Loading and unloading clamping fixture for punching machine

A clamping and punching technology, used in feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of low safety factor, low placement efficiency, easy to cause injuries, etc., to achieve fast placement, reduce enterprise costs, and improve processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

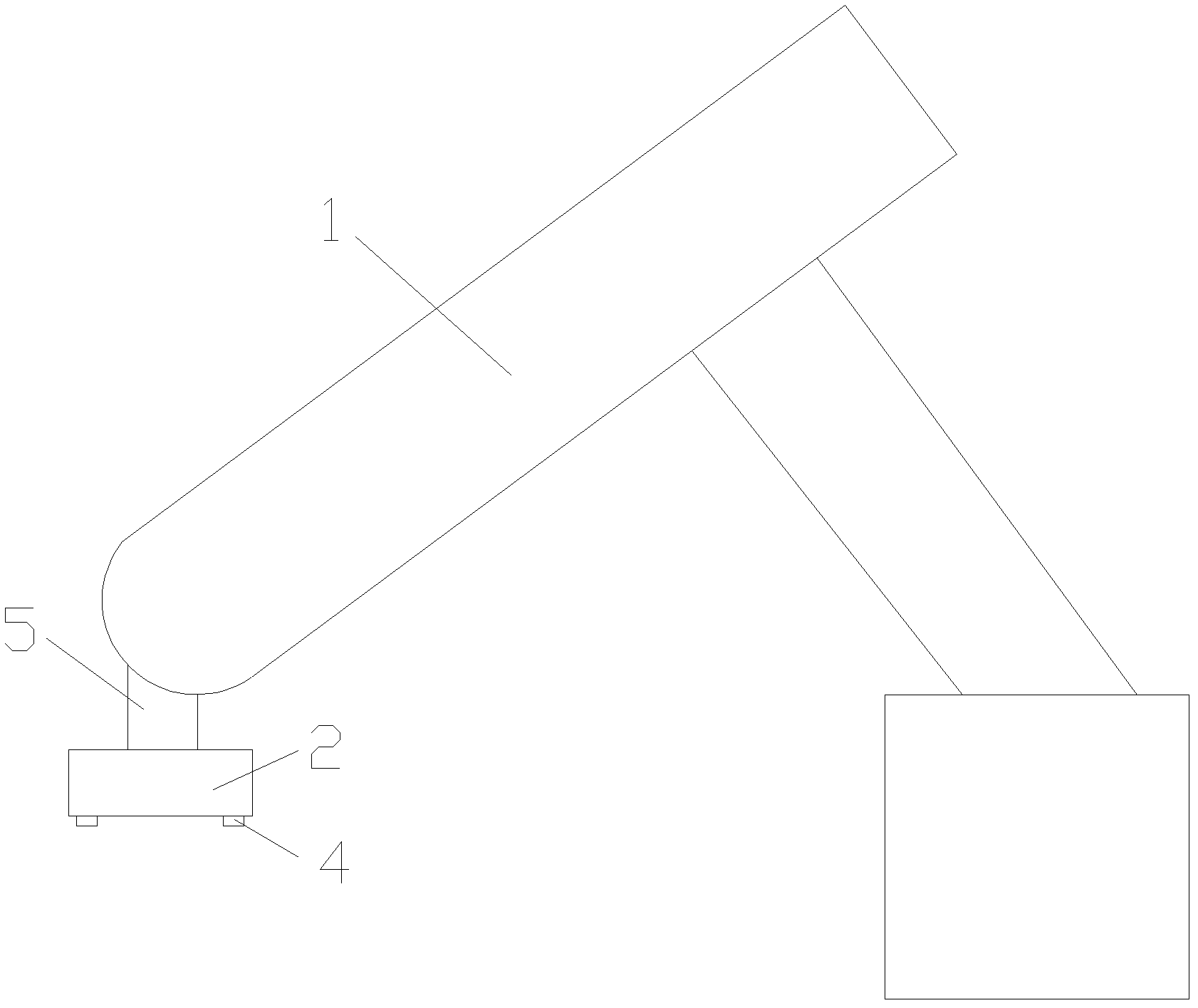

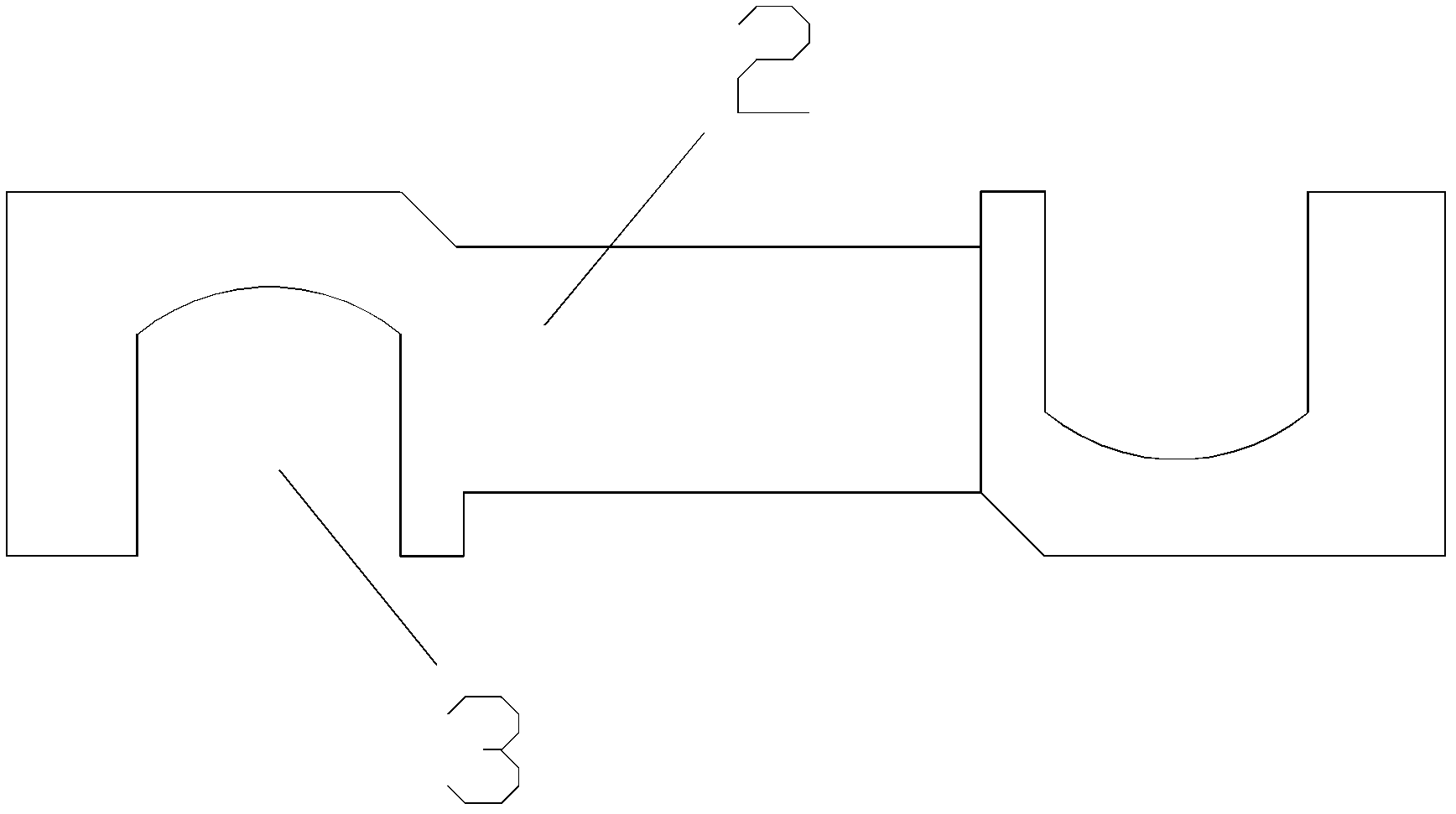

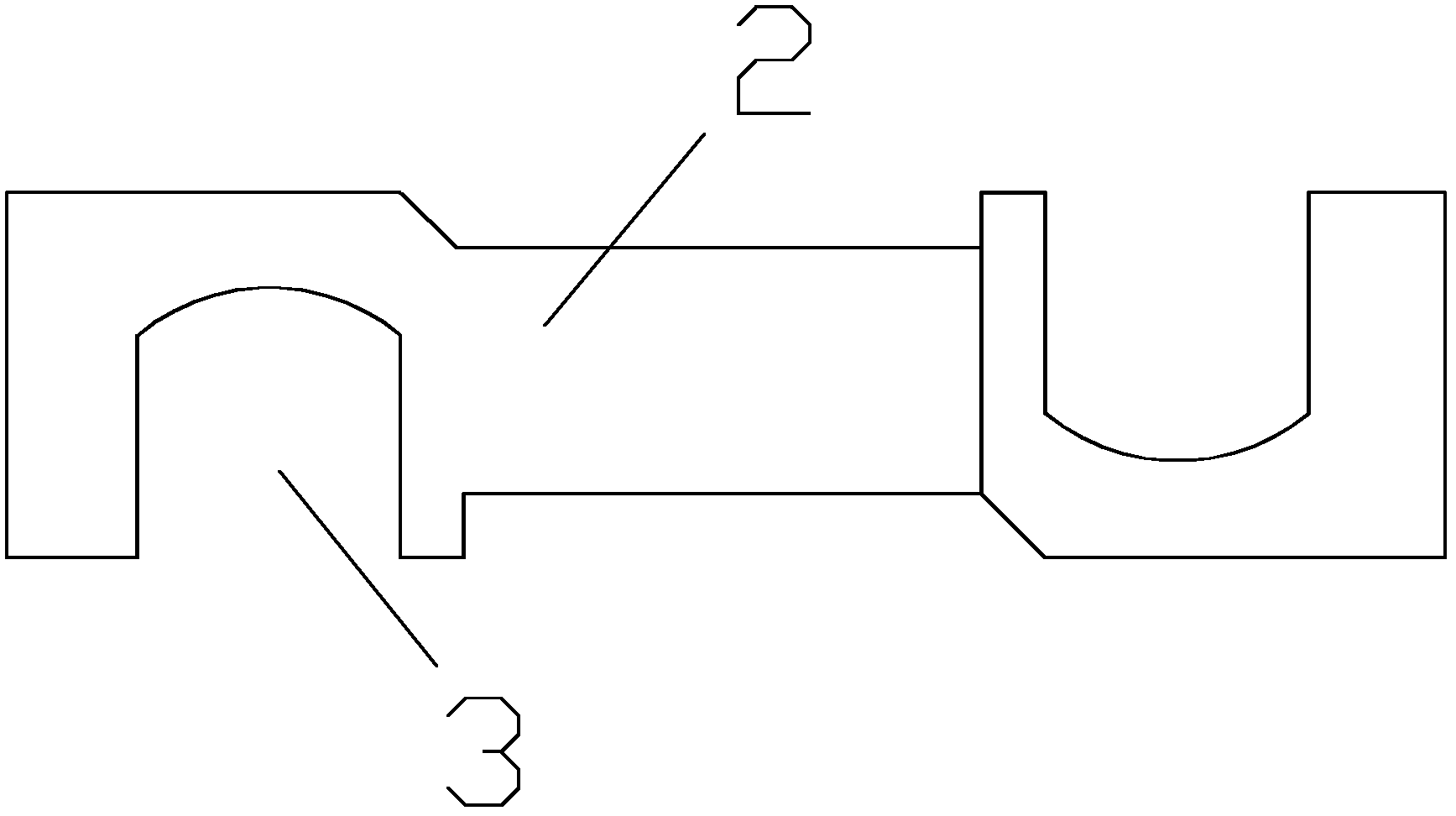

[0017] like Figure 1-2 As shown, a clamping fixture for loading and unloading on a punching machine includes a manipulator 1 and a clamp plate 2. U-shaped openings 3 are respectively provided at both ends of the clamp plate 2, and the two U-shaped openings 3 are arranged in opposite directions. The upper middle part of the fixture plate 2 is connected with the control arm 5 of the manipulator 1 , and vacuum suction cups 4 are symmetrically arranged on both sides below the fixture board 2 , and the vacuum suction cups 4 are connected with the vacuum generator.

[0018] There are two uprights beside the punching machine, one upright is used to place the parts to be punched, the other is used to place the punched parts, and the placement height of the parts to be punched is higher than the placement height of the punched parts. The vacuum generator is turned on, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com