Rotary table/swing table with high-frequency angle measurement mechanism and angle measurement method

A rocking table, angle measurement technology, applied in the field of angle measurement, can solve the problems of lengthening the reading time of a frame of angle value, unable to meet the requirements of the control system, unable to complete the angle measurement feedback, etc., to achieve high equipment control bandwidth, shorten the Angle measurement time, the effect of meeting the requirements of high frequency control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

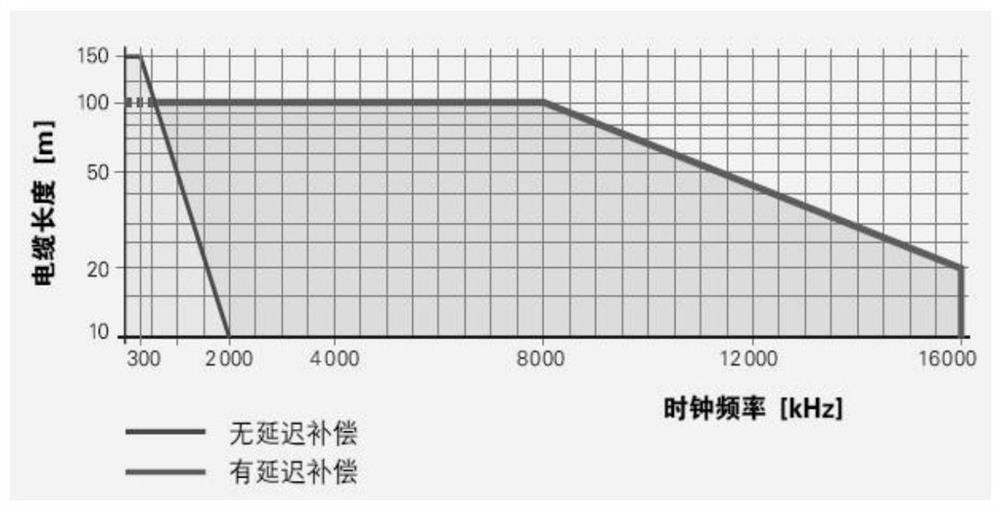

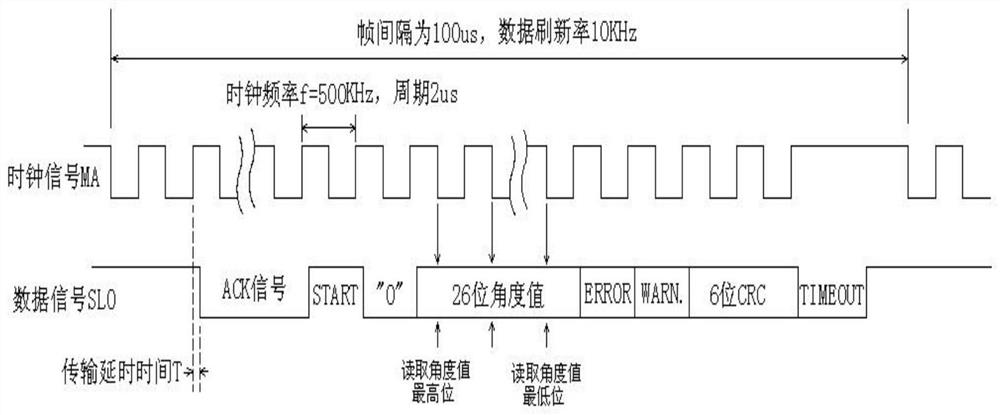

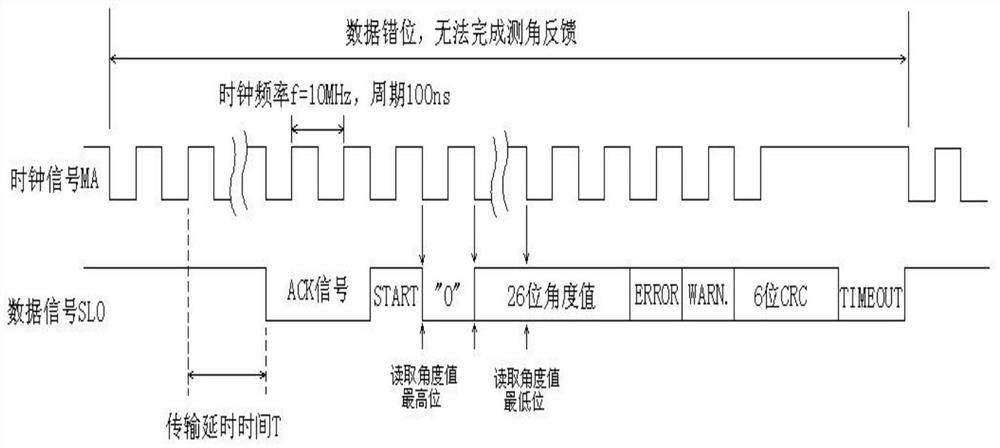

[0042] see Figure 4 and Figure 5 As shown, the embodiment of the present invention provides a turntable / swing table with a high-frequency angle-measuring mechanism, including several encoders 1, a high-frequency angle-measuring mechanism 2 and a host computer controller 3, and the encoder 1 is installed on the turntable / swing table The shaft end of the pitch axis and the shaft end of the azimuth axis of the stage, the pitch angle measurement element is installed at the shaft end of the pitch axis, and the azimuth angle measurement element is installed at the shaft end of the azimuth axis. The reading head adopts the one-way BISS-C synchronous serial protocol (an interface protocol) to output angle information, the reading head is a master-slave interface structure, the master interface controls the position acquisition timing and data transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com