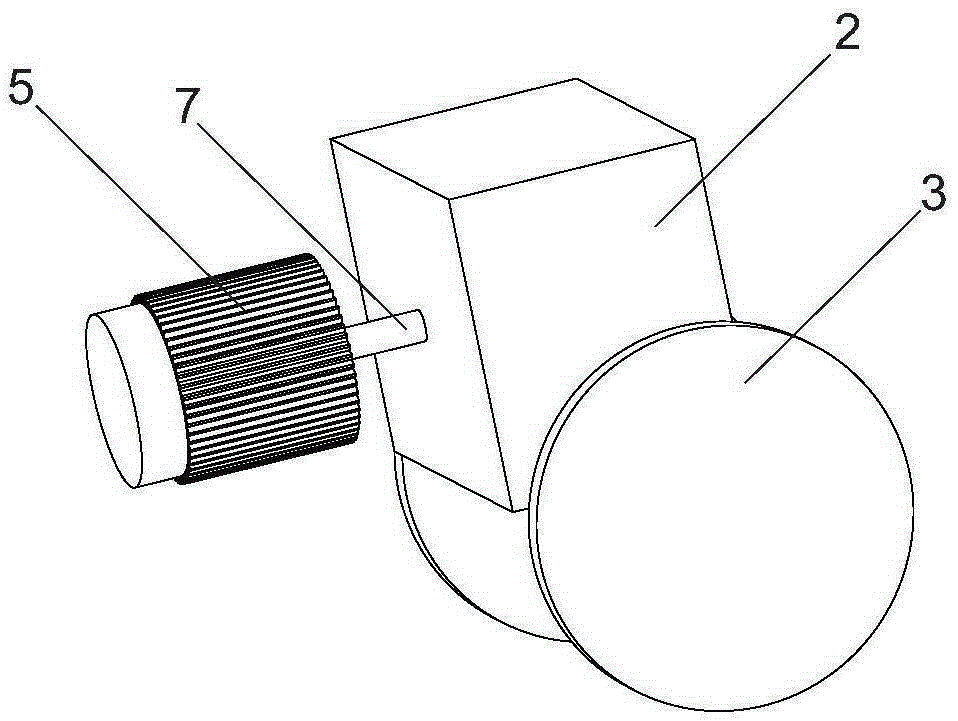

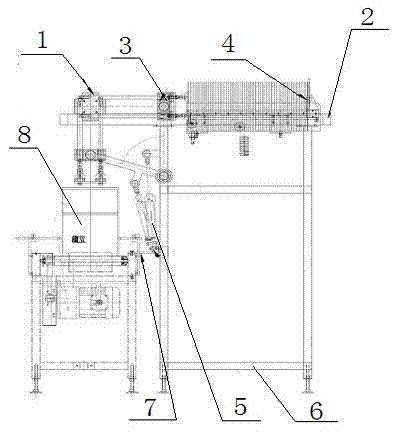

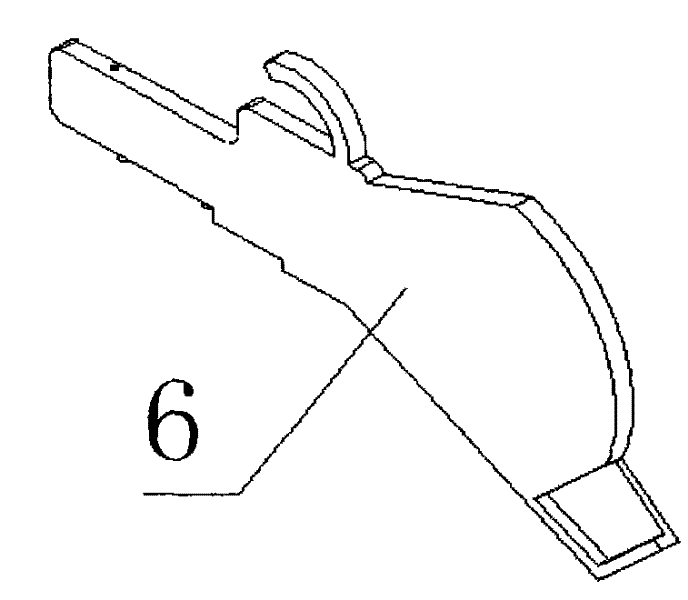

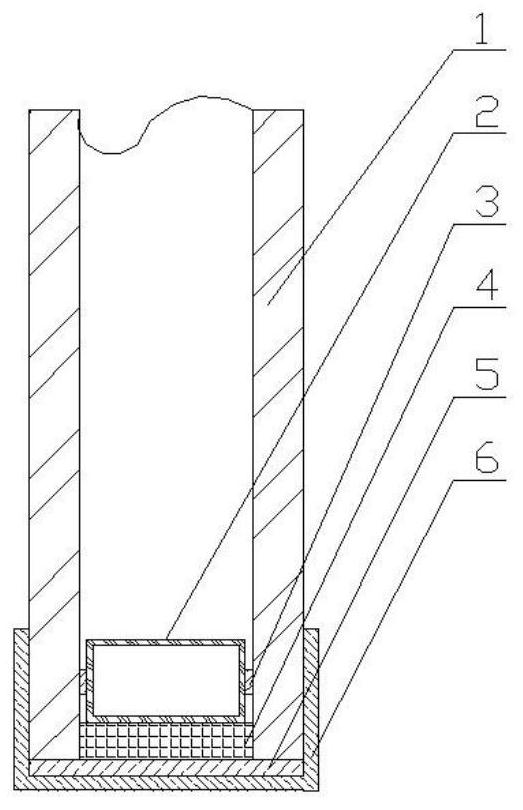

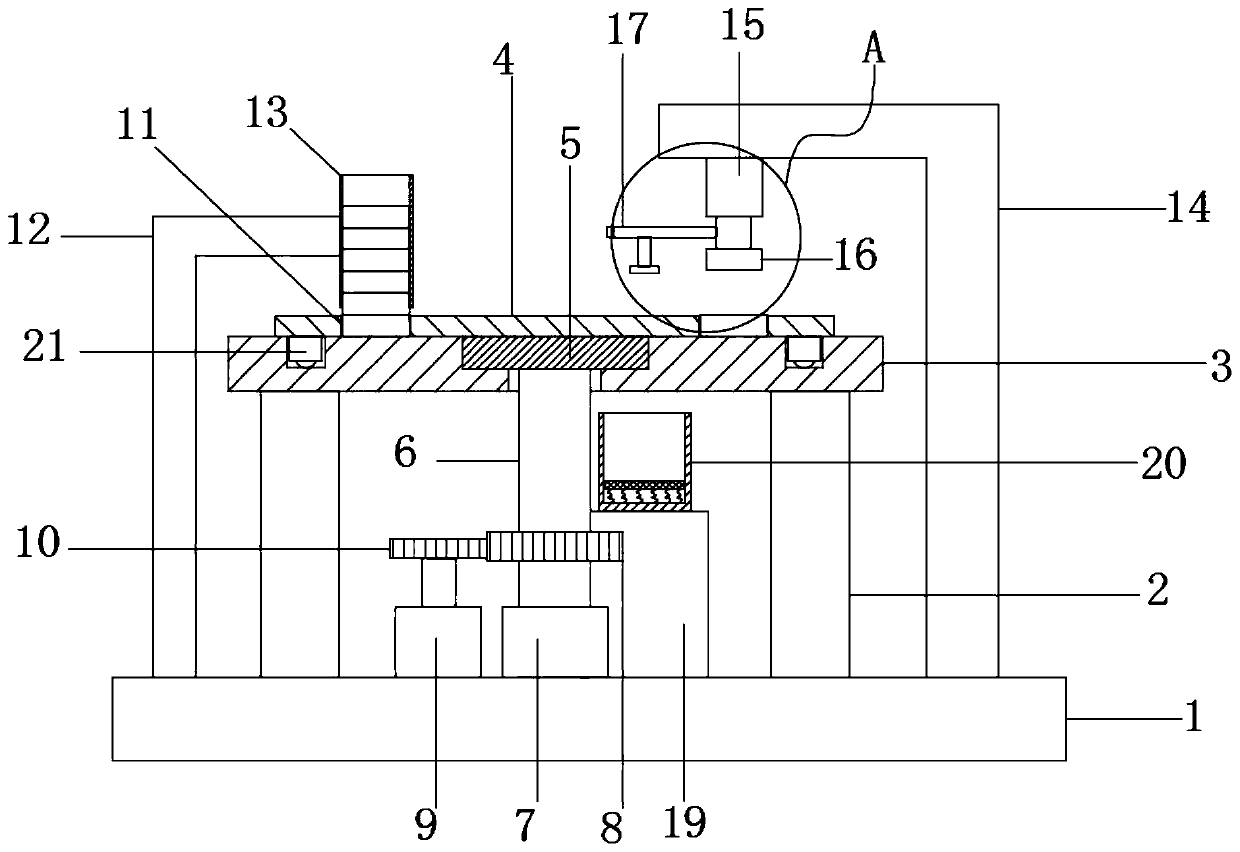

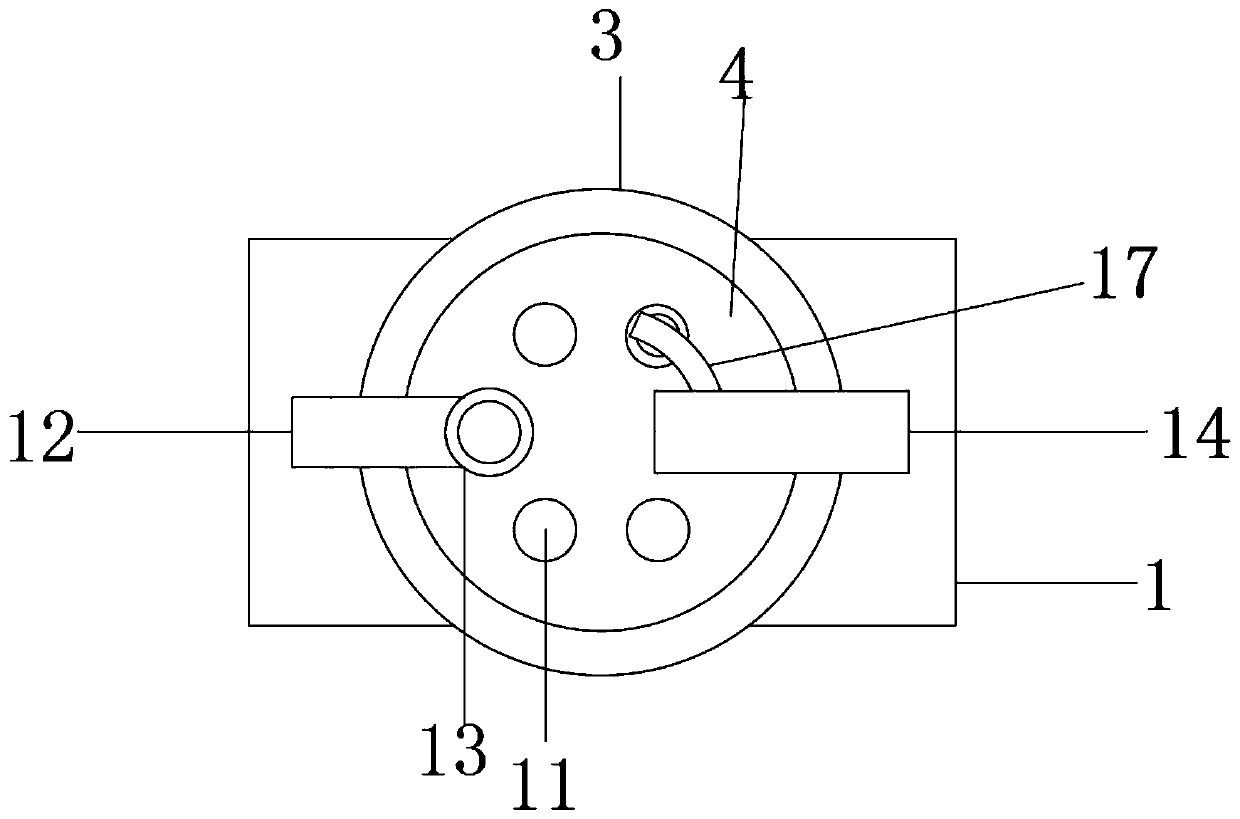

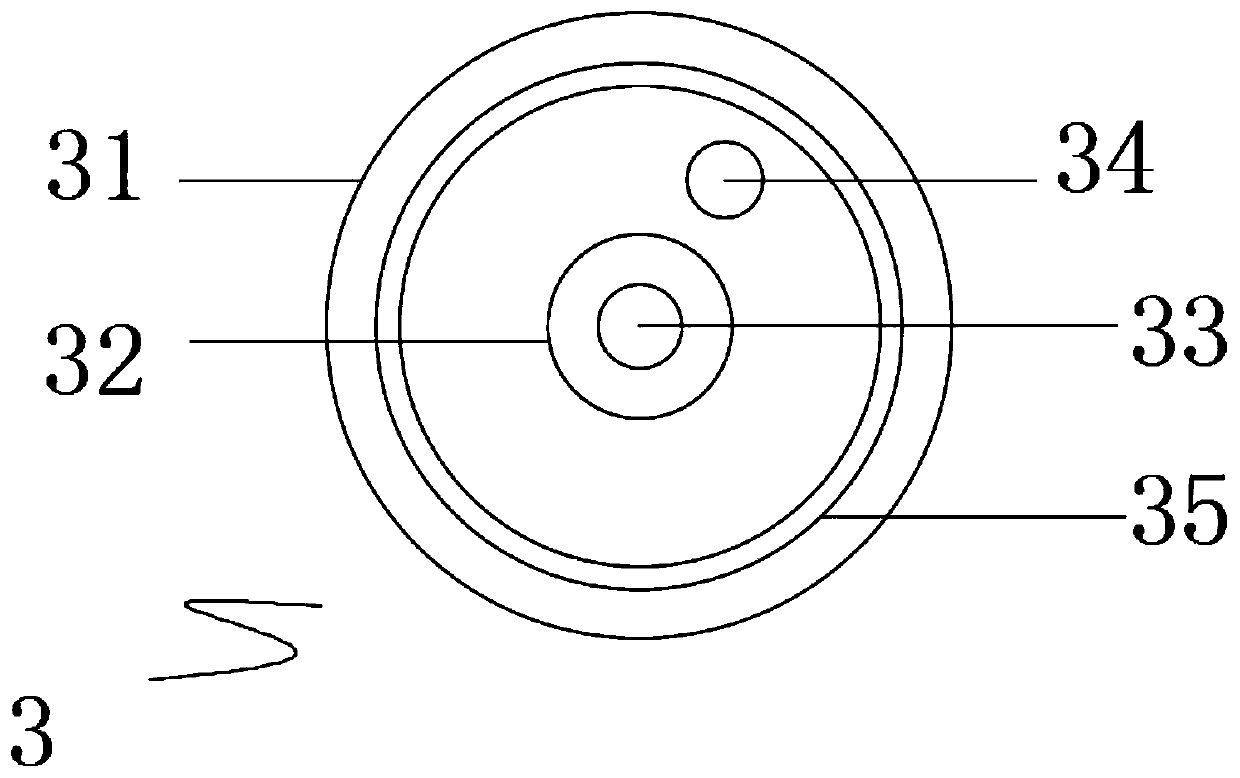

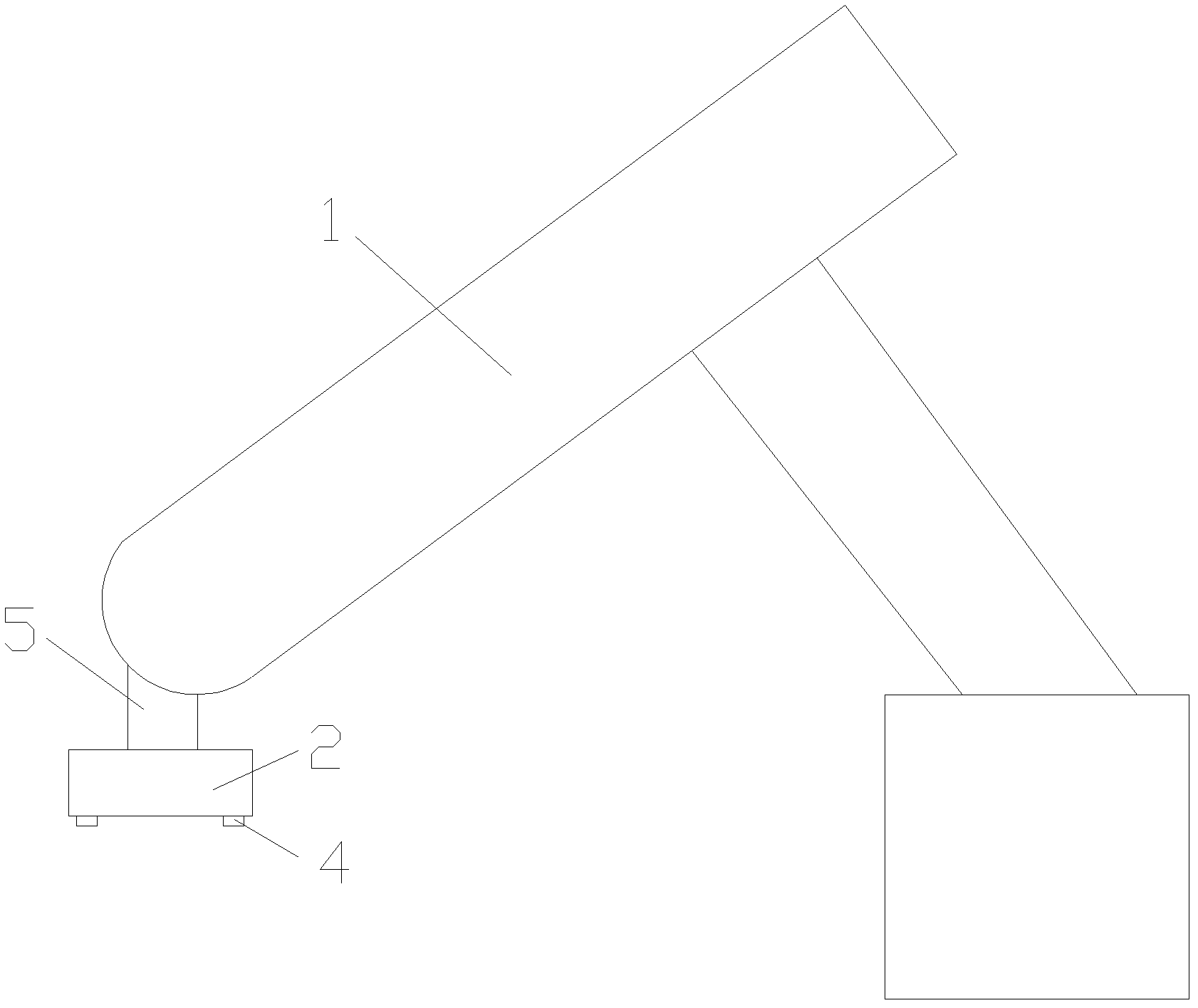

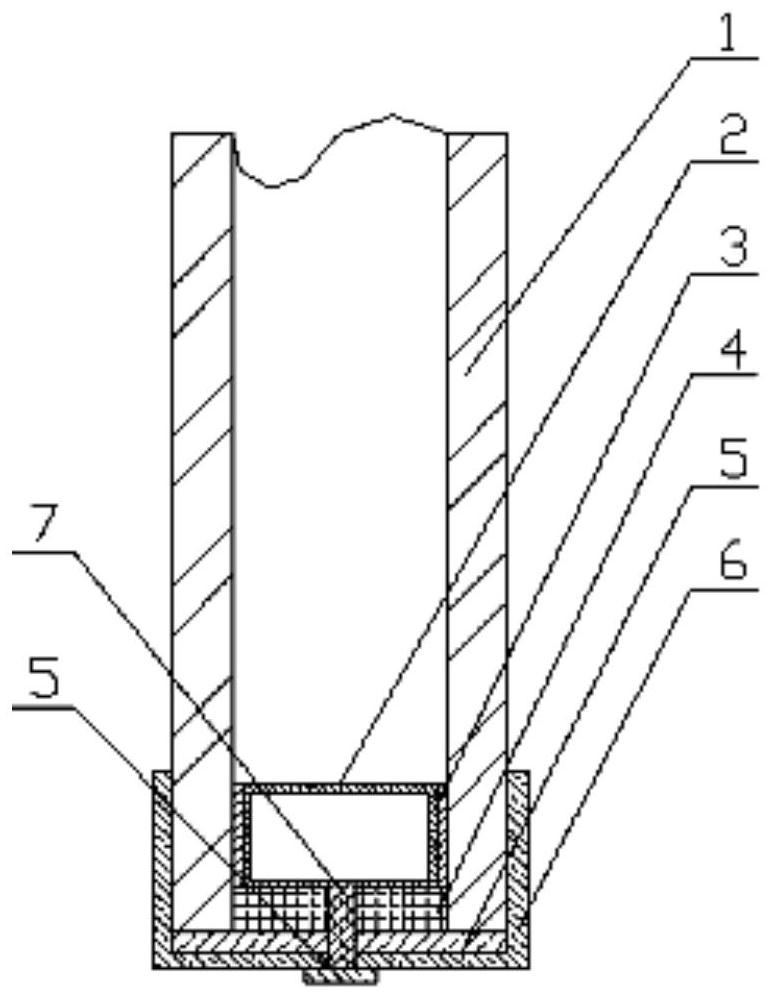

High speed paperboard placing machine

The invention discloses a high speed paperboard placing machine, which comprises a rotary mechanism (1), a frame (2), a swing rod mechanism (3), a storage mechanism (4), an air cylinder (5), a landing leg (6), and a connecting plate (7). The rotary mechanism (1), the swing rod mechanism (3) and the storage mechanism (4) are installed on a frame (2) respectively. The air cylinder (5) is installed on the landing leg (6). The return point of the swing rod mechanism (3) is assembled with the rotary mechanism (1) through a linear bearing. The connecting plate (7) is connected with the air cylinder (5). The high speed paperboard placing machine provided by the invention is simple in structure, stable in grabing, high in placing speed and strong in adaptability to products, and is appropriate for urgent demand of large scale automatic production.

Owner:DALIAN JIALIN EQUIP MFG

Double-head light-emitting diode (LED) lamp strip chip mounter

The invention discloses a double-head light-emitting diode (LED) lamp strip chip mounter which comprises a base platform, an X-axis servo motor, a Y-axis servo motor, a printed circuit board (PCB) sliding table, a chip mounting head and an automatic feeder. The X-axis servo motor is in charge of feeding in the X-axis direction of the chip mounting head, the Y-axis servo motor is in charge of feeding in the Y-axis direction of the chip mounting head, LED lamp strip boards are arranged on the PCB sliding table which is slidably connected with the base platform, and double suction nozzles are arranged on the chip mounting head. The double-head LED lamp strip chip mounter overcomes the shortcomings of high manufacturing cost and low speed, is high in automation degree and capable of replacing import devices and accordingly reduces cost.

Owner:北京博瑞精电科技有限公司

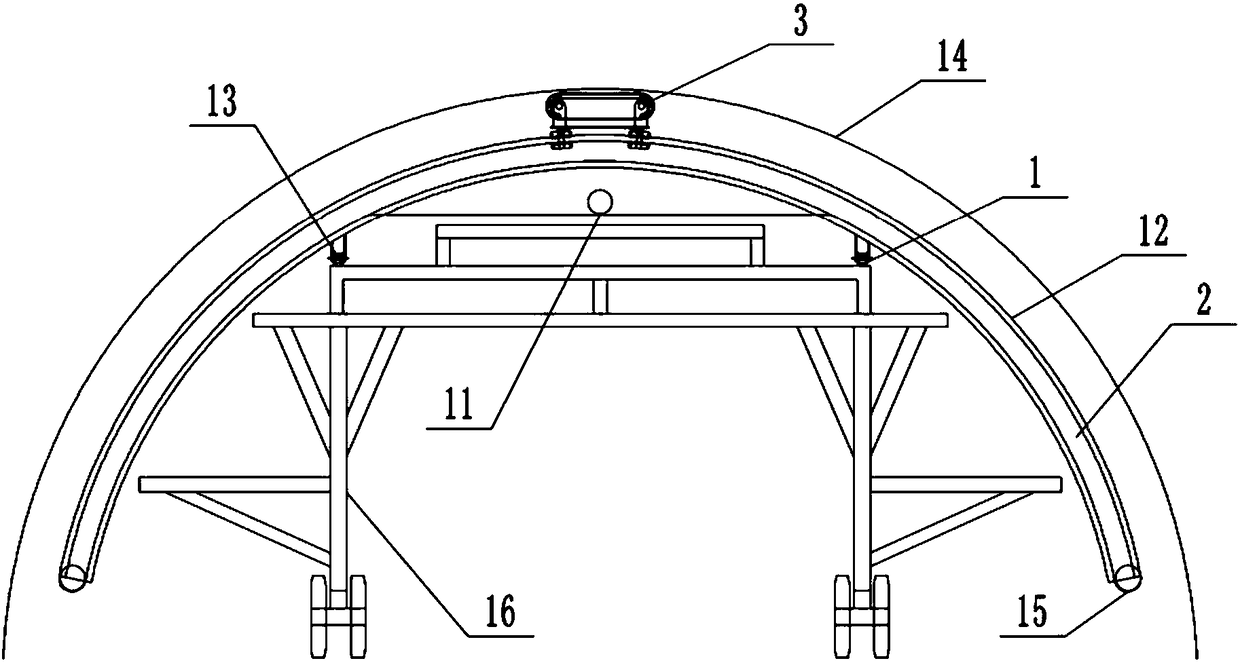

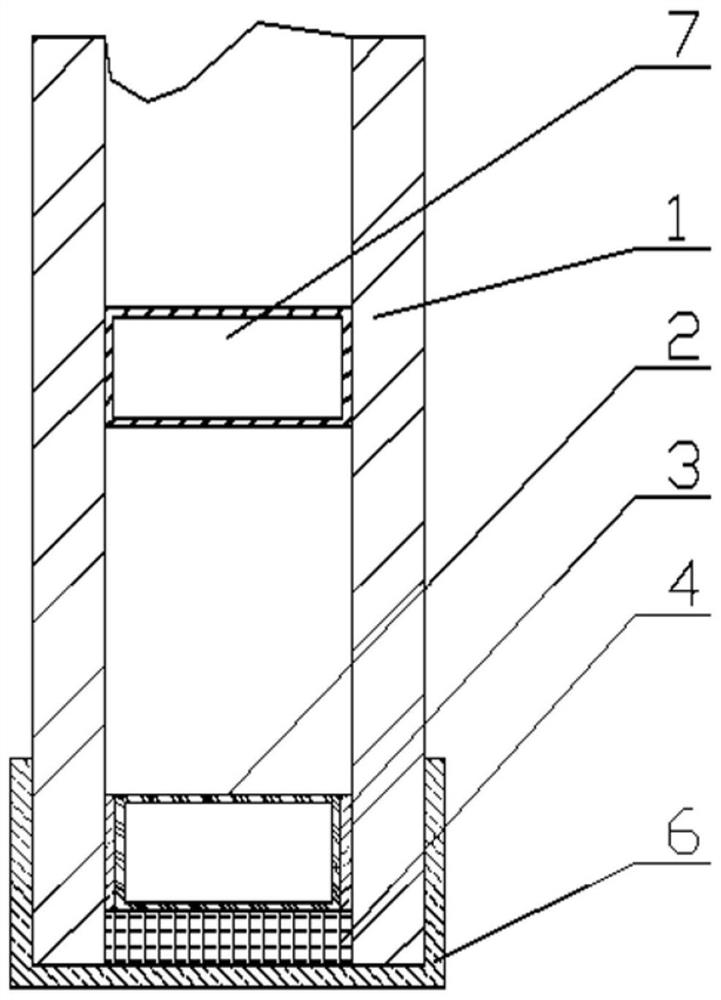

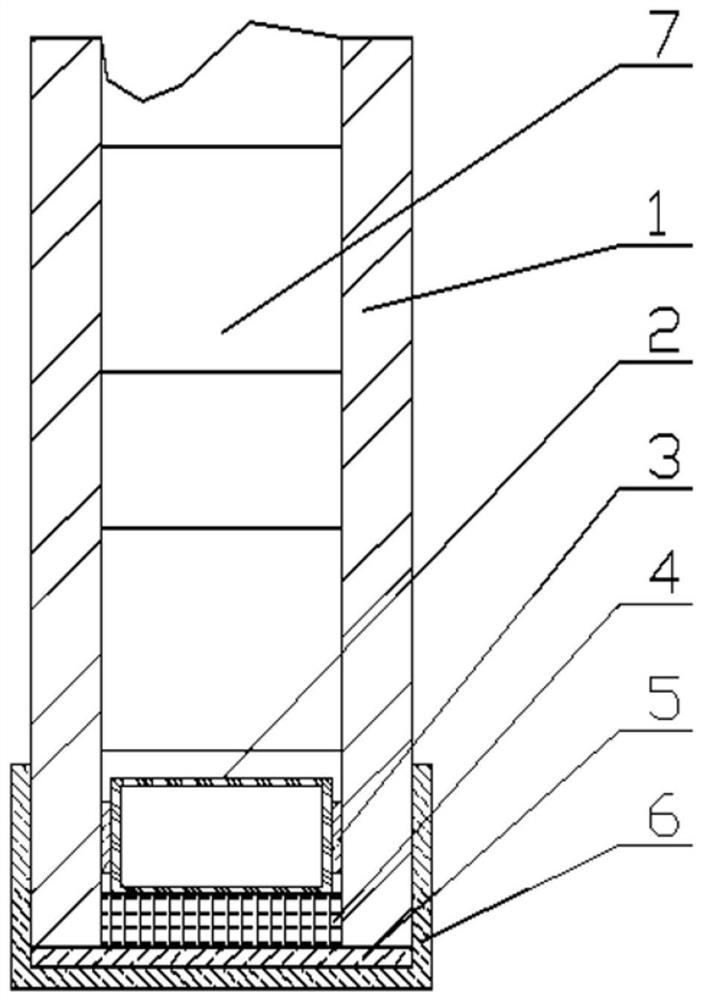

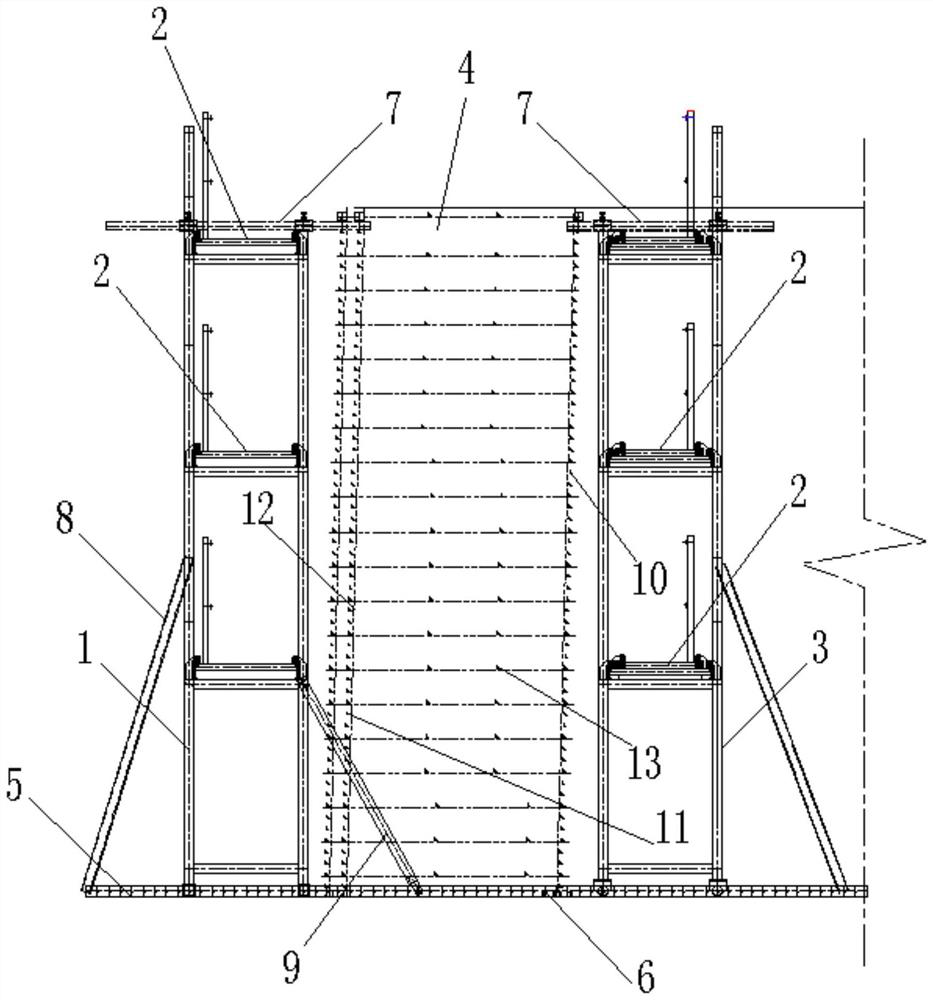

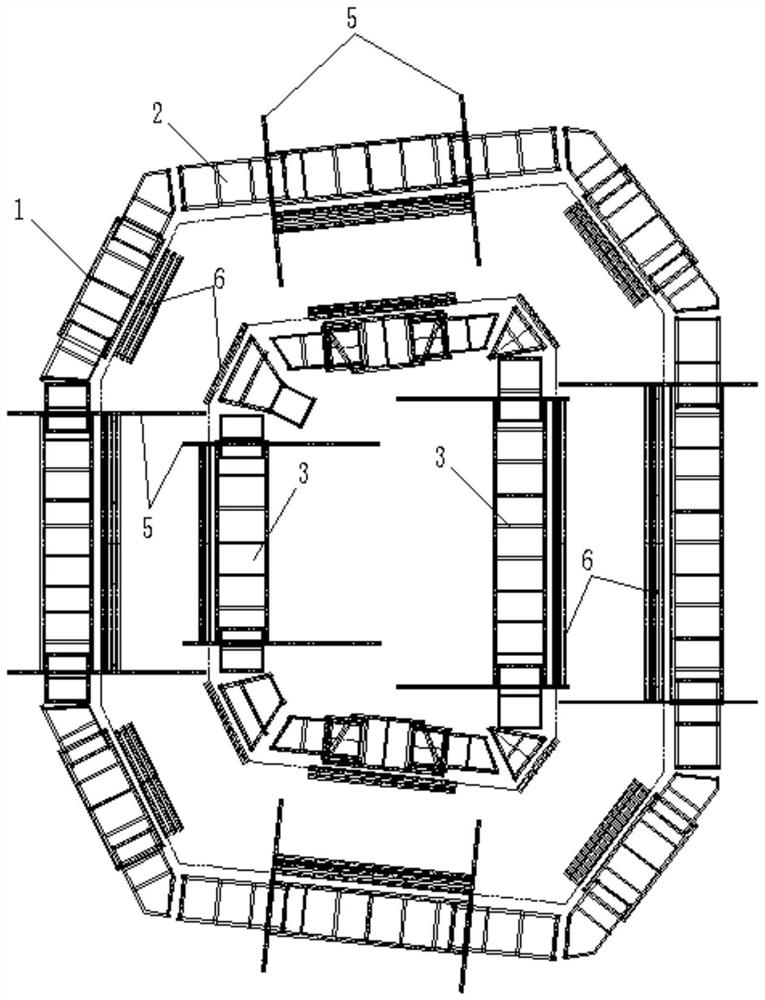

Movable filling template for tunnel bolt-shotcrete support concrete trolley and construction technology thereof

ActiveCN108194106AAvoid wastingShort construction timeUnderground chambersTunnel liningTunnel constructionShotcrete

The invention relates to the field of tunnel construction, and specifically discloses a movable filling template for a tunnel bolt-shotcrete support concrete trolley and a construction technology thereof. The construction technology specifically includes the following steps that first, a sprayed rock surface is treated; second, concrete is stirred and transported; third, a cave wall is closed; fourth, the movable filling template is arranged in place; fifth; the filling operation is carried out; and sixth, the maintenance is carried out. Bolt-shotcrete supporting is carried out successively through a slipping form trolley, and the waste caused by concrete rebound is avoided. The construction time is short, the automation level is high, and the labor cost is reduced.

Owner:涪特智能装备(重庆)有限公司

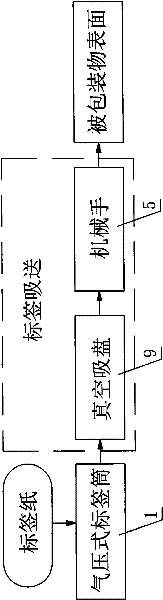

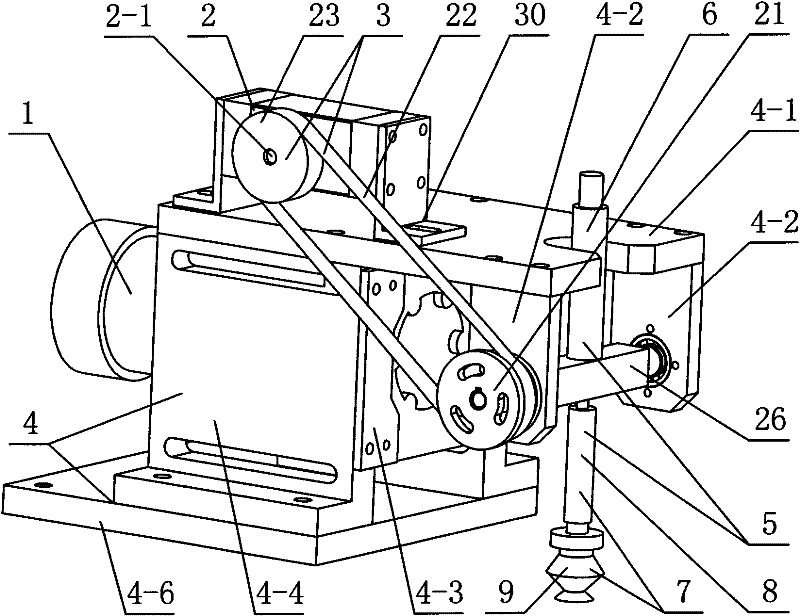

Paper label suction and conveying mechanism

The invention particularly relates to a paper label suction and conveying mechanism. The paper label suction and conveying mechanism comprises a pneumatic label cylinder (1), a swing cylinder (2), a synchronous belt transmission device (3), a support saddle (4), a mechanical hand (5) and a rotating shaft (26), wherein a synchronous belt wheel II (23) of the synchronous belt transmission device (3) is connected with the swing cylinder (2), a synchronous belt wheel I (21) is connected with the rotating shaft (26), and the rotating shaft (26) is movably connected with the support saddle (4); and the mechanical hand (5) comprises a cylinder (6) and a vacuum paw combination (7), the vacuum paw combination (7) comprises a cylinder connecting rod (8) and a vacuum sucking disc (9), the cylinder (6) is connected with the rotating shaft (26), the cylinder connecting rod (8) is respectively connected with the cylinder (6) and the vacuum sucking disc (9), an airway hole (8-1) is formed in the cylinder connecting rod (8), and one end of the airway hole (8-1) is communicated with the vacuum sucking disc (9). The paper label suction and conveying mechanism disclosed by the invention has the advantages of high production efficiency of placing label paper, low cost, high speed and good quality.

Owner:CHANGZHOU YONGSHENG NEW MATERIALS EQUIP CO LTD

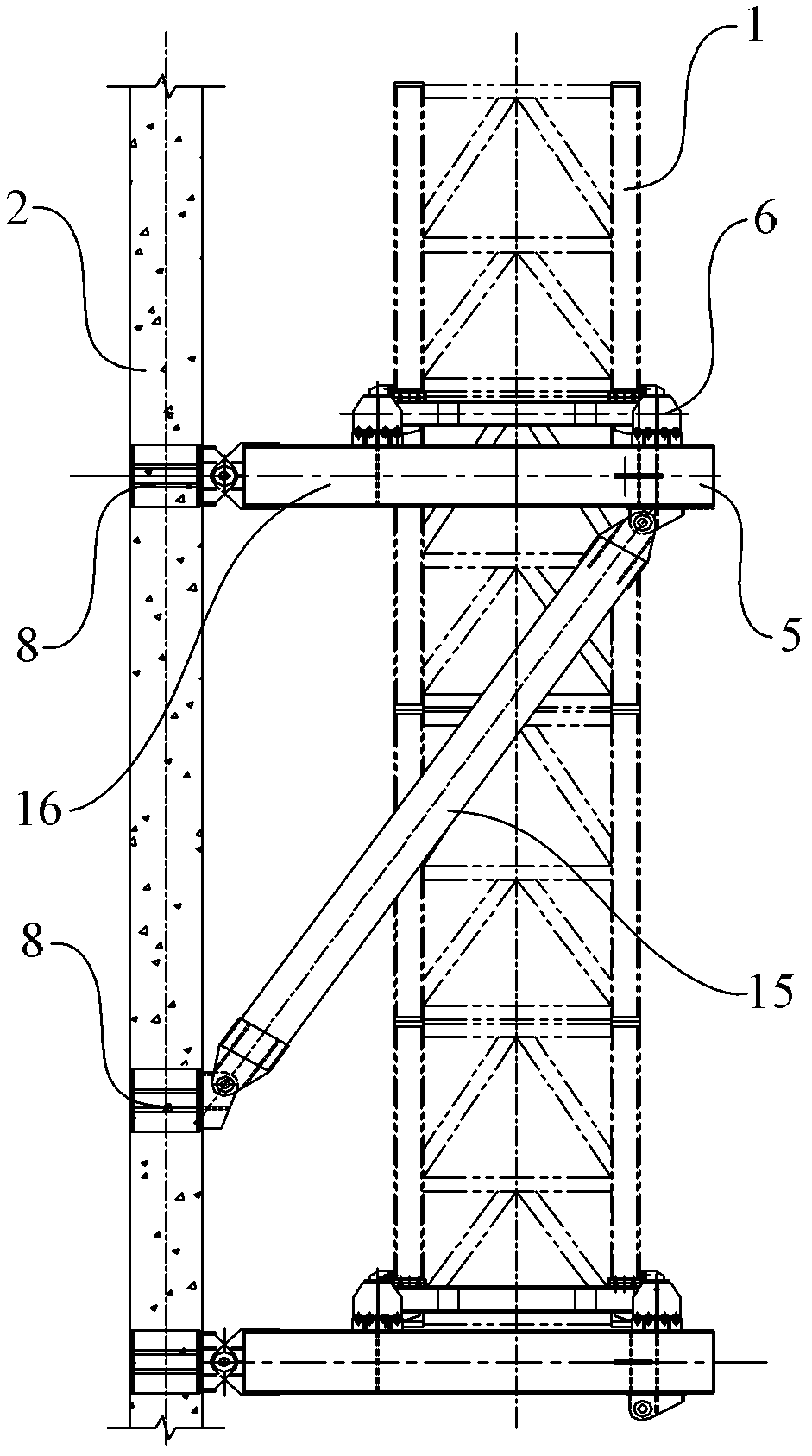

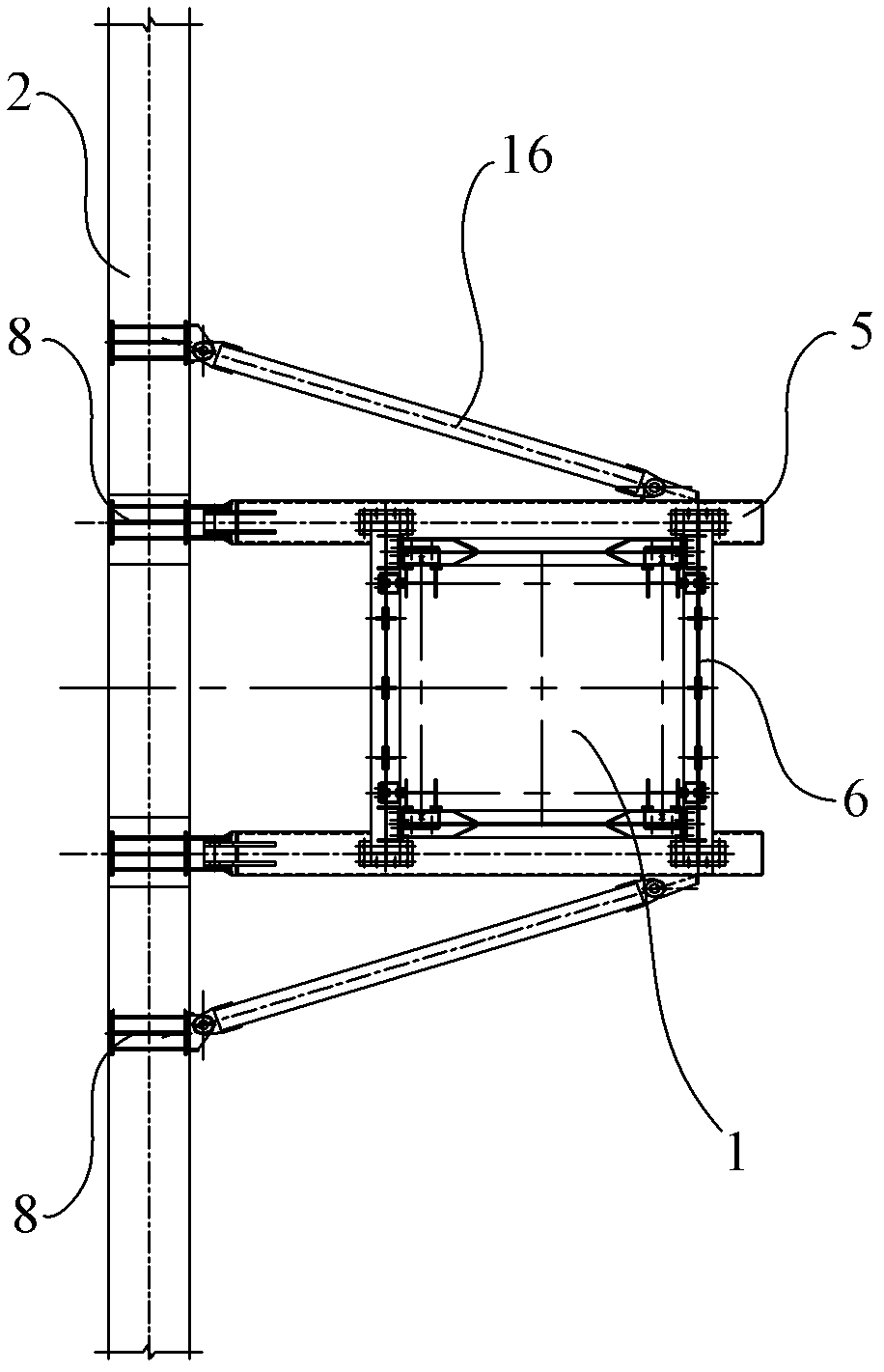

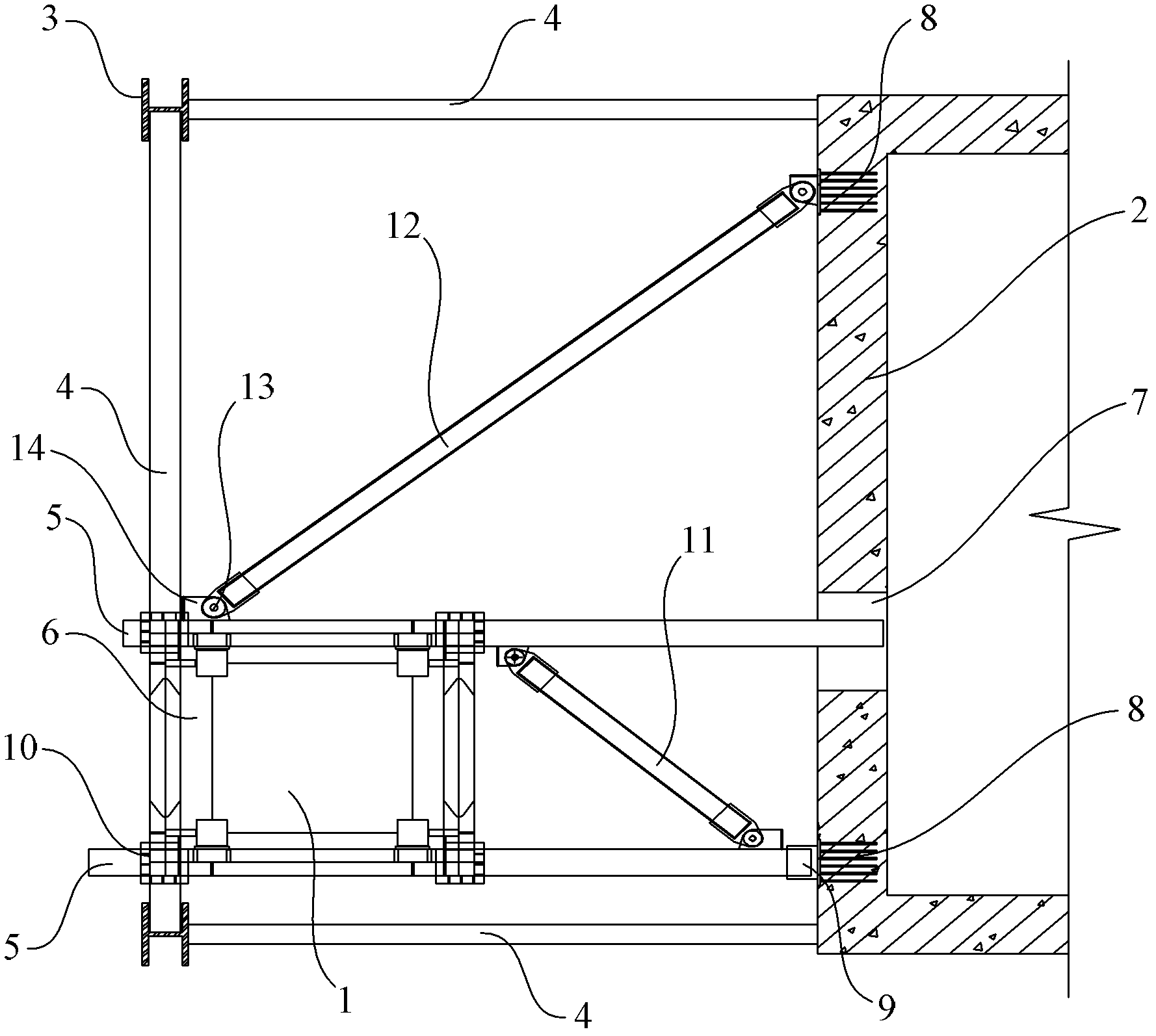

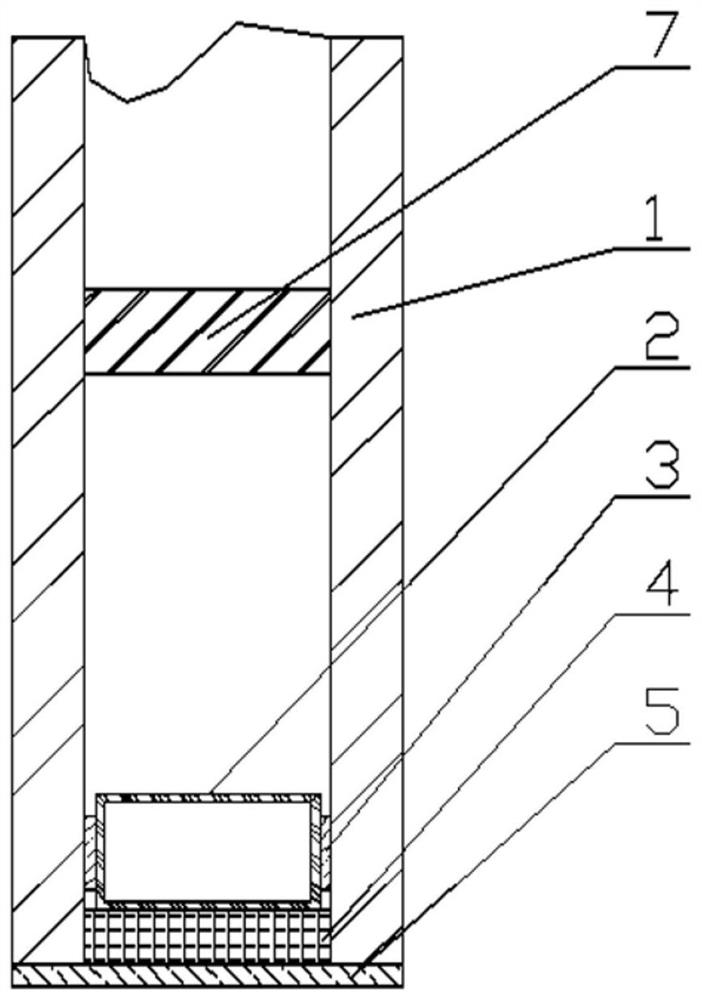

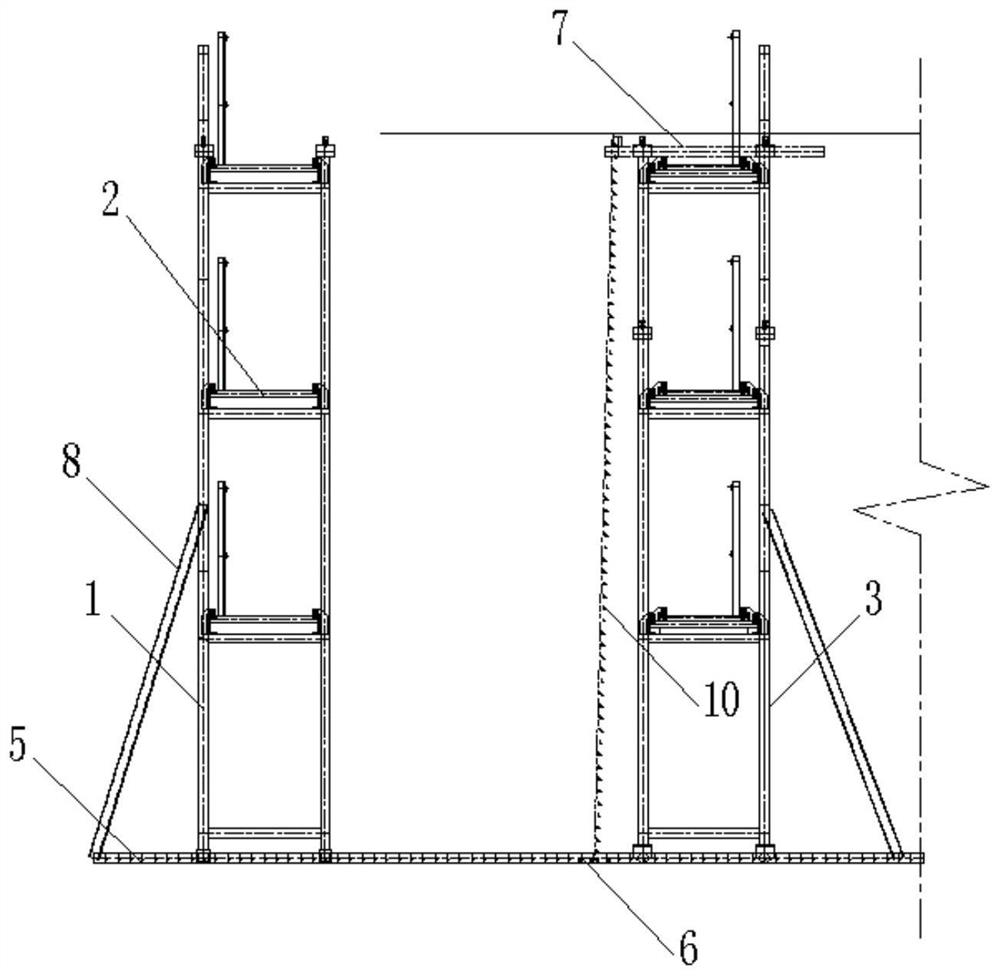

Support structure of internal-climbing tower crane

The invention provides a support structure of an internal-climbing tower crane, which is used for supporting an internal-climbing tower crane body and arranged on the outer side of a core tube shear wall. The support structure of the internal-climbing tower crane comprises two steel columns, a steel beam, two support beams and an internal-climbing frame. Compared with a support structure of an external-hanging internal-climbing tower crane in the prior art, the support structure of the internal-climbing tower crane is provided with the steel columns and the steel beam, reduces quantity of embedded parts required by each support, enables the support beams to obtain four-point support, enables the internal-climbing frame arranged on the two support beams to be firm, and improves safety of the internal-climbing tower crane in climbing or use.

Owner:SHANGHAI CONSTRUCTION GROUP +1

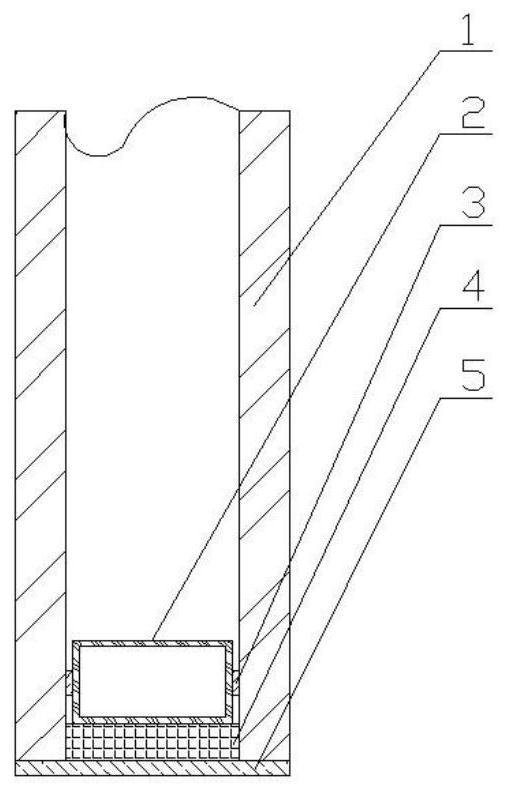

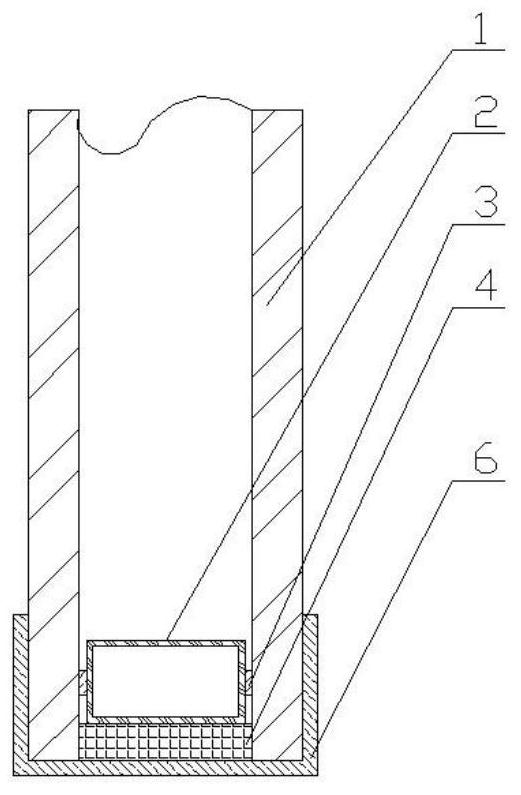

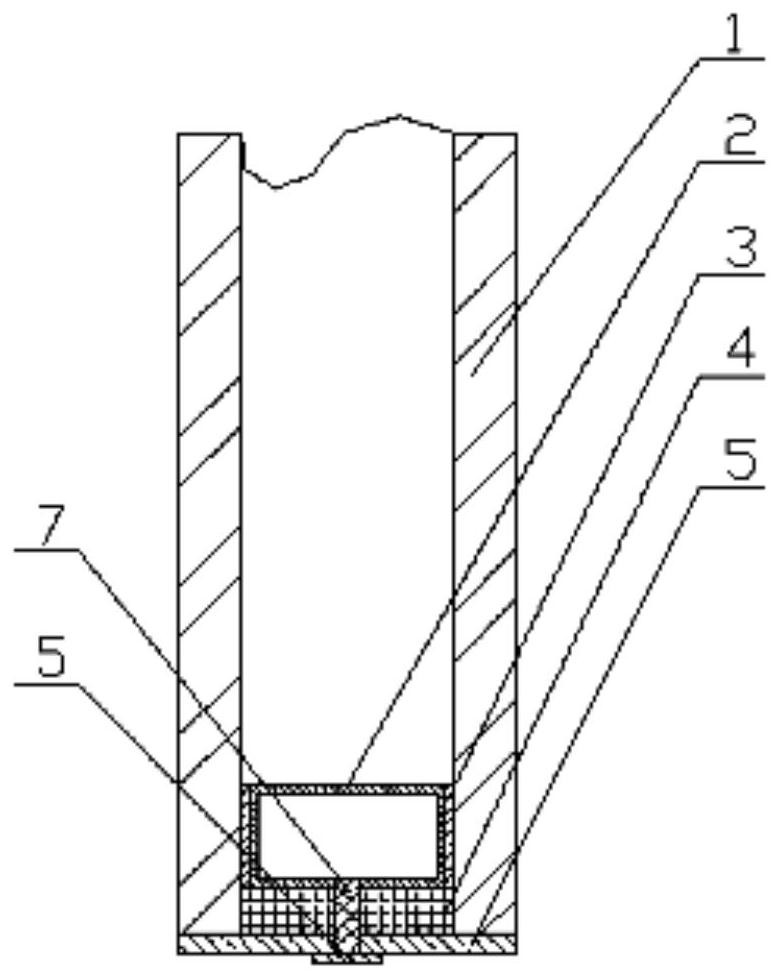

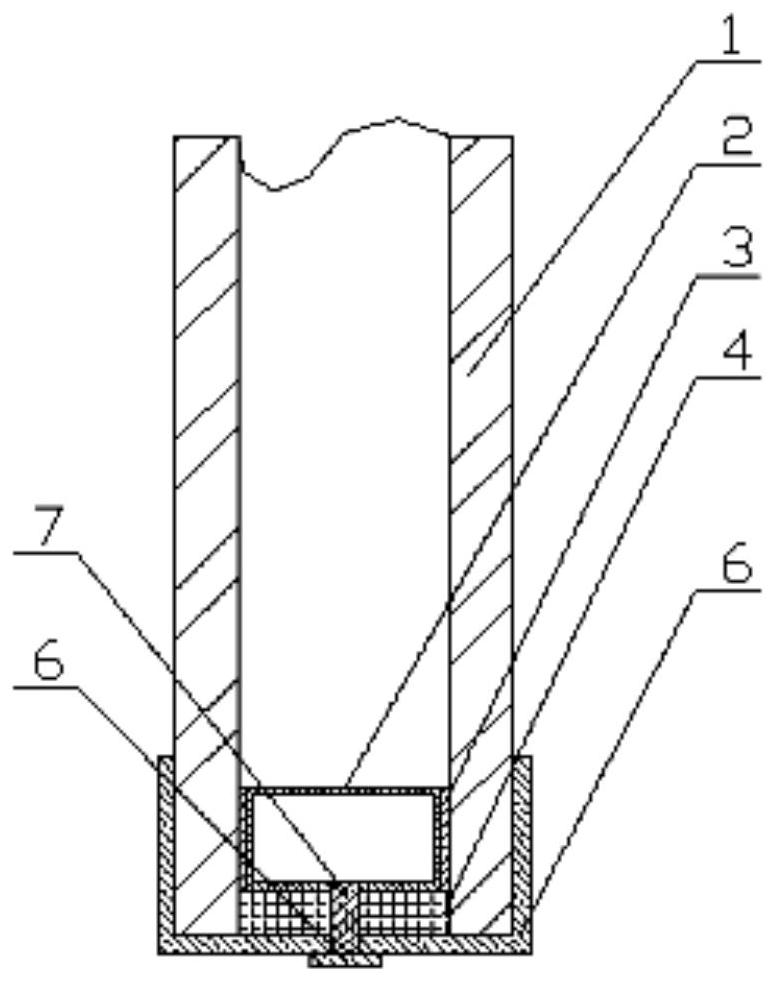

Negative-pressure hollow glass, manufacturing method and application

PendingCN112431519AEliminate respirationExtended service lifeConstruction materialWallsMolecular sievePumping vacuum

The invention belongs to the technical field of hollow glass production, and discloses negative-pressure hollow glass, a manufacturing method and application. The negative-pressure hollow glass comprises glass, spacing bars, molecular sieves, supporting materials, sealing layers bonded between the glass and the spacing bars, and sealing layers bonded between the glass and the peripheries of the spacing bars. A hollow layer is vacuumized to be in a negative pressure state, the air pressure of the hollow layer is smaller than the external pressure all the time in the use process of the hollow glass, the breathing phenomenon of the hollow glass is eliminated, an edge sealing structure is not subjected to repeated acting force generated by the breathing phenomenon, and the service life of theedge sealing structure and the service life of the hollow glass can be remarkably prolonged; due to the fact that the supporting materials are arranged in the hollow layer, the glass cannot deform, agood mirror surface effect can be kept all the time, and the appearance of a building is more attractive; and the spacing bars are adopted to replace spacing frames to be directly bonded on the glass,the technological process of manufacturing the spacing frames is omitted, mechanical and automatic production is facilitated, the placement speed is high, and the installation precision is high.

Owner:WEIHAI RUNFENG GLASS

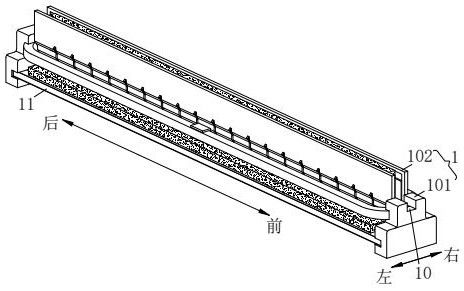

Method for quickly positioning reinforcing mesh and precisely forming and assembling segmental reinforcing bar components

ActiveCN112342920AControl precisionFast placementBridge erection/assemblyArchitectural engineeringMesh reinforcement

The invention discloses a method for quickly positioning a reinforcing mesh and precisely forming and assembling segmental reinforcing steel bar components. The method comprises the following steps of: 1, a rail sliding device is arranged, and inner and outer side moving platforms are erected; 2, a bottom positioning device is installed, and a reinforcing mesh is hoisted in; 3, after the inner-layer steel bar mesh is hoisted in, the tops of the steel bars are fixed through an inner-layer top positioning device; 4, after the secondary outer-layer reinforcing mesh is hoisted in, a temporary supporting device is adopted for fixing; 5, after the outermost layer of reinforcing mesh is hoisted in, the two outer layers of reinforcing meshes are fixed through an outer side top positioning device;6, the drag hook ribs are inserted and bound in a penetrating mode, and assembling and splicing of the steel bar components are completed; and 7, the top positioning device is dismounted, the sectionof steel bar component is lifted out, and the next section of steel bar component is assembled. According to the method, high-altitude operation of high piers, high towers and the like is effectivelyconverted into bottom surface operation, the specialization and industrialization degree of steel bar construction is remarkably improved, cost reduction and efficiency increase are achieved, and highpopularization value is achieved.

Owner:CCCC SECOND HARBOR ENG +2

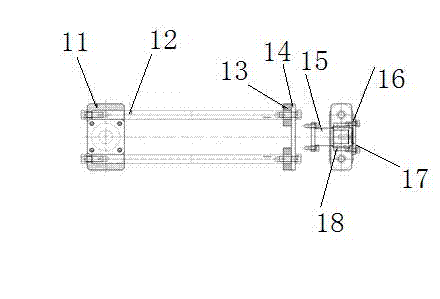

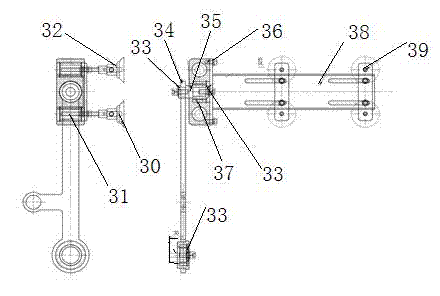

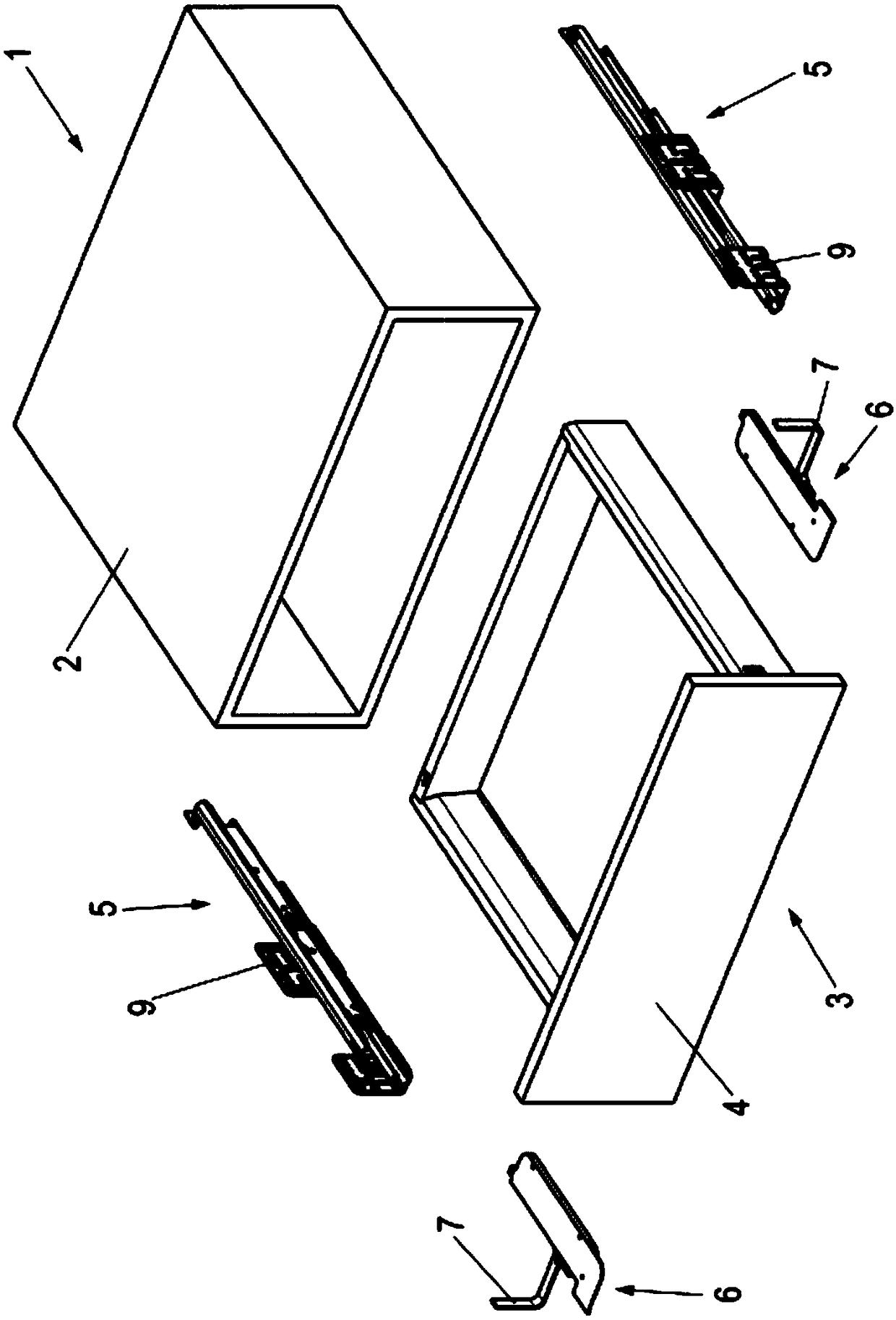

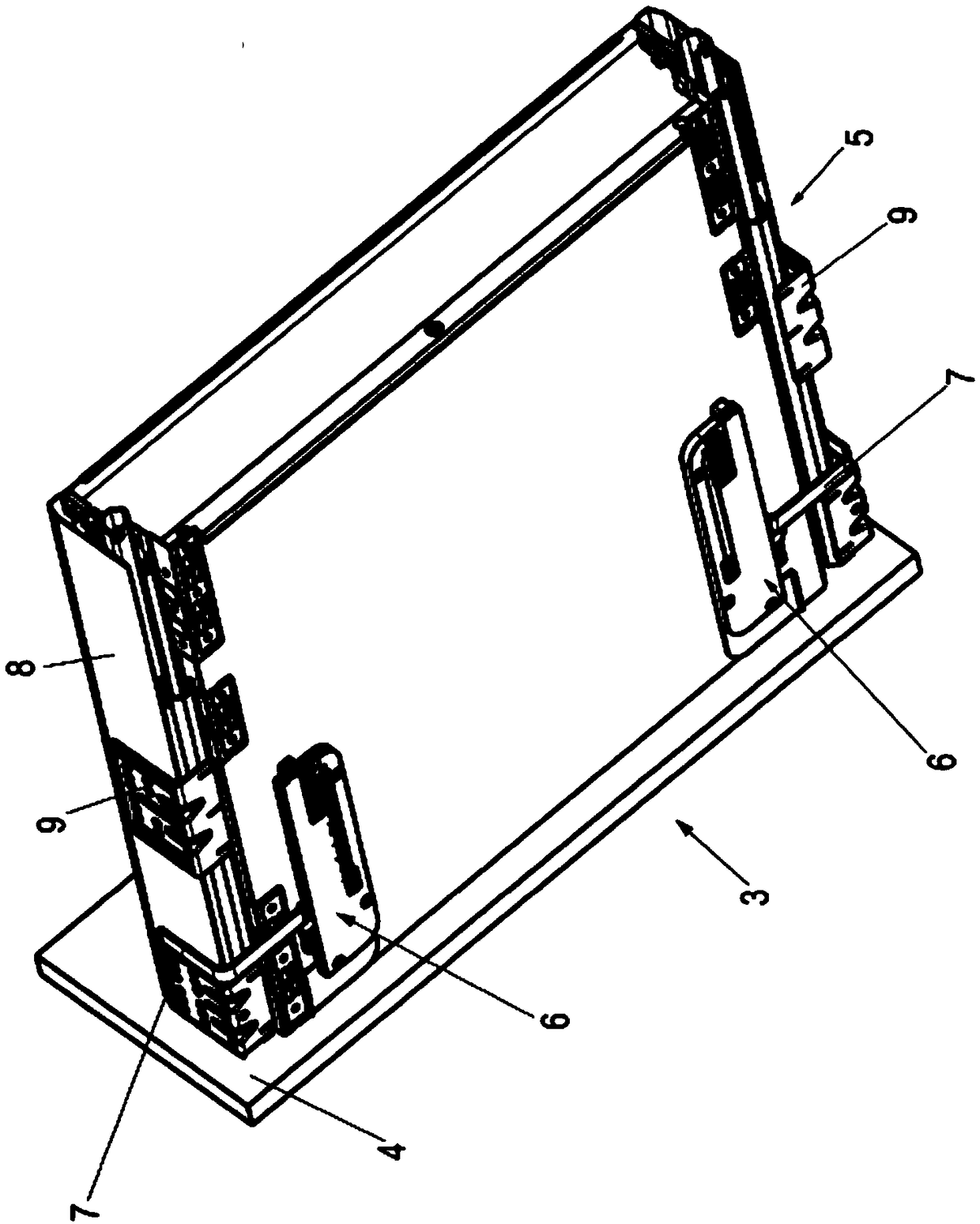

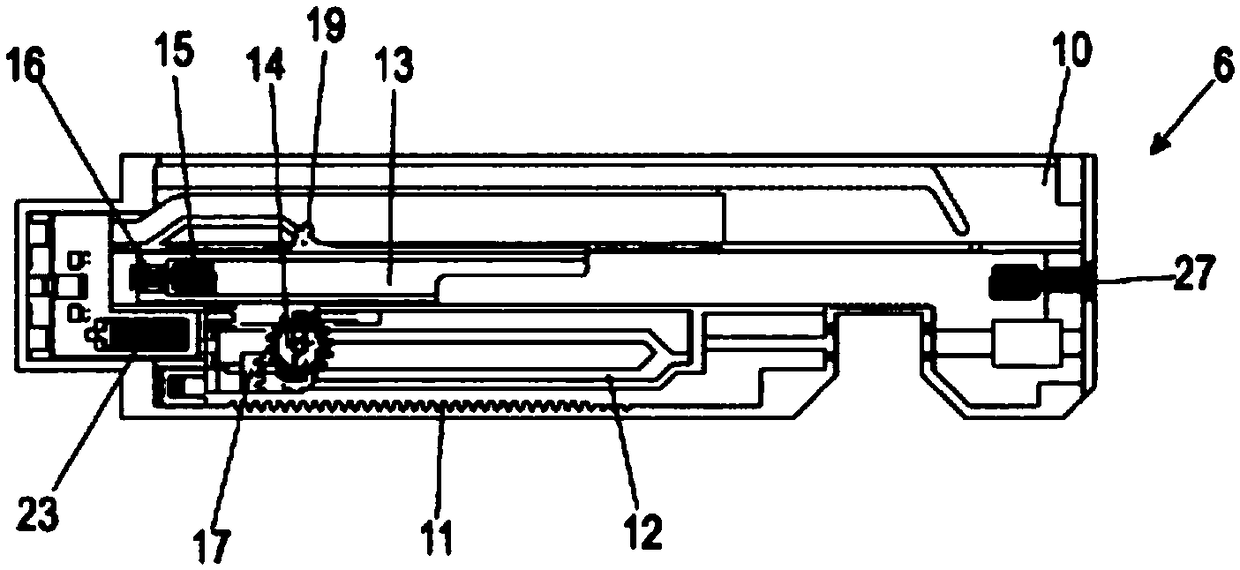

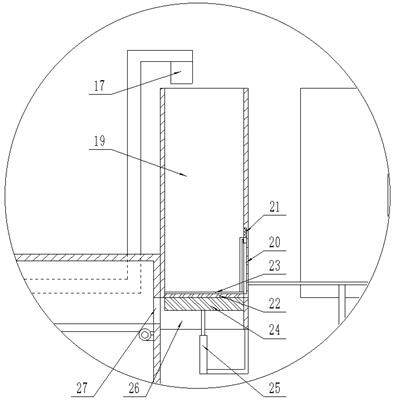

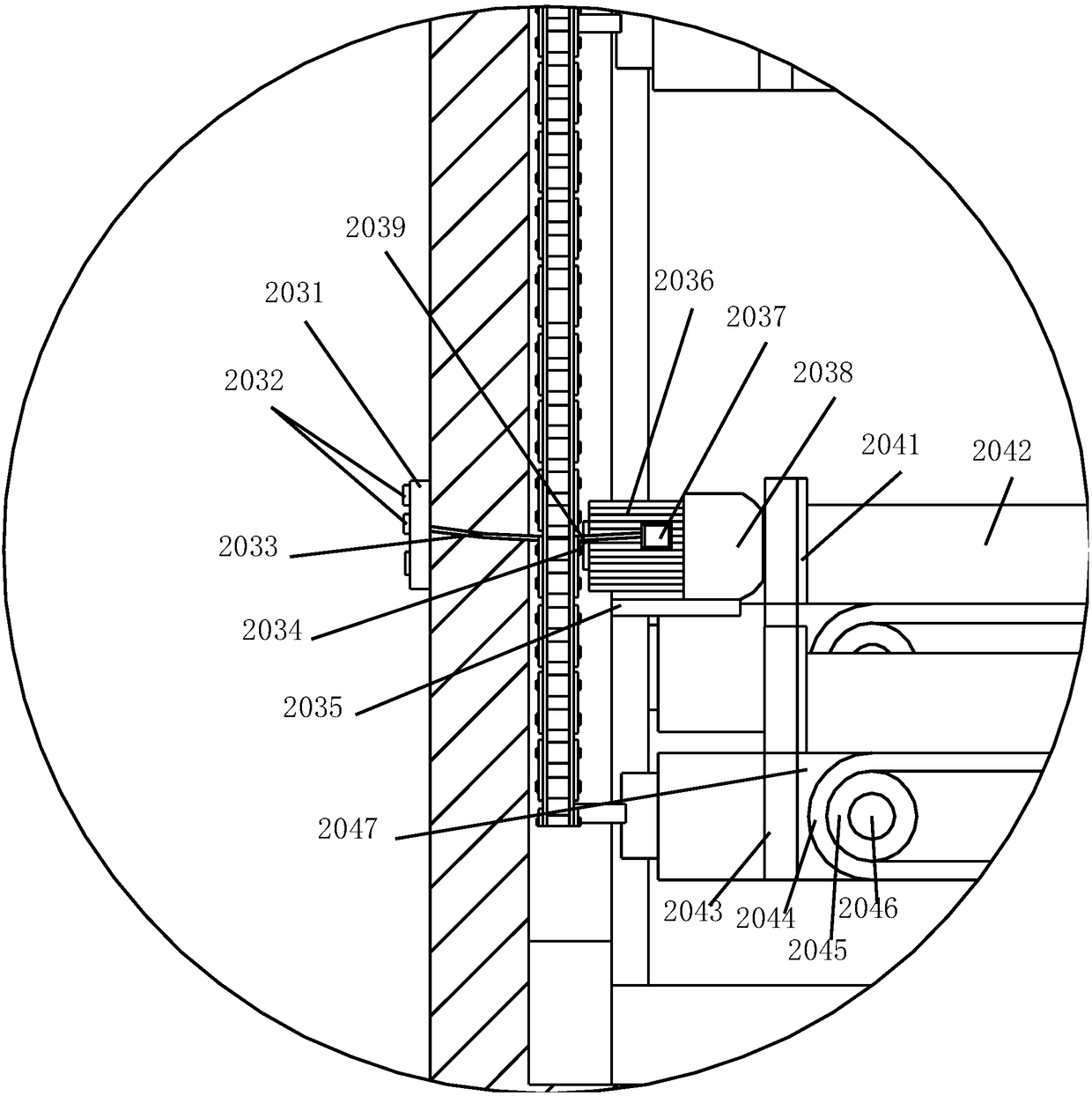

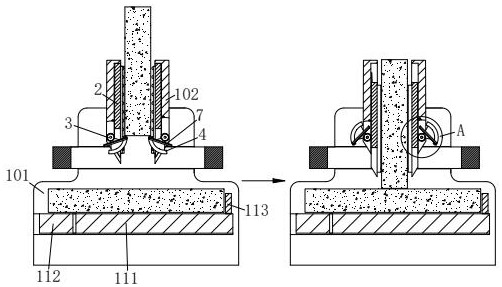

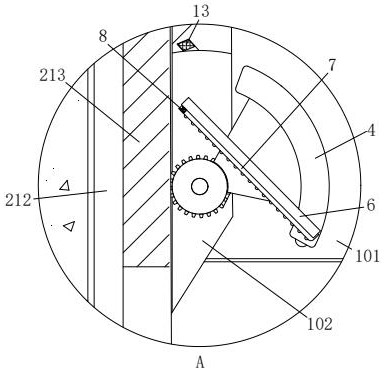

Ejection device for movable furniture part, and piece of furniture

The invention relates to an ejection device (6, 6') for a movable furniture part (3) comprising a drive element (19, 19'), which is preloaded by at least one spring (15) and by means of which the movable furniture part (3) can be moved from a closed position into an open position, wherein the at least one spring (15) can be moved into a loaded position during a closing or opening motion of the furniture part (3) along a displacement distance and the furniture part (3) can be locked with the at least one loaded spring (15) in the closed position, wherein a backstop is provided, which limits a closing or opening motion of the movable furniture part (3) if the loading of the spring (15) during a closing or opening motion of the furniture part (3) is not yet concluded, wherein the backstop hasa pinion (14) guided in a guide track (12, 12'), which pinion engages with a gear rack (11, 11') during a closing motion and can be locked by means of a locking element (17). The backstop can thus absorb high holding forces.

Owner:PAUL HETTICH

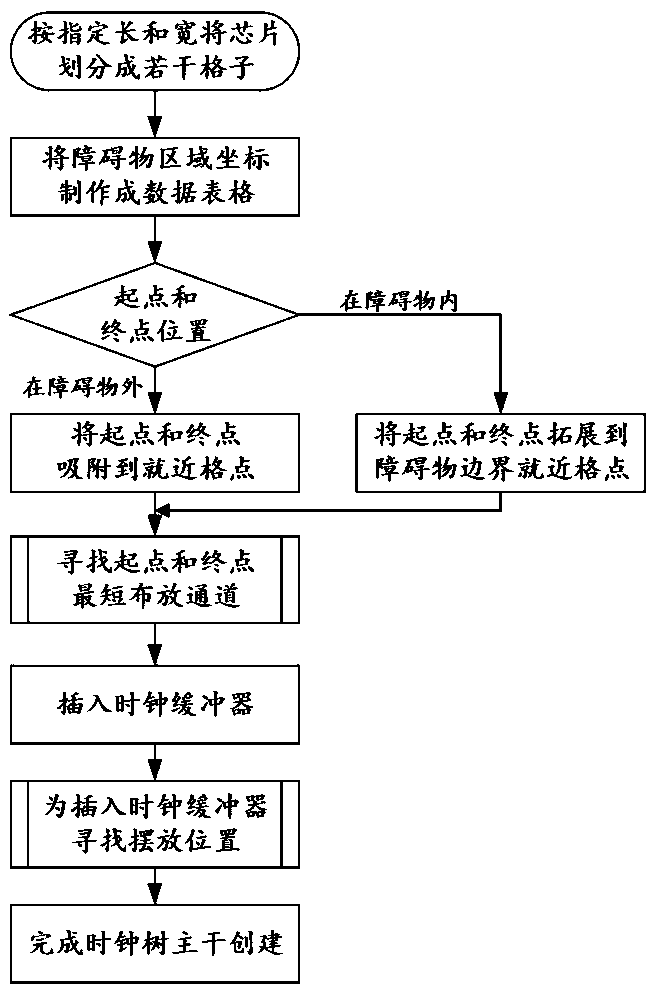

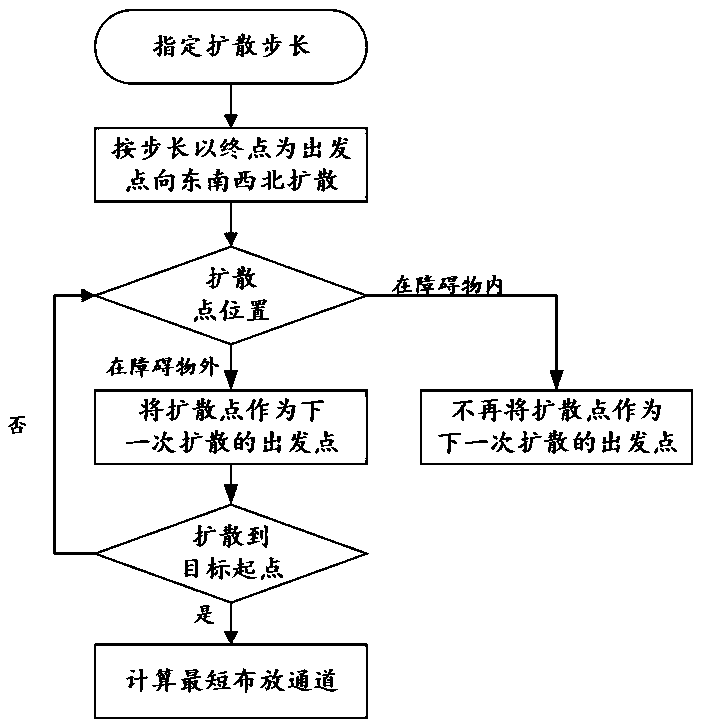

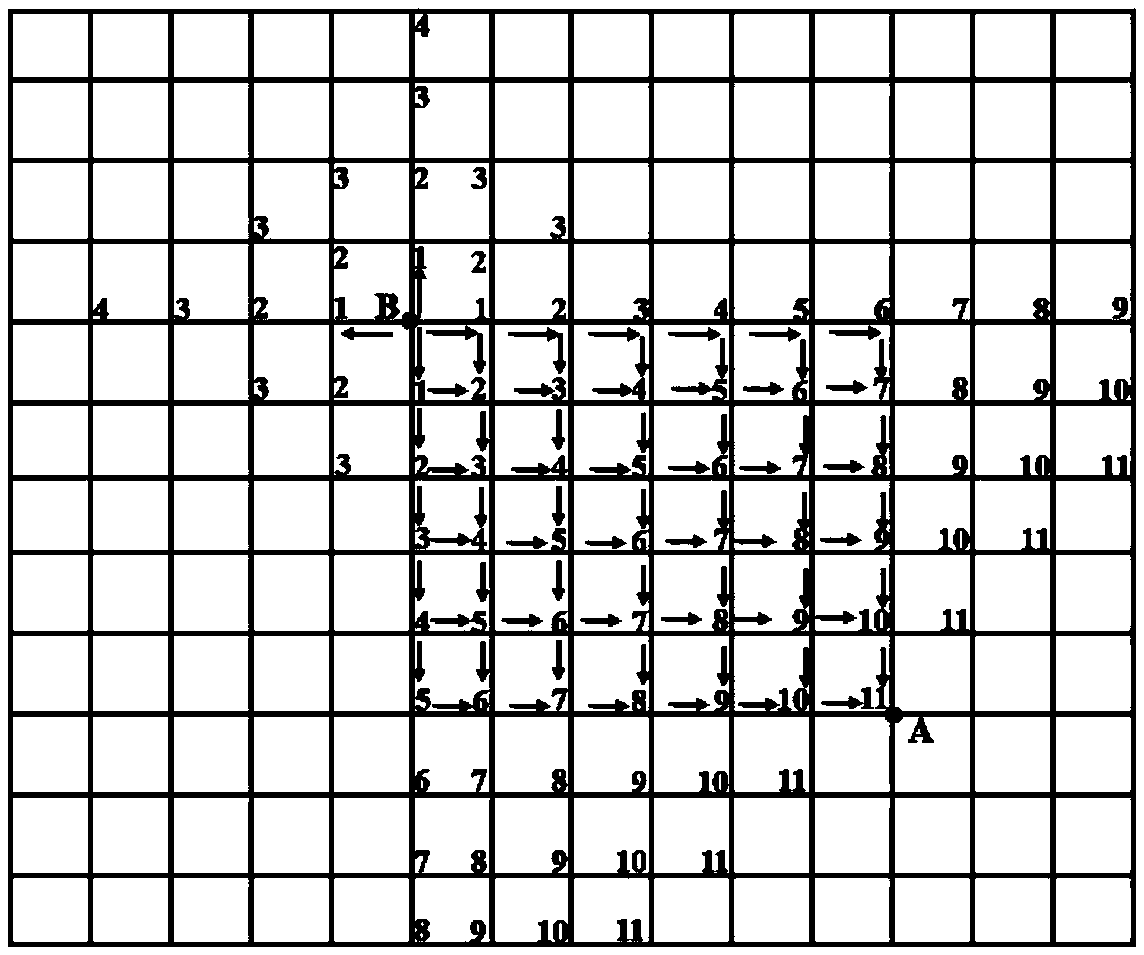

A clock tree trunk topology generation method and system capable of perceiving integrated circuit layout information

ActiveCN109933857AImprove performanceFast placementEnergy efficient computingSpecial data processing applicationsCapacitanceClock tree

The invention discloses a clock tree trunk topology generation method and system capable of perceiving integrated circuit layout information. The clock tree trunk topology generation method comprisesthe following implementation steps: dividing a full-chip layout into a plurality of grids; Finding out an obstacle position area in the full chip; Judging the position relation between the target point and the obstacle position area, and adhering or expanding the starting point and the end point coordinate point to grid intersection points near the obstacle boundary; Obtaining a shortest grid distribution channel between the target point and the terminal point; And inserting clock buffers into the channel with the shortest total step length according to a specified interval, searching an available placement position near an insertion point of the clock buffers to finish placement of the clock buffers, and finishing generation of clock tree trunks. Through path finding of the clock tree trunk of the core and protection of clock signal winding, the clock tree trunks of a plurality of clocks are created on the CPU chip, the coupling capacitance of other signals to clock signals is reducedto the minimum, the transmission quality of the clock signals is ensured, and the performance of the chip is improved.

Owner:PHYTIUM TECH CO LTD

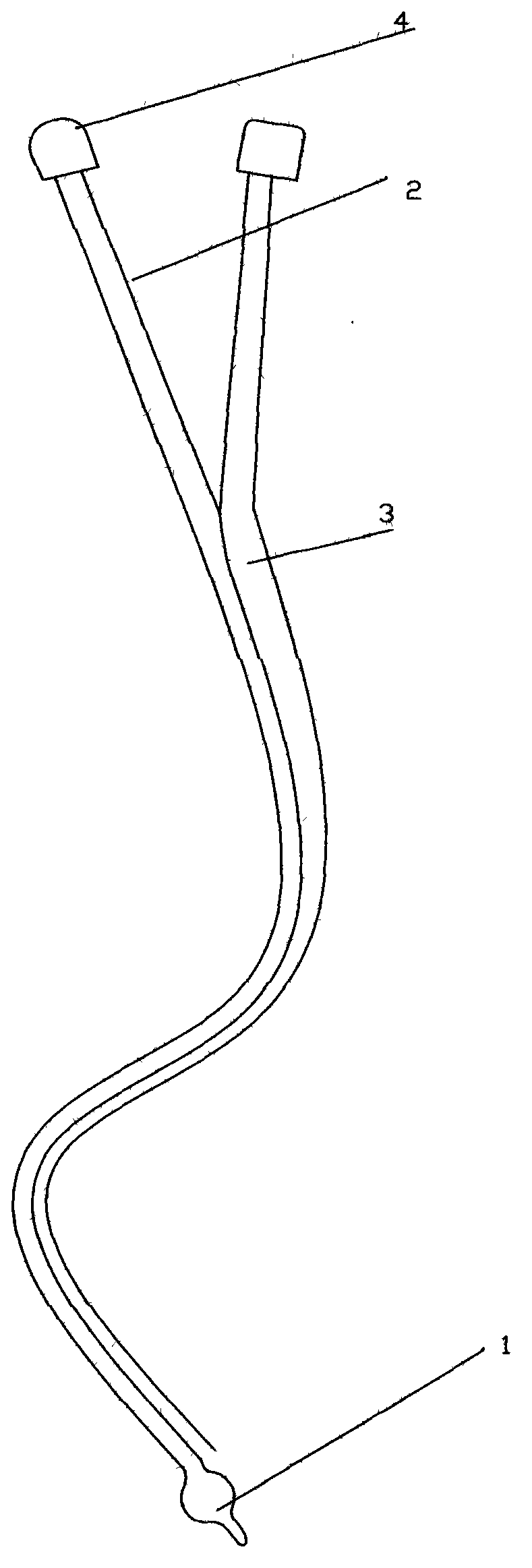

Balloon type double-cavity duodenum or jejunum nutrient canal

InactiveCN103767880ARelieve painImprove placement success rateFeeding-tubesIntestinal wallsNutrient canal

The invention relates to a medical supply, in particular to a balloon type double-cavity duodenum or jejunum nutrient canal. A nutrient liquid filling opening is formed in the upper end of the nutrient canal, and an opening is formed in the lower portion of the nutrient canal. The balloon type double-cavity duodenum or jejunum nutrient canal is characterized in that gas filling tubes are synchronously arranged on the nutrient canal in parallel, a gas filling opening is formed in the upper end of each gas filling tube, and an inflating balloon is arranged at the lower end of each gas filling tube; in use, after the balloon type double-cavity duodenum or jejunum nutrient canal is placed in the duodenum or the jejunum through a gastroscope, the inflating balloons are filled with a certain amount of air so that the nutrient canal can be fixed to the intestinal wall of the duodenum or the jejunum and will not retract along with the gastroscope, and gas in the inflating balloons is pumped out after the gastroscope retracts.

Owner:杨廷旭

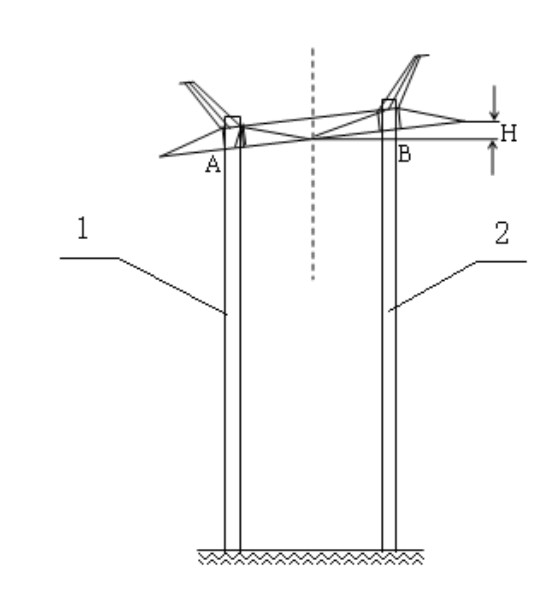

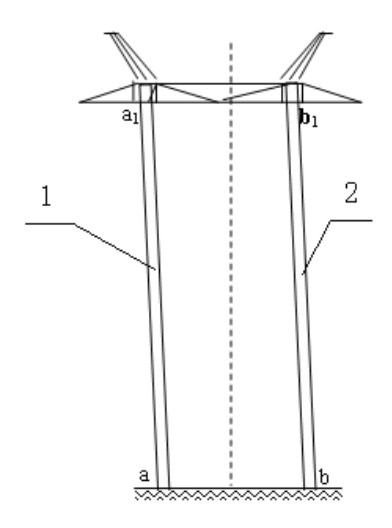

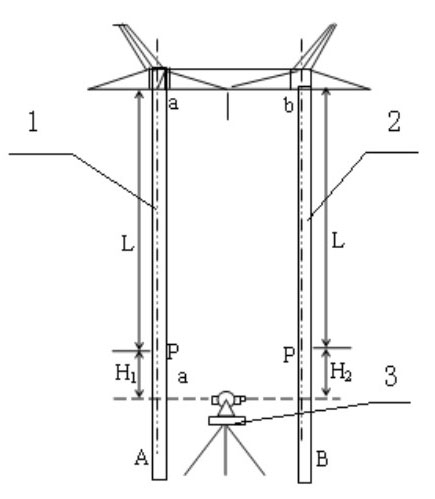

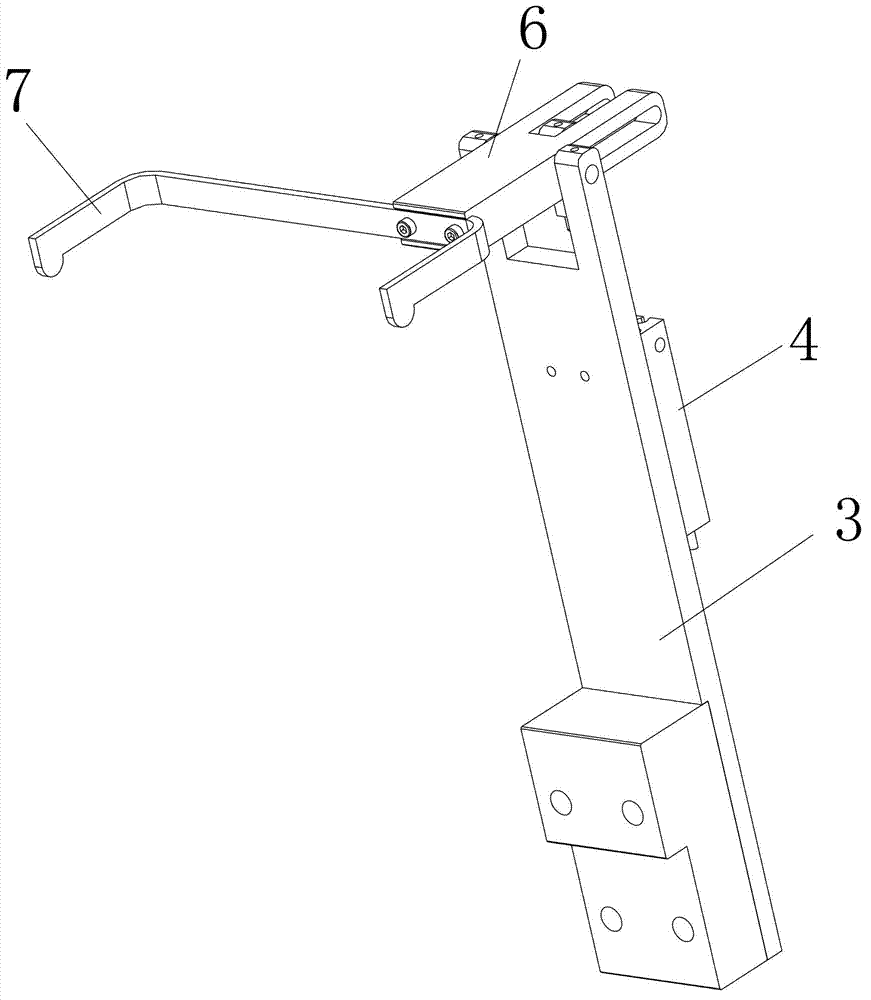

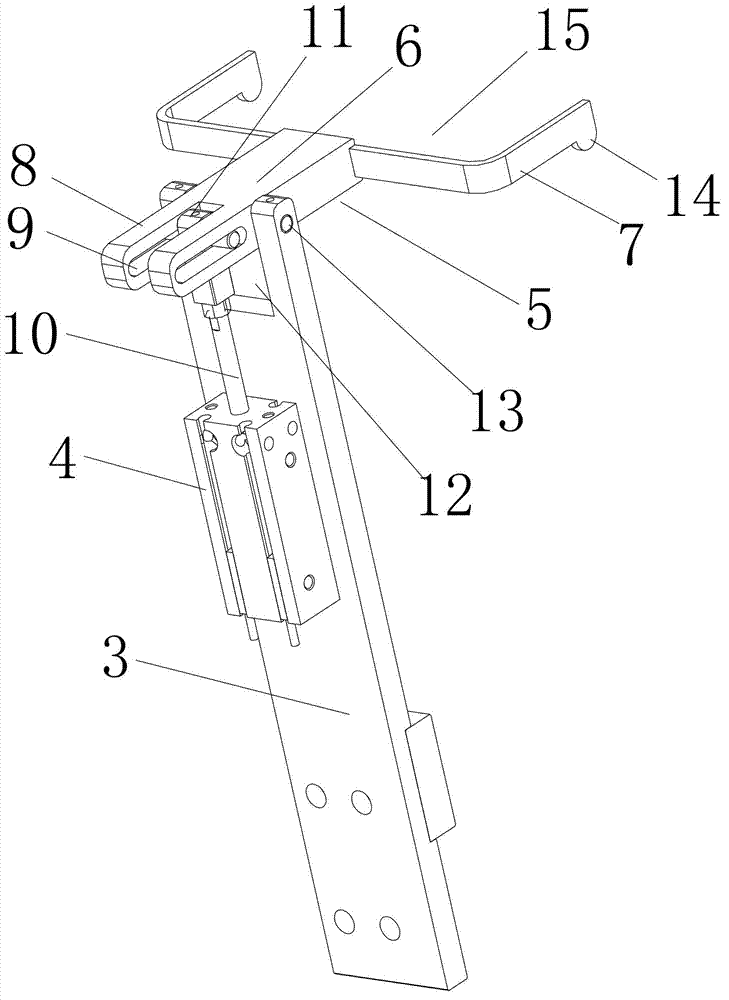

Method for checking height difference between joints of cross arms for cross arms of dual-column pole tower

InactiveCN102023001ASolve problems with measurement inspectionsFast placementHeight/levelling measurementMechanical measuring arrangementsElevation angleTheodolite

Owner:ELECTRIC POWER OF HENAN LUOYANG POWER SUPPLY +1

Glass coating machine and coating process thereof

PendingCN112808523AAvoid damageQuick positioning clampingLiquid surface applicatorsCoatingsElectric machineTransmission belt

The invention discloses a glass coating machine and a coating process thereof. The device comprises a main supporting frame; a main motor is fixedly connected to the upper end of the main supporting frame; a rotating support is horizontally and fixedly connected to the main shaft end of the main motor; main hydraulic telescopic rods are fixedly connected to the upper side of the left end of the rotating support in a vertically symmetrical mode; and a glass conduction mechanism and a coating box are arranged on the rear side of the left end of the rotating support. An auxiliary driving motor is started, so that the auxiliary driving motor drives a rotating guide plate to slowly rotate anticlockwise, and coating slurry on the rotating guide plate downwards flows to fall on a glass plate due to inclination of the rotating guide plate; a high-speed driving motor is started, and the high-speed driving motor drives a transmission disc to rotate at a high speed, so that cutters linearly distributed on a transmission belt are operated and translated rightward along with a coating box to cut off a coating slurry part higher than the lower end of a lifting side plate, and it is guaranteed that the slurry attached to the upper end surface of the glass plate is uniform in thickness.

Owner:尚刘镇

Point-bonding sealed hollow glass and manufacturing method thereof

PendingCN112412275AReduce contact areaImprove insulation performanceConstruction materialClimate change adaptationMolecular sieveAdhesive

The invention discloses point-bonding sealed hollow glass. The hollow glass comprises a plurality of pieces of glass, a plurality of spacing bars, a first sealing adhesive, a molecular sieve, and at least one of a second sealing adhesive, a third sealing adhesive and a fourth sealing adhesive; the spacing bars are arranged between the adjacent pieces of glass; the spacing bars are arranged on theperiphery of the glass in a segmented mode to form a closed spacing frame; the molecular sieve is filled in the spacing frame; the first sealing adhesive is arranged between the glass and the spacingbars; the second sealing adhesive is arranged between the adjacent pieces of glass and is positioned on the outer side edges of the spacing bars; or the third sealing adhesive is arranged between theadjacent pieces of glass and located on the outer side edges of the spacing bars; or the third sealing adhesive is arranged between the adjacent pieces of glass and located on the outer side edge of the second sealing adhesive; or the fourth sealing adhesive is arranged at the edge parts of the side surface and the outer surface of the adjacent glass. The point-bonding sealed hollow glass is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality, and the service life of the hollow glasscan be greatly prolonged.

Owner:WEIHAI RUNFENG GLASS

Safe forging press for machining automobile starter rotor

InactiveCN110350730AAutomate the placement processEasy to storeManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a safe forging press for machining an automobile starter rotor, and belongs to the technical field of rotor machining. The device comprises a bottom plate, and supporting columns are arranged at the middle of the top end of the bottom plate in bilateral symmetry. A supporting table is arranged at the top ends of the supporting columns. A disc workbench is arranged at the top end of the supporting table. A limiting round block is fixedly arranged at the middle of the bottom end of the disc workbench. According to the invention, through the arrangement of the disc workbench and a matched driving part, the automatic forging and pressing process of the rotor punching sheet can be realized; meanwhile, through the arrangement of a storage sleeve, the automatic placing process of a punching sheet can be realized; through the arrangement of a discharging round hole, an ejector rod, an arc plate, a collecting box and the like on the workbench, the automatic discharging and collecting can be achieved. When the forging press is in use, only a batch of punching sheets need to be manually placed into the storage sleeve, the subsequent continuous punching process can be completed, the punching sheet storage process is simple, the placing speed is high, manual operation is greatly reduced, and potential safety hazards are avoided.

Owner:MAANSHAN HETENG AUTO PARTS

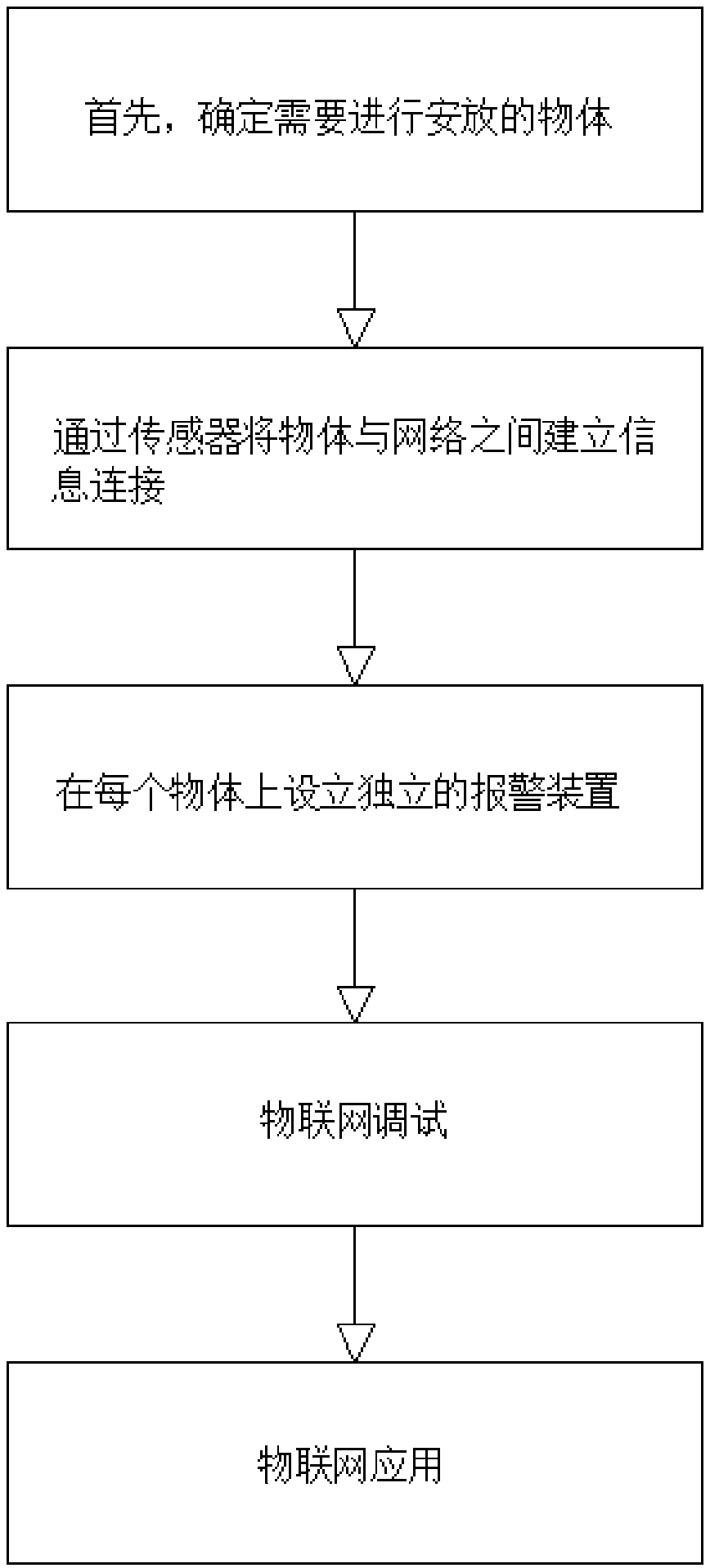

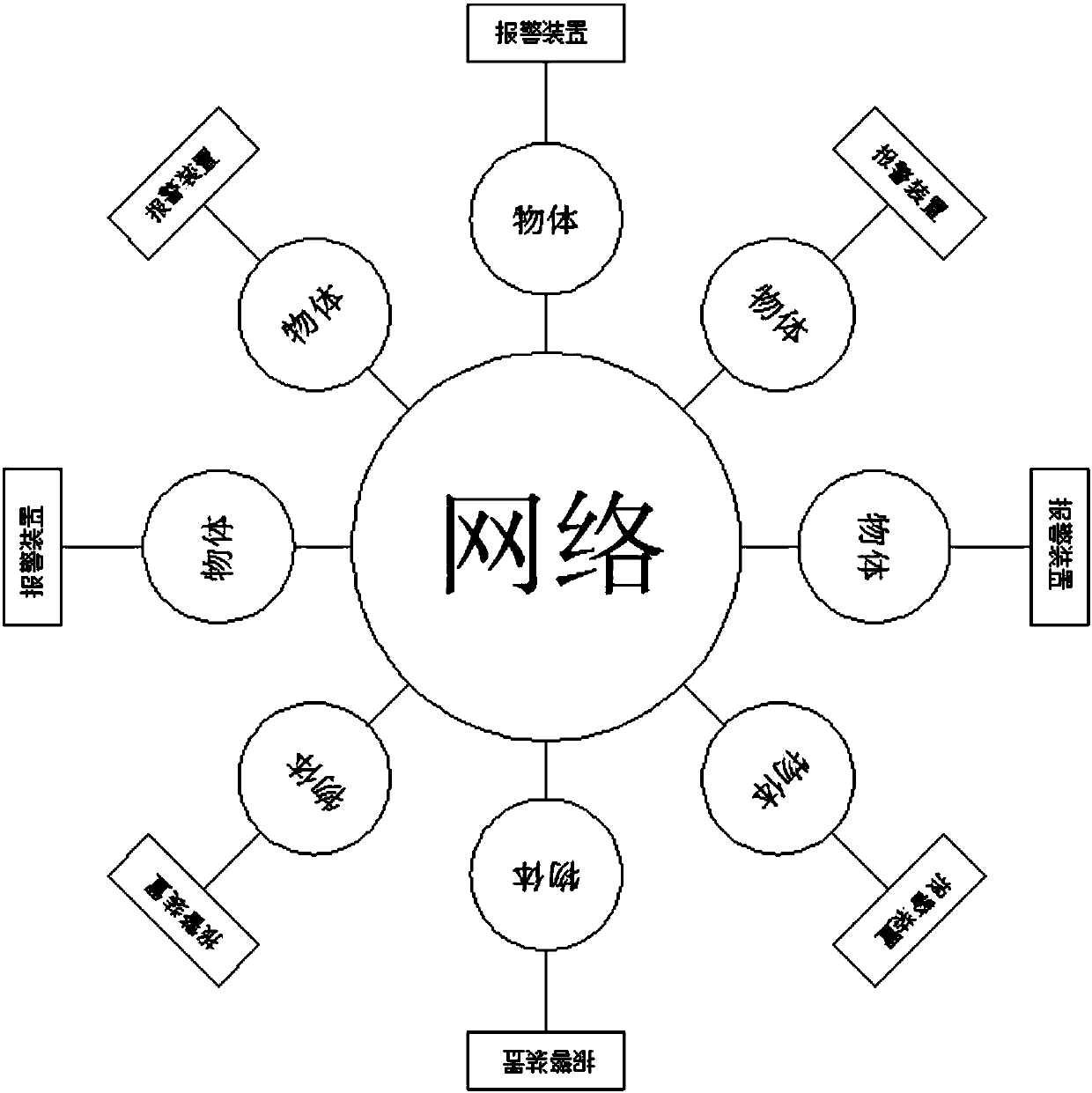

Internet of Things (IoT) installation method capable of warning automatically and automatic warning system

InactiveCN108055332AThe installation process is tightReasonable stepsAlarmsTransmissionSoftware engineeringThe Internet

The invention discloses an Internet of Things (IoT) installation method capable of warning automatically and an automatic warning system. The method comprises the following steps of collecting the information of objects to be installed to grasp a working principle and a connection method of the object, so as to determine multiple kinds of objects needing to build information connections, arrangingthe objects according to a certain space sequence, selecting different sensors and installing the same on each object according to differences of the working principles of the objects, and building the information connections between the sensors and a network, wherein the network separately builds information connection with each object, an alarm device is installed on each object, and each alarmdevice builds information connection with the corresponding object, for detecting whether the alarm device is installed on each object. The method is compact in process and reasonable in step, and can effectively reduce the operation mistake appearing during the installation process, so that the installation speed of the Internet of Things is significantly improved, the degree of intelligence isrelatively high, the problem existing in the installation process can be conveniently found in time, and the overhauling efficiency of the Internet of Things is improved.

Owner:大连威迪欧信息技术有限公司

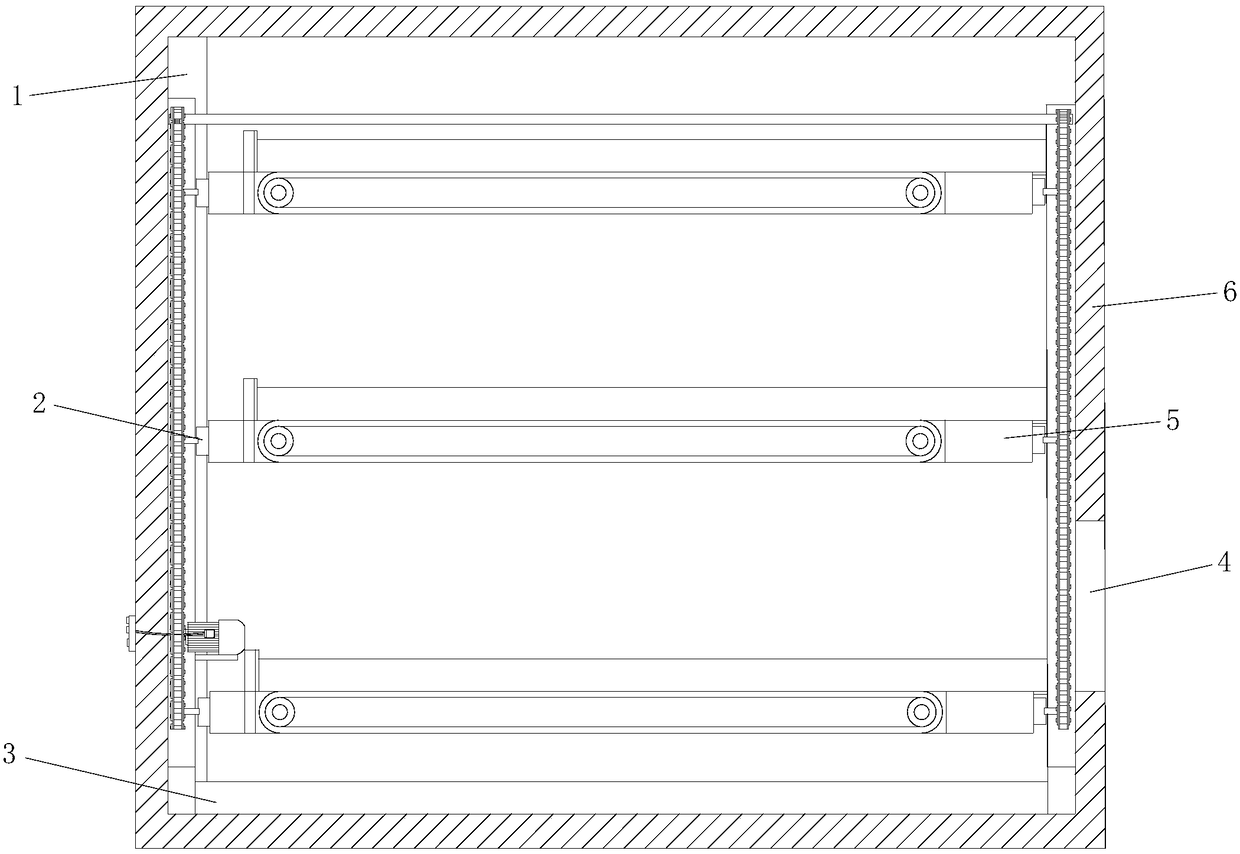

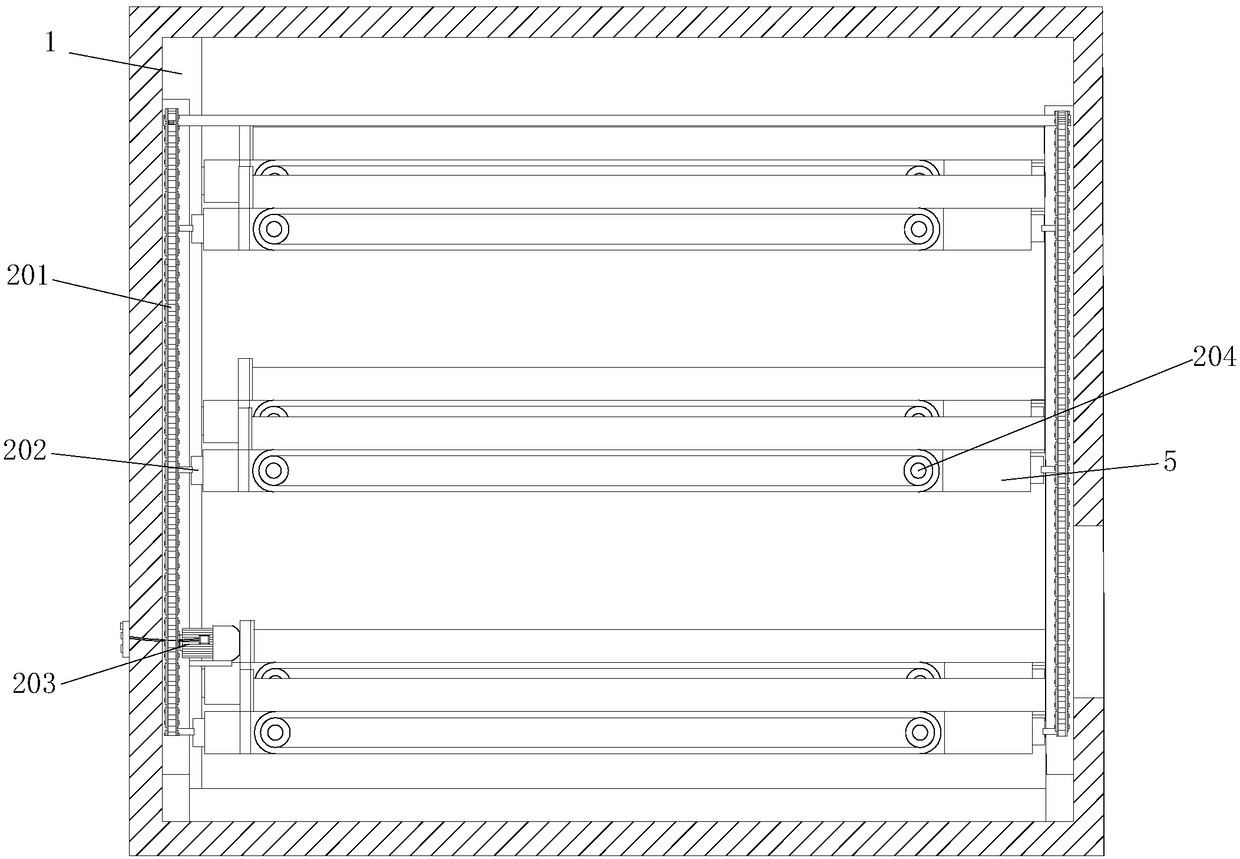

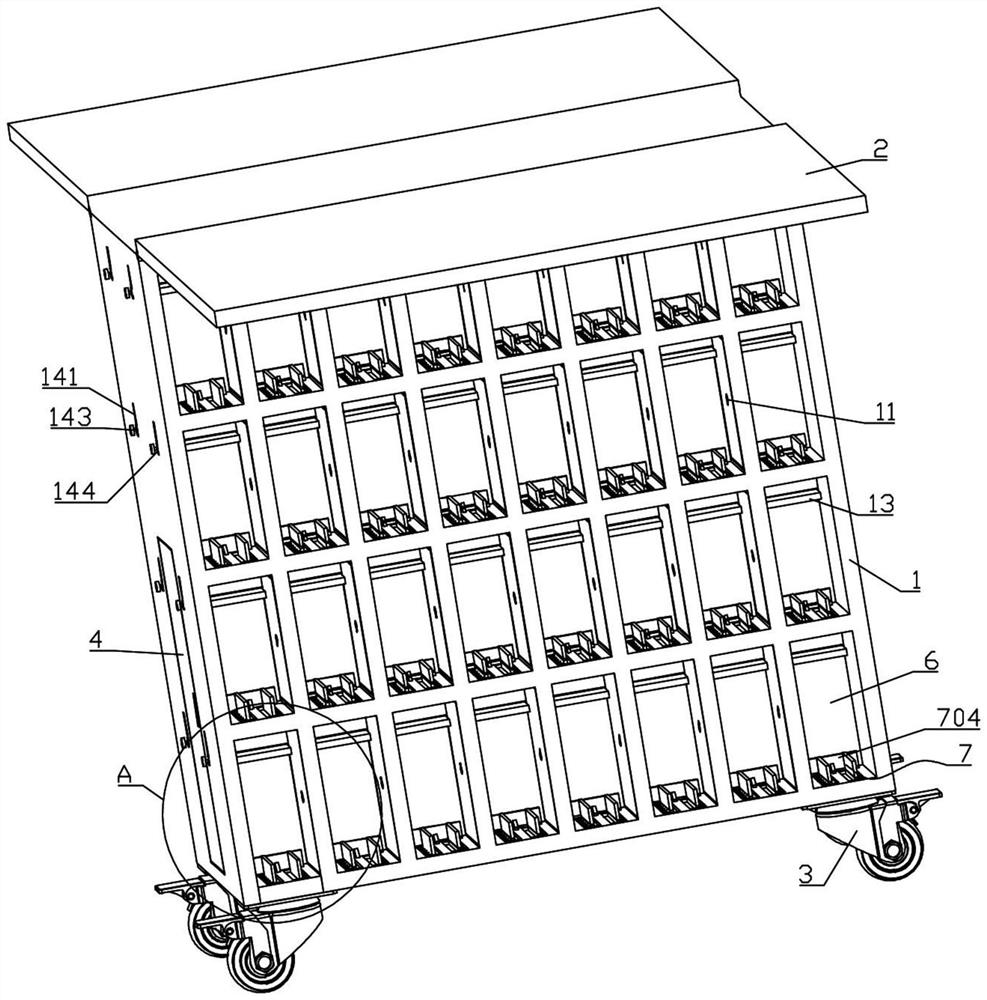

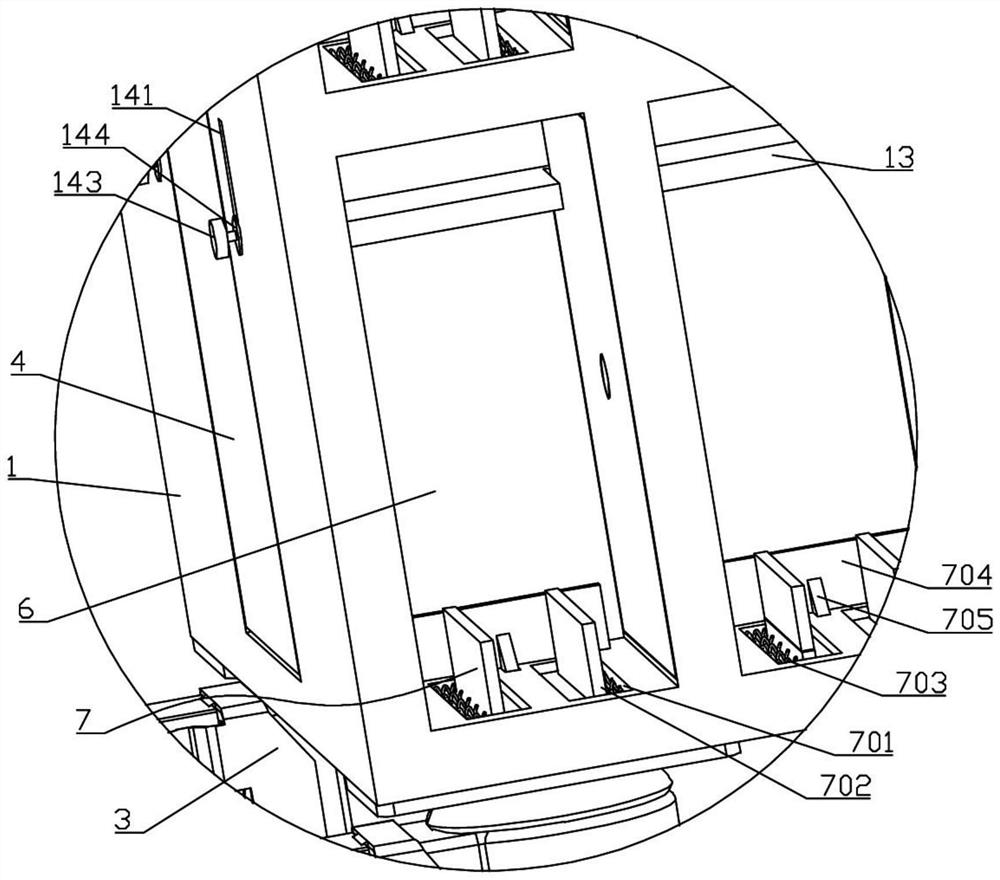

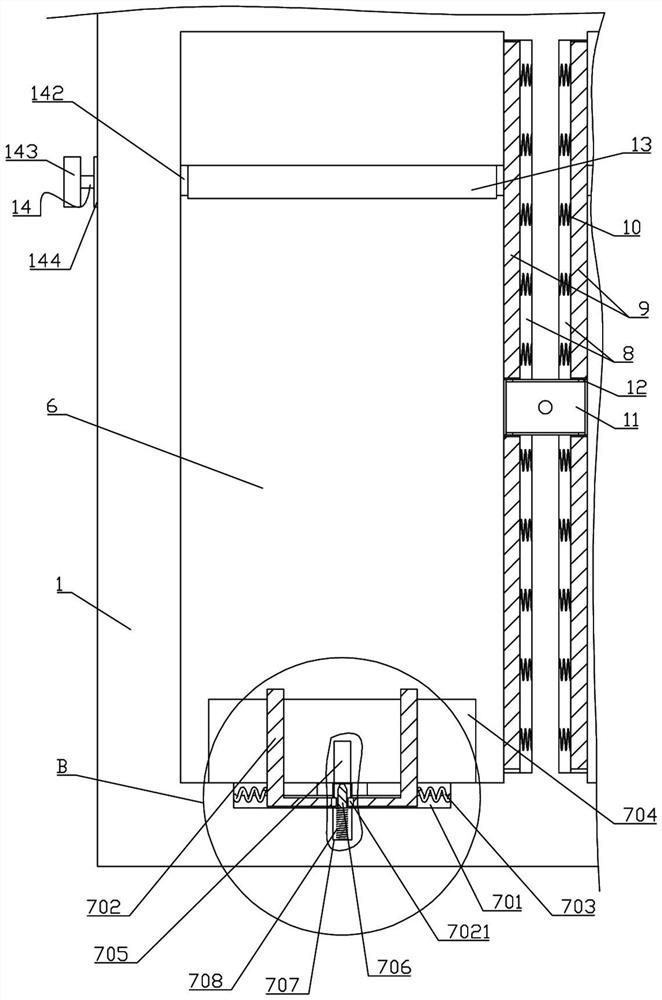

Classified storage type multi-layer logistics warehouse

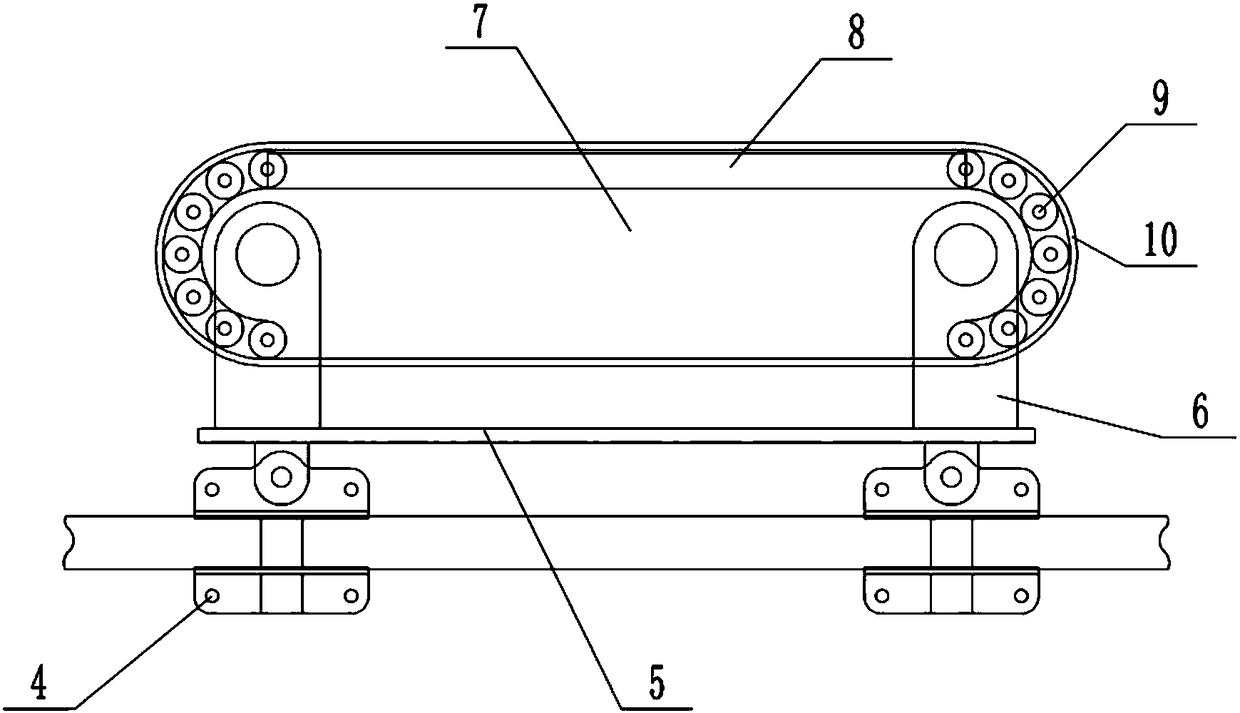

ActiveCN108373000AAchieve liftingThe connection is tight and firmStorage devicesLogistics managementEngineering

The invention discloses a classified storage type multi-layer logistics warehouse which structurally comprises a fixing plate, a rotating transmission mechanism, a supporting base, an in-out passage,placement plates and a warehouse cover shell. The upper surface of the fixing plate is welded to the inner surface of the warehouse cover shell, the rotating transmission mechanism is connected with the placement plates at the two ends of the rotating transmission mechanism, and the bottom end of the fixing plate is welded to the supporting base. The rotating transmission mechanism comprises a chain transmission device, connection supporting mechanisms, a braking device and conveying devices. The chain transmission device is connected with the connection supporting mechanisms at the two ends of the chain transmission device, the conveying devices are embedded into the placement plates, and the brake device is engaged with the chain transmission device through a brake rotating gear. By means of the classified storage type multi-layer logistics warehouse, the purpose that goods do not need to be placed with mechanical carrying tools such as a forklift is realized, the goods simply need to be pushed into the placement plates, in a conveying and chain braking manner, the goods are placed easily till the warehouse is filled with the goods, the placement speed is increased, and thus thedamage in the work process is reduced.

Owner:SHENZHEN XINNING MODERN LOGISTICS

Lithium battery storage explosion-proof device and mode thereof

PendingCN114306987APrevention of chain explosion situationsReduce lossesFire rescueContainers to prevent mechanical damageStructural engineeringFire extinguisher

The invention belongs to the technical field of lithium batteries, and discloses a lithium battery storage explosion-proof device which comprises a cabinet body, a cabinet door is hinged to the cabinet body, moving wheels are installed on the cabinet body, the cabinet body is provided with a placement bin, a fire extinguisher is placed in the placement bin, the cabinet body is provided with placement openings, fixing structures are installed in the placement openings, and two sliding grooves are formed in the common wall between every two adjacent placement openings. The cabinet body is provided with a position adjusting structure, the cabinet body is internally provided with a plurality of row pipes, the row pipes are arranged in the position adjusting structure, the row pipes are arranged in the position adjusting structure, the row pipes are arranged in the row pipes, and the row pipes are arranged in the row pipes. When the lithium battery in the placing opening explodes, black particles splashed from the lithium battery can impact the anti-explosion sliding sheet, the anti-explosion sliding sheet moves, the spraying opening is exposed, and therefore fire extinguishing substances in the fire extinguisher are sprayed to the lithium battery, and the effect of preventing serial explosion is achieved.

Owner:SHENZHEN LITHTECH ENERGY CO LTD

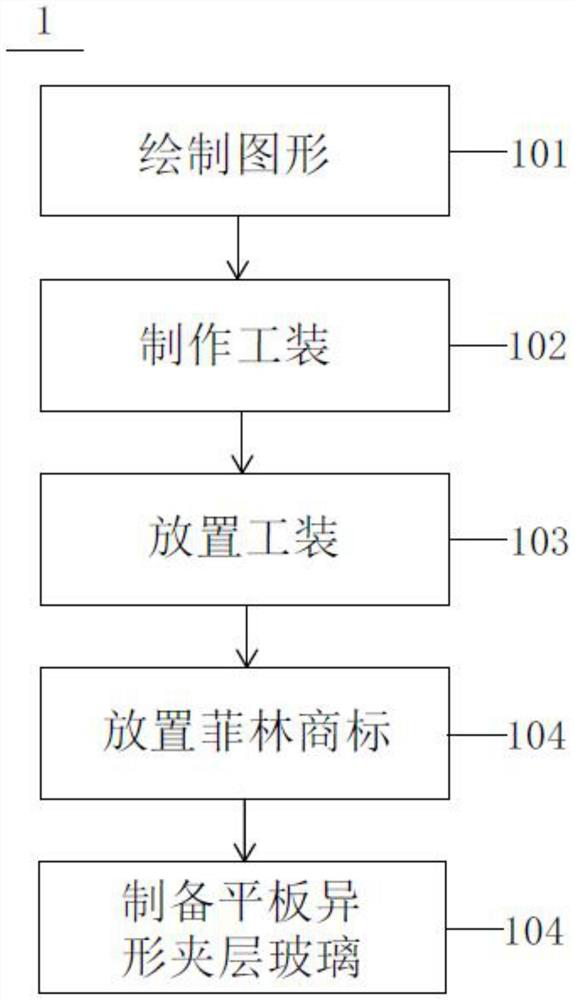

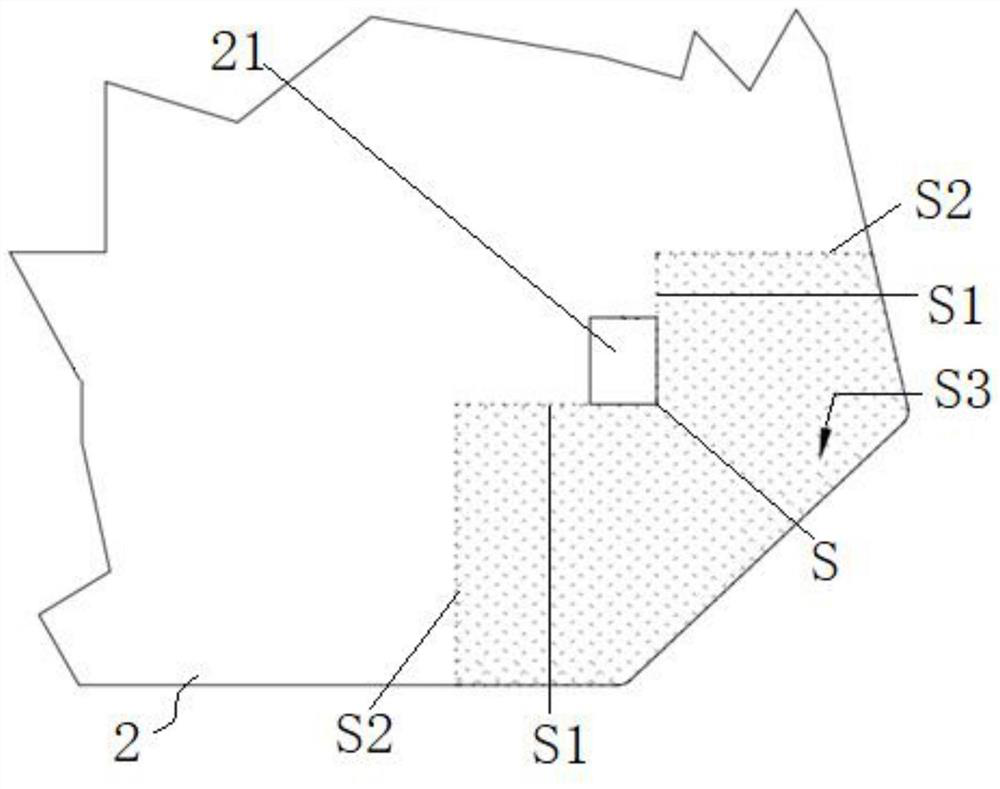

Method for quickly placing film trademark on flat special-shaped laminated glass

InactiveCN111976253AAvoid misalignmentAvoid tilting etc.LaminationLamination apparatusMechanical engineeringMaterials science

The invention relates to a method for quickly placing a film trademark on flat special-shaped laminated glass. The method comprises the following steps: drawing a pattern of which the shape is the same as that of the peripheral area of a position where the film trademark is to be placed on the flat special-shaped glass; manufacturing a tool corresponding to the pattern, and heating and drying thetool; placing the tool at a corresponding position of the flat special-shaped glass; placing the film trademark at the position where the film trademark is to be placed on the flat special-shaped glass according to the positioning of the tool; and taking out the tool, and performing sandwiching treatment on the flat special-shaped glass to form the flat special-shaped laminated glass. According tothe method for quickly placing the film trademark on the flat special-shaped laminated glass, the tool of which the shape is the same as that of the peripheral area of the position where the film trademark is to be placed on the flat special-shaped glass is manufactured, and then the film trademark is positioned by adopting the tool, so that the phenomena of dislocation, inclination and the likeduring placement of the film trademark can be avoided, only one-time positioning is needed, repeated measurement and positioning are not needed, the placement speed is increased, and the operation time is saved.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

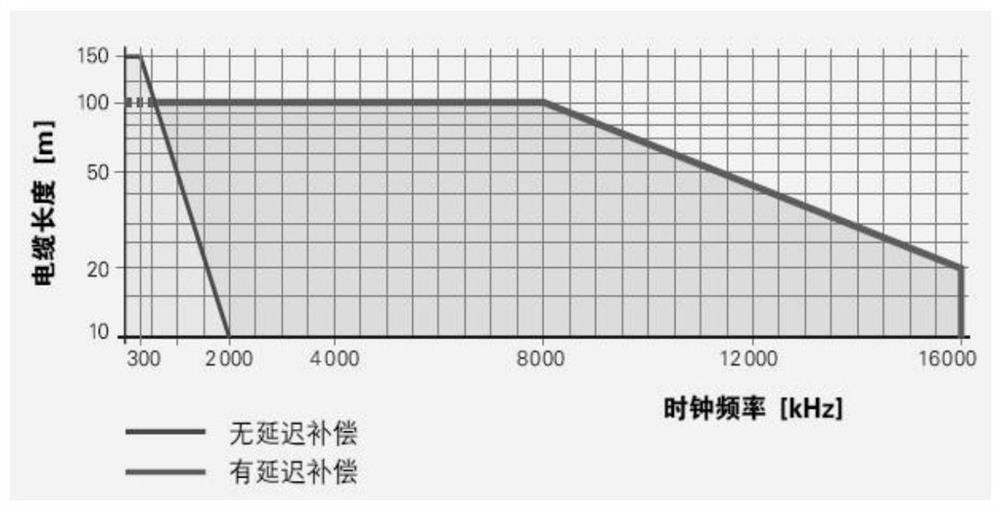

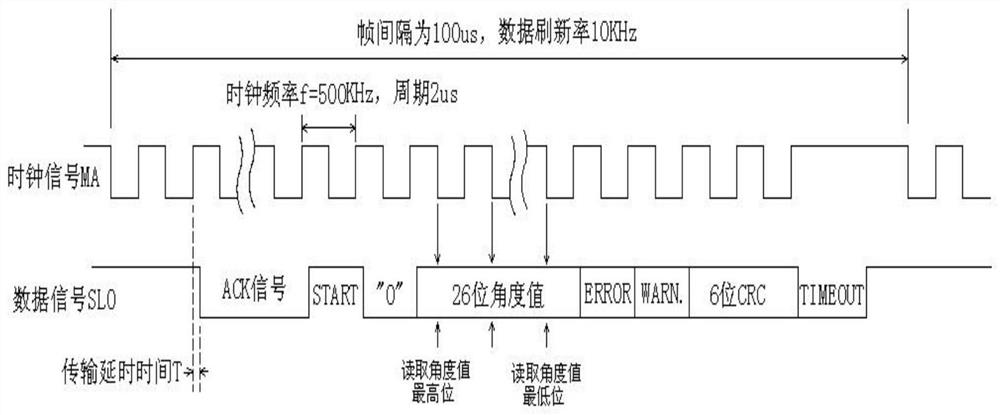

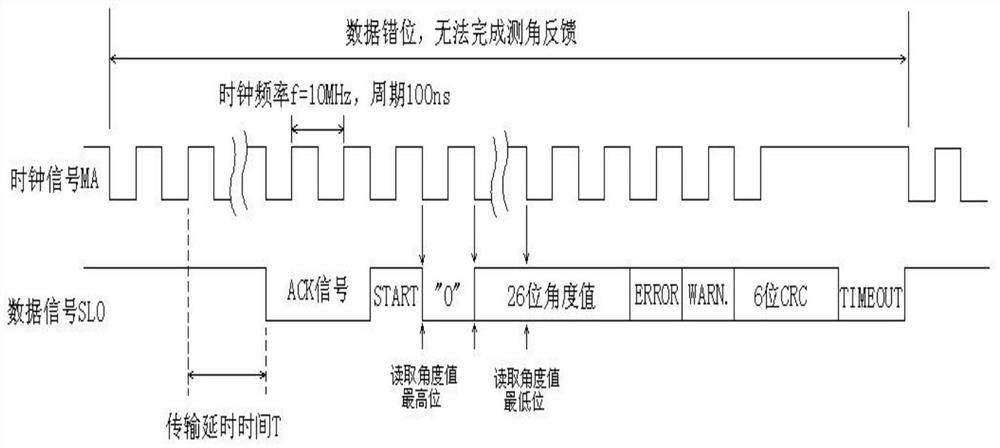

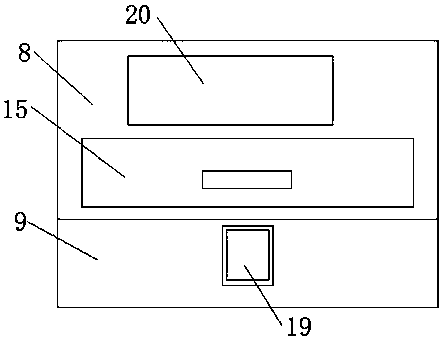

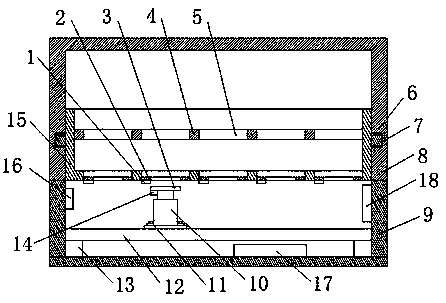

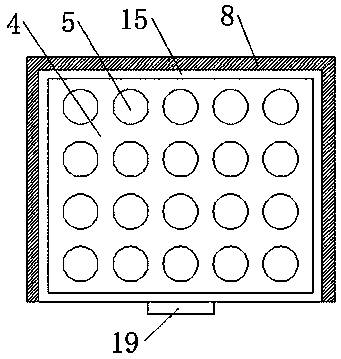

Rotary table/swing table with high-frequency angle measurement mechanism and angle measurement method

PendingCN112306112AShorten angle measurement timeMeet high frequency control requirementsSpeed/accelaration control using electric meansControl systemControl engineering

The invention discloses a rotary table / swing table with a high-frequency angle measurement mechanism and an angle measurement method, and relates to the technical field of angle measurement, the rotary table / swing table comprises the high-frequency angle measurement mechanism, an upper computer controller and a plurality of encoders, and the encoders are installed at the pitch axis end and the azimuth axis end of the rotary table / swing table. Each encoder is connected with a high-frequency angle measurement mechanism through a corresponding connecting piece, and the high-frequency angle measurement mechanism is connected with an upper computer controller; the high-frequency angle measurement mechanism comprises a delay error detector, an error calibrator, a clock generator, a data receiver, a global clock generator and a multi-path switcher, the multi-path switcher is connected with the encoder and performs information interaction with the encoder, and one end of each of the delay error detector, the clock generator and the data receiver is connected with the multi-path switcher, and the other end is connected with the error calibrator. The high-frequency servo control system has high feedback frequency and can meet the high-frequency control requirement of the servo control system.

Owner:武汉华之洋科技有限公司

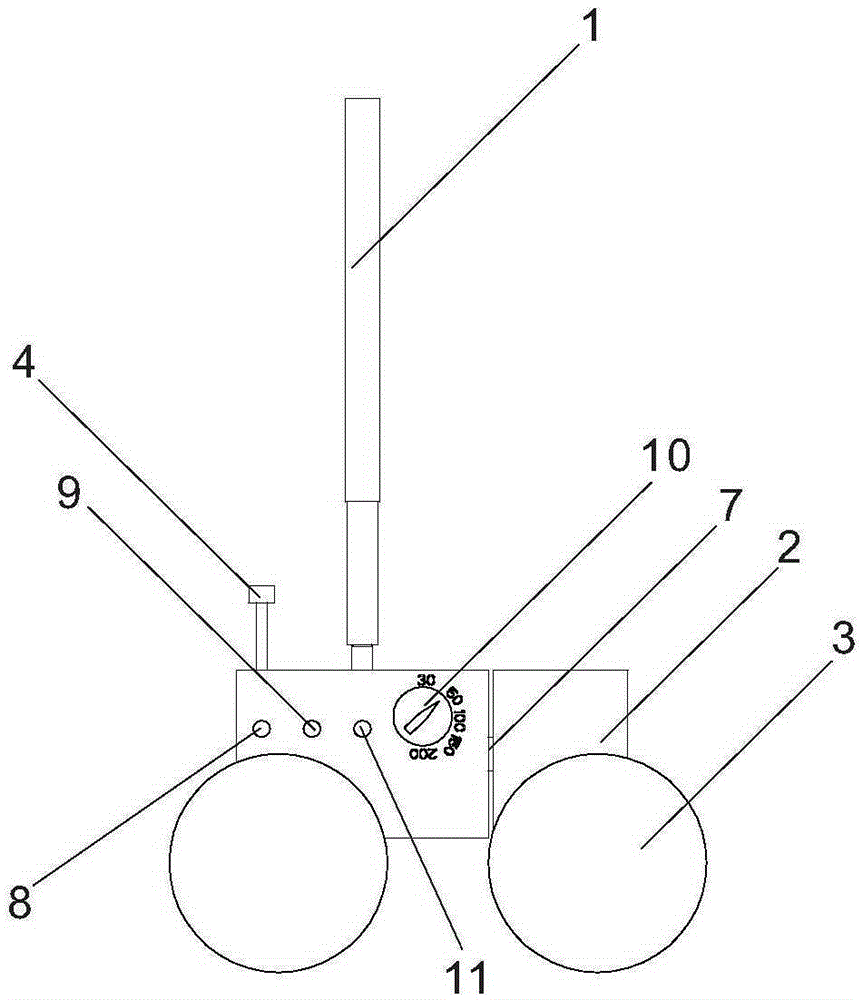

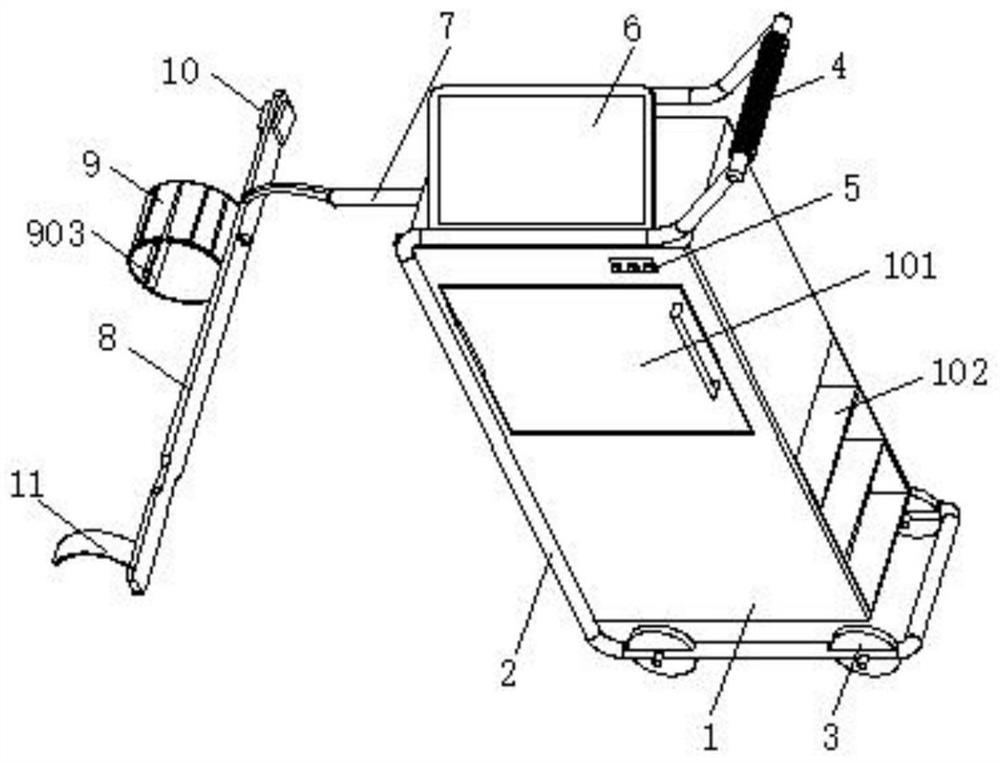

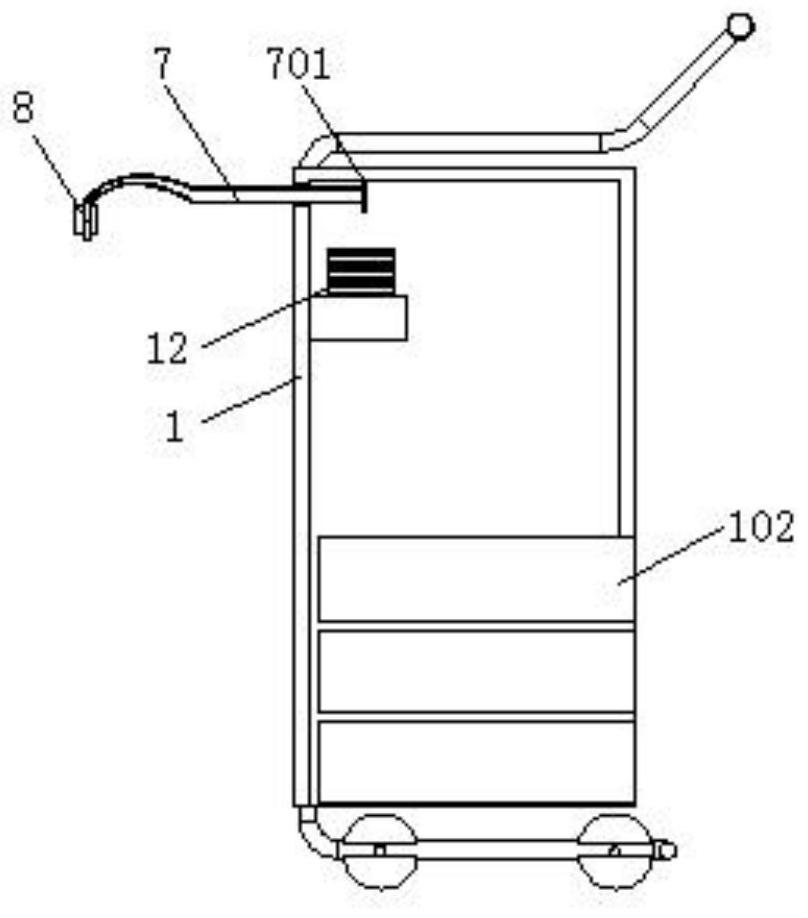

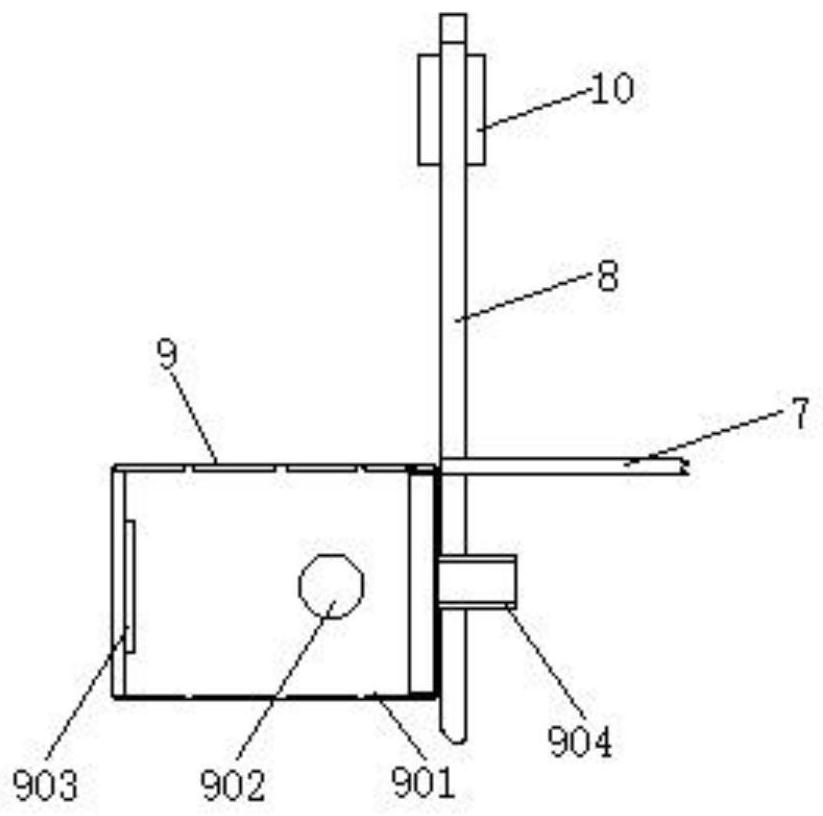

Portable western medicine putting device

InactiveCN111392201AEasy to placeImprove placement efficiencyShock-sensitive articlesDischarging meansWestern medicinePharmacy medicine

The invention discloses a portable western medicine putting device. The portable western medicine putting device comprises an operation box and a storage box, the storage box is fixed to the upper surface of the operation box, the storage box is slidingly connected into the storage box, a limiting plate is fixedly mounted in the storage box, multiple limiting holes are correspondingly formed in the upper surface of the limiting plate and the lower surface in the storage box, a longitudinal sliding rail is fixed to the lower surface of the interior of the operation box, a transverse sliding rail is connected to the upper surface of the longitudinal sliding rail, a transverse sliding table is mounted on the upper surface of the transverse sliding rail, an electric push rod is fixed to the upper surface of the transverse sliding table, an a top plate is fixed to the upper surface of the electric push rod. Medicine bottles can be conveniently stored, the putting speed is high, the medicines can be conveniently recognized and taken, and the wrong taking condition is avoided.

Owner:朱宗波

Buttoning machine for suit pants

InactiveCN113080555AImprove placement accuracyHigh degree of automationClothes making applicancesIndustrial engineeringSewing machine

The invention relates to the field of button processing, in particular to a button sewing machine for suit pants, which comprises a machine body, a lower button pushing mechanism, an upper button pushing mechanism and an automatic cloth feeding and cutting mechanism, and feeding assemblies connected with the lower button pushing mechanism and the upper button pushing mechanism and used for conveying buttons A and buttons B are respectively arranged on the left side and the right side of the machine body; the lower push button mechanism comprises a lower die button punching assembly and a lower push button assembly, the upper push button mechanism comprises an upper die button punching assembly and an upper push button assembly, and the lower die button punching assembly and the upper die button punching assembly punch oppositely so that buttons can be installed on the suit pants. By arranging the lower button pushing mechanism, the upper button pushing mechanism and the automatic cloth feeding and cutting mechanism, a button A is pushed to the lower die button punching assembly through the lower button pushing assembly, a button B is pushed to the upper die button punching assembly through the upper button pushing assembly, material placement is achieved through a mechanical structure, the placement precision is high, the placement speed is high, safety is good. The device is high in automation degree and working efficiency, and can be suitable for mass production.

Owner:东莞市德舜机械有限公司

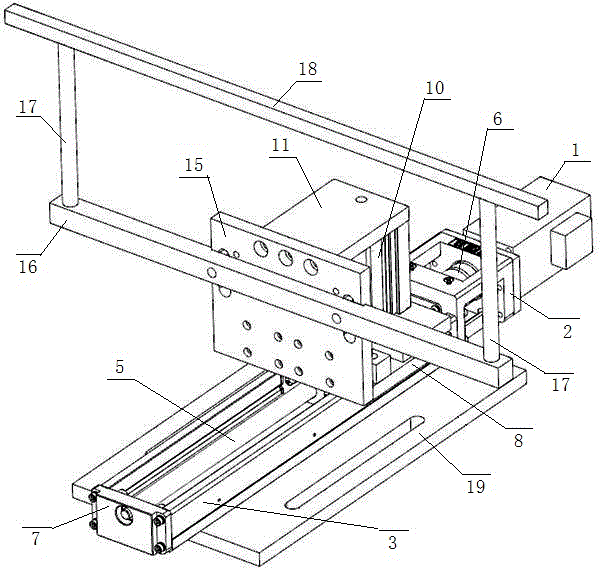

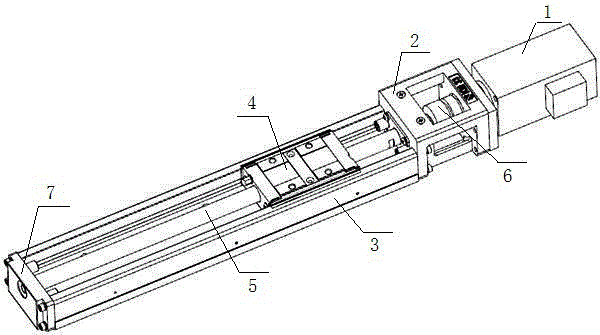

Feed mechanism

The invention relates to a feed mechanism which comprises a horizontal movement mechanism, a vertical movement mechanism, a workpiece clamping mechanism and a bottom plate. The horizontal movement mechanism comprises a servo motor, a motor rack, a sliding groove, a sliding block with a thread, a rod with a thread, a coupling, a sliding groove end plate and a horizontal movement plate. The vertical movement mechanism comprises an air cylinder base plate, an up-down air cylinder, an up-down air cylinder plate, a guide rail strip, sliding blocks with grooves, a guide rail strip seat and a vertical movement plate. The workpiece clamping mechanism comprises a feed bar seat and magnet bars. According to the feed mechanism, the horizontal movement mechanism can be used for driving the vertical movement mechanism and the workpiece clamping mechanism to do horizontal linear movement, the vertical movement mechanism can be used for driving the workpiece clamping mechanism to do vertical movement, and the workpiece clamping mechanism can be used for clamping a bar workpiece; the defects of manual operation are avoided; the placement speed is high; the placement positions are accurate; the frequency of jamming and shutdown is effectively reduced; and the production efficiency is effectively improved.

Owner:GUANGXI BINYANG TIANXIANG ELECTRONICS

Hot-rolled steel plate vertical welding equipment

ActiveCN114193053AEasy to placeReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesWelding processSteel plates

The invention provides a hot-rolled steel plate vertical welding device, and belongs to the technical field of steel plate welding, the hot-rolled steel plate vertical welding device comprises a placing supporting part and a welding part, the placing supporting part comprises a movable supporting part and a bearing placing part, and the movable supporting part and the bearing placing part cooperate with each other to be used for placing a vertical steel plate on a horizontal steel plate and supporting and limiting the vertical steel plate; the welding part is used for welding the bottom face of the vertical steel plate to the upper surface of the horizontal steel plate. According to the vertical welding equipment for the hot-rolled steel plate, the placing process of the steel plate is optimized, so that the whole placing process has the advantages of low labor intensity, simplicity, convenience, high stability, high placing precision and high placing speed, the integrity of the steel plate and the continuity of the welding process are improved, and the welding efficiency and the welding quality are correspondingly improved.

Owner:TANGSHAN YANSHAN IRON & STEEL CO LTD

Physical sign measuring device for emergency nursing

InactiveCN111603148ASimple structureReduce shakingEvaluation of blood vesselsSensorsPhysical medicine and rehabilitationNursing care

The invention discloses a physical sign measuring device for emergency nursing. The device comprises a box body; and protective frames are oppositely fixed to the front side and the rear side of the box body. Walking wheels are installed on the horizontal part of the lower side of the protective frames. The upper ends of the two protective frames are fixedly connected through a handle. The structure of the device is simple, the box body with walking wheels is used as a carrier; the device is convenient to move; medical instruments or articles can be placed in the inner cavity of the box body;the nursing is facilitated by the device; a blood pressure probe, a temperature probe and a pulse probe can be reasonably arranged on a flexible plate; the device can be clamped on the inner side of an arm to monitor the heart rate of a radial artery, detect the blood pressure of the upper arm, and detect the body temperature of the armpit; the device is integrally placed to detect the basic physical signs; the placing speed is high, an air bag sleeve wraps the upper arm during blood pressure measurement, shaking of the flexible plate, the temperature probe and the pulse probe is reduced therefore, and the accuracy and effectiveness of the detection result are guaranteed.

Owner:韩伟伟

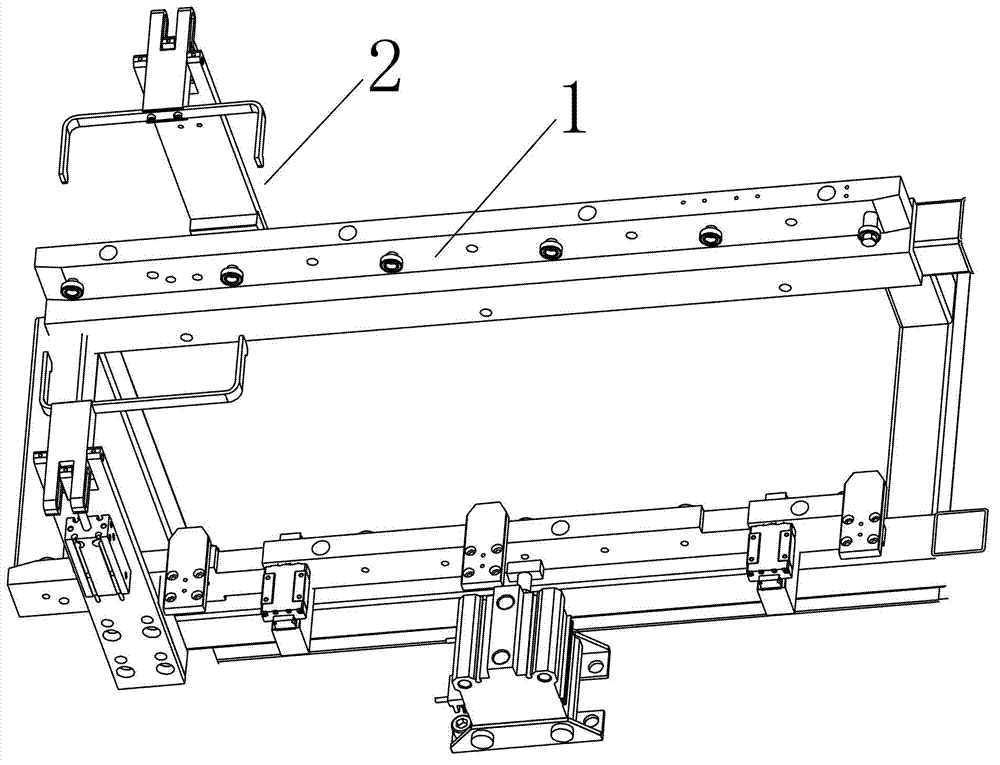

Loading and unloading clamping fixture for punching machine

InactiveCN102527866AFast placementCooperate wellMetal-working feeding devicesPositioning devicesPunch pressLow speed

The invention discloses a loading and unloading clamping fixture for a punching machine, which comprises a fixture plate, and is characterized by further comprising a manipulator, and two reverse U-shaped openings are arranged at two ends of the fixture plate respectively. The upper middle of the fixture plate is connected with a control arm of the manipulator, and vacuum chucks are arranged on two lower sides of the fixture plate respectively and connected with a vacuum generator. The loading and unloading clamping fixture for the punching machine solves the problems of low placement efficiency, low speed, poor precision, low safety factor and easiness in causing injury accidents of a punching machine in the prior art adopting manual displacement of parts to be punched, and is simple in structure, high in safety factor and capable of rapidly and accurately placing parts to be punched.

Owner:昆山艾博机器人股份有限公司

Stator loading and unloading device with fast knockout function

ActiveCN102847841AEasy to separateFast placementMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses a stator loading and unloading device with a fast knockout function. The stator loading and unloading device comprises an annular machine platform, adsorption equipment, a material filling mechanism and a knockout mechanism, and the knockout mechanism is characterized by comprising a support plate, an air cylinder and a knockout frame; the air cylinder is arranged on a back surface of the support plate, the air cylinder is mutually connected with the knockout frame installed on a top end of the support plate through an air cylinder shaft, the knockout frame is capable of winding the top end of the support plate to turn. The stator loading and unloading device solve problems that in the prior art, a stator and a rotor are arranged mostly by means of a manual manner, a speed of separating the stator and the rotor is slow, arranging efficiency is low, a processing speed of a punch can not achieved, simultaneously, the stator and the rotor are very easily arranged in a wrong material filling mechanism to cause much trouble to subsequent processing; the invention provides a stator loading and unloading device which is simple in structure and convenient to use, can quickly separate the rotor and the stator, and is capable of accurately arranging in a corresponding working position.

Owner:昆山艾博机器人股份有限公司

Fireproof hollow glass, manufacturing method and application

InactiveCN112431521ARealize automatic placementGuaranteed straightnessFireproof doorsNoise insulation doors/windowsSealantCeramic materials

The invention belongs to the technical field of fireproof glass, and discloses fireproof hollow glass, a manufacturing method and application. The fireproof hollow glass is provided with two pieces ofglass, bonding sealing between the glass and spacing bars, and bonding sealing at the periphery of the glass; the two pieces of glass are equal in length and width; at least one piece of glass is fireproof glass; the fireproof glass is preferentially installed on the indoor side; the spacing bars are directly adhered to the periphery of the adhering surface of the first piece of glass in sectionsto form a closed frame, or the spacing bars are adhered to the periphery of the adhering surface of the first piece of glass after being manufactured into a spacing frame; the second piece of glass is adhered to the other surfaces of the spacing bars; the peripheries of the two pieces of glass are aligned; and the glass and the spacing bars are adhered together through sealant or structural adhesive or double-sided adhesive tape or edge sealant. The fireproof hollow glass is simple in structure, good in fireproof performance and long in service life, and the fireproof hollow glass not only has a fireproof effect, but also has good heat insulation and sound insulation effects.

Owner:WEIHAI RUNFENG GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com